When it comes to maintaining and troubleshooting your chainsaw, having a clear understanding of its various elements is essential. This knowledge empowers users to effectively manage repairs and ensure optimal performance. Whether you’re a professional or a weekend warrior, familiarity with the inner workings of your equipment can make all the difference.

Visual representations of the internal structure can serve as invaluable resources, offering insights into how each part interacts within the machinery. These guides not only simplify the process of identification but also assist in locating specific components that may require attention. By consulting these visual aids, you can enhance your ability to diagnose issues and carry out repairs efficiently.

As you delve deeper into the mechanics of your chainsaw, consider the significance of each element in relation to overall functionality. Recognizing the role of every piece can lead to more informed decisions during maintenance and repairs. With a solid grasp of these essentials, you’ll be better equipped to keep your equipment in top-notch condition.

Understanding the Stihl MS 271

This section aims to explore a popular model of chainsaw known for its reliability and efficiency. It is designed for both professional and amateur users, making it versatile for various tasks. By examining its components, users can enhance their understanding of its operation and maintenance.

Power and Performance: This tool is equipped with a robust engine that delivers excellent cutting power, making it ideal for heavy-duty tasks. Its efficient design allows for extended use without overheating, ensuring optimal performance.

Maintenance and Care: Regular upkeep is crucial for longevity. Understanding the various elements, such as the fuel system and bar chain, will aid users in keeping their equipment in top condition, ultimately enhancing its lifespan.

User Experience: Many users appreciate the balance and weight of this chainsaw, which contributes to ease of handling. Feedback highlights its user-friendly features, making it accessible for those new to chainsaw operation.

Key Features of the MS 271

This model offers a range of essential attributes designed for optimal performance and user satisfaction. Each feature contributes to its reliability and efficiency, making it a favored choice among users.

- Powerful Engine: Provides excellent cutting performance and durability.

- Lightweight Design: Ensures easy handling and reduced fatigue during extended use.

- Efficient Fuel Consumption: Enhances productivity by minimizing downtime for refueling.

- Advanced Safety Features: Incorporates mechanisms to protect the operator during use.

- Easy Maintenance: Simplifies upkeep to ensure longevity and reliability.

Overall, these characteristics make this model a versatile tool suitable for various tasks, appealing to both professionals and casual users alike.

Common Parts and Their Functions

Understanding the essential components of a chainsaw is crucial for effective maintenance and operation. Each element plays a specific role that contributes to the overall functionality, ensuring safety and performance during use. Below are some key components along with their primary functions.

| Component | Function |

|---|---|

| Engine | Powers the chainsaw, converting fuel into mechanical energy. |

| Bar | Guides the chain and provides a surface for cutting. |

| Chain | Interconnected links that perform the cutting action. |

| Clutch | Engages and disengages the chain from the engine, allowing for safe operation. |

| Fuel Tank | Holds the fuel required for engine operation. |

| Air Filter | Prevents dust and debris from entering the engine, ensuring efficient performance. |

| Chain Brake | Stops the chain rapidly in case of kickback, enhancing user safety. |

| Handle | Provides grip for controlling the tool and enhances user comfort. |

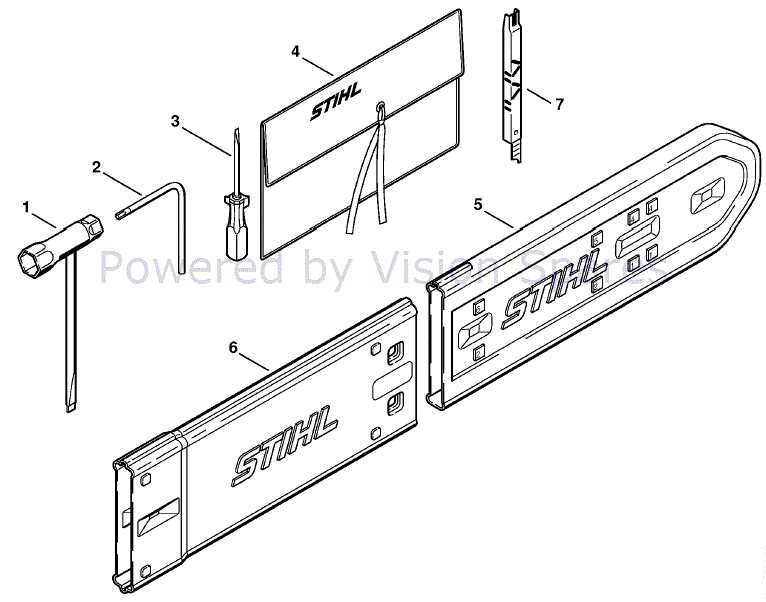

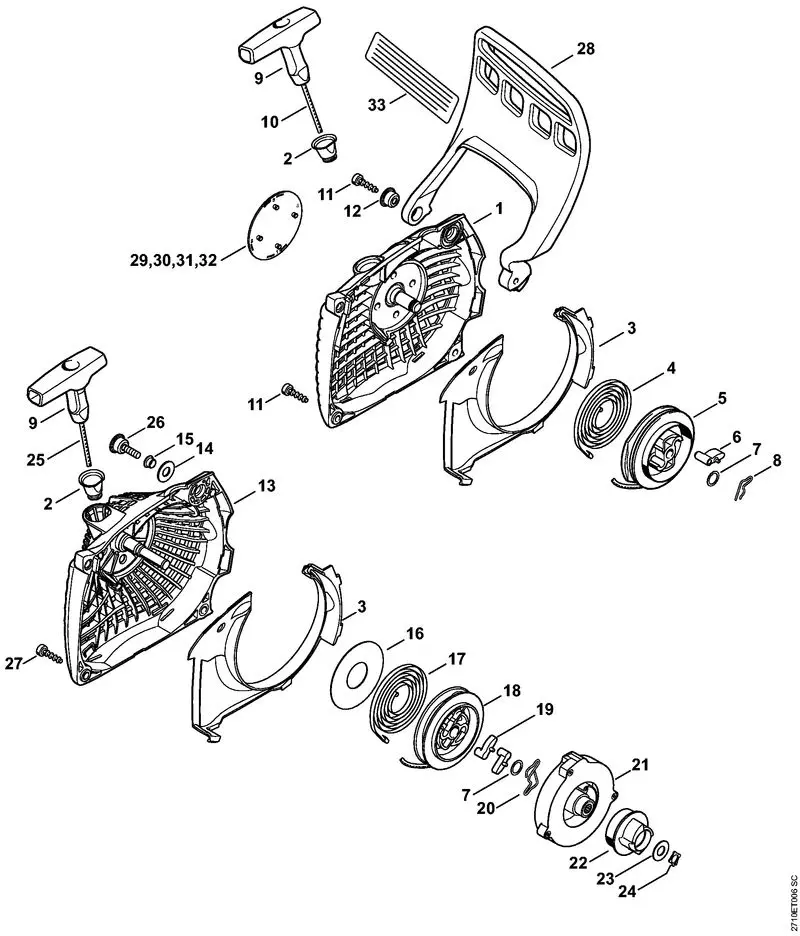

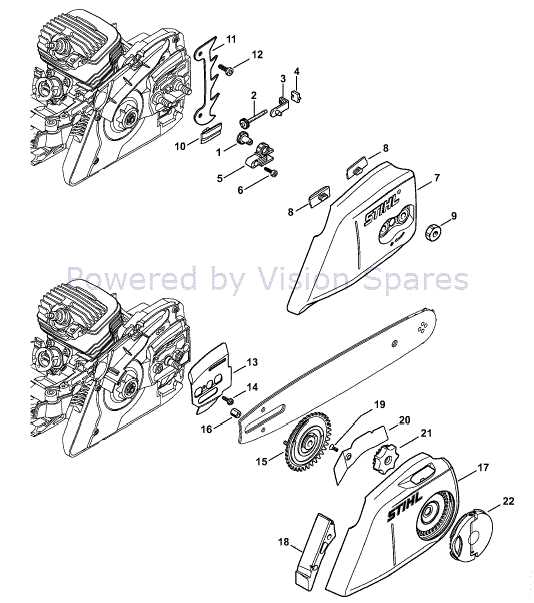

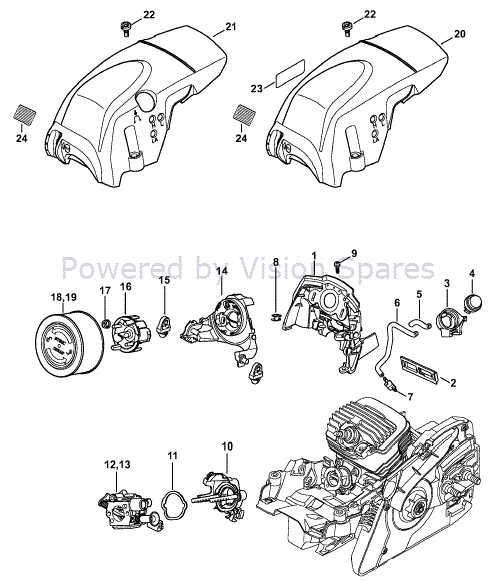

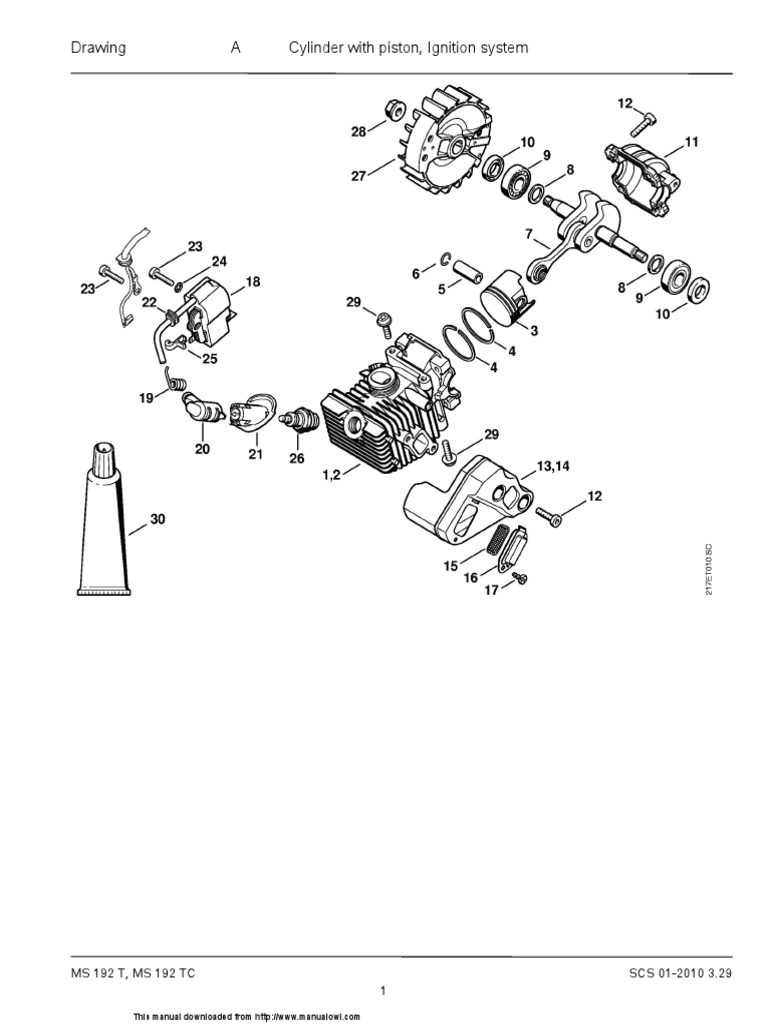

Exploring the Parts Diagram

This section offers an in-depth look into the intricate components that make up a popular tool. Understanding how each element interconnects can enhance maintenance and repair skills, ultimately leading to improved performance and longevity.

Understanding Component Functions

Each part plays a vital role in the overall functionality of the equipment. From the engine to the cutting mechanism, recognizing the purpose of every section allows users to troubleshoot issues more effectively.

Benefits of Familiarity

Becoming acquainted with the assembly aids in the identification of wear and tear, making it easier to replace faulty elements promptly. This knowledge not only saves time but also ensures optimal operation, allowing users to tackle their tasks with confidence.

Maintenance Tips for Your Chainsaw

Regular upkeep of your power saw is essential for ensuring its longevity and optimal performance. By following some straightforward maintenance practices, you can prevent common issues and enhance the efficiency of your tool, ultimately making your cutting tasks smoother and safer.

Firstly, always keep the cutting chain sharp. A dull chain not only makes the job harder but also increases the risk of accidents. Regularly check the sharpness and file the teeth as needed to maintain an effective cutting edge.

Next, pay attention to the tension of the chain. An appropriately tightened chain is crucial for effective operation. Make adjustments according to the manufacturer’s guidelines, as both loose and overly tight chains can lead to serious damage.

It’s also important to clean the air filter regularly. A clogged filter restricts airflow, causing the engine to work harder and potentially leading to overheating. Remove the filter and clean it gently to ensure proper ventilation.

Don’t forget to inspect the bar and chain oil levels. Adequate lubrication is vital for reducing friction and wear during use. Always refill with the recommended oil type before starting your work.

Lastly, after each use, clean the saw thoroughly. Remove debris and sawdust, especially around the chain and bar area. This not only helps maintain performance but also prevents rust and other forms of damage.

How to Replace Stihl MS 271 Parts

Maintaining your outdoor power tool is essential for optimal performance and longevity. Replacing worn or damaged components can significantly enhance efficiency and ensure safe operation. This guide outlines the necessary steps and considerations for effectively swapping out various elements in your equipment.

Before beginning the replacement process, gather the appropriate tools and new components required for the task. Familiarize yourself with the assembly and ensure you have a clean workspace to prevent loss of small parts.

| Component | Replacement Steps |

|---|---|

| Air Filter | 1. Remove the cover. 2. Take out the old filter. 3. Insert the new filter and secure the cover. |

| Chain | 1. Loosen the tension. 2. Remove the guide bar. 3. Replace the chain and reassemble. |

| Spark Plug | 1. Disconnect the lead. 2. Unscrew the old plug. 3. Install the new plug and reconnect the lead. |

| Fuel Filter | 1. Access the fuel tank. 2. Remove the old filter. 3. Place the new filter and reassemble. |

Following these procedures will help ensure that your equipment remains in top shape. Always consult the manufacturer’s guidelines for specific recommendations and safety precautions related to your model.

Tools Needed for Repairs

When it comes to maintaining outdoor equipment, having the right instruments is essential for ensuring efficient and effective repairs. The following tools are crucial for tackling various issues, helping to streamline the process and achieve optimal performance.

Essential Tools

The basic toolkit for repairs should include a mix of hand tools and specialized equipment. Here’s a list of must-have items:

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen bolts and nuts |

| Screwdriver Set | For fastening and removing screws |

| Socket Set | To work on various sizes of fasteners |

| Pliers | For gripping, twisting, and cutting |

| Torque Wrench | To apply specific torque settings |

Safety Equipment

Safety should always be a priority during repairs. Proper gear protects against potential hazards. Here’s what you should include:

| Equipment | Function |

|---|---|

| Safety Glasses | To shield eyes from debris |

| Gloves | To protect hands from sharp edges |

| Ear Protection | To reduce noise exposure |

| Face Shield | For additional facial protection |

Where to Buy Genuine Parts

When it comes to maintaining equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Reliable sources not only provide quality but also offer peace of mind that the items will fit correctly and function as intended. In this section, we will explore various avenues for acquiring these essential elements.

Authorized Dealers

One of the best places to find original components is through authorized retailers. These outlets typically have a wide selection and can guarantee the authenticity of the items they sell. Additionally, staff at these locations are often well-trained and can assist with any inquiries regarding compatibility and installation.

Online Marketplaces

The internet offers numerous platforms where you can find genuine components. Websites that specialize in equipment often have sections dedicated to original items. When purchasing online, it’s important to verify the seller’s reputation and ensure they provide quality guarantees. Look for reviews and ratings from previous buyers to ensure a satisfactory experience.

Whether you choose a local shop or an online platform, investing in authentic components is key to maintaining your machinery in peak condition.