In the world of machinery and tools, having a clear understanding of the internal mechanisms is essential for maintenance and repair. A well-structured representation of these elements not only aids in identifying individual components but also streamlines the troubleshooting process. This guide aims to provide insights into the layout of various parts, enhancing your familiarity with your equipment.

Accurate identification of each segment is crucial for anyone looking to ensure optimal performance. Whether you are a seasoned technician or a DIY enthusiast, having access to a detailed schematic can significantly simplify the task at hand. This resource will help you navigate through the complexities of assembly and functionality.

Moreover, familiarity with the arrangement of each piece contributes to better decision-making when it comes to repairs and upgrades. By visualizing how components interact, you can develop a more comprehensive understanding of the overall system, leading to more effective maintenance strategies.

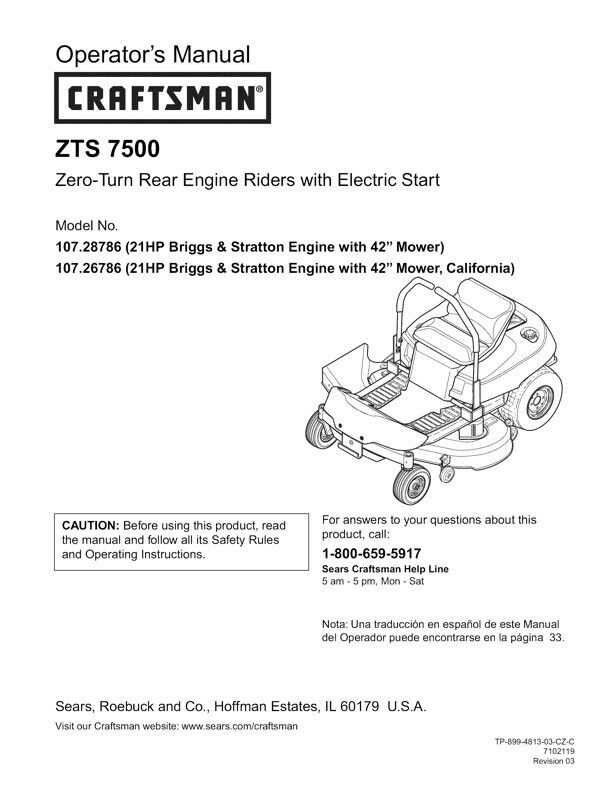

Understanding Craftsman ZTS 7500

This section aims to explore the intricate details and essential components of a specific model, highlighting its design and functionality. By examining its construction and operational principles, we can appreciate how each element contributes to its overall performance.

| Component | Description |

|---|---|

| Engine | Power source that drives the machine, ensuring efficiency and reliability. |

| Transmission | System responsible for transferring power from the engine to the wheels. |

| Chassis | The framework that supports various parts, enhancing stability and durability. |

| Control System | Interface for the user, allowing for precise operation and adjustments. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations enhance clarity, allowing users to identify specific elements quickly and accurately. This not only streamlines the repair process but also minimizes the risk of errors, ensuring that each component is handled appropriately.

| Benefit | Description |

|---|---|

| Efficiency | Facilitates quicker repairs by providing a clear view of the assembly. |

| Accuracy | Reduces mistakes in identifying and replacing components. |

| Learning | Helps users understand the function of each part and their interrelationships. |

| Safety | Promotes safe handling practices by detailing assembly instructions. |

Key Components of the ZTS 7500

This section highlights the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these crucial components is vital for effective maintenance and optimal performance.

- Engine: The powerhouse that drives the entire system.

- Transmission: Ensures smooth power delivery to the wheels.

- Chassis: The framework that supports all other components.

- Hydraulic System: Facilitates movement and control of attachments.

- Electrical System: Powers essential functions and controls.

Each of these parts plays a pivotal role in the overall operation, making it crucial to delve into their specific functions and maintenance requirements.

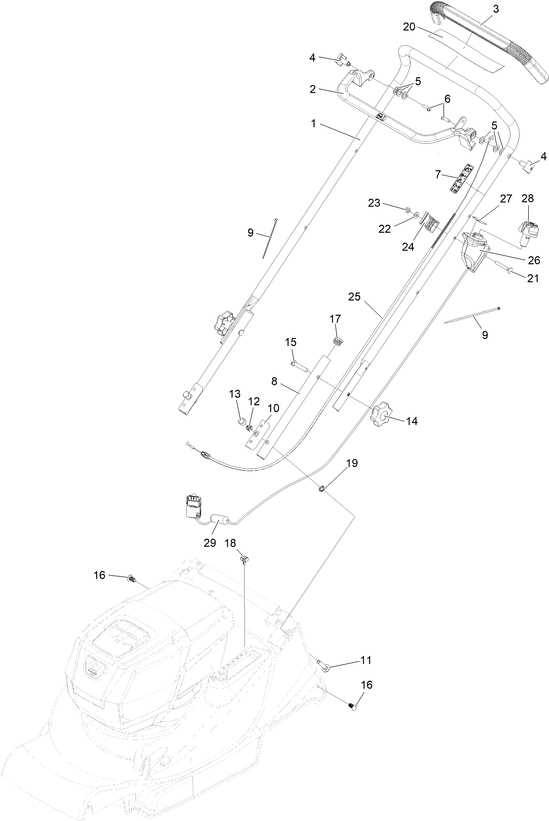

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to repair and maintain machinery. These visual guides provide essential insights into the arrangement and interaction of various elements, making it easier to identify what you need for your project.

Here are key steps to effectively interpret such illustrations:

- Familiarize Yourself with Symbols: Each icon represents a specific part. Take time to learn what each symbol means to avoid confusion.

- Identify the Layout: Notice how parts are organized. Typically, these visuals show how components fit together, often from a top-down perspective.

- Refer to the Legend: Most visuals come with a legend that explains the symbols and lines used. Make sure to consult this section to grasp the meanings fully.

- Pay Attention to Numbers: Each part is usually labeled with a number or code that corresponds to a list. Use this list to find specific details about each item.

- Understand Connections: Look for lines that indicate how components interact. These connections can show the flow of energy or materials, which is crucial for troubleshooting.

By following these steps, you will become more adept at navigating these visual aids, ultimately leading to more efficient repairs and maintenance of your equipment.

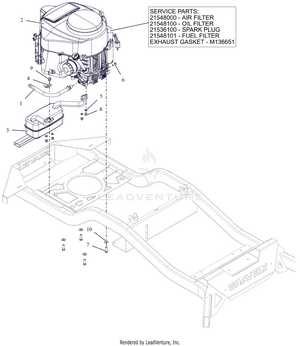

Common Replacement Parts Available

When maintaining outdoor power equipment, understanding which components frequently need to be replaced can enhance longevity and performance. Many users encounter wear and tear on various elements, making it essential to identify these common items for easy replacement.

| Component | Description | Function |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine. | Enhances engine efficiency and performance. |

| Spark Plug | Ignites the air-fuel mixture in the combustion chamber. | Ensures smooth engine operation and starting. |

| Fuel Filter | Removes impurities from the fuel supply. | Protects the engine from harmful particles. |

| Blades | Sharp edges that cut grass or other materials. | Provides a clean and precise cut. |

| Batteries | Power source for electric start models. | Facilitates easy starting of the engine. |

Maintenance Tips for Your Craftsman

Proper upkeep of your tools ensures longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Here are some essential practices to keep your equipment in top shape.

First, always clean your tools after use. Removing dirt, debris, and residue will help maintain functionality and prevent corrosion. Use a soft brush or cloth, and for stubborn grime, consider mild cleaning agents.

Next, check for loose or damaged components regularly. Tightening screws and bolts can prevent bigger issues and ensure safety during operation. Replace worn-out parts promptly to avoid further damage.

Lubrication is crucial for moving parts. Use appropriate oils or greases to reduce friction and wear. Refer to the manufacturer’s guidelines for specific lubrication points and products.

Store your equipment in a dry, clean environment. Proper storage protects against moisture and dust, which can lead to deterioration over time. Consider using protective covers or cases.

Lastly, follow the recommended service schedule. Routine inspections and servicing by professionals can identify potential problems early and keep your tools running smoothly.

Where to Find Official Diagrams

Accessing authentic illustrations for your equipment is crucial for proper maintenance and repairs. These resources ensure you have accurate information, enhancing your understanding of components and their functionalities.

Official Manufacturer Websites

- Visit the support section for downloadable resources.

- Check for user manuals that often contain detailed schematics.

Authorized Dealers and Repair Shops

- Contact local dealers for access to proprietary resources.

- Inquire at repair shops that may provide copies of official materials.

DIY Repairs: A Step-by-Step Guide

Embarking on a do-it-yourself repair project can be a rewarding experience, allowing you to save money and gain valuable skills. Whether you’re fixing a malfunctioning device or enhancing an existing item, having a clear plan can make the process smoother and more efficient. This guide will walk you through essential steps to ensure your repair is successful.

- Assess the Situation:

Before diving into repairs, carefully examine the item. Identify the specific issues and take note of any visible damage.

- Gather Necessary Tools:

Collect all required tools and materials. Common items include:

- Screwdrivers

- Wrenches

- Pliers

- Replacement parts

- Cleaning supplies

- Disassemble with Care:

Begin the disassembly process. Keep track of screws and components by organizing them in a labeled container.

- Conduct Repairs:

Replace or fix the damaged parts as needed. Follow any instructions you have, or consult online resources for guidance.

- Reassemble the Item:

Once repairs are complete, carefully reassemble the item, ensuring all pieces fit snugly and securely.

- Test Functionality:

After reassembly, conduct a thorough test to ensure everything is functioning correctly. Address any remaining issues if necessary.

By following these steps, you can tackle various repair projects with confidence, transforming your skills and resources into effective solutions.

Enhancing Performance with Upgrades

Improving efficiency and effectiveness in your machinery can often be achieved through strategic enhancements. Upgrading specific components can lead to significant gains in power, durability, and overall performance. By selecting the right modifications, you can ensure your equipment operates at its best, tailored to meet your specific needs.

Key upgrades typically focus on enhancing functionality and reliability. Whether it’s optimizing engine performance, increasing fuel efficiency, or enhancing user comfort, each upgrade plays a crucial role in elevating the overall experience. Understanding which modifications to pursue can transform your equipment into a more powerful and versatile tool.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Enhancements | Modifications to increase horsepower and torque. | Improved acceleration and load capacity. |

| Fuel System Upgrades | Improvements to optimize fuel delivery and efficiency. | Better fuel economy and reduced emissions. |

| Suspension Adjustments | Upgrades for better handling and stability. | Enhanced ride quality and control. |

| Electrical System Enhancements | Upgrades to the battery and wiring for greater reliability. | Increased starting power and accessory performance. |

Each of these modifications can be tailored to fit specific operational requirements, ensuring that your machinery remains efficient and effective over time. Prioritizing these enhancements will not only extend the lifespan of your equipment but also provide a superior working experience.