In the realm of heavy-duty vehicles, comprehending the intricate design and functionality of various structural elements is crucial. These components play a pivotal role in ensuring optimal performance, safety, and durability on the road. A detailed examination of these elements provides valuable insights for both enthusiasts and professionals alike.

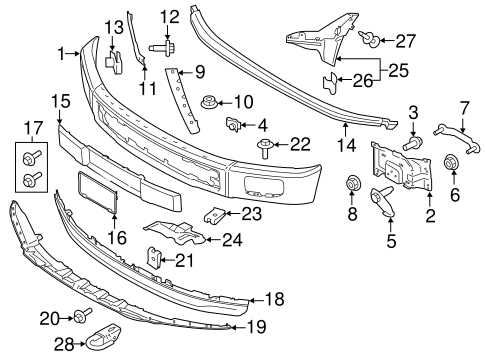

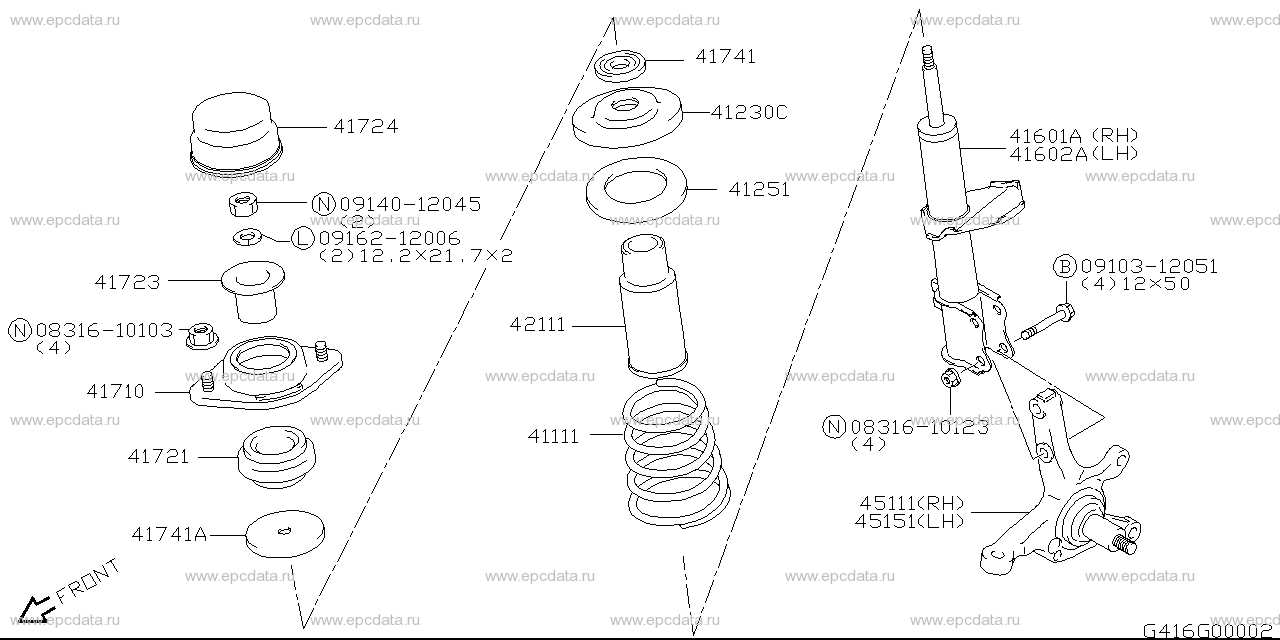

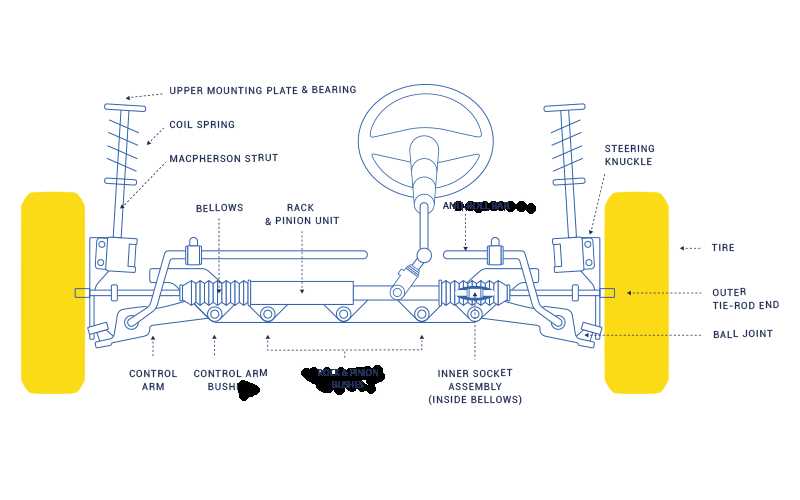

Visual representations of these components can significantly enhance understanding, allowing for easier identification and comprehension of each element’s purpose. By familiarizing oneself with these diagrams, one can better appreciate how each piece contributes to the overall efficiency and reliability of the vehicle.

Moreover, a deeper knowledge of these structures aids in effective maintenance and troubleshooting, ensuring that vehicles operate at their best. As we delve into the specifics, we uncover not just their roles but also the intricate relationships between each component, ultimately enriching our grasp of automotive engineering.

Understanding Truck Front End Components

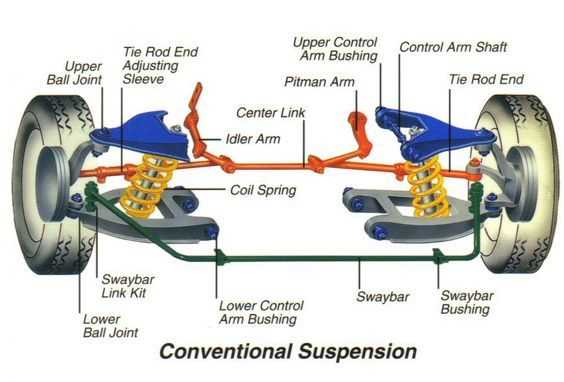

Exploring the crucial elements at the forefront of a vehicle reveals their significant role in overall functionality and safety. These components work in harmony to ensure stability, control, and durability on the road.

- Steering Mechanism: Essential for direction control.

- Suspension System: Provides comfort and absorbs shocks.

- Frame: Supports all other components, ensuring strength.

- Axles: Transfer power from the engine to the wheels.

Understanding these components helps in identifying maintenance needs and enhancing performance, leading to the ultimate driving experience.

Importance of Front End Parts

The components located at the front of a vehicle play a crucial role in ensuring safety, stability, and overall performance. These elements are integral to maintaining control and enhancing the driving experience.

Key Functions

- Enhance steering responsiveness

- Absorb impacts during collisions

- Support alignment and balance

- Facilitate smooth handling

Maintenance and Longevity

- Regular inspections prevent wear and tear.

- Timely replacements ensure optimal performance.

- Proper alignment extends the lifespan of tires.

Common Types of Truck Front Ends

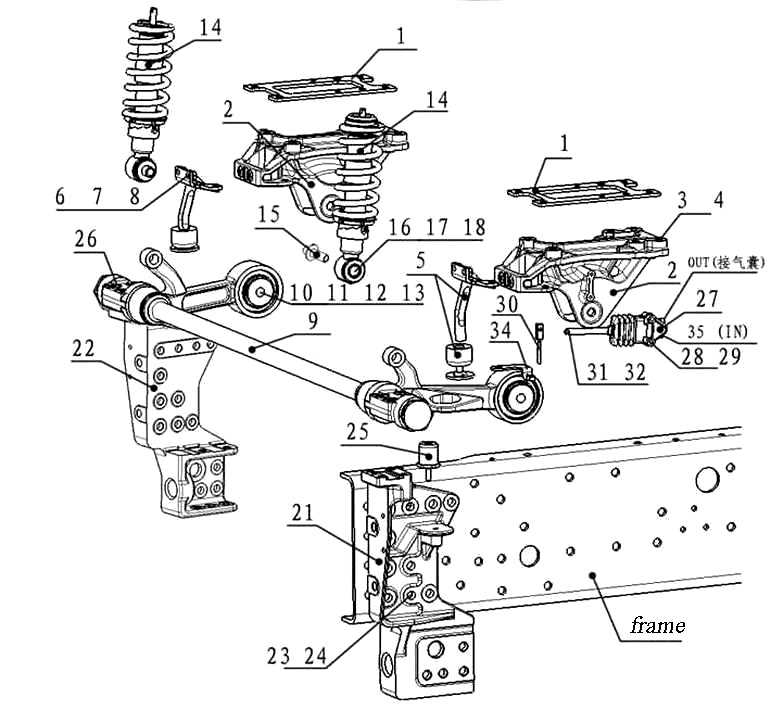

The structure at the forefront of heavy vehicles plays a crucial role in their functionality and performance. Different configurations serve various purposes, enhancing stability and support while navigating diverse terrains. Understanding these variations is essential for maintenance and improvement.

Popular Configurations

Various designs are employed to optimize handling and load capacity. Each configuration offers unique benefits and is tailored for specific applications.

| Configuration Type | Description |

|---|---|

| Independent Suspension | Allows each wheel to move independently, improving ride quality and handling. |

| Solid Axle | A single beam connecting both wheels, providing durability and strength for heavy loads. |

| Beam Axle | Utilizes a straight beam that enhances stability, commonly found in off-road applications. |

Choosing the Right Structure

Selecting the appropriate configuration is vital for achieving optimal performance. Factors such as load requirements, terrain type, and vehicle use must be considered to ensure the best results.

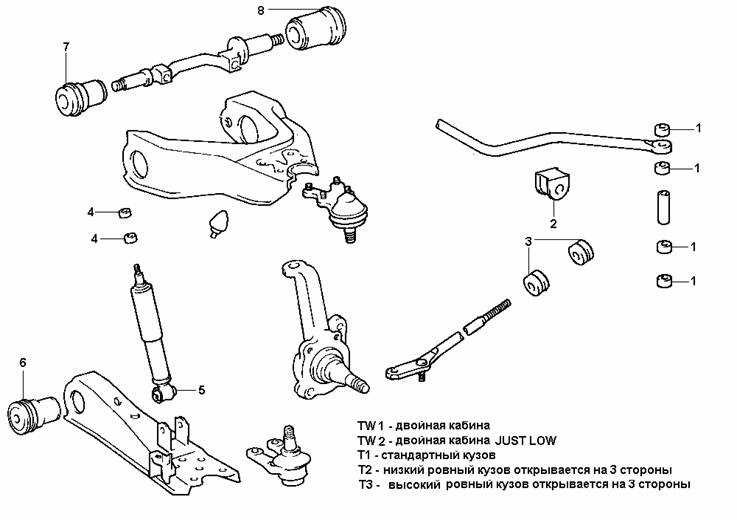

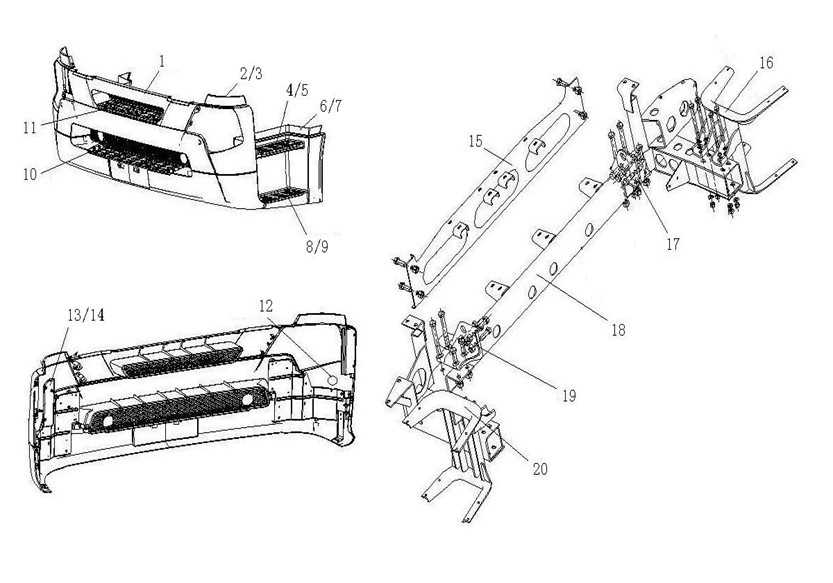

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations serve as a roadmap, guiding you through the intricacies of assembly and disassembly. Familiarizing yourself with the symbols and layout can significantly enhance your ability to tackle mechanical issues.

Start by identifying the key elements in the illustration, such as labels and reference numbers. Each component is usually associated with a specific identifier that correlates with a list. Pay attention to the orientation and placement, as this can affect how parts fit together.

Next, observe the connections between components. Lines and arrows often indicate relationships, showing how different pieces interact. This understanding is crucial for troubleshooting and ensuring proper assembly.

Lastly, always refer to the accompanying documentation for detailed descriptions and specifications. This combination of visual and textual information will empower you to make informed decisions and ensure optimal performance of your machinery.

Key Functions of Each Component

Understanding the essential roles of various elements in a vehicle’s structure is crucial for optimal performance and safety. Each component plays a significant part in ensuring stability, control, and overall functionality. By examining their unique contributions, one can appreciate the intricate design that supports efficient operation.

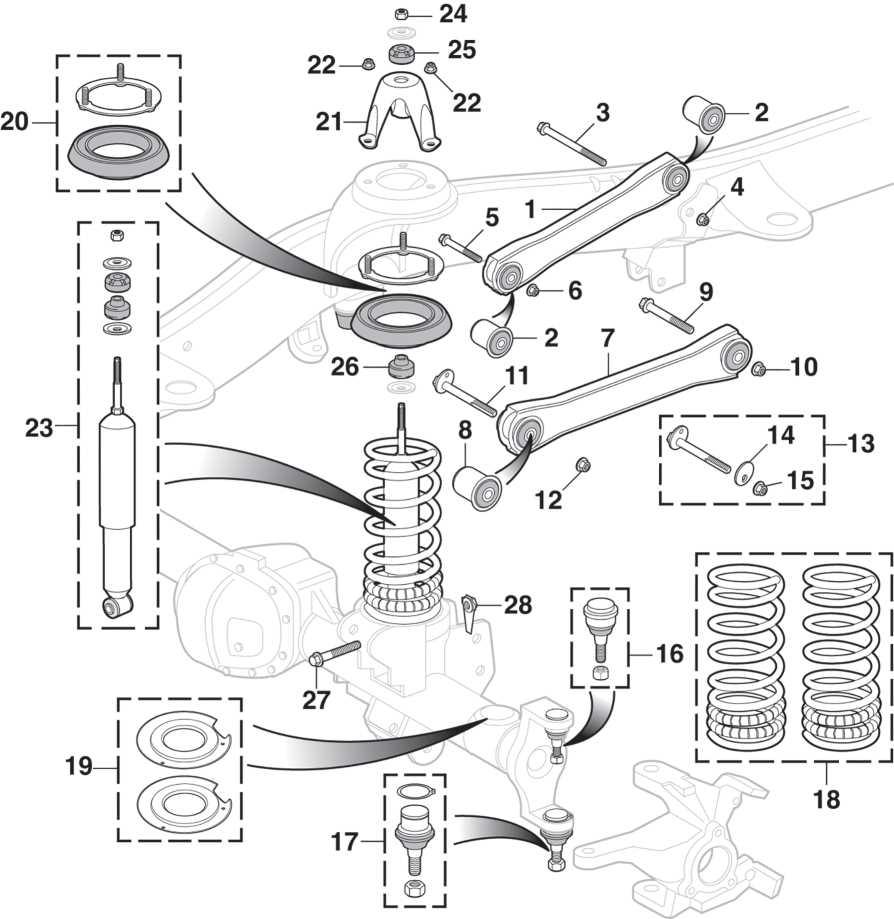

Steering Knuckle: This critical element connects the wheel hub to the suspension system, allowing for precise maneuverability. It supports the weight of the vehicle and facilitates smooth turns.

Control Arm: This part connects the suspension system to the chassis, maintaining proper wheel alignment. It absorbs shocks and impacts, enhancing ride comfort.

Ball Joint: Acting as a pivot point, this component enables movement between the control arm and steering knuckle. It plays a vital role in facilitating smooth steering and suspension travel.

Sway Bar: This element minimizes body roll during cornering, promoting stability. It connects the left and right suspension systems, ensuring a balanced ride.

Shock Absorber: Vital for dampening vibrations, this component controls the impact of road irregularities. It enhances ride quality by maintaining tire contact with the ground.

Spring: This crucial part supports the weight of the vehicle while absorbing shocks. It ensures that the vehicle maintains a stable posture during driving.

Signs of Front End Wear

Understanding the indicators of wear in the steering and suspension components is essential for maintaining vehicle safety and performance. These signs often manifest through changes in handling, noise, or tire wear patterns. Recognizing these symptoms early can help prevent more severe issues and costly repairs.

Uneven Tire Wear: One of the most noticeable signs of deterioration in suspension elements is uneven wear on tires. If you observe bald spots or excessive wear on one side, it may indicate misalignment or worn bushings.

Pulling to One Side: If the vehicle consistently drifts to the left or right while driving on a straight road, this could signal issues with the alignment or worn tie rod ends.

Vibration in the Steering Wheel: Excessive vibrations felt through the steering mechanism can point to imbalances or wear in the components. It’s important to address this promptly to avoid further damage.

Noises While Turning: Clunking or popping sounds when making turns are often signs of failing joints or bushings. These noises should not be ignored, as they can lead to more significant mechanical failures.

Loose Steering: If steering feels less responsive or has excessive play, it may indicate worn components such as the steering rack or tie rods. This condition can compromise vehicle control and safety.

Regular inspections and maintenance can help mitigate these issues and ensure a smooth and safe driving experience.

Maintenance Tips for Longevity

Ensuring the durability of essential components in your vehicle requires a proactive approach to care and upkeep. Regular attention to specific areas can significantly extend their lifespan and enhance overall performance.

Regular Inspections: Conduct frequent assessments to identify any signs of wear or damage. Early detection of issues can prevent more significant problems down the line.

Proper Lubrication: Utilize the appropriate lubricants for moving elements to minimize friction. This practice not only enhances efficiency but also reduces the likelihood of premature failure.

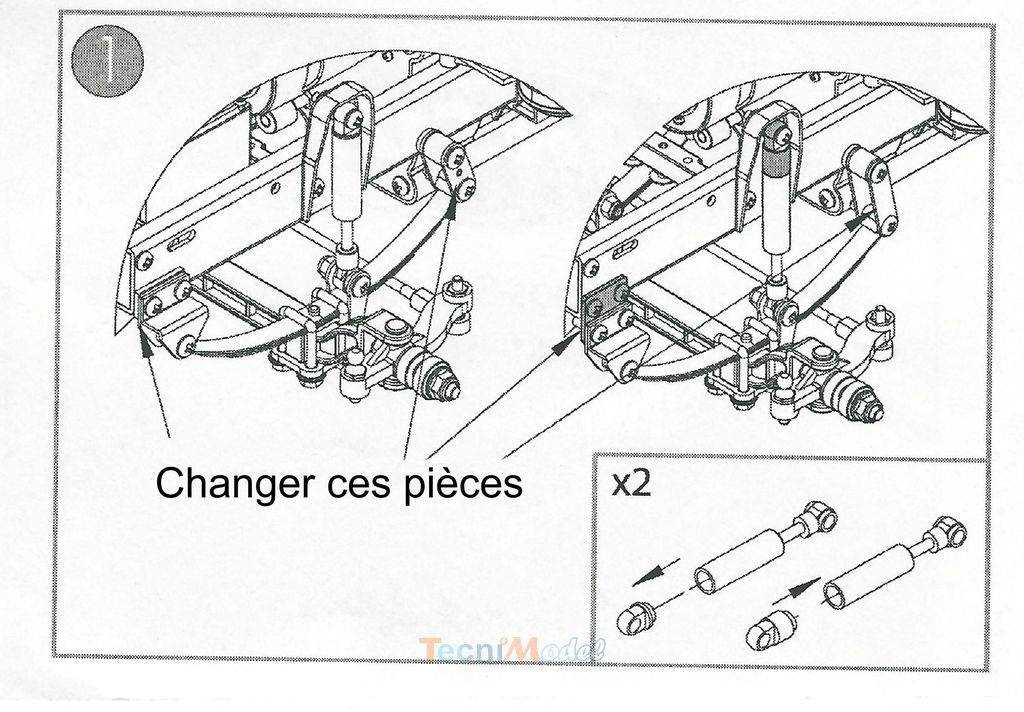

Timely Replacements: Stay vigilant about replacing components that show signs of deterioration. Utilizing high-quality replacements ensures better performance and longevity.

Keep It Clean: Regular cleaning of critical areas prevents the buildup of dirt and grime, which can lead to corrosion and other forms of damage. Implement a routine cleaning schedule to maintain optimal conditions.

Adhere to Manufacturer Guidelines: Follow the recommended maintenance schedule provided by the manufacturer. This ensures that you perform necessary tasks at the right intervals for optimal performance.

By incorporating these strategies into your maintenance routine, you can significantly enhance the lifespan and efficiency of your vehicle’s crucial systems.

Replacing Front End Parts Safely

Ensuring the security and efficiency of your vehicle requires careful attention when replacing critical components. Proper safety measures and a systematic approach can prevent accidents and ensure a successful replacement process. This section outlines essential guidelines for executing these tasks safely and effectively.

Before starting, it is vital to gather the necessary tools and equipment. Ensure you have access to a well-lit workspace, suitable lifting devices, and protective gear. Understanding the specific requirements of the components you are handling is crucial for a smooth operation.

| Safety Tip | Description |

|---|---|

| Use Personal Protective Equipment (PPE) | Always wear gloves, goggles, and appropriate clothing to protect yourself from injuries. |

| Secure the Vehicle | Ensure the vehicle is parked on a level surface and use wheel chocks to prevent rolling. |

| Lift Safely | Use jack stands to support the vehicle securely after lifting it with a jack. |

| Follow Manufacturer Instructions | Refer to the specific guidelines provided by the manufacturer for the components being replaced. |

| Check for Damage | Inspect surrounding components for any signs of wear or damage before installation. |

By adhering to these principles, you can ensure a safer and more efficient replacement process, ultimately contributing to the longevity and reliability of your vehicle’s performance.

Upgrades for Improved Performance

Enhancing the functionality of your vehicle requires a thoughtful approach to modifications that boost efficiency and responsiveness. Whether you’re aiming for better handling, increased stability, or superior power transfer, selecting the right enhancements is essential. This section delves into key upgrades that can significantly elevate your ride’s overall performance.

Suspension Enhancements

Upgrading the suspension system is one of the most effective ways to improve driving dynamics. High-quality shock absorbers and springs can provide better road feedback, allowing for a more controlled and comfortable experience. Adjustable coilovers offer the flexibility to tailor the vehicle’s stance and performance characteristics, making them a popular choice among enthusiasts.

Braking System Improvements

Enhancing the braking system not only increases safety but also contributes to improved handling. Upgrading to larger rotors and performance brake pads can significantly reduce stopping distances and enhance pedal feel. Additionally, incorporating stainless steel brake lines can provide a firmer brake response, ensuring that the vehicle remains responsive during high-speed maneuvers.