In the world of outdoor equipment maintenance, having a clear understanding of the various elements that contribute to efficient operation is essential. Properly functioning machinery not only enhances performance but also extends the lifespan of the device. This section delves into the intricacies of a specific model’s essential components, offering insights into their arrangement and functionality.

By exploring the layout and interconnections of these vital parts, users can gain valuable knowledge for troubleshooting and repairs. Each segment plays a crucial role in ensuring the overall effectiveness of the equipment, making it imperative for owners to familiarize themselves with how everything fits together.

Equipped with this understanding, enthusiasts and professionals alike can make informed decisions when it comes to maintenance, upgrades, or replacements. This guidance aims to empower users, enabling them to navigate the complexities of their machines with confidence and precision.

Understanding the Craftsman LT1000 Mower

This section explores the essential features and components of a popular lawn care machine. Understanding its functionality can enhance maintenance and improve performance, ensuring a well-kept yard. This device is designed for efficiency, offering various options for tackling different terrains.

Key Features

The machine is equipped with a robust engine, providing reliable power for a range of cutting tasks. With adjustable settings, users can customize the height of the cut, making it versatile for different grass types. Additionally, the ergonomic design facilitates ease of use, allowing for comfortable operation during prolonged sessions.

Maintenance Tips

Regular upkeep is crucial for longevity. Checking the oil level, cleaning the air filter, and inspecting the blades are fundamental practices. Furthermore, ensuring that the wheels are in good condition can greatly enhance mobility. By delving into these maintenance routines, users can ensure optimal performance and durability.

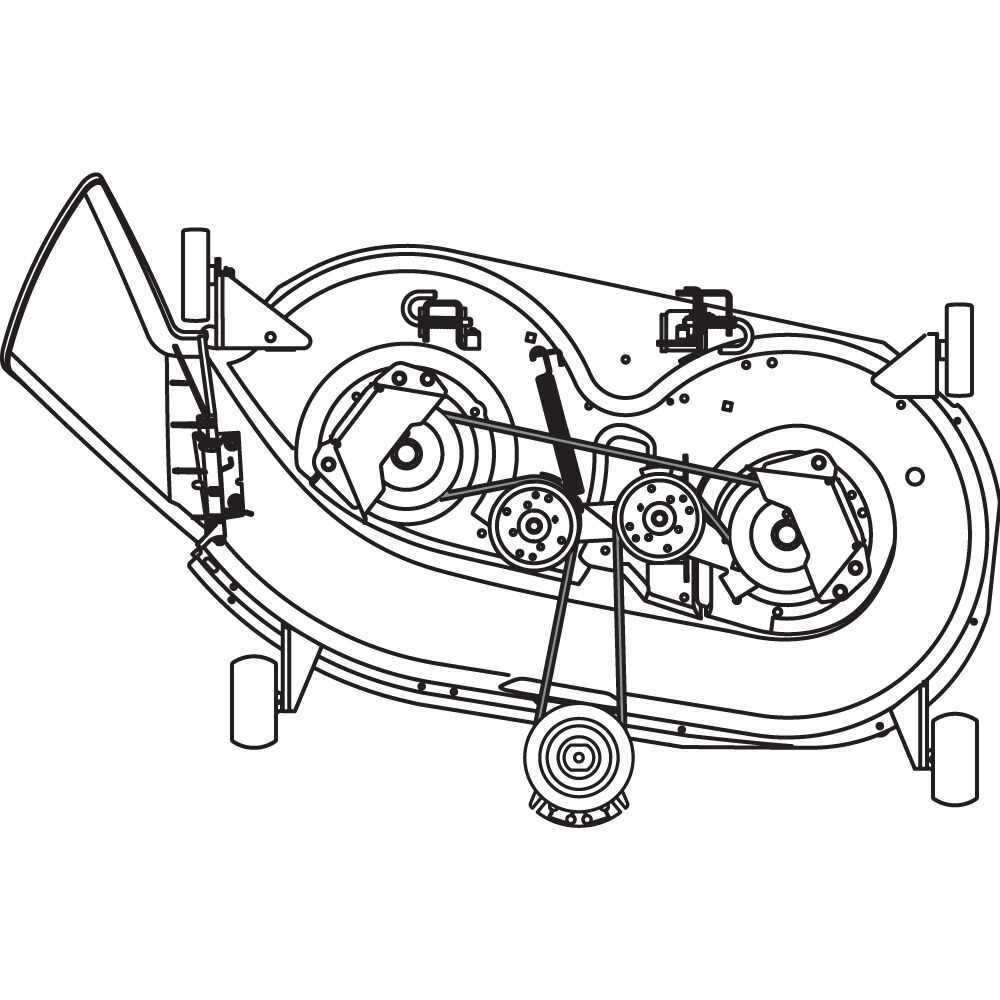

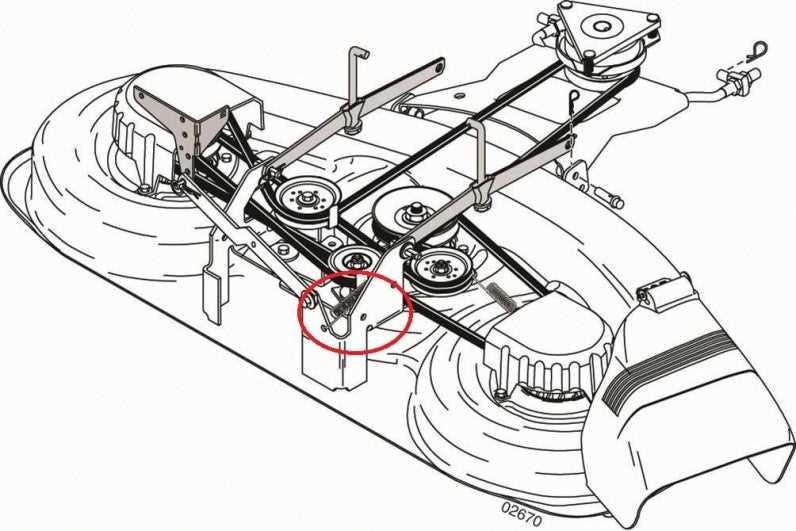

Key Components of Mower Decks

Understanding the essential elements of cutting equipment can significantly enhance maintenance and performance. Each component plays a vital role in ensuring optimal functionality and longevity, contributing to a more efficient lawn care experience.

Main Elements

- Blades: Crucial for achieving a clean cut, they come in various shapes and sizes.

- Spindles: These house the blades and facilitate their rotation.

- Housing: The outer shell protects internal components and directs grass clippings.

- Wheels: They aid in maneuverability and height adjustment during operation.

Supportive Structures

- Brackets: Provide stability and secure attachment to the main unit.

- Belts: Transfer power from the engine to the blades for effective cutting.

- Guards: Enhance safety by preventing debris from being ejected during use.

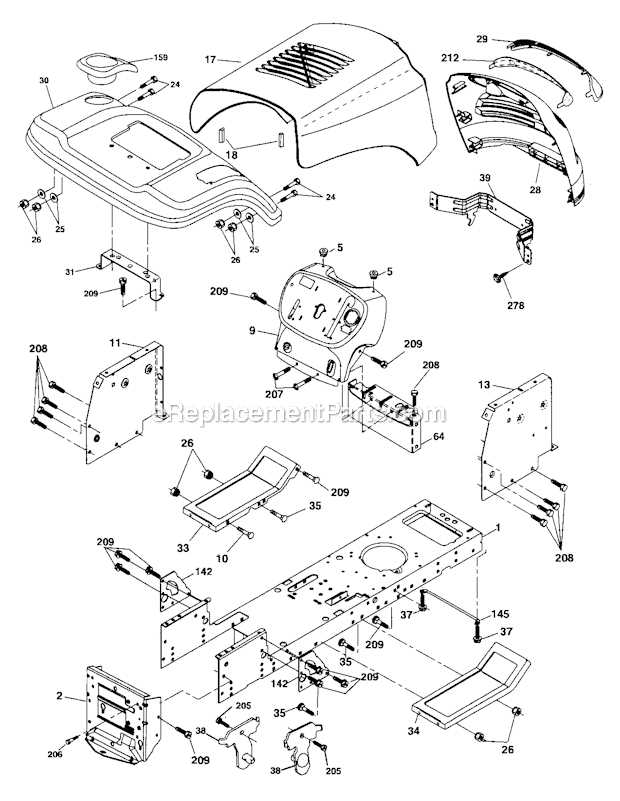

Importance of Accurate Parts Diagrams

Having precise representations of components is essential for effective maintenance and repair. These visuals serve as invaluable resources, enabling users to identify and locate each element within a system. When individuals have access to reliable schematics, they can ensure that replacements are correct and that assembly is conducted seamlessly.

Facilitating Troubleshooting

When issues arise, accurate illustrations simplify the diagnostic process. Users can refer to these detailed layouts to pinpoint the origin of a malfunction. With a clear understanding of how each part fits and functions, they can swiftly address problems, reducing downtime and enhancing efficiency.

Enhancing Repair Accuracy

Correctly identifying necessary components is vital for successful repairs. Clear schematics minimize the risk of errors, ensuring that individuals select the right items for replacements. This not only saves time but also minimizes costs associated with purchasing incorrect or incompatible pieces. In the long run, having precise representations significantly boosts the reliability and longevity of equipment.

Common Issues with Mower Decks

Maintaining a lawn care machine is essential for optimal performance and longevity. Various problems can arise that affect the efficiency of the cutting mechanism, leading to uneven results and increased wear. Understanding these common challenges can help owners troubleshoot and maintain their equipment more effectively.

| Issue | Description | Potential Solutions |

|---|---|---|

| Clogging | Debris accumulation can hinder cutting efficiency, causing poor results. | Regularly clean the cutting area and check for obstructions. |

| Uneven Cutting | When the blades are not properly aligned, it results in inconsistent grass height. | Inspect and adjust blade height and alignment as necessary. |

| Worn Blades | Dull blades can tear rather than cut, leading to damage and a ragged appearance. | Sharpen or replace blades regularly to ensure clean cuts. |

| Vibration | Excessive movement during operation can indicate loose components or imbalanced blades. | Check for tightness in bolts and assess blade balance. |

| Rust and Corrosion | Moisture exposure can lead to deterioration of metal components. | Store equipment in a dry area and apply protective coatings as needed. |

How to Identify Replacement Parts

Identifying the correct components for maintenance and repairs can significantly enhance the performance and longevity of your equipment. Understanding the features and specifications of these elements is crucial for ensuring compatibility and efficiency.

Step-by-Step Identification

Begin by consulting the owner’s manual, which often contains detailed information about specifications and compatible replacements. If the manual is unavailable, examine the equipment for any serial or model numbers that can assist in identifying the right components. Additionally, consider taking photographs of the existing parts to compare with catalogs or online resources.

Utilizing Online Resources

Many online platforms offer extensive databases where you can delve into various components and their specifications. Utilize search filters to narrow down your options based on the model or specific features, making it easier to find the ultimate replacement.

Maintenance Tips for Mower Decks

Proper care and attention to key components are essential for ensuring the longevity and optimal performance of your lawn equipment. Regular maintenance not only improves efficiency but also enhances the quality of your mowing experience. Here are some valuable tips to keep in mind.

Regular Cleaning

Debris buildup can hinder performance and lead to rust and corrosion. To maintain your equipment, consider the following steps:

- After each use, remove grass clippings and dirt.

- Use a soft brush or cloth to clean hard-to-reach areas.

- Inspect for any signs of wear or damage.

Inspection and Adjustment

Routine checks help identify issues before they escalate. Focus on these areas:

- Check blades for dullness or damage; sharpen or replace as needed.

- Examine belts for wear; ensure they are properly tensioned.

- Inspect for any loose bolts or connections; tighten where necessary.

By following these maintenance practices, you can extend the life of your equipment and ensure it operates at peak performance for years to come.

Where to Purchase Replacement Parts

Finding the right components for your outdoor machinery is essential for maintaining its performance. Various sources offer the necessary items, ensuring you can easily restore your equipment to optimal condition.

| Source | Description |

|---|---|

| Local Hardware Stores | These establishments often carry a selection of components for common models, allowing for quick access and immediate assistance. |

| Online Retailers | Websites specializing in outdoor equipment provide extensive catalogs, making it easy to compare prices and find specific items. |

| Manufacturer Websites | Direct purchases from the original equipment maker ensure authenticity and compatibility with your machinery. |

| Auto Parts Stores | Some auto parts retailers stock equipment components, often at competitive prices. |

| Local Repair Shops | These services may have access to parts and can assist with installation, ensuring proper function. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues related to lawn maintenance equipment. By following a structured method, you can effectively identify problems, gather necessary tools, and execute repairs with confidence, ensuring optimal performance for your machinery.

Identifying the Problem

The first step in any repair process is to accurately diagnose the issue. Start by observing any unusual sounds or behaviors during operation. Check for signs of wear or damage, such as rust, cracks, or loose components. Take notes on your findings, as this will help you determine the necessary actions for a successful fix.

Gathering Tools and Materials

Once the problem is identified, collect the tools and materials required for the repair. Essential items may include wrenches, screwdrivers, replacement components, and lubricants. Ensure that you have everything at hand before beginning the repair process, as this will streamline your efforts and minimize downtime.

Frequently Asked Questions About Mower Decks

This section addresses common inquiries related to the assembly and functionality of grass cutting equipment. Understanding these elements can significantly enhance maintenance and performance, ensuring optimal results during use.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven Cutting | Improper height adjustment | Check and adjust the height settings. |

| Excessive Vibration | Worn or damaged blades | Inspect blades for wear and replace if necessary. |

Maintenance Tips

Regular upkeep is essential for longevity. Keep the equipment clean, sharpen blades frequently, and check for loose components to ensure everything operates smoothly.