| Belt Drive |

Low |

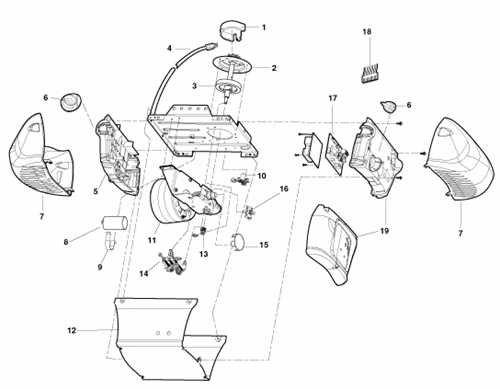

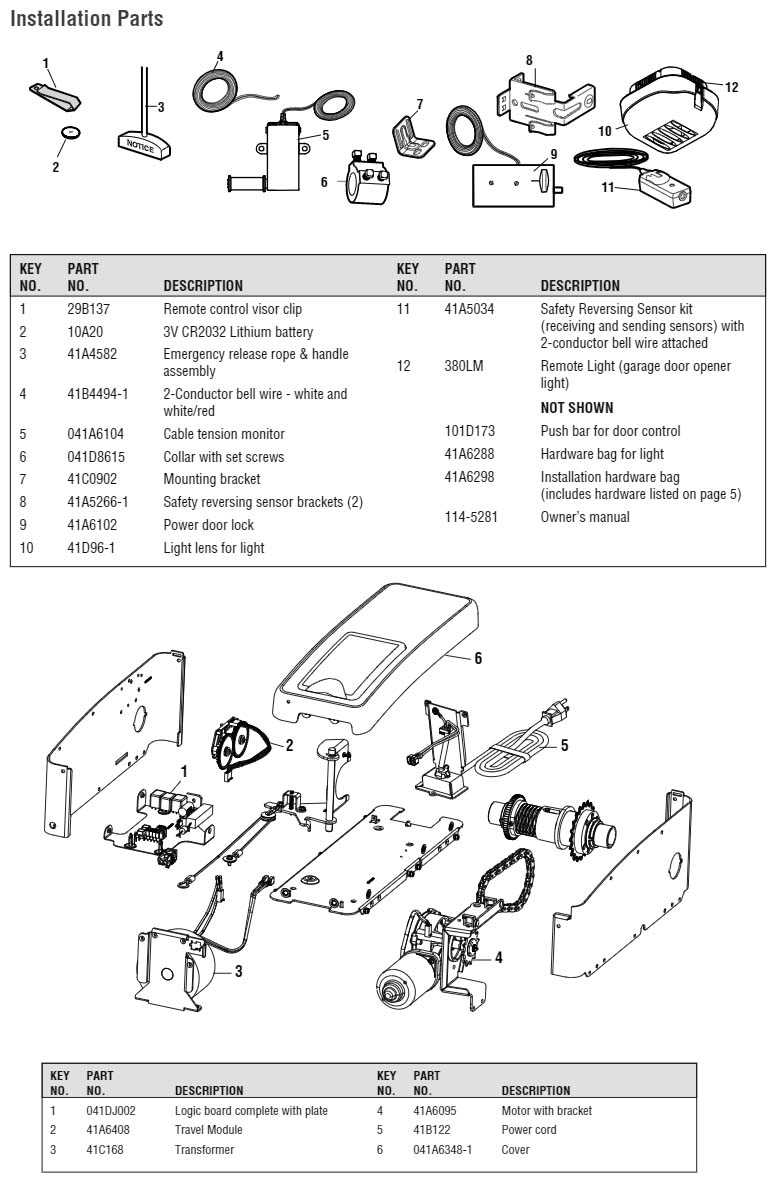

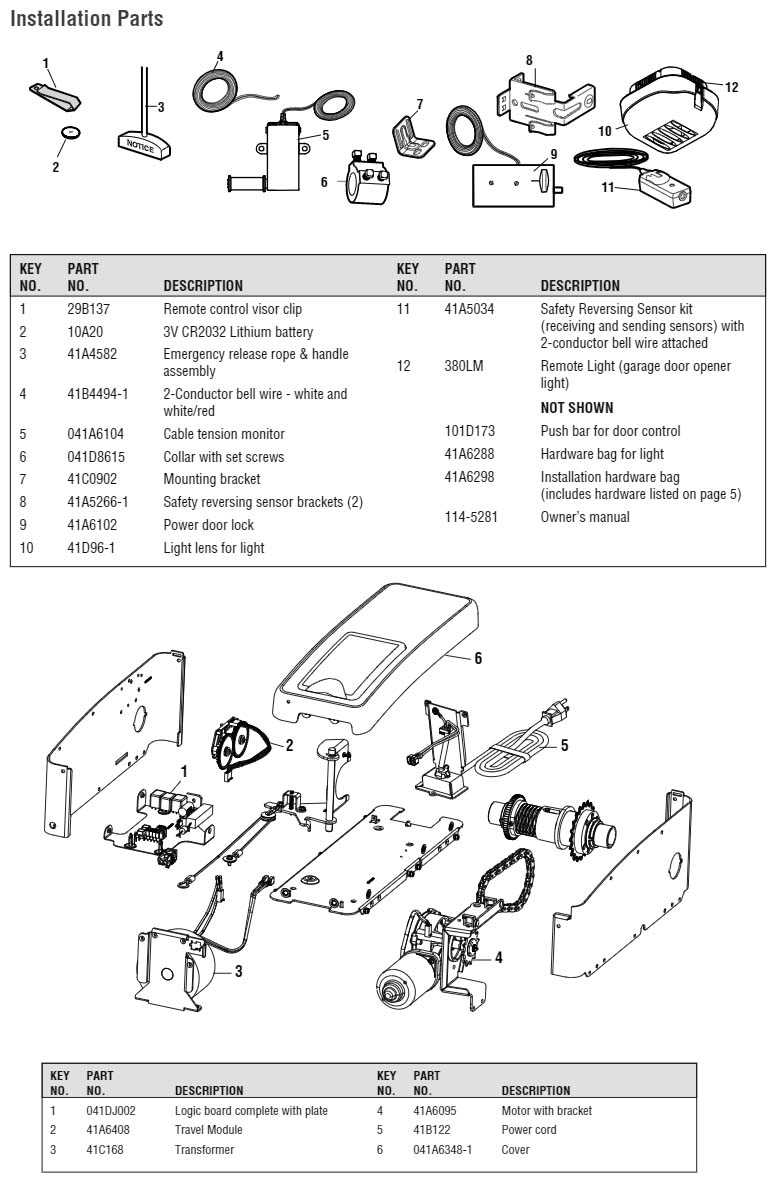

How the Safety Sensors Operate

Safety sensors are critical devices designed to enhance the overall functionality and reliability of automated systems. Their primary role is to detect obstructions within a specific area, ensuring that the mechanism halts or reverses to prevent accidents or damage. These sensors work by transmitting a signal across a defined space, and when this signal is interrupted, the system responds accordingly. This creates a safeguard that improves the overall safety of the operation.

The Role of Infrared Technology

One of the key technologies used in safety sensors is infrared detection. A pair of sensors emit and receive invisible infrared beams, creating an invisible barrier. When an object crosses this barrier, the connection between the sensors is broken, triggering a response from the system. This interruption acts as a signal for the mechanism to either stop or reverse, preventing any potential risks.

Proper Alignment for Optimal Function

To ensure reliable operation, it is essential that the sensors remain properly aligned. Even slight misalignment can disrupt the transmission of the signal, causing the system to malfunction. Regular checks and adjustments help maintain the sensors’ accuracy, ensuring consistent performance and minimizing the risk of accidents.

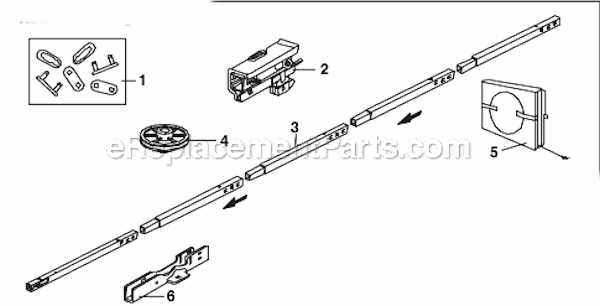

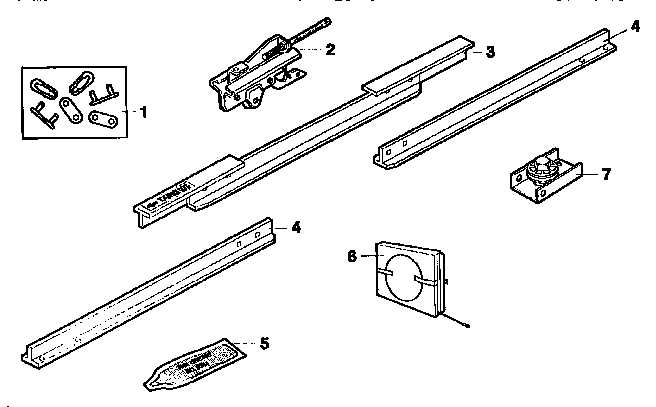

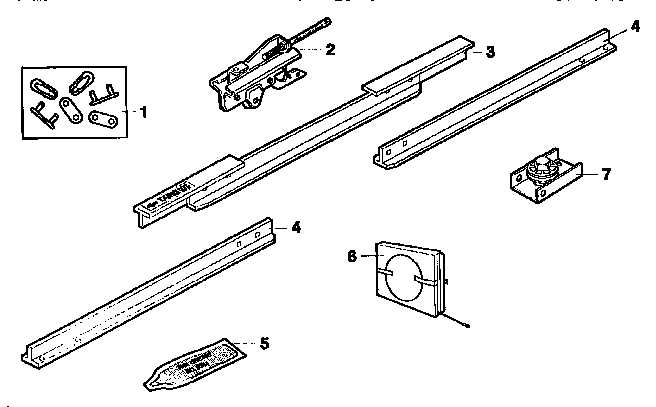

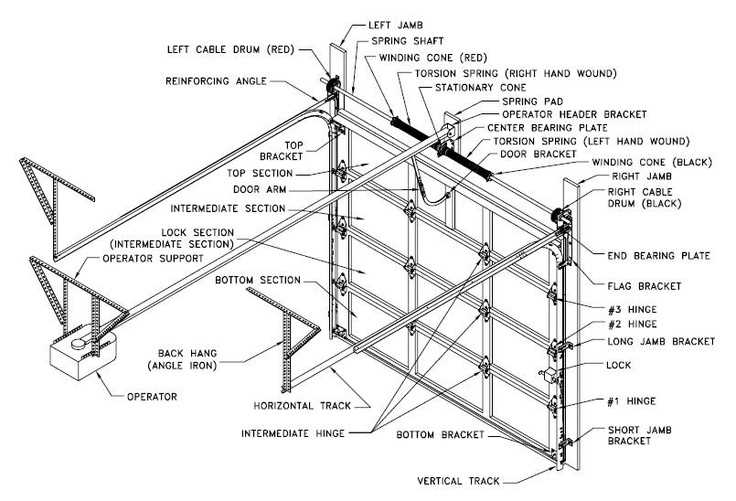

The Role of the Trolley and Rail Assembly

The trolley and rail assembly serves as a critical component in the operation of automated systems, allowing for smooth and efficient movement. This mechanism ensures the guided motion of the system, transferring energy between the motor and the moving section, providing both control and stability. Understanding its function is essential for maintaining the overall efficiency and performance of the system.

Ensuring Smooth Movement

The trolley works in conjunction with the rail to facilitate precise movement along the designated path. The rail acts as the track, while the trolley glides along it, delivering a seamless connection between the driving force and the moving section. Proper alignment and maintenance of these elements are key to preventing issues like jerky movements or operational failures.

Key Maintenance Tips

To ensure the longevity and optimal performance of the trolley and rail system, regular inspections are vital. Check for any signs of wear or misalignment, and apply lubrication to the moving parts to reduce friction. Addressing potential issues early can help prevent costly repairs and extend the lifespan of the system.

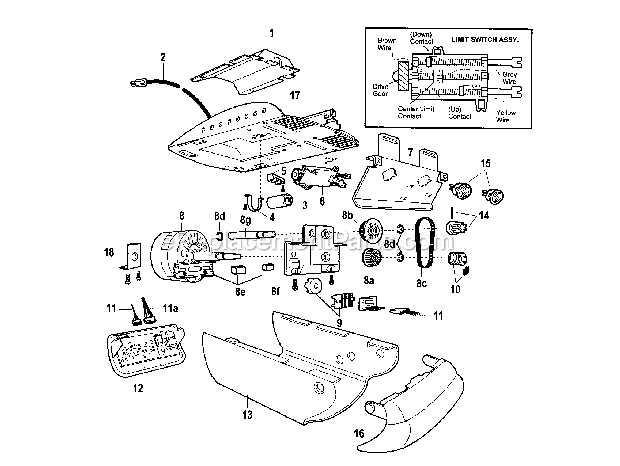

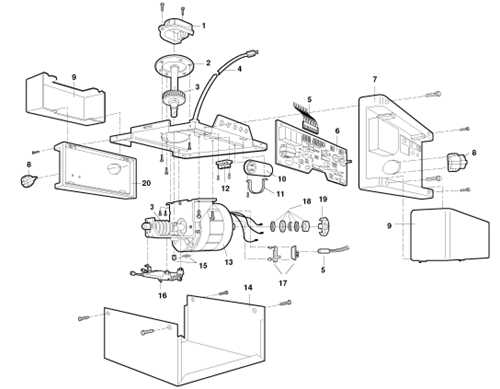

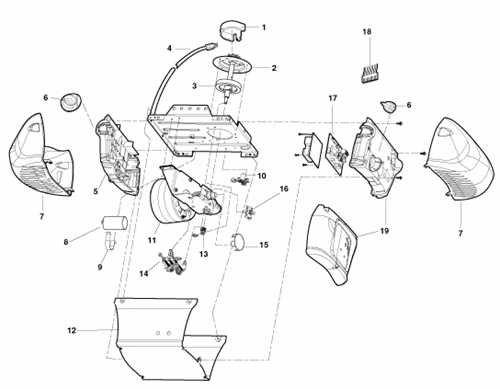

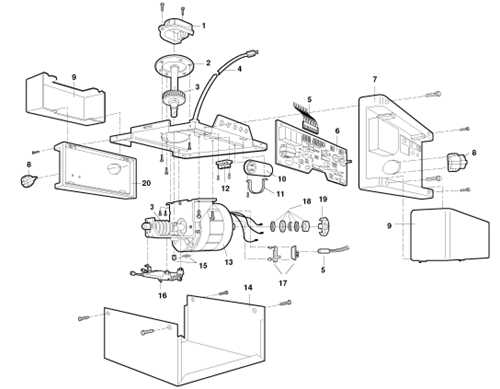

Motor Unit Breakdown and Explanation

The motor assembly plays a crucial role in the operation, providing the necessary force to initiate and complete movements. Understanding the various components that make up this unit is essential for maintaining smooth and efficient performance.

Main Components Overview

- Drive Mechanism: This element transfers the force generated by the motor to the rest of the system, ensuring proper movement.

- Motor Housing: The casing that protects the internal components from dust, debris, and potential damage, while also aiding in cooling.

- Control Circuit: This circuit ensures the motor operates efficiently, responding to commands and regulating power usage to avoid overheating.

Common Issues and Maintenance Tips

- Check for signs of wear or loose connections in the drive mechanism to prevent mechanical failure.

- Regularly clean the motor housing to maintain optimal airflow and cooling.

- Inspect the control circuit for any signs of corrosion or faulty wiring to ensure consistent performance.

Understanding these components and performing routine maintenance will extend the life of the motor assembly and ensure reliable function over time.

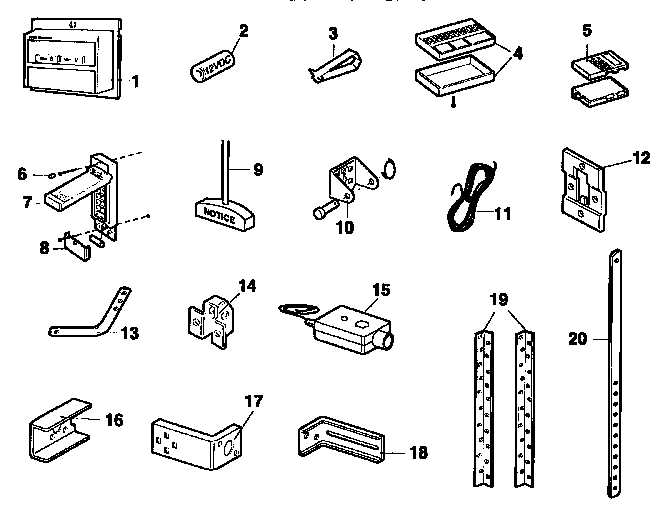

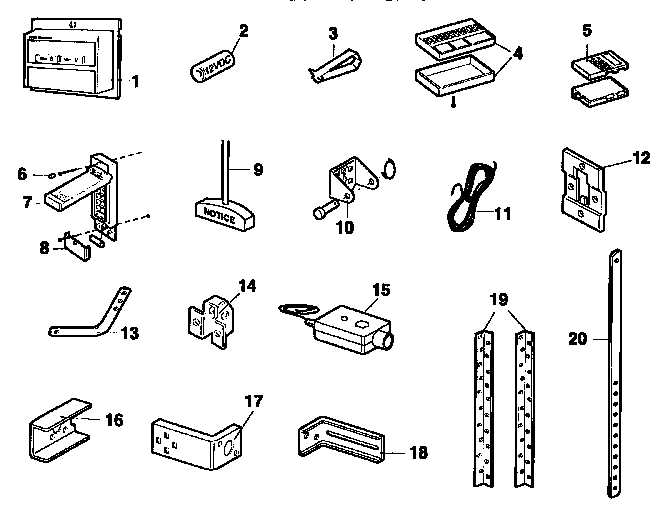

Remote Control and Wall Button Overview

The control system in any automatic mechanism often includes both handheld transmitters and fixed control units. These components work together to ensure smooth and convenient operation, allowing users to interact with the system from a distance or directly on-site. Understanding the function of these controllers is essential for optimal use and troubleshooting.

- The remote transmitter allows for wireless operation, typically with a simple press of a button from a comfortable distance.

- The wall-mounted button provides a more permanent and direct control option, installed in a convenient location for immediate access.

- Both controllers are designed to communicate with the main system unit, ensuring safety and efficiency in daily usage.

- Different models may offer varying features, such as additional buttons for auxiliary functions or advanced security options.

Familiarity with these controllers can help prevent common issues, making it easier to address functionality concerns or perform maintenance when necessary

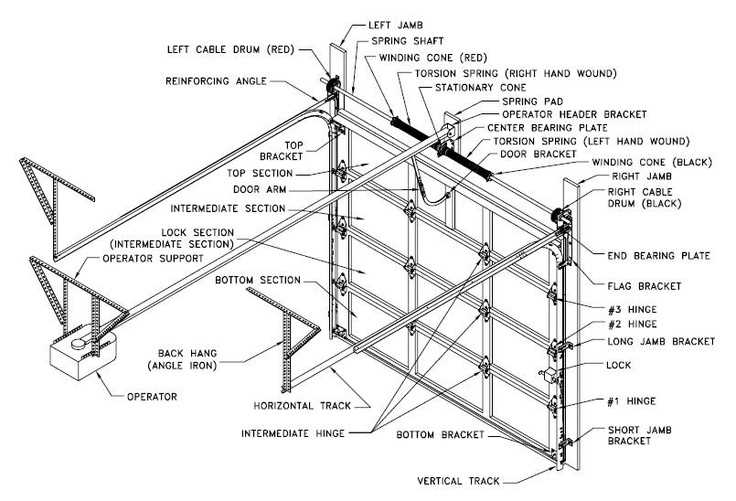

Examining the Chain and Belt Systems

The chain and belt mechanisms play a vital role in ensuring the smooth and efficient operation of automated systems. These systems are responsible for providing the necessary force and movement that drive the connected components. While both types serve the same function, their design and materials influence performance, durability, and maintenance needs.

- Chain-driven system: Known for its robust construction, this mechanism typically offers greater strength and longevity. However, it tends to be slightly noisier due to the metal links that create friction during operation.

- Belt-driven system: This option provides a quieter experience due to the rubber material used. It offers smooth motion, but over time, the belt may require replacement as it wears out more quickly than its metal counterpart.

Understanding the differences between these two mechanisms helps in making informed decisions about maintenance and replacement, depending on the specific needs of the system and the environment in which it operates.

Light System: Purpose and Maintenance

The lighting mechanism in a residential entry system plays a crucial role in enhancing visibility and safety during operation. It ensures that the surroundings are well-lit when the system is engaged, providing convenience and security, especially during the night or in low-light environments. The light typically activates when the system is in motion and shuts off after a set period to conserve energy.

Regular maintenance of this component is essential to keep it functioning properly. Checking the bulbs for wear and tear, ensuring the wiring is secure, and testing the sensor that controls the light are vital steps. Replacing damaged or outdated parts can prevent electrical issues and prolong the life of the system. Cleaning the light fixture and ensuring no obstructions are blocking its path helps maintain its efficiency and reliability.

Battery Backup: Importance and Setup

A reliable backup power source is essential for ensuring uninterrupted operation during power outages. It allows systems to function smoothly, providing continued convenience and safety. The integration of such a backup ensures that critical functions remain operational, even in adverse conditions.

Setting up this backup involves selecting an appropriate unit that matches the system’s power requirements. The installation typically includes connecting the backup unit to the main power system, ensuring that it activates automatically when the primary power supply fails. Proper maintenance and testing are also important to ensure that the system performs optimally when needed.