Maintaining outdoor machinery can be a complex task, especially when it comes to identifying and replacing key elements. Each piece of this essential tool is intricately connected, working in unison to ensure optimal performance during its tasks. A thorough understanding of how these elements are structured together allows for better upkeep and troubleshooting in the long run.

Visualizing the internal framework is crucial for anyone looking to keep their equipment in top shape. Knowing the function of each component and how they fit within the overall assembly can streamline repairs and minimize downtime. With the right guidance, navigating through the structure becomes more intuitive, making it easier to address common issues that may arise over time.

By breaking down the inner workings into a clear and organized format, users can better appreciate the design and engineering that goes into crafting reliable lawn care tools. This approach not only helps in resolving problems but also in preventing potential issues by understanding how each section contributes to the whole.

Overview of the Craftsman YS4500 Lawn Tractor

This riding mower stands out for its durability and ease of use, offering a powerful solution for maintaining large outdoor spaces. It combines user-friendly features with reliable performance, making it a preferred choice for those looking to simplify their lawn care routine. With a focus on efficiency and convenience, this machine is designed to handle diverse terrains and various cutting conditions.

Engine and Power

The machine is powered by a robust engine, providing enough strength to handle thick grass and uneven grounds with ease. Its fuel-efficient design allows for extended use without frequent refueling, making it suitable for large lawns. The transmission system ensures smooth transitions between gears, offering better control and maneuverability, especially in tight corners or challenging landscapes.

Key Specifications

| Feature | Details | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | High-powered, fuel-efficient model | |||||||||||||||||||||

| Cutting Width | Wide deck for efficient mowing | |||||||||||||||||||||

| Transmission |

| Component | Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Belt | Trans

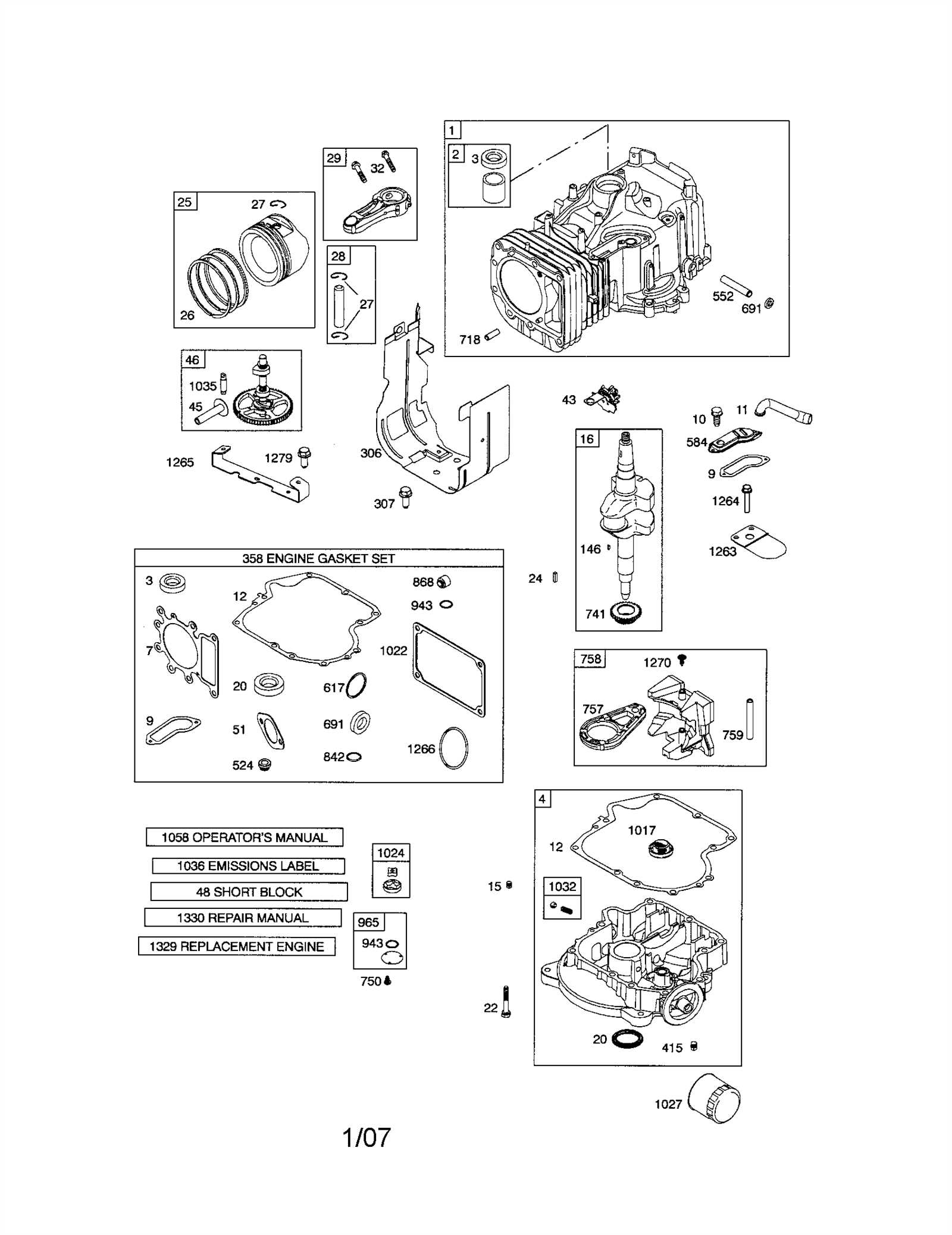

Engine Assembly and FunctionalityThe engine is the heart of any machine, providing the necessary power to drive all its components. Understanding how it operates and how its parts work together is essential for ensuring smooth performance. This section delves into the assembly of the engine and its key operational principles.

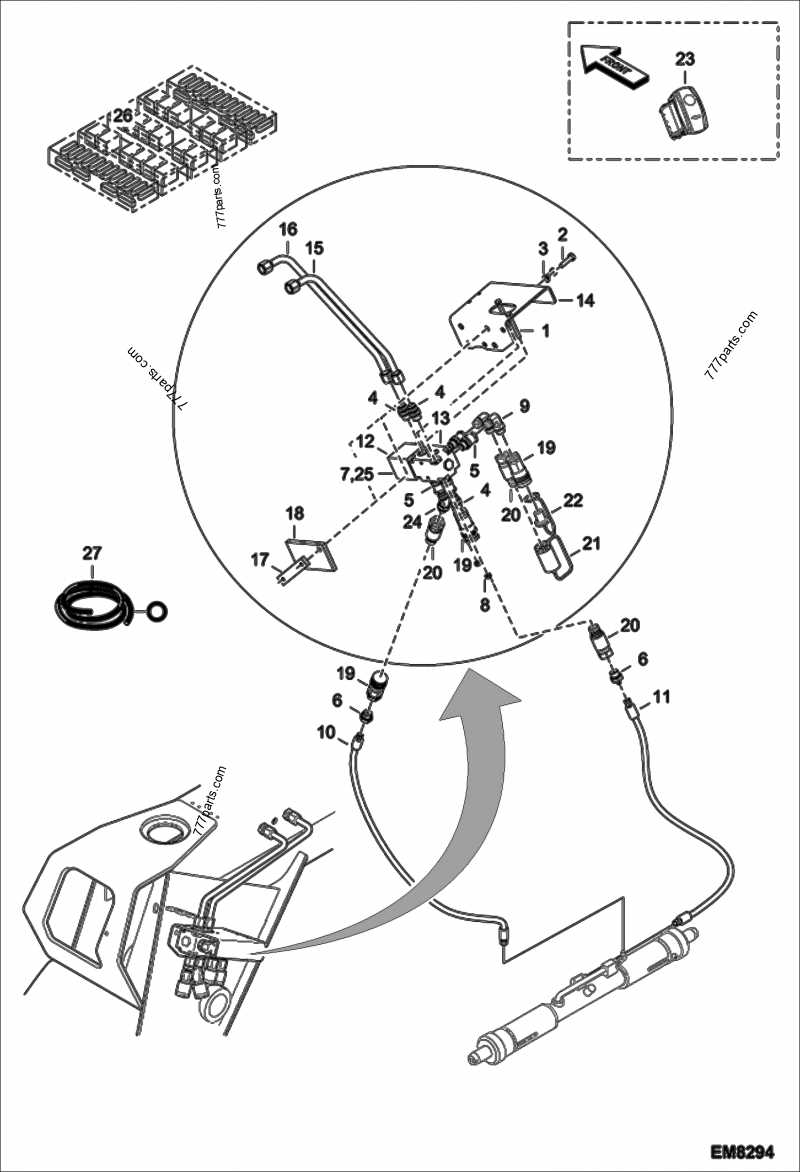

By maintaining and properly understanding the engine’s assembly, you can ensure that the machine continues to function reliably and efficiently over time. Blade and Deck Diagram ExplanationThe layout of the cutting system and its surrounding components plays a crucial role in the functionality of lawn maintenance equipment. Understanding how the blades are positioned and how the deck interacts with other mechanical elements ensures smooth and efficient operation during mowing. This section provides an overview of how these essential parts work together to achieve optimal cutting performance. At the heart of the system lies the rotating blade, designed to handle tough grass and uneven terrain. The deck, which shields the blade, is engineered for protection and to maintain the correct airflow, which helps guide the clippings and prevent clogging. The interaction between the blade and the deck allows for consistent cutting and a clean finish with each pass. Key to this process is the precise alignment and balance of these elements, which minimizes wear and ensures longevity. Regular maintenance of these systems, including checking for damage or misalignment, can greatly enhance both performance and durability, keeping the equipment running at its best. Steering System Parts and MaintenanceThe steering mechanism plays a vital role in ensuring precise maneuverability and control of your vehicle. Understanding its components and how to maintain them can enhance performance and prolong lifespan.

Regular upkeep of these components is essential for optimal performance. Here are some maintenance tips:

By staying attentive to these elements, you can ensure a well-functioning steering system, providing safety and reliability on the road. Exploring the Electrical Wiring of the YS4500

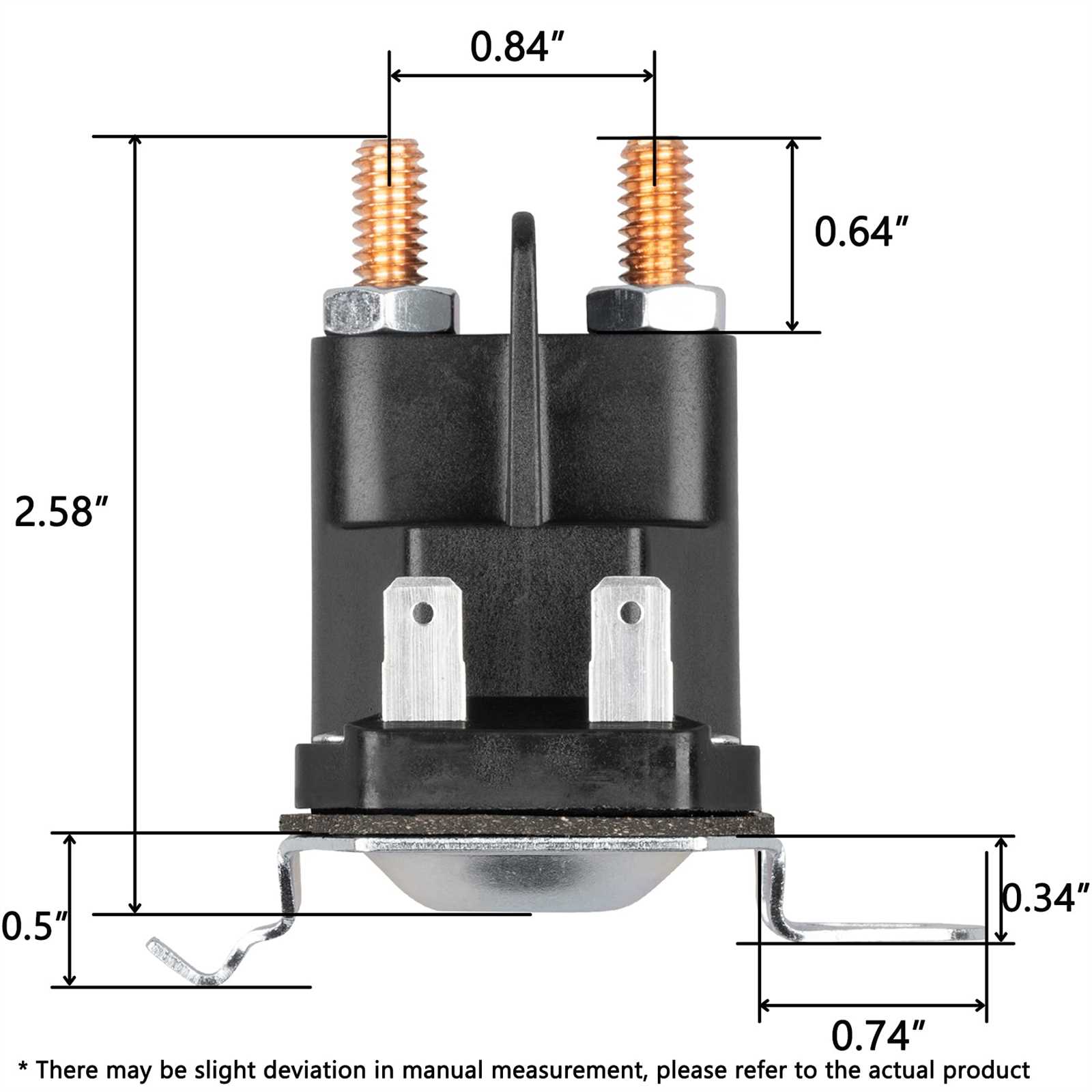

Understanding the electrical connections of your outdoor equipment is crucial for ensuring optimal performance and safety. This section delves into the intricate network of wires and components that work together to power various functions, providing insights into their arrangement and purpose. By gaining familiarity with these connections, you can effectively troubleshoot issues and maintain your machinery. Overview of the Electrical System

The electrical system serves as the backbone of any machine, enabling communication between different parts. It consists of a series of wires, connectors, and components that facilitate the flow of electricity, powering everything from ignition to lighting. Each element plays a vital role, and recognizing their functions can simplify repairs and upgrades. Key Components and Their FunctionsAmong the essential elements are the ignition system, battery, and starter motor. The ignition system initiates combustion, ensuring the engine runs smoothly. The battery stores energy, supplying power to various systems when needed. The starter motor is responsible for turning the engine over during startup. Understanding these components allows for better diagnostics and efficient maintenance. Troubleshooting Common Issues with Key PartsAddressing typical challenges associated with essential components is vital for maintaining the optimal performance of your outdoor machinery. Understanding how to identify and resolve these issues can enhance efficiency and prolong the lifespan of your equipment. Below are some common problems and their potential solutions.

Regular maintenance and timely troubleshooting of these critical elements can help avoid more significant repairs down the line. Stay proactive in your approach to ensure smooth operation. |