In the world of machinery, comprehending the intricacies of individual components is crucial for effective maintenance and repair. Each element plays a significant role in ensuring optimal performance, and being familiar with their layout can simplify troubleshooting and enhance functionality.

Visual representations of the various sections help in identifying specific parts, aiding users in grasping the relationships between different elements. Such insights empower operators to manage their tools more efficiently, reducing downtime and promoting longevity.

By exploring detailed layouts, enthusiasts and professionals alike can equip themselves with the knowledge necessary to tackle repairs confidently. Understanding how everything fits together not only enhances practical skills but also fosters a deeper appreciation for the craftsmanship involved in designing these intricate systems.

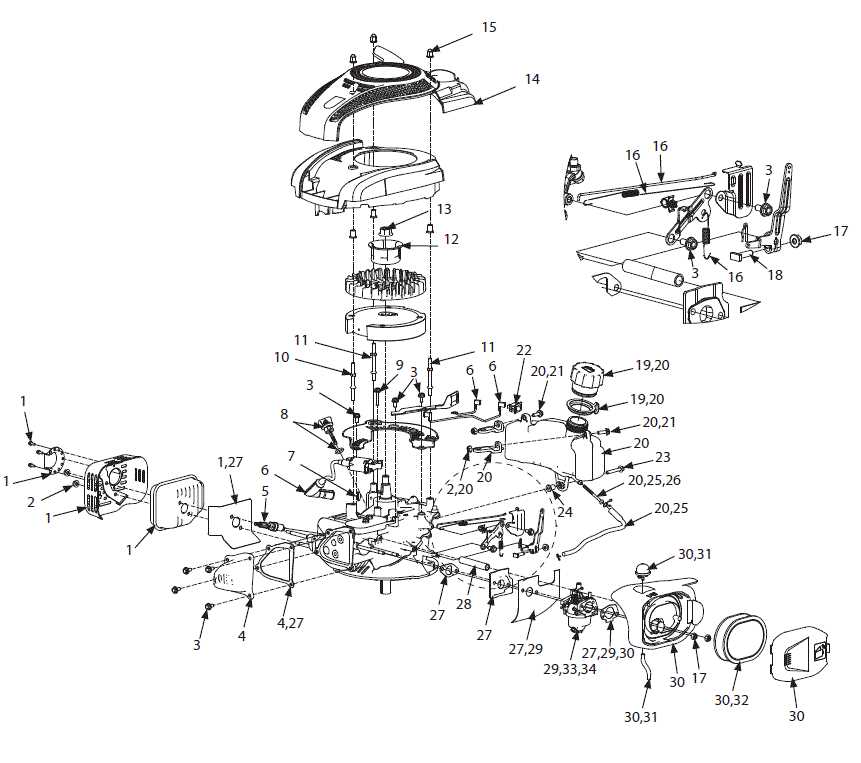

Understanding the Craftsman M220 Diagram

The schematic representation of a machine is an essential tool for both users and technicians. It provides a visual layout that helps in identifying individual components and their interconnections. Grasping this layout can significantly enhance maintenance efforts and troubleshooting processes, ensuring the equipment operates smoothly and efficiently.

Typically, such illustrations are categorized into sections that reflect different operational areas of the device. Familiarity with these sections can guide users in understanding functionality and the relationships between various elements. A detailed analysis of the schematic can reveal potential issues and assist in the replacement or repair of specific components.

| Component | Description |

|---|---|

| Engine | Power source that drives the entire mechanism. |

| Deck | The platform where primary operations take place. |

| Blade | Cutting element responsible for the primary function. |

| Handle | Control mechanism for guiding and operating the device. |

| Wheels | Facilitate movement and maneuverability on various terrains. |

By studying this representation, one can efficiently pinpoint areas that may require attention, making it a valuable resource for effective upkeep and repair tasks. A clear understanding of this schematic not only improves usability but also prolongs the lifespan of the equipment.

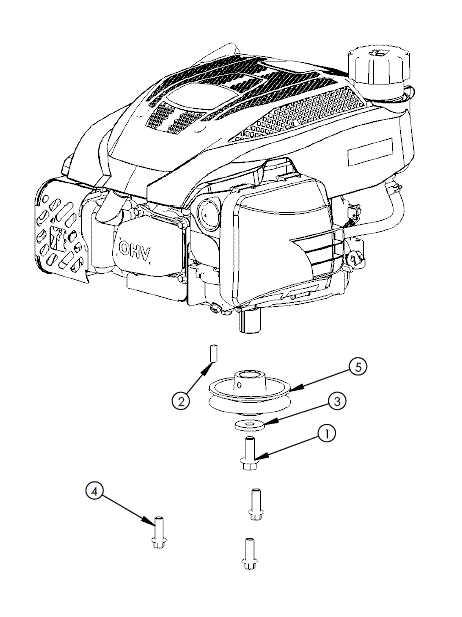

Key Components of the M220 Model

The functionality and performance of this particular model depend heavily on several crucial elements. Each component plays a significant role in ensuring efficiency and reliability during operation. Understanding these key parts can enhance the user experience and aid in maintenance and troubleshooting.

- Engine: The heart of the machine, responsible for power generation and overall performance.

- Blade Assembly: Vital for executing tasks effectively, this part determines cutting precision and quality.

- Chassis: Provides structural integrity and houses essential components, ensuring stability during use.

- Fuel System: Facilitates efficient energy transfer, impacting the performance and longevity of the engine.

- Electrical System: Powers various features and controls, enhancing user convenience and operational safety.

Each of these components works in harmony to deliver a seamless experience, making it essential for users to familiarize themselves with their functions and maintenance requirements.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides, showcasing how different elements fit together and function within a larger system. By familiarizing yourself with the conventions used in these visuals, you can enhance your troubleshooting skills and ensure that your equipment operates smoothly.

Familiarize with Symbols: Each representation uses specific icons and notations to denote various parts. Take time to learn what these symbols mean, as they often indicate not only the components but also their relationships and functions.

Follow the Layout: Typically, these visuals are organized in a logical manner, often reflecting the physical assembly. Start from one end and work your way through to grasp the overall structure. This approach helps in identifying how each piece interacts with others.

Cross-reference Numbers: Many illustrations include numerical references that correspond to a list of items. Make sure to cross-check these numbers with the accompanying documentation, as they provide crucial details such as specifications and part availability.

Look for Annotations: Notes and labels can offer additional insights, highlighting important information or common issues related to specific components. Pay attention to these annotations, as they can guide you in the maintenance process.

Practice Regularly: Like any skill, becoming proficient at interpreting these visuals takes practice. Regularly engaging with different illustrations will help solidify your understanding and improve your efficiency when working with equipment.

Common Repairs for Craftsman M220

Maintaining a high-performing lawn care tool often involves addressing common issues that can arise during use. Familiarizing yourself with typical repairs can help ensure that your equipment operates smoothly and efficiently. This section covers frequent problems and the steps needed to resolve them, enhancing the longevity of your machine.

One of the most prevalent issues is the difficulty in starting the engine. This can be caused by a variety of factors, including stale fuel, a clogged air filter, or spark plug problems. Regularly checking and replacing these components can significantly improve the starting process.

Another common repair involves blade maintenance. Dull or damaged blades can hinder performance and result in uneven cuts. Sharpening or replacing blades as needed will ensure optimal cutting efficiency and a healthier lawn.

Additionally, issues with the drive system can lead to poor movement or lack of propulsion. Inspecting the drive belts and wheels for wear and tear is crucial. Replacing these parts when necessary can restore functionality and ease of use.

Lastly, keeping an eye on the fuel system is essential. Clogged fuel lines or a dirty fuel filter can restrict flow and affect performance. Regular maintenance and cleaning of these components will help keep your tool running at peak performance.

Importance of Regular Maintenance

Benefits of Regular Upkeep

- Enhanced Efficiency: Regular checks ensure that all components are functioning correctly, leading to improved overall efficiency.

- Extended Lifespan: Proper care and timely repairs can significantly prolong the life of equipment.

- Cost Savings: Preventative maintenance often costs less than major repairs or replacements.

- Safety Assurance: Routine inspections help identify hazards, ensuring a safer working environment.

Key Maintenance Practices

- Regular Inspections: Conduct thorough examinations to identify wear and tear.

- Clean Components: Keep parts clean to prevent buildup that can hinder performance.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction.

- Replace Worn Parts: Timely replacement of damaged components is crucial to prevent further issues.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. Whether you are performing maintenance or need to replace a worn item, several reliable sources can provide you with what you need.

Online Retailers

The internet is a treasure trove of options for sourcing essential components. Many retailers specialize in various tools and equipment. Consider the following:

- Official manufacturer websites often have dedicated sections for accessories and replacements.

- Major e-commerce platforms feature numerous sellers, allowing for price comparisons and user reviews.

- Specialty sites focused on tool repair may offer hard-to-find items and advice.

Local Stores and Repair Shops

Visiting physical locations can also be beneficial. Explore these alternatives:

- Home improvement stores typically carry a selection of accessories and can order specific items if needed.

- Local repair shops may provide expertise and might have spare components available.

- Automotive supply stores often stock a range of items that could suit your needs, especially if they relate to outdoor equipment.

By leveraging both online and local resources, you can efficiently find the necessary components to keep your equipment in optimal condition.

Troubleshooting Issues with M220

Encountering problems with your outdoor equipment can be frustrating, but understanding common issues and their solutions can make the process easier. This section aims to guide you through typical challenges you may face, providing insights into identifying and resolving them effectively.

Common Problems and Solutions

One prevalent issue is the device failing to start. This can often be attributed to a lack of fuel, a drained battery, or a faulty spark plug. To resolve this, check the fuel levels and ensure the battery is charged. If necessary, replace the spark plug to restore functionality.

Maintenance Tips

Regular maintenance is crucial for optimal performance. Ensure that air filters are clean and replace them when needed. Additionally, inspect the blades for dullness; sharpening or replacing them can enhance cutting efficiency. Keeping the equipment clean and well-lubricated will also extend its lifespan and prevent many common issues.

Remember, addressing minor problems promptly can save you from more significant repairs down the line. Stay proactive to enjoy smooth operation throughout the season.

Upgrades for Improved Performance

Enhancing the functionality of your equipment can significantly elevate its overall performance and efficiency. By integrating specific modifications, users can achieve better results, extend the lifespan of their tools, and increase productivity. Below are some key upgrades to consider for optimal performance.

1. Engine Enhancements

Improving the engine is crucial for boosting power and efficiency. Here are some effective modifications:

- Upgrade to a high-performance air filter for better airflow.

- Install a more efficient spark plug to ensure optimal combustion.

- Consider using synthetic oil for reduced friction and better lubrication.

2. Cutting Performance Improvements

Enhancing the cutting capabilities can lead to cleaner results and faster operation. Consider the following options:

- Switch to a sharper blade for improved cutting efficiency.

- Adjust the cutting height settings for various tasks.

- Utilize specialized attachments for different surfaces and materials.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the quality and reliability of any product. Insights gained from individual experiences provide potential buyers with valuable information, helping them make informed decisions. In this section, we explore various testimonials and reviews, highlighting the overall satisfaction and common concerns expressed by customers.

Positive Feedback

Many users have reported high levels of satisfaction with their purchases, praising the durability and efficiency of the equipment. Customers appreciate the straightforward assembly process and the effectiveness in various tasks. Here are some highlights from their feedback:

| Customer | Experience |

|---|---|

| John D. | Exceptional performance and easy to use. Highly recommended for homeowners. |

| Lisa K. | Great value for money. It exceeded my expectations in terms of reliability. |

| Mike T. | Impressive build quality. Perfect for my gardening needs. |

Common Concerns

While many customers are satisfied, some have expressed concerns regarding certain aspects. Issues such as availability of replacement components and customer service responsiveness have been noted. Below are a few comments reflecting these challenges:

| Customer | Concern |

|---|---|

| Sara L. | Had difficulty finding specific components for repairs. |

| Tom R. | Customer support took longer than expected to respond. |

| Emily J. | Would like to see more instructional resources available. |