In the realm of outdoor machinery, comprehending the layout of individual components is essential for effective maintenance and repair. Familiarity with these intricate arrangements not only facilitates troubleshooting but also empowers users to perform repairs with confidence. By diving into the structure of various assemblies, operators can ensure the longevity and performance of their equipment.

Exploring the various sections of a machine provides insights into how each element contributes to overall functionality. This knowledge allows for informed decision-making when it comes to replacing worn or damaged components. Whether you are a seasoned professional or a novice, grasping these essential details can enhance your understanding and capability.

Furthermore, having access to a clear illustration of the various parts and their connections aids in visualizing the machinery’s inner workings. This clarity can prevent common errors during repairs and maintenance, ultimately leading to a smoother operation. In the following sections, we will delve deeper into the specifics of these arrangements and their significance.

Understanding Craftsman 12avb2aq793 Parts

Gaining insight into the components of your equipment is essential for effective maintenance and optimal performance. Familiarizing yourself with each element ensures a smoother operation and prolongs the lifespan of your machine.

Components can be categorized into several key areas:

- Engine Elements: These include parts responsible for power generation and drive.

- Chassis and Frame: The structural foundation that supports all other components.

- Transmission System: This area encompasses gears and belts that facilitate movement.

- Control Mechanisms: Handles and switches that allow the user to operate the machinery effectively.

- Safety Features: Essential components designed to protect the user during operation.

Understanding how these sections work together is vital. For example, a malfunction in the engine can lead to performance issues, affecting the entire system. Regular inspections can help identify wear and tear, allowing for timely replacements.

- Identify the main components of your machine.

- Consult the manual for specific details on each section.

- Regularly check for signs of damage or inefficiency.

- Replace worn parts to maintain optimal functionality.

By paying attention to these crucial aspects, you can enhance the reliability and efficiency of your equipment. A well-maintained machine not only performs better but also ensures safety and satisfaction during use.

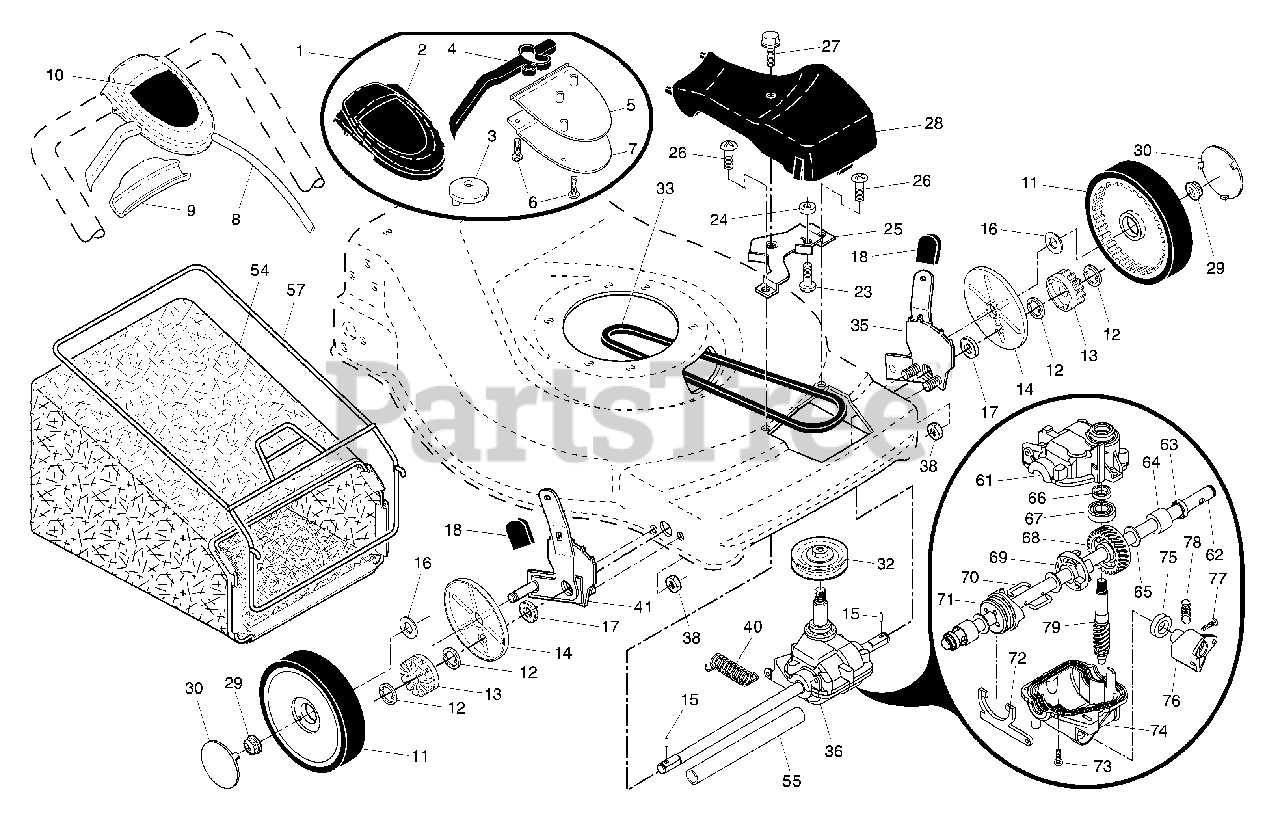

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations that outline each element enable users to identify and locate specific items easily. These illustrations not only simplify the troubleshooting process but also enhance the overall comprehension of the equipment’s structure.

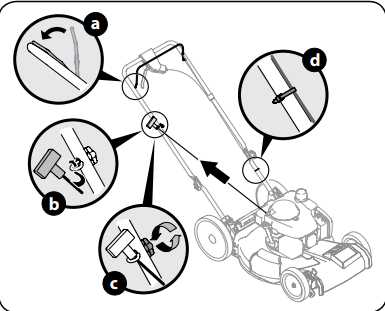

Enhanced Understanding

Detailed visuals provide clarity on how different elements interact and function together. By examining these representations, individuals can grasp the assembly and disassembly processes, reducing the likelihood of errors during repairs. Clear communication of complex structures fosters confidence in handling machinery, whether for professionals or hobbyists.

Efficient Repairs

When repairs are needed, having a visual reference can significantly expedite the process. Users can quickly identify which components require attention, thereby minimizing downtime. Effective maintenance not only prolongs the life of the equipment but also ensures optimal performance, making these illustrations invaluable tools for anyone involved in machinery care.

Key Components of the Craftsman Model

Understanding the essential elements of a well-designed machinery unit is crucial for maintenance and performance. Each component plays a significant role in ensuring the overall functionality and efficiency of the equipment. A comprehensive grasp of these parts allows users to troubleshoot effectively and enhance the longevity of the device.

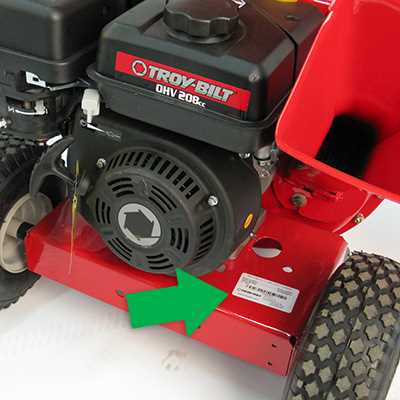

At the core of any robust model, the engine stands out as the powerhouse, driving the entire system. Alongside the engine, the transmission system serves to efficiently transfer power, enabling smooth operation and responsiveness. Coupled with these, the frame provides structural integrity, supporting various components while withstanding operational stress.

Additional elements, such as the cutting mechanism and drive system, are integral for specific tasks, impacting performance and precision. Furthermore, electrical systems, including wiring and ignition components, are vital for reliable startup and operation. Each part, whether mechanical or electrical, contributes to the seamless interaction required for optimal functioning.

Regular inspection and understanding of these key components not only assist in identifying wear and tear but also facilitate timely repairs. This proactive approach ensures that the unit remains in peak condition, ultimately enhancing user experience and productivity.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effectively maintaining and repairing machinery. These visuals provide a comprehensive overview of components and their relationships, facilitating a smoother repair process.

Here are some key points to help you interpret these visuals:

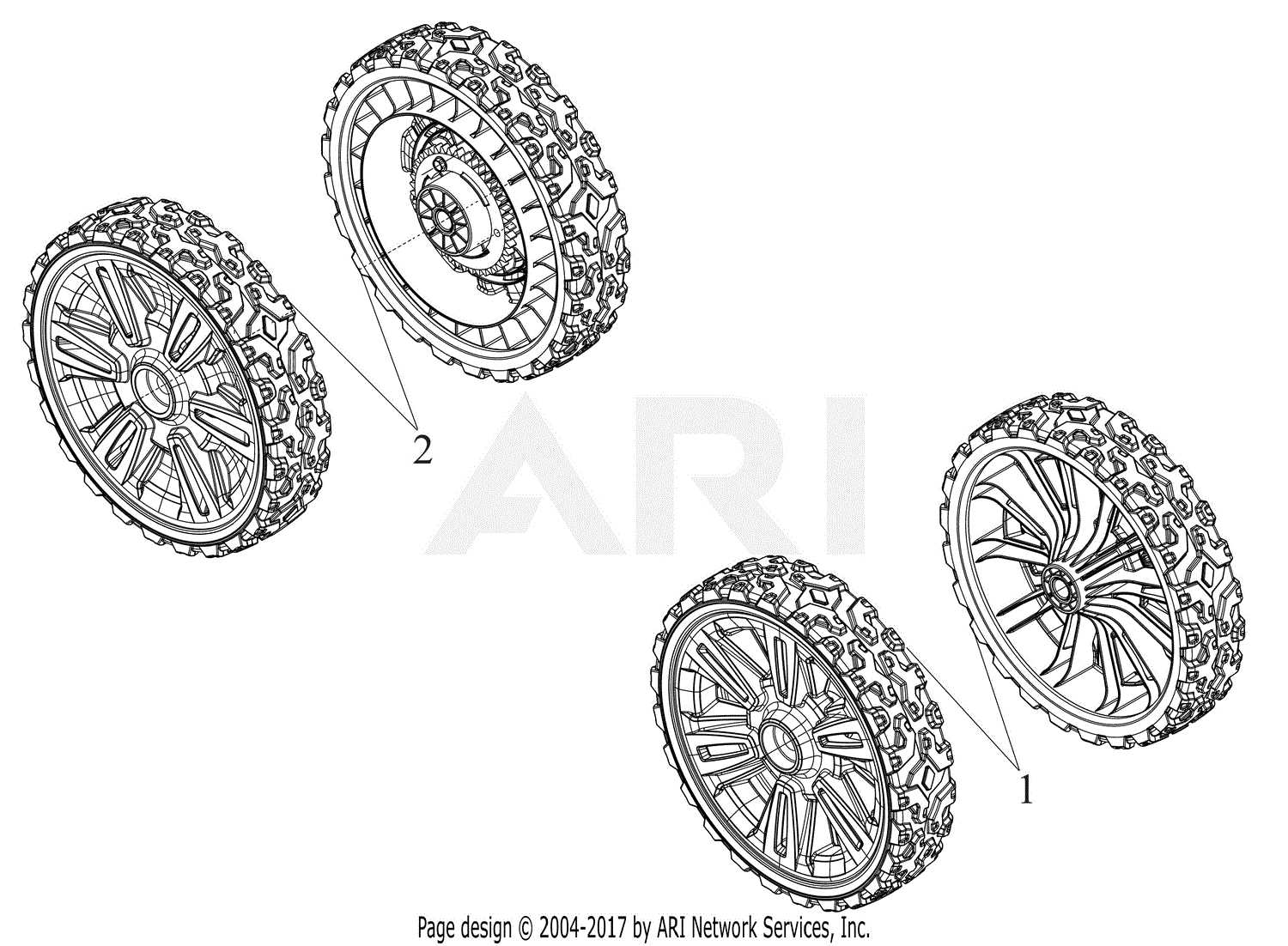

- Familiarize Yourself with Symbols: Different shapes and lines represent various elements. Knowing what each symbol means will help you navigate the illustration more easily.

- Identify Key Components: Focus on the main parts first. These are often highlighted or labeled, making them easier to locate.

- Study the Connections: Pay attention to how parts are linked. Arrows and lines typically indicate relationships, showing how components fit together.

- Look for Numbers or Codes: Many illustrations include references that correspond to a list of items. This can be essential for ordering replacements.

By following these steps, you can efficiently decode an assembly illustration, making your repair tasks more manageable and effective.

Common Issues with Craftsman Equipment

Tools and machinery often encounter various challenges during operation, which can affect performance and efficiency. Identifying these frequent problems can aid users in maintaining equipment and prolonging its lifespan.

| Issue | Description |

|---|---|

| Engine Won’t Start | Commonly caused by fuel issues, battery problems, or ignition failures. |

| Overheating | May result from insufficient lubrication or blocked air vents. |

| Vibration | Often linked to unbalanced parts or loose components. |

| Excessive Noise | Can indicate worn bearings or misaligned parts needing adjustment. |

| Fuel Leaks | Typically arise from damaged seals or hoses, posing safety hazards. |

Finding Replacement Parts Easily

Locating the right components for your equipment can often feel like a daunting task. However, with the right approach and resources, you can simplify the process significantly. The key lies in understanding your device’s specifications and utilizing various platforms to streamline your search.

Start by identifying the model and type of your equipment. This information is crucial as it allows you to narrow down your options effectively. Make sure to check the user manual or any labels present on the machine for detailed information.

Once you have the necessary details, explore online marketplaces and manufacturer websites. These platforms often provide comprehensive catalogs that can help you find what you need. Additionally, many sites offer filtering options to refine your search based on compatibility and price.

Don’t overlook local repair shops or specialty stores, as they can be valuable resources for acquiring items quickly. Engaging with community forums can also yield helpful insights, as fellow users often share their experiences and recommendations for sourcing components.

Lastly, always keep an eye out for warranty options or return policies when making a purchase. This will ensure that you can make adjustments if the component does not meet your needs. By following these steps, you can efficiently navigate the search for essential items, saving time and effort in the process.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention to detail. By implementing a systematic maintenance routine, you can extend the lifespan of your tools and enhance their performance. Here are some key strategies to keep your machinery in top condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Cleaning | After Each Use | Remove dirt, debris, and residues to prevent corrosion and wear. |

| Lubrication | Every Month | Apply appropriate lubricant to moving parts to reduce friction. |

| Inspection | Weekly | Check for any signs of damage or wear, and address issues promptly. |

| Sharpening | As Needed | Keep blades and cutting tools sharp for optimal performance. |

| Storage | Seasonally | Store equipment in a dry, climate-controlled environment to prevent damage. |

By following these maintenance tips, you can significantly enhance the reliability and functionality of your tools, ensuring they serve you well for years to come.

Resources for Craftsman Owners

For those who own and maintain outdoor equipment, having access to reliable materials and support is essential. Various resources can help users effectively manage their tools, ensuring optimal performance and longevity. From instructional manuals to online forums, these assets provide invaluable guidance.

Manuals and Guides: Detailed manuals offer insights into maintenance routines and troubleshooting. They serve as a reference for both novice and experienced users, simplifying complex tasks.

Online Communities: Engaging with fellow enthusiasts through forums and social media groups fosters a sense of camaraderie. Users can exchange tips, share experiences, and solve common challenges together.

Replacement Parts Suppliers: Identifying trustworthy suppliers for components is crucial. Many vendors specialize in original and compatible parts, ensuring that repairs are straightforward and efficient.

Tutorial Videos: Visual learners benefit from a wealth of online tutorials. These resources provide step-by-step instructions, making repairs and maintenance accessible to everyone.

Utilizing these resources enhances the ownership experience, enabling individuals to delve deeper into the care and functionality of their equipment.

Comparing Similar Craftsman Models

When evaluating various models from a well-known brand, it is essential to examine their similarities and differences. This approach enables potential buyers to make informed decisions based on features, performance, and overall value. By analyzing comparable options, consumers can determine which unit best fits their needs and preferences.

Key Features to Consider

One of the primary aspects to compare is the set of features offered by each model. Look for attributes such as engine power, cutting width, and ease of operation. For instance, some units may provide enhanced maneuverability, while others focus on durability and reliability. Assessing these characteristics can significantly influence the user experience and efficiency.

Performance and Reliability

Another crucial factor is the performance metrics of the equipment. Users should evaluate how well similar models handle different tasks and conditions. Consider aspects like fuel efficiency, maintenance requirements, and longevity. Understanding these performance factors allows buyers to select a model that will perform optimally for their specific applications and provide lasting service.