In the world of home heating solutions, having a comprehensive understanding of the various elements that contribute to efficient operation is essential. Each component plays a crucial role in ensuring optimal performance and longevity. Familiarity with these individual pieces can empower users to make informed decisions regarding maintenance and troubleshooting.

Detailed visual representations of these mechanisms provide invaluable insight into how they function together. By examining the layout and relationships between different sections, one can better appreciate the intricate design that enhances energy efficiency and comfort within the living space.

Moreover, knowing the specific features and functions of each segment can significantly aid in identifying potential issues. This knowledge not only facilitates timely repairs but also promotes a deeper understanding of how to maximize the effectiveness of the entire system, leading to a more comfortable home environment.

Understanding Whitfield Pellet Stoves

This section provides insights into a specific type of heating appliance that utilizes biomass for efficient warmth. These devices are designed for ease of use and optimal performance, making them a popular choice for many households.

Key features of these heating units include:

- Environmentally friendly fuel options

- Programmable settings for convenience

- Efficient heat distribution throughout spaces

To maintain optimal functionality, it’s essential to understand the various components that make up these systems. Here are some critical elements:

- Burner assembly – where combustion occurs

- Feed mechanism – controls the flow of fuel

- Heat exchanger – maximizes heat transfer

- Exhaust system – ensures safe venting of gases

Regular maintenance and understanding of each element’s role can significantly enhance performance and longevity, allowing users to enjoy a reliable and warm environment throughout the colder months.

Key Components of Pellet Stoves

Understanding the essential elements of modern heating appliances is crucial for effective operation and maintenance. Each unit is comprised of various integral components that work together to provide efficient warmth and comfort. Familiarity with these elements can aid users in troubleshooting and enhancing the overall performance of their heating systems.

Essential Elements

These heating devices are built with several critical components, each serving a unique function. From the ignition system to the exhaust mechanism, every part plays a vital role in ensuring optimal performance and safety.

| Component | Description |

|---|---|

| Burn Pot | Holds the fuel and allows for controlled combustion. |

| Auger | Delivers the fuel from the storage compartment to the burn pot. |

| Blower | Circulates air for combustion and distributes heat throughout the space. |

| Heat Exchanger | Transfers heat from combustion gases to the air being circulated. |

| Control Panel | Allows users to adjust settings and monitor performance. |

Maintenance and Care

Regular upkeep of these essential components is crucial for longevity and efficiency. Cleaning and inspecting each part can prevent malfunctions and ensure that the heating system operates smoothly throughout the colder months.

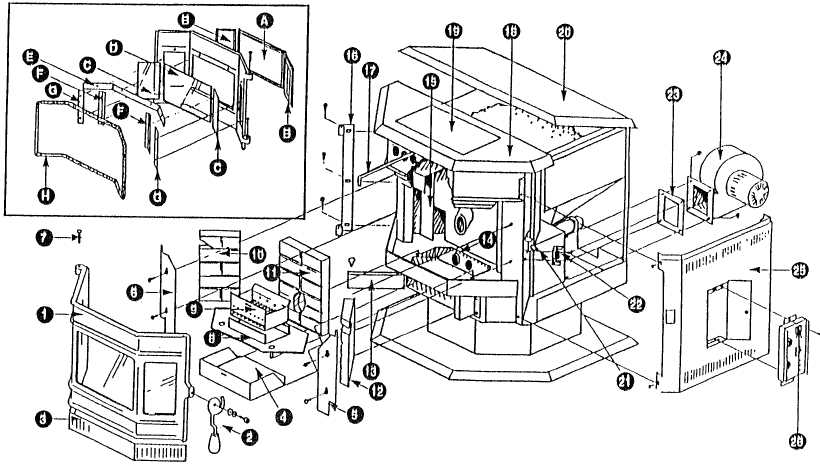

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding the functionality and assembly of any mechanical system. Such illustrations enable users to identify each element’s position and relationship with others, facilitating maintenance and troubleshooting processes.

Enhancing Understanding

Clear visual aids enhance comprehension, allowing users to grasp complex structures more effectively. By studying these representations, individuals can familiarize themselves with various components, making it easier to diagnose issues or perform repairs.

Streamlining Maintenance

Having an accurate representation of the system not only simplifies routine upkeep but also minimizes the risk of errors during reassembly. Detailed illustrations can guide users in ensuring that every component is correctly positioned, thereby optimizing overall performance and longevity.

Common Issues with Pellet Stoves

Operating a heating appliance can lead to various challenges that affect its efficiency and performance. Understanding these issues is crucial for maintaining optimal functionality and ensuring safety during use. Below are some frequent problems users may encounter.

Common Problems

- Poor Combustion: Inadequate airflow or improper fuel quality can lead to incomplete burning.

- Overheating: Blocked vents or malfunctioning sensors may cause excessive temperatures.

- Auger Malfunctions: Jamming or motor failures can disrupt fuel delivery.

- Clogged Exhaust: Accumulation of soot or debris can hinder proper venting.

- Electrical Failures: Issues with wiring or control boards may lead to operational failures.

Preventive Measures

- Regular Maintenance: Schedule routine inspections and cleanings to ensure proper function.

- Quality Fuel: Use only recommended fuel types to prevent combustion issues.

- Monitor Airflow: Ensure that vents and ducts are clear to promote efficient operation.

- Check for Leaks: Inspect seals and connections to prevent air and fuel leaks.

- Keep the Area Clean: Remove any debris or buildup around the appliance to enhance safety.

How to Read the Diagram

Understanding the visual representation of components can significantly enhance your ability to maintain and troubleshoot your heating unit. These illustrations are designed to simplify the complex arrangement of various elements, allowing users to identify and locate them with ease. Grasping the key features of the visual aid will empower you to perform necessary tasks more efficiently.

Key Components and Their Functions

Begin by familiarizing yourself with the primary sections depicted in the illustration. Each segment corresponds to a specific function, often labeled for your convenience. Take note of the legend, which usually explains the symbols and colors used. This will help you understand what each part does and how it interacts with the overall system.

Following the Flow of Operation

As you analyze the illustration, trace the flow of operation from start to finish. This will provide insights into how each element contributes to the entire mechanism. Pay attention to arrows or lines that indicate movement or connections, as they are crucial for understanding the sequence of operations. By doing so, you will gain a clearer picture of the system’s functionality and be better equipped for any maintenance tasks.

Finding Replacement Parts Online

In today’s digital age, sourcing components for your heating appliance has become more accessible than ever. With a few clicks, you can explore various options that cater to your specific needs. Whether you’re looking to enhance efficiency or replace a malfunctioning element, the internet offers a plethora of resources to assist you in this journey.

Steps to Locate Components

- Identify the Component: Begin by determining the exact part you need. Refer to your user manual or search for common issues.

- Research Reliable Retailers: Look for reputable online stores that specialize in heating solutions.

- Compare Prices: Check multiple websites to ensure you are getting the best deal.

- Read Reviews: Customer feedback can provide insights into product quality and seller reliability.

Useful Online Resources

- Manufacturer Websites: Often the most reliable source for original components.

- Online Marketplaces: Websites like eBay and Amazon can offer a variety of options from different sellers.

- Forums and Community Groups: Engaging with other users can provide recommendations and advice on where to buy.

By following these steps and utilizing available resources, you can efficiently find the necessary components to maintain your heating appliance’s performance.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended life and optimal performance of your heating appliance. By following a few simple practices, you can minimize wear and tear, enhance efficiency, and prevent costly repairs.

Routine Cleaning

Cleaning is one of the most crucial aspects of maintenance. Accumulation of dust and debris can hinder functionality. Schedule periodic cleanings, focusing on the combustion chamber and ventilation pathways. Using a vacuum with a brush attachment can effectively remove soot and ash, improving airflow and reducing the risk of malfunction.

Inspection of Components

Conduct regular inspections of essential components to identify any signs of damage or wear. Pay close attention to the ignition system, fans, and any seals. Replace worn-out parts promptly to maintain efficiency and safety. Keeping a log of inspections can help track performance over time and anticipate future needs.

Safety Precautions When Repairing

When undertaking maintenance on any heating appliance, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions ensure a smooth repair process and help protect both the individual performing the work and the surrounding environment.

Before You Start

- Always disconnect the device from the power source to avoid electric shock.

- Allow the unit to cool down completely before handling any components.

- Wear appropriate personal protective equipment, such as gloves and safety goggles.

- Ensure you are working in a well-ventilated area to avoid inhaling harmful fumes.

During the Repair

- Follow the manufacturer’s guidelines and instructions closely.

- Use tools that are in good condition and suitable for the task.

- Avoid using flammable materials near the unit during the repair process.

- Keep a fire extinguisher nearby in case of emergencies.

- Be cautious of sharp edges and hot surfaces when handling components.

By adhering to these safety measures, you can significantly reduce the risk of accidents and ensure a successful repair experience.

Enhancing Efficiency with Upgrades

Improving the overall performance of a heating unit can significantly impact both energy consumption and comfort levels in your space. By integrating advanced components and implementing strategic enhancements, users can experience a marked increase in efficiency, leading to reduced operational costs and a smaller carbon footprint.

Key Components for Improvement

To achieve optimal functionality, consider upgrading essential components. Enhanced burners and improved air circulation systems can facilitate better combustion, maximizing heat output while minimizing waste. Additionally, incorporating smart technology allows for precise temperature control, ensuring that energy is used only when necessary.

Regular Maintenance and Upgrades

Regular inspections and timely updates are crucial for maintaining high performance. Cleaning and replacing worn-out elements not only prolongs the lifespan of your heating apparatus but also ensures that it operates at peak efficiency. Investing in quality materials and modern accessories can yield significant long-term savings, enhancing both comfort and sustainability.