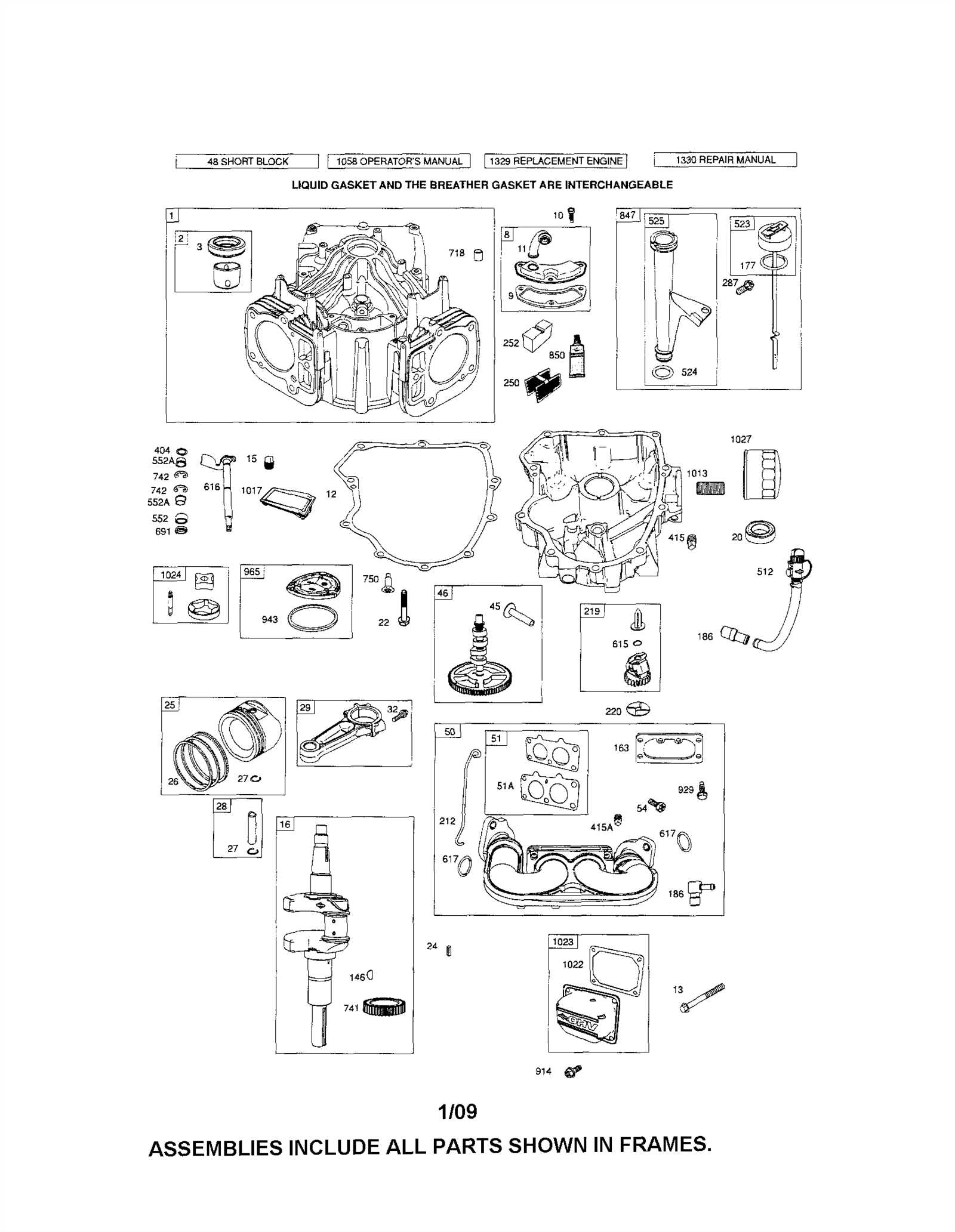

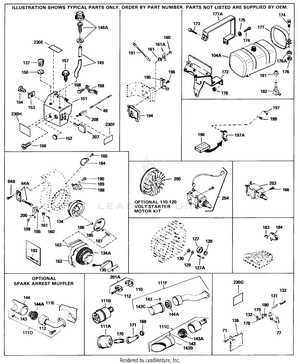

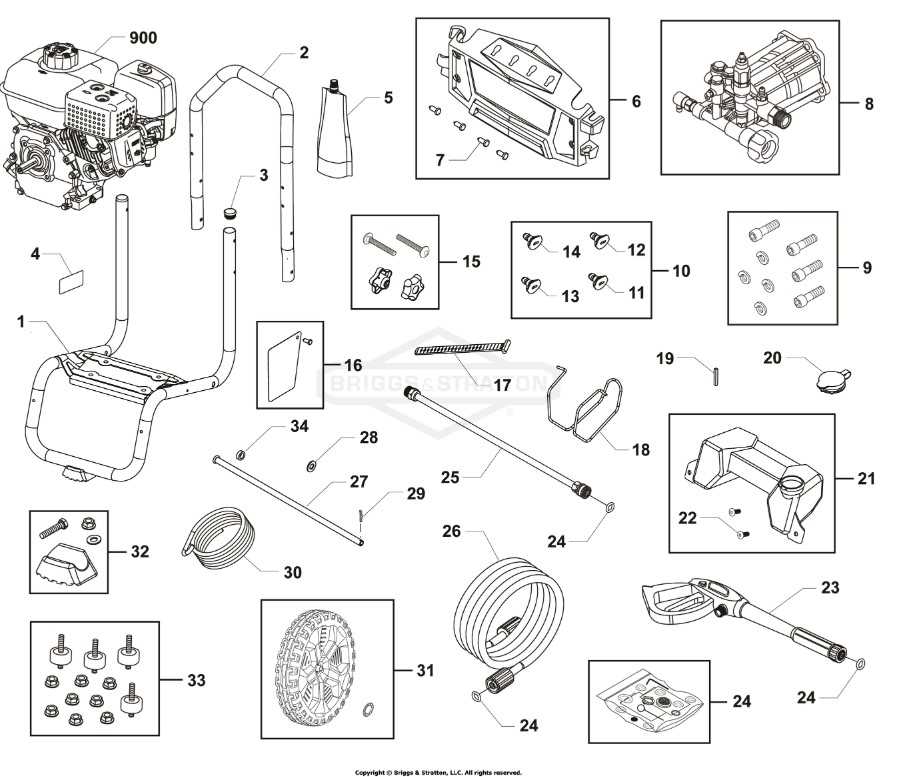

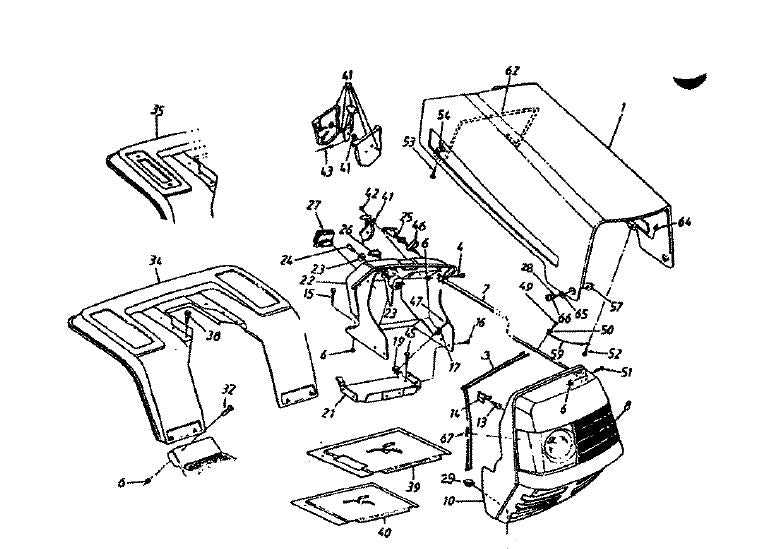

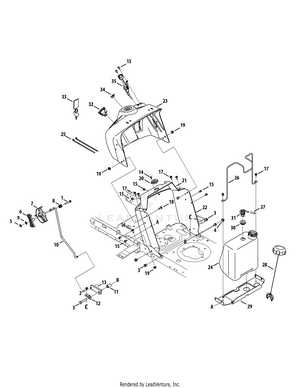

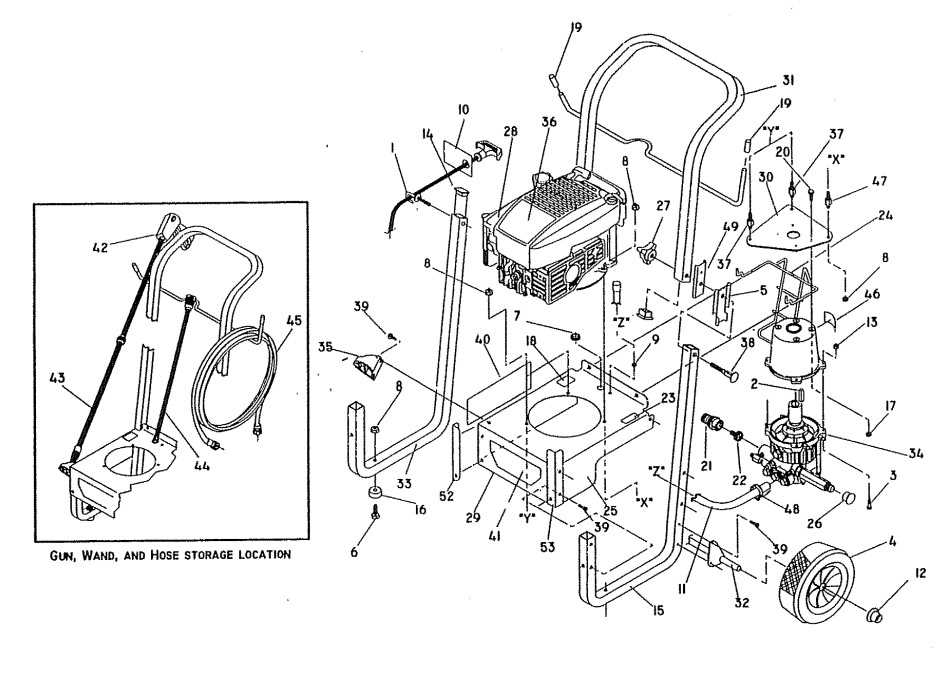

Every mechanical device is made up of multiple elements that work together to ensure optimal performance. Knowing how each of these individual parts functions can help in maintaining, repairing, or upgrading your equipment. Whether you’re a professional or a hobbyist, having access to a clear visual reference of how these components fit together is essential.

By familiarizing yourself with the internal workings of the tool, you can easily identify issues when they arise. This knowledge not only aids in diagnosing problems but also ensures that repairs are carried out efficiently and correctly. A well-organized visual guide can be the key to understanding the structure and interaction of each component, making it easier to recognize the necessary replacement or adjustment.

Understanding the assembly and placement of individual elements can lead to smoother maintenance tasks and prolong the lifespan of the equipment. Through careful analysis of these visual guides, users gain a comprehensive understanding of the device’s mechanics, fostering a more productive and informed approach to tool care.

Understanding Craftsman Parts Diagrams

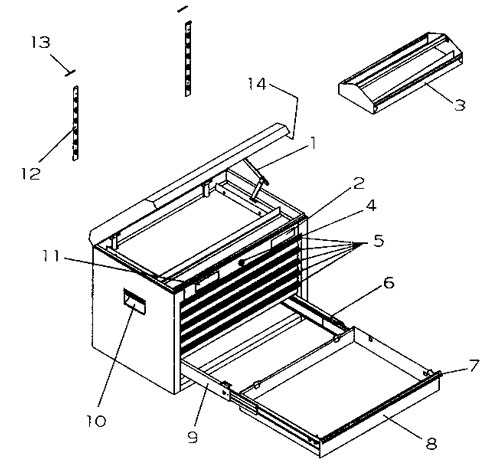

When working with mechanical devices or tools, it’s essential to have a clear visual representation of how individual components fit together. These illustrations are key for identifying each part’s function, location, and assembly process. They act as a map, helping users navigate the complex structure of equipment to ensure proper repairs, upgrades, or maintenance.

These detailed visuals provide a step-by-step guide for understanding the intricate assembly and disassembly processes, allowing users to manage tasks more effectively. They offer insight into various components that may need to be replaced or adjusted for optimal performance.

- Easy identification of individual parts

- Clear depiction of how each component interacts within the system

- Visual aid for more accurate troubleshooting and repair

- Helps with understanding the flow and sequence of assembly

By following the instructions in these visual resources, users can quickly become familiar with the necessary tools and techniques to complete their work. Understanding how the system operates is the first step toward ensuring its longevity and functionality.

How to Read a Parts Diagram

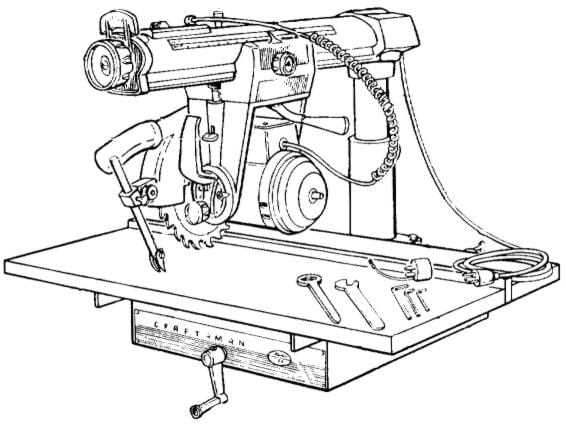

Understanding technical drawings that display the components of a machine or tool is essential for effective assembly, repair, or maintenance. These illustrations provide a visual representation of how various elements fit together, and each component is typically labeled for identification. The goal is to grasp how each piece interacts within the larger system, allowing you to efficiently navigate the repair or construction process.

Familiarize Yourself with Symbols and Numbers

Technical drawings often include symbols, numbers, and annotations that provide vital information. Each element in the drawing is usually labeled with a unique number, corresponding to a list of items that explains their function or additional details. Understanding these references is key to ensuring you can accurately match the parts with their corresponding labels.

Follow the Assembly Sequence

The arrangement of components in the visual representation often mirrors the order in which they should be assembled. Following this layout helps prevent errors and simplifies the overall process. Be sure to pay attention to how components connect, ensuring that every piece is placed in its correct position for proper operation.

Common Symbols Used in Diagrams

In technical illustrations, symbols play a crucial role in conveying essential information quickly and clearly. These graphical representations help users understand complex structures and components at a glance. By using a standardized set of symbols, anyone familiar with the system can interpret the visual cues without needing detailed descriptions for every element.

Circles often represent connectors or junctions, showing where different parts come together. Squares are typically used to denote structural elements or key mechanical components, while arrows indicate movement direction or flow paths. Additionally, dashed lines may symbolize invisible or hidden connections, offering clarity for parts that are not directly visible but still important to the overall design.

Understanding these basic symbols enables users to interpret the information presented in a way that enhances accuracy and efficiency in assembling or repairing machinery. The consistent use of these visual cues reduces confusion, making it easier to follow instructions and troubleshoot issues when necessary.

Locating the Right Parts for Your Tool

Finding the correct components for your equipment can be a challenging task, but understanding how to identify and select the right pieces will make the process much easier. Whether you’re repairing an old tool or upgrading to newer parts, it’s important to know where to look and how to choose the best option for your specific needs.

Identify Your Tool Model and Specifications

The first step in locating the right components is knowing exactly what model of tool you are working with. Check the manufacturer’s label or user manual for the precise model number. Understanding the specifications of your device, such as its size, usage, and any particular features, will also guide your search for compatible replacements.

Consult Reputable Sources

Once you’ve identified the tool and its specifications, turn to trusted sources for the parts you need. Many manufacturers and authorized dealers provide detailed catalogs or online search tools to help you pinpoint the exact items. Be sure to use resources that offer reliable information, including official websites and verified suppliers. Avoid third-party sellers who may not provide high-quality or compatible products.

The Importance of Accurate Parts Identification

Ensuring precise identification of components is essential for the seamless operation of any mechanical system. Properly recognizing each element allows for effective maintenance, repair, and replacement, preventing potential damage and improving overall functionality. When every piece is correctly identified, the chances of errors or mismatches during assembly are significantly reduced, ultimately saving time and resources.

Inaccurate identification can lead to costly mistakes, including delays in repairs, unnecessary purchases, and even damage to the equipment itself. Without clear identification, the risk of using incompatible or incorrect elements increases, which may cause malfunction or further breakdowns. Thus, having a well-structured reference or guide is crucial in avoiding such complications and ensuring that all necessary components are used correctly.

Moreover, a clear understanding of the specific elements involved fosters better communication between individuals working on the system. Whether it is a technician, engineer, or user, everyone involved benefits from a unified approach to recognizing the required components. This collective knowledge leads to improved efficiency and consistency in maintenance practices.

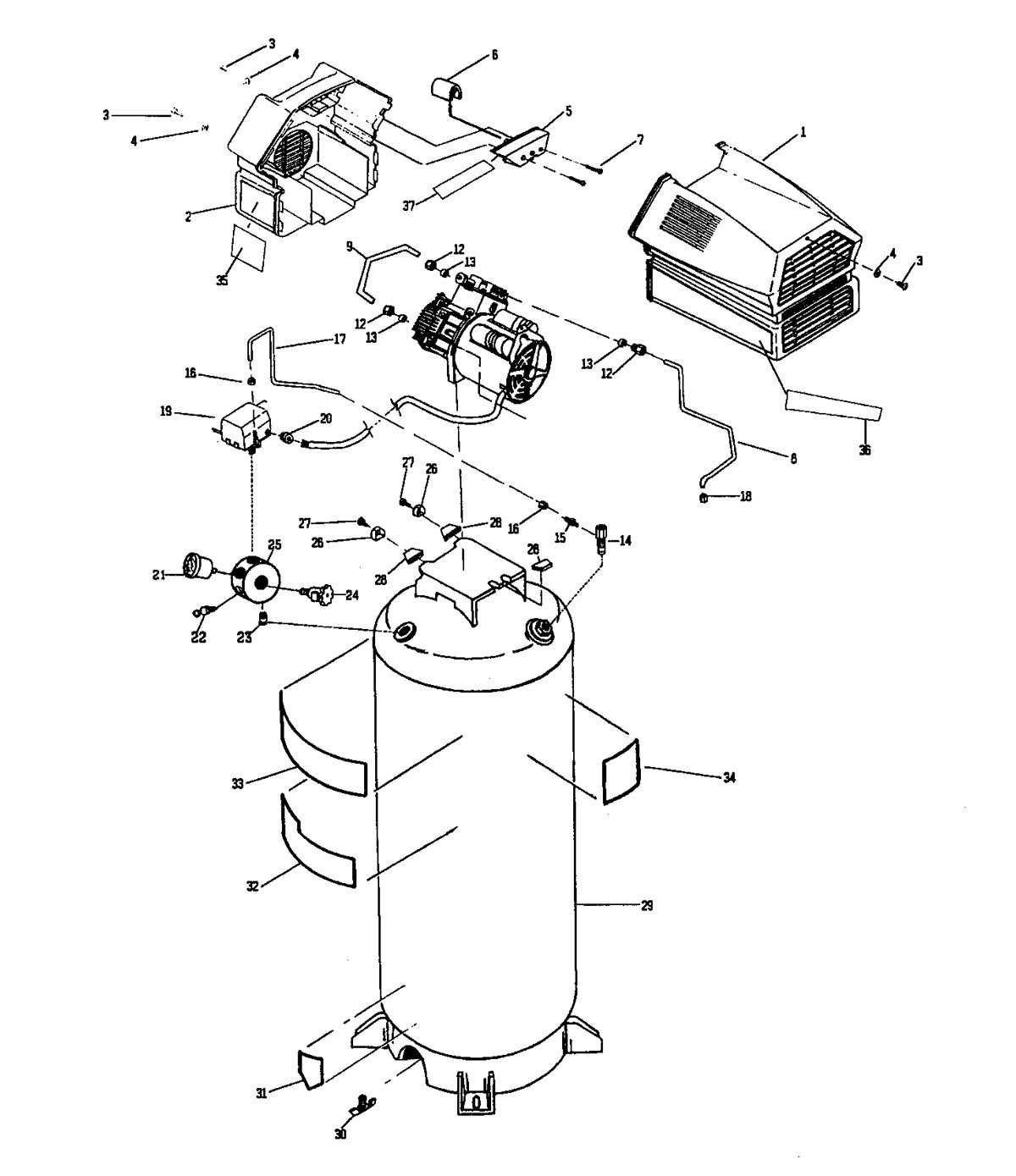

Craftsman Diagrams: A Visual Guide

Understanding the layout of tools and their components is essential for efficient maintenance and repairs. Visual representations provide a clear understanding of how different elements come together, ensuring that every piece is properly placed for optimal functionality. These visual aids simplify the assembly and disassembly processes, especially when handling complex equipment or machinery.

Exploring the power of visuals helps to break down complicated structures into manageable sections. By looking at these illustrations, users can easily identify which items are compatible with each other, reducing the chances of error during repairs or replacements. The clarity of these images also aids in troubleshooting by showing where the issue may lie within the overall system.

Step-by-step guidance is one of the major advantages of using these illustrations. They offer an organized approach to assembling different units, which is crucial for those who are not as familiar with the product. Instead of relying solely on verbal instructions, users can follow each step visually, making the process much smoother and more intuitive.

Where to Find Reliable Parts Information

For any project involving machinery, having access to accurate information regarding components is essential. Whether you are repairing an item or looking to replace certain elements, knowing where to gather trustworthy details ensures proper maintenance and longevity of the equipment. There are numerous resources available, but identifying the most reliable ones can save time and effort in the long run.

Manufacturer Websites

One of the most dependable sources for component details is the official website of the equipment’s manufacturer. These platforms often provide comprehensive reference materials, including user manuals, model specifications, and reference charts that are specifically designed for various models.

- Official support pages

- Online catalogs of components

- Direct access to technical documentation

Online Communities and Forums

Another valuable resource is online communities where enthusiasts and professionals gather to share insights. These forums can provide practical advice, troubleshooting tips, and sometimes even recommendations on compatible items from various manufacturers. Be cautious, though, as the quality of information can vary.

- Discussion boards related to DIY and repair

- Specialized groups for different machinery types

- Review platforms with user feedback on specific components

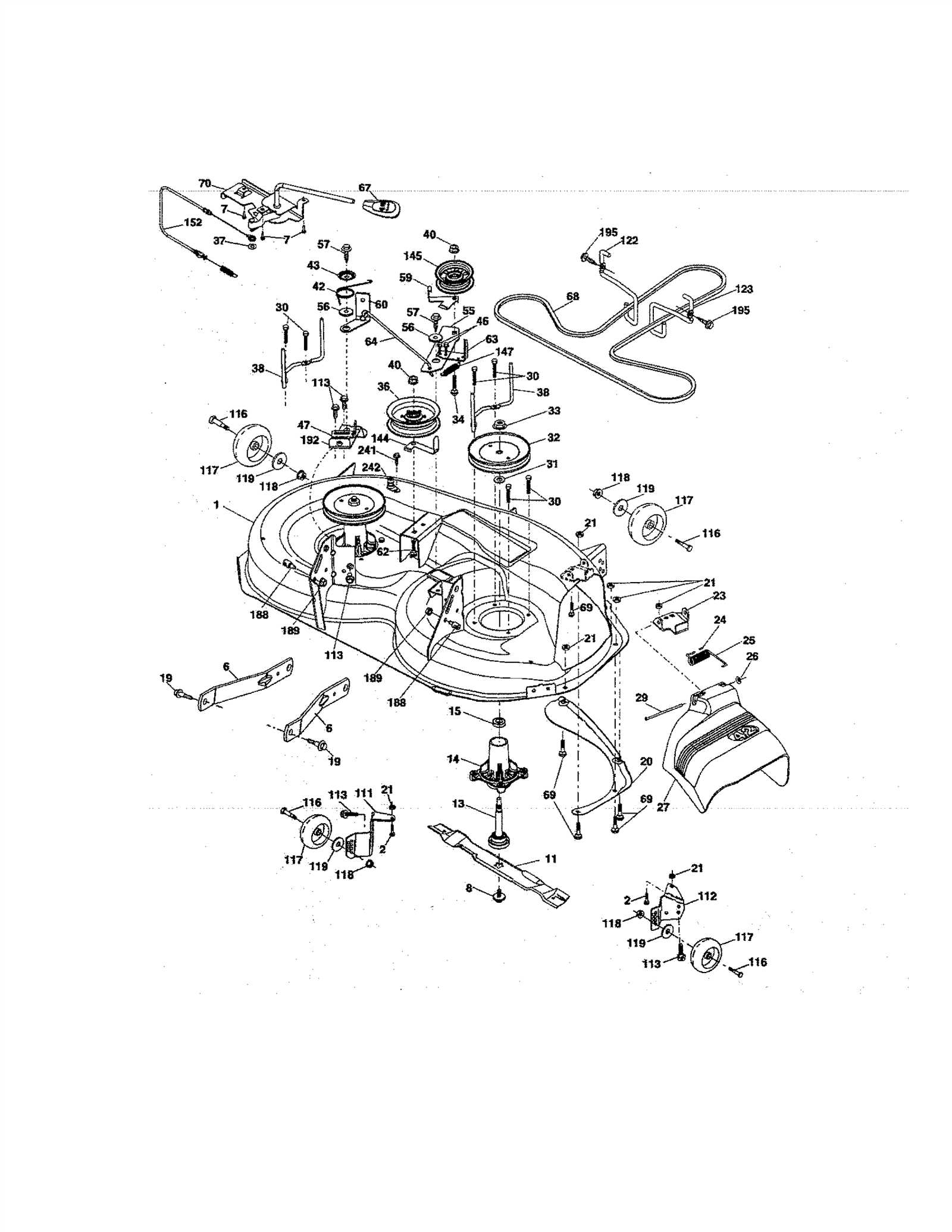

Tips for Replacing Parts Based on Diagrams

Replacing components in tools and machinery can be a daunting task, but with the right resources, the process becomes much simpler. Understanding how to read and follow visual guides can help you ensure that each part is correctly installed. Accurate replacement is essential to keep your equipment functioning at its best.

1. Identify the Correct Component

Before beginning the replacement process, make sure you have identified the exact component you need. Look for identifying marks, numbers, or codes that correspond to the part you are replacing. It is crucial to match the new piece with the old one to avoid compatibility issues.

2. Follow the Sequence

- Start by studying the visual guide thoroughly to understand the sequence of assembly.

- Take note of the orientation and position of each part, ensuring you follow the exact steps shown.

- If the guide is unclear, refer to manufacturer manuals or online resources for clarification.

3. Use the Right Tools

Having the right set of tools is vital for efficient and accurate replacement. Using incorrect tools may cause damage to the components or make the task more difficult. Always ensure that the tools you use are appropriate for the task at hand.

4. Double-Check Connections

- Verify that all connections are secure before reassembling your equipment.

- Take the time to inspect all connections twice or even three times to avoid mistakes.

5. Test the Equipment

After completing the replacement process, run a test to ensure that everything is functioning correctly. Listen for any unusual noises or check for improper functioning, which could indicate an issue with installation.

How to Order Craftsman Parts Online

Finding the right components for your tools and equipment can be a straightforward process when done online. Many websites offer an easy way to purchase essential items, ensuring your machinery remains in optimal condition. By understanding the online ordering process, you can quickly get the specific items you need without leaving your home.

1. Identify the Model and Serial Numbers

Before making a purchase, it is important to know the exact model and serial numbers of your equipment. This information ensures that you find the correct replacement pieces. If you are unsure where to locate this information, refer to the user manual or check the manufacturer’s plate on the machine.

2. Visit a Reputable Supplier’s Website

Several trusted online retailers specialize in tool components. Look for a website with a user-friendly search function and a wide variety of available items. Many platforms allow you to filter search results by machine type, brand, and part number, which simplifies finding exactly what you need.

3. Use a Product Lookup Tool

- Enter the machine’s model number in the site’s lookup tool.

- Browse through the different categories to find the appropriate item.

- Check if the component is compatible with your equipment before purchasing.

4. Compare Prices and Check Shipping Options

Once you have identified the correct part, compare prices from different suppliers to ensure you are getting the best deal. Additionally, consider the shipping options available, as some suppliers offer faster delivery times or free shipping for larger orders.

5. Complete the Checkout Process

- Provide accurate shipping and billing information.

- Select your preferred payment method.

- Review the order before confirming the purchase.

By following these steps, you can efficiently order the items you need for maintenance or repairs, ensuring that your tools remain in top working order.