In the realm of mechanical systems, the intricate arrangement of elements plays a crucial role in ensuring optimal performance and longevity. A thorough grasp of how various pieces interconnect can significantly enhance maintenance and troubleshooting efforts. This section delves into the structural configuration of essential machinery, offering insights into each segment’s function and significance.

Accurate visualization of these assemblies not only aids technicians in their work but also empowers operators with knowledge to better understand the equipment they utilize. By breaking down the composition of these systems, users can identify potential issues before they escalate, thereby fostering a more efficient operational environment.

Whether you’re a seasoned professional or a novice in the field, comprehending these layouts is vital. Engaging with detailed illustrations and descriptions will enable you to navigate the complexities of your machinery with confidence and expertise, ultimately leading to enhanced reliability and productivity.

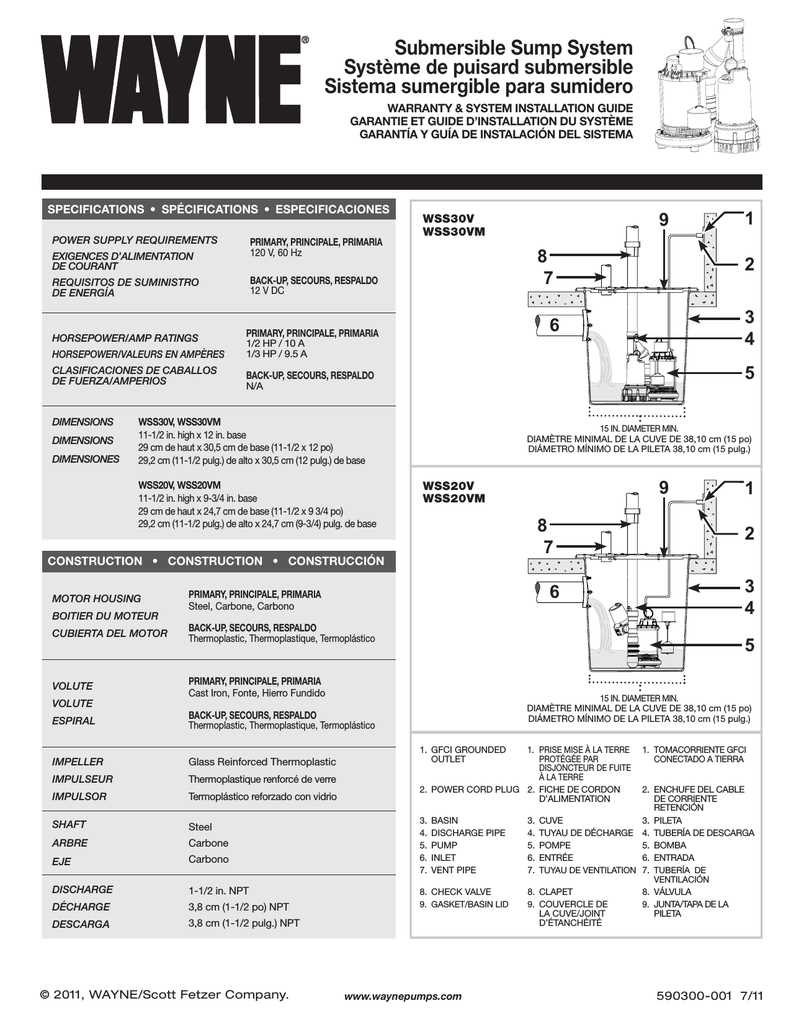

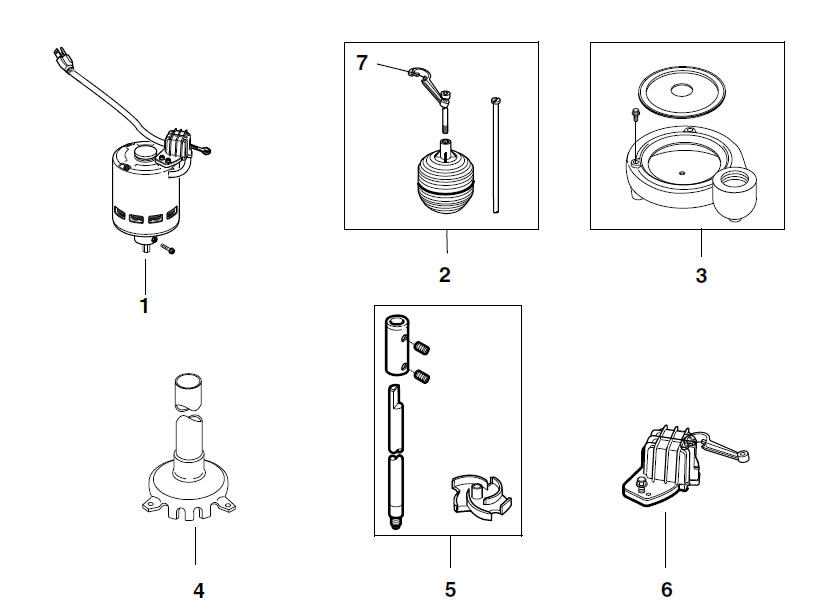

Understanding Wayne Pump Components

Grasping the various elements of a fluid transfer system is crucial for effective maintenance and optimal performance. Each component plays a specific role, contributing to the overall functionality and efficiency of the assembly. By familiarizing oneself with these integral pieces, one can ensure proper operation and longevity of the entire mechanism.

Key Components

The main elements include the motor, casing, and impeller. The motor provides the necessary power, while the casing protects internal mechanisms and directs fluid flow. The impeller, designed to enhance fluid movement, is vital for creating the pressure needed to transport liquids effectively.

Maintenance and Care

Regular inspection and upkeep of each component can prevent unexpected failures. Ensuring that the motor is clean and free from debris, checking the integrity of the casing, and assessing the impeller for wear are essential practices that enhance performance and extend the lifespan of the system.

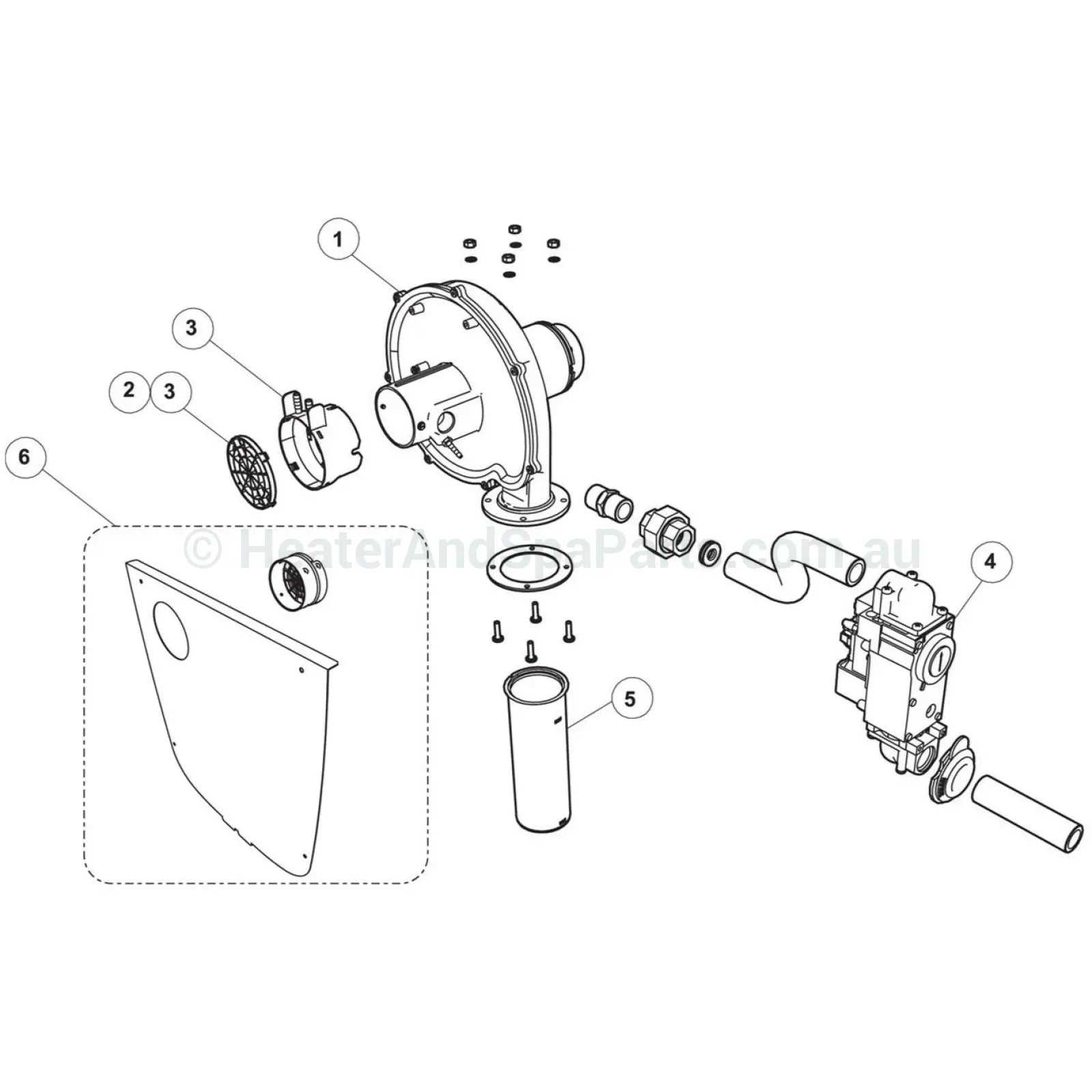

Importance of Accurate Diagrams

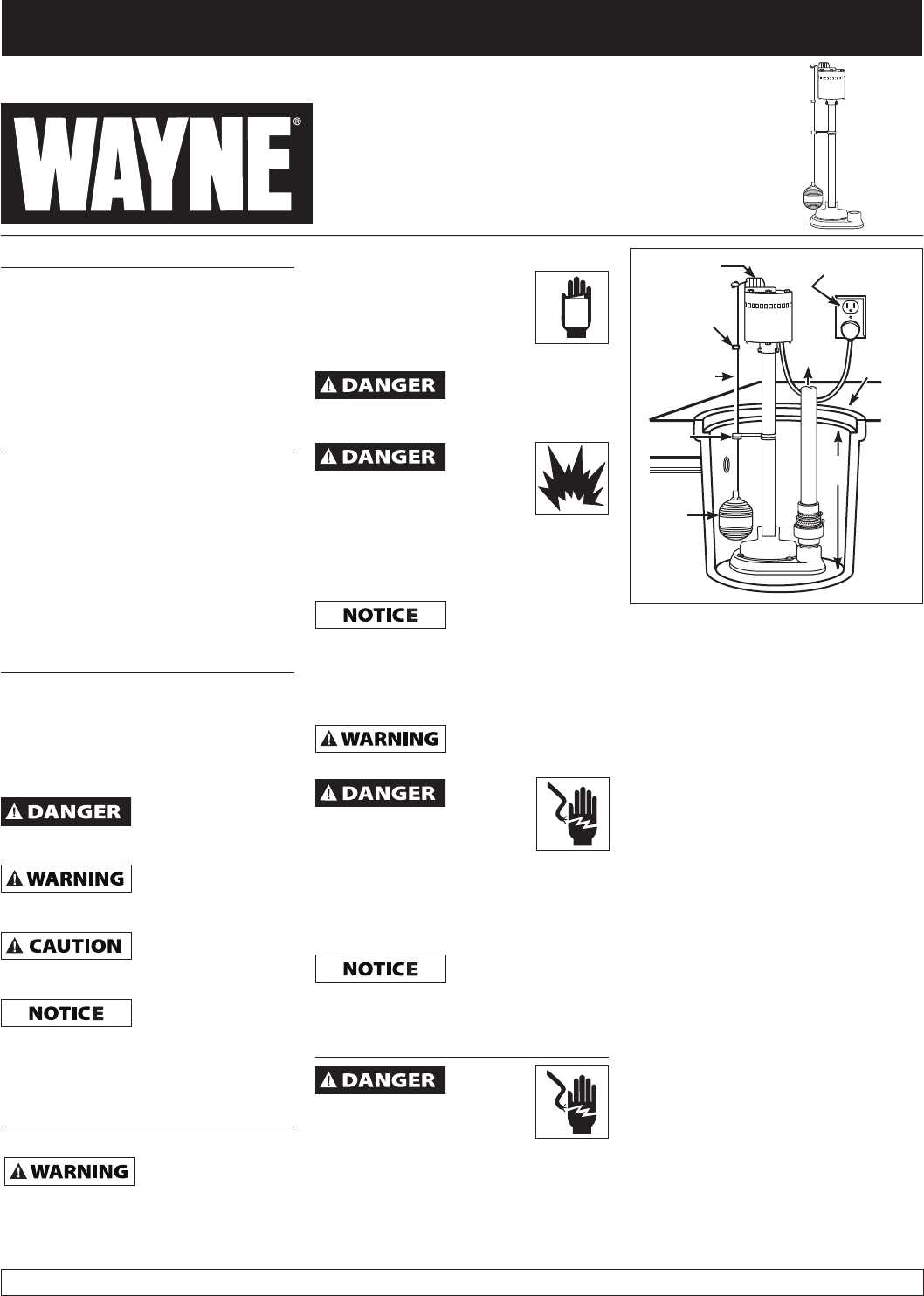

Having precise illustrations is crucial in various fields, especially in technical and mechanical domains. These visual representations serve as essential tools for understanding complex systems, guiding users through the intricacies of assembly, maintenance, and troubleshooting. When created with attention to detail, they enhance clarity and ensure that every component is easily identifiable, reducing the likelihood of errors.

Enhancing Efficiency

Accurate visuals significantly boost efficiency by allowing individuals to quickly locate and understand the necessary components. This clarity saves time during installation or repairs, as users can follow the illustrated steps without confusion. Moreover, it minimizes the risk of damage caused by misinterpretation, ensuring that all elements function harmoniously.

Facilitating Training and Education

Illustrations play a vital role in training environments. They aid learners in grasping complex concepts, making it easier to visualize how different elements interact within a system. Additionally, well-structured visuals can serve as reference materials, supporting ongoing education and professional development.

Common Wayne Pump Models Overview

This section provides an overview of various popular models known for their efficiency and reliability in fluid transfer applications. Understanding these models can help users make informed decisions based on their specific needs and operational requirements.

Popular Models

- Model A: Ideal for residential use, offering a balance of power and compact design.

- Model B: Designed for heavy-duty applications, capable of handling larger volumes.

- Model C: A versatile choice, suitable for both residential and commercial settings.

- Model D: Focused on energy efficiency, perfect for prolonged operation with minimal energy consumption.

Key Features

- Durability: Built to withstand harsh conditions and provide long-term service.

- Ease of Maintenance: Designed for simple upkeep, ensuring minimal downtime.

- Performance: Engineered for high efficiency and reliable operation across various applications.

- Versatility: Compatible with a range of configurations, making them suitable for different environments.

Identifying Key Parts and Functions

Understanding the essential components of a fluid transfer system is crucial for optimal performance and maintenance. Each element plays a specific role, contributing to the overall efficiency and effectiveness of the mechanism. Recognizing these key components allows for better troubleshooting, repairs, and enhancements.

Critical Components

Among the various elements, the motor serves as the driving force, converting electrical energy into mechanical energy. The impeller is vital for creating fluid motion, while the volute guides the flow to the discharge area. Additionally, the seals prevent leakage, ensuring safe and efficient operation.

Understanding Functions

Each component’s function is interconnected, impacting overall system reliability. The strainer filters out debris, protecting the internal mechanisms from damage. The pressure switch monitors the system’s performance, automatically activating or deactivating the motor based on the required flow. By familiarizing oneself with these functions, operators can enhance system longevity and reduce the likelihood of malfunctions.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires a proactive approach to care and upkeep. Regular attention can prevent wear and tear, allowing for optimal performance and extending the lifespan of essential components.

1. Regular Inspections: Frequently examine all critical elements for signs of wear, leaks, or other issues. Early detection can save time and resources.

2. Cleanliness is Key: Maintain a clean environment around your machinery. Debris and contaminants can lead to malfunctions or decreased efficiency.

3. Lubrication: Ensure all moving parts are adequately lubricated. This reduces friction and minimizes the risk of overheating.

4. Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and procedures provided by the manufacturer. This ensures compliance with industry standards.

5. Store Properly: When not in use, store your equipment in a dry and secure location to protect it from environmental damage.

6. Educate Yourself: Stay informed about the latest maintenance practices and technologies. This knowledge can lead to better care and improved performance.

By following these strategies, you can significantly enhance the functionality and lifespan of your system, ensuring it operates effectively for years to come.

Troubleshooting Common Issues

Understanding and addressing frequent challenges is essential for optimal operation. By identifying symptoms and analyzing their causes, users can effectively rectify malfunctions and ensure long-lasting performance. This section delves into the most prevalent problems encountered, along with their potential solutions.

Low Efficiency

A decrease in effectiveness often signals underlying issues. Check for blockages in the intake and ensure that all connections are secure. Regular maintenance can also prevent wear that leads to decreased functionality.

Unusual Noises

Uncommon sounds may indicate mechanical problems. Inspect for loose components and listen for signs of strain. Lubricating moving parts can often alleviate these disturbances and enhance overall operation.

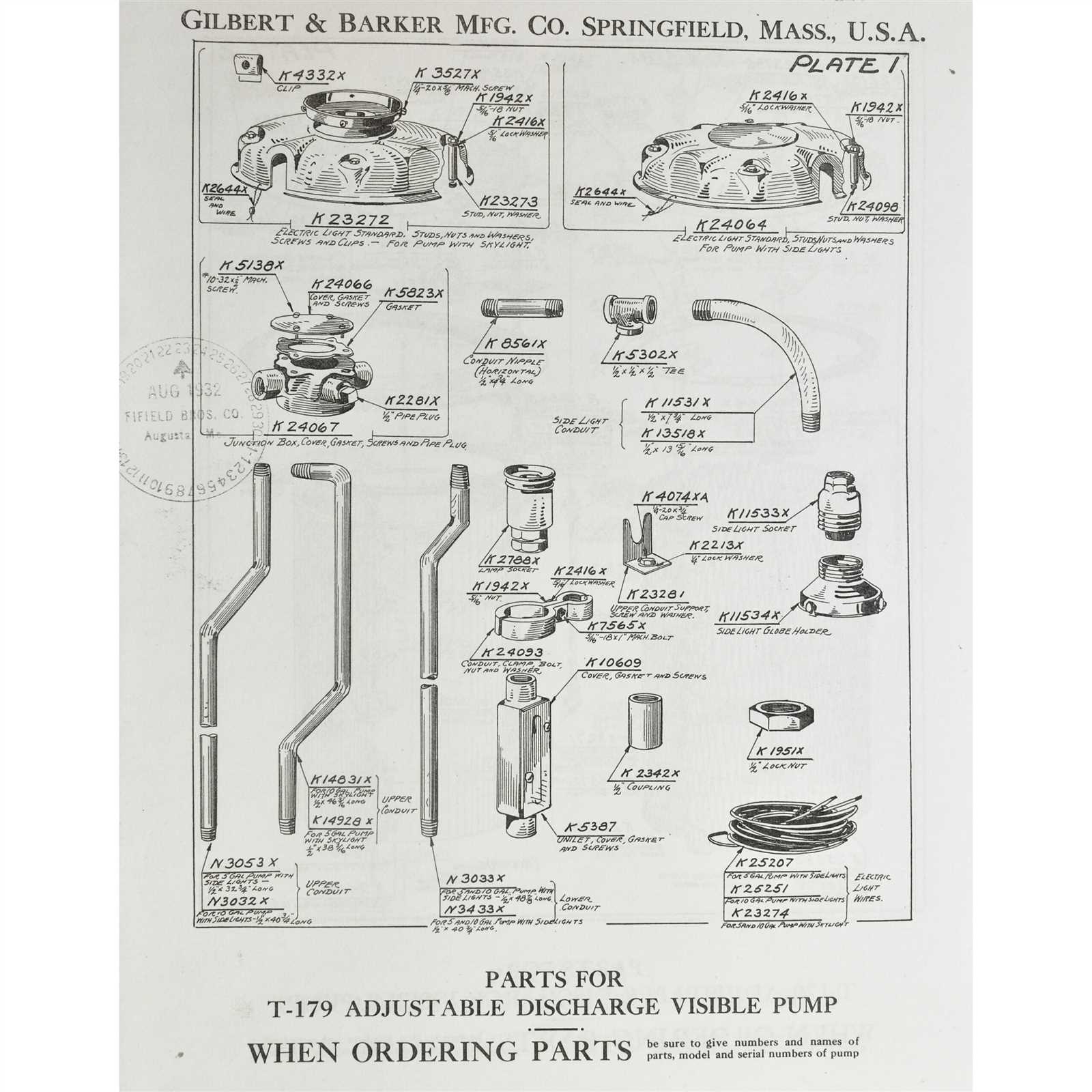

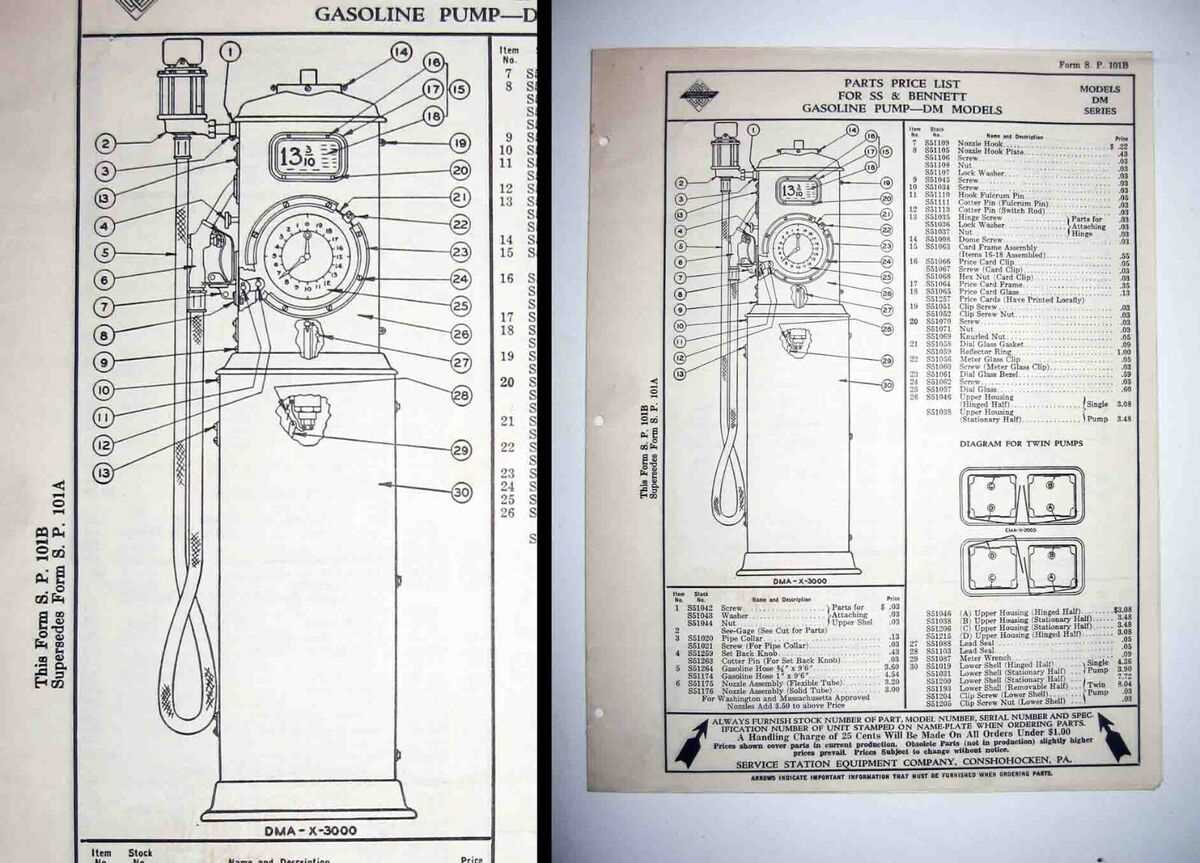

Replacement Parts and Options

When it comes to maintaining essential equipment, understanding the available components is crucial for optimal performance. Ensuring the right substitutes can significantly extend the life and efficiency of your system. This section explores various alternatives and the advantages of choosing quality replacements.

Types of Alternatives

Several options exist to address different needs, from original specifications to compatible substitutes. Selecting the correct type can enhance functionality and reliability.

| Component | Description | Benefits |

|---|---|---|

| Seals | Prevent leakage and maintain pressure. | Improved durability and performance. |

| Motor | Drives the mechanism’s operation. | Increased efficiency and power. |

| Housings | Encases the internal components. | Enhanced protection against damage. |

Choosing Quality Options

Investing in high-quality alternatives can yield significant long-term savings. It is essential to evaluate reliability and compatibility to ensure the ultimate performance of your equipment.

Where to Find Reliable Diagrams

Accessing trustworthy visual representations is crucial for effective maintenance and repair. Numerous resources exist for locating accurate schematics that can assist in understanding the components of various equipment. It’s essential to utilize credible platforms that offer comprehensive information.

Online databases often provide extensive libraries of illustrations, allowing users to search by specific models or types. Websites dedicated to technical resources or manufacturer support pages are particularly valuable.

Additionally, community forums and social media groups can serve as excellent venues for exchanging insights and obtaining recommendations. Engaging with experienced individuals in these spaces often leads to discovering hidden gems of information.

Lastly, consider investing in printed manuals or guides, as these can be invaluable references that stand the test of time. Combining various sources enhances the likelihood of finding the most reliable and detailed visual aids available.