Understanding the individual elements and their arrangement is essential for anyone working with mechanical cutting tools. These tools consist of multiple parts that work in harmony to provide precise cutting and long-lasting performance. A detailed look at how these components fit together can be extremely helpful for maintenance, repairs, or upgrades.

Each element serves a specific function, contributing to the overall operation and efficiency. By familiarizing yourself with the structure and functions of various elements, you can ensure smoother operation and make informed decisions regarding replacements or improvements. This guide provides a comprehensive breakdown, highlighting essential details for easy reference.

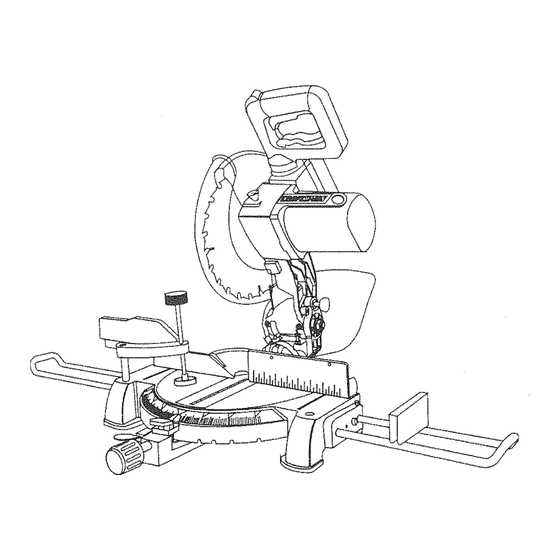

Craftsman Miter Saw Overview

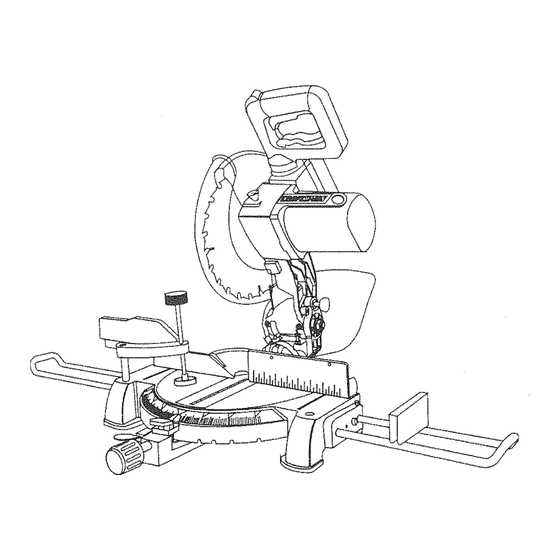

This section highlights the essential aspects of a versatile power tool commonly used for precise cuts in woodworking and other projects. Known for its functionality and durability, it serves both professionals and hobbyists, offering a range of features that enhance accuracy and convenience.

- Engineered for precision in cutting various materials.

- Equipped with adjustable components to achieve different cutting angles and depths.

- Compact design, suitable for workshop environments or on-site tasks.

- Safety features integrated to protect users during operation.

- Compatible with a range of attachments and accessories for enhanced versatility.

This overview emphasizes the tool’s adaptability and ability to handle detailed work, making it a reliable choice for anyone looking to perform accurate, clean cuts in diverse settings.

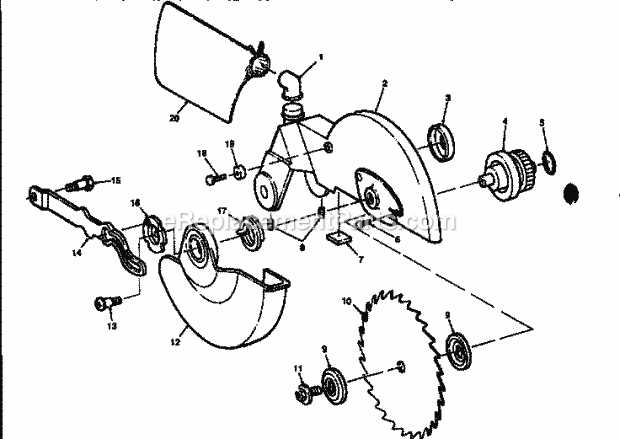

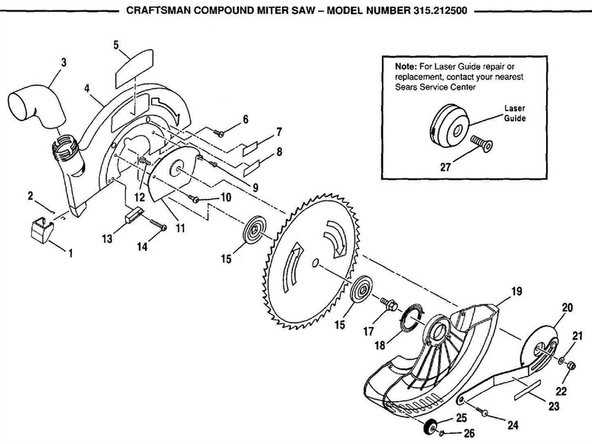

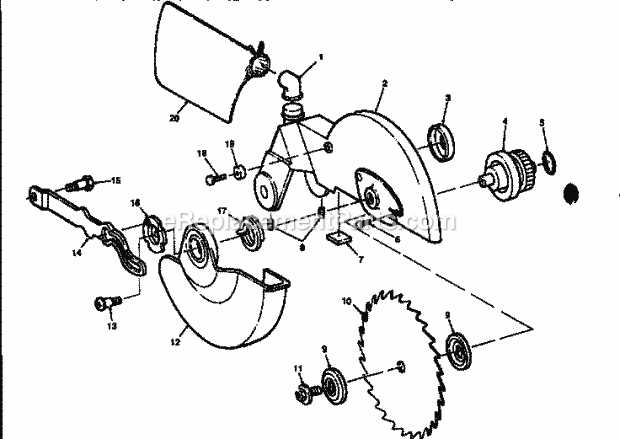

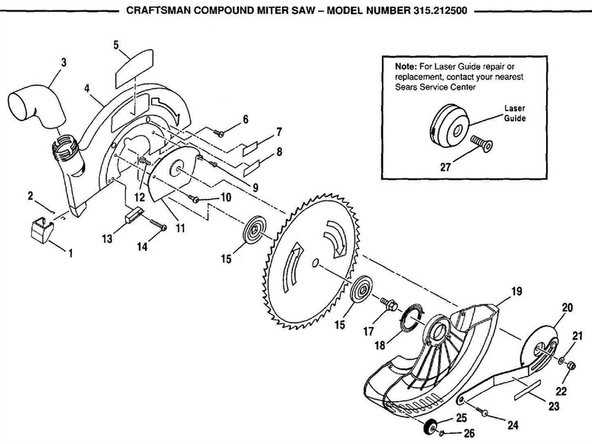

Main Components of a Miter Saw

Understanding the core elements of this cutting tool is essential for efficient operation and maintenance. These components work together to ensure accurate cuts and smooth performance, making the tool highly versatile for a variety of woodworking tasks.

- Base: The sturdy foundation that supports the entire tool and ensures stability during use.

- Blade Guard: A safety feature designed to protect the user by covering the cutting edge when not in operation.

- Motor: Powers the cutting mechanism, driving the blade at high speeds for precision work.

- Fence: Provides support for the workpiece, helping to keep it in place and ensuring accurate alignment during cutting.

- Handle: The control point for guiding the cutting head and applying pressure during operation.

- Adjustment Knobs: Allow for setting specific angles and depths for customized cutting tasks.

Each of these components plays a crucial role in the functionality and safety of the tool, ensuring that it performs efficiently in various woodworking projects.

Blade Guard and Its Role

The blade guard serves as a crucial safety feature designed to protect users from the cutting edge during operation. Its primary function is to cover the sharp edges, minimizing the risk of accidental contact. Whether performing precise cuts or adjusting materials, this component ensures a safer working environment by limiting exposure to the moving blade.

How the Blade Guard Enhances Safety

The guard automatically retracts when cutting and returns to its protective position once the task is complete. This mechanism significantly reduces the chance of injury, especially during repositioning or material handling. The guard’s movement is smooth and synchronized with the cutting tool, allowing for efficient protection without hindering the cutting process.

Maintenance and Care for Optimal Function

Regular maintenance of the guard ensures its long-lasting performance. Keeping it free from debris and ensuring smooth movement prevents potential hazards caused by malfunction. Additionally, periodic checks for wear and tear will help maintain its protective capabilities, ensuring consistent safety during every operation.

Understanding the Fence Mechanism

The fence mechanism plays a crucial role in ensuring precise and stable cutting operations. It serves as a guiding support, maintaining the workpiece in a secure position to prevent any unwanted movement during the cutting process. A well-functioning fence ensures accuracy, allowing for straight and consistent cuts with minimal effort.

One of the key aspects of a reliable fence system is its adjustability. It allows users to fine-tune the position according to the size and type of the material being worked on, ensuring optimal results. Let’s take a closer look at the common components involved in this mechanism:

| Component |

Description |

| Locking Knobs |

Used to secure the fence in the desired position, ensuring stability during operation. |

| Sliding Rails |

Allow smooth movement of the fence, enabling precise adjustments for various material sizes. |

| Alignment Markings |

Provide visual guidance for positioning the fence accurately according to the desired cut length. |

Exploring the Bevel Adjustment System

The bevel adjustment mechanism plays a crucial role in achieving accurate angled cuts. This system allows for precise angular movements of the cutting tool, ensuring that materials can be shaped to the desired angles without error. Understanding how to properly use and maintain this feature enhances overall performance and longevity.

Key Components of the Adjustment Mechanism

The system consists of several essential components that work together to allow smooth adjustments and accurate angle setting. These parts are designed to provide flexibility and precision.

- Adjustment Handle: Used to release and lock the angle settings.

- Angle Scale: Provides a clear reading of the current angle for exact positioning.

- Locking Mechanism: Ensures the selected angle stays securely in place during operation.

How to Properly Adjust and Lock Angles

To adjust the bevel, release the locking mechanism by turning the handle, then align the tool using the angle scale to the desired position. Once the correct angle is selected, securely lock the handle back in place to ensure stability.

- Release the adjustment handle.

- Select the desired angle using the scale.

- Lock the handle to secure the setting.

Trigger Switch and Power Control

The trigger mechanism and power regulation components play a crucial role in the functionality of cutting tools. These elements are designed to offer precise control over the device’s operation, ensuring that users can execute their tasks efficiently and safely. Understanding how these components work together can enhance the overall experience and extend the lifespan of the equipment.

Functionality of the Trigger Switch

The trigger switch serves as the primary interface for initiating and terminating the tool’s operation. By pressing the switch, users can easily manage the power flow to the motor, allowing for immediate responsiveness to various cutting tasks. The design often incorporates safety features to prevent accidental activation, which is essential for user safety.

Power Control Mechanisms

Power control systems are integral in regulating the voltage and current supplied to the motor, enabling optimal performance under different load conditions. These mechanisms can include variable speed settings that allow users to adjust the cutting speed based on material type and thickness. Proper maintenance of these components is vital for ensuring consistent power delivery and preventing electrical issues.

Guide to the Miter Scale

The angle measurement system on your cutting tool is essential for achieving precise cuts. Understanding this scale can significantly enhance your accuracy and efficiency when working on various woodworking projects. This guide aims to provide insights into utilizing the angle markings effectively, ensuring you can achieve the desired results every time.

Understanding the Scale

The scale typically displays a range of angles, often marked in degrees. Each increment allows you to set the tool to a specific angle, facilitating bevel and compound cuts. Familiarizing yourself with these measurements will enable you to make quick adjustments without having to rely on external tools. Whether you’re crafting frames or intricate furniture pieces, the ability to manipulate these angles accurately is crucial.

Tips for Accurate Settings

To optimize your cutting experience, always double-check the angle setting before making a cut. Calibration of the scale can vary between different models, so ensure that your tool is correctly adjusted for consistent performance. Additionally, practice using the scale on scrap materials before tackling your main project to enhance your confidence and precision.

Proper Maintenance of Moving Parts

Ensuring the longevity and efficiency of machinery hinges on the appropriate care of its dynamic components. Regular upkeep not only enhances performance but also prevents unexpected malfunctions, thereby prolonging the equipment’s lifespan. By focusing on the pivotal elements that experience continuous motion, users can maintain optimal functionality and safety.

Regular Cleaning and Lubrication

One of the essential practices for maintaining moving elements is routine cleaning and lubrication. Dust, debris, and other contaminants can accumulate, causing friction and wear. Cleaning these surfaces with a soft cloth and applying suitable lubricants help minimize resistance and keep components operating smoothly. It is crucial to follow manufacturer recommendations for lubricant types and application intervals to avoid damage.

Inspection and Adjustment

Frequent inspections of mobile mechanisms are vital to identify signs of wear or misalignment. Users should check for any unusual noises or vibrations during operation, which can indicate underlying issues. Tightening loose screws and adjusting components to ensure proper alignment can significantly enhance performance and safety. Addressing minor problems early can prevent more extensive repairs down the line.