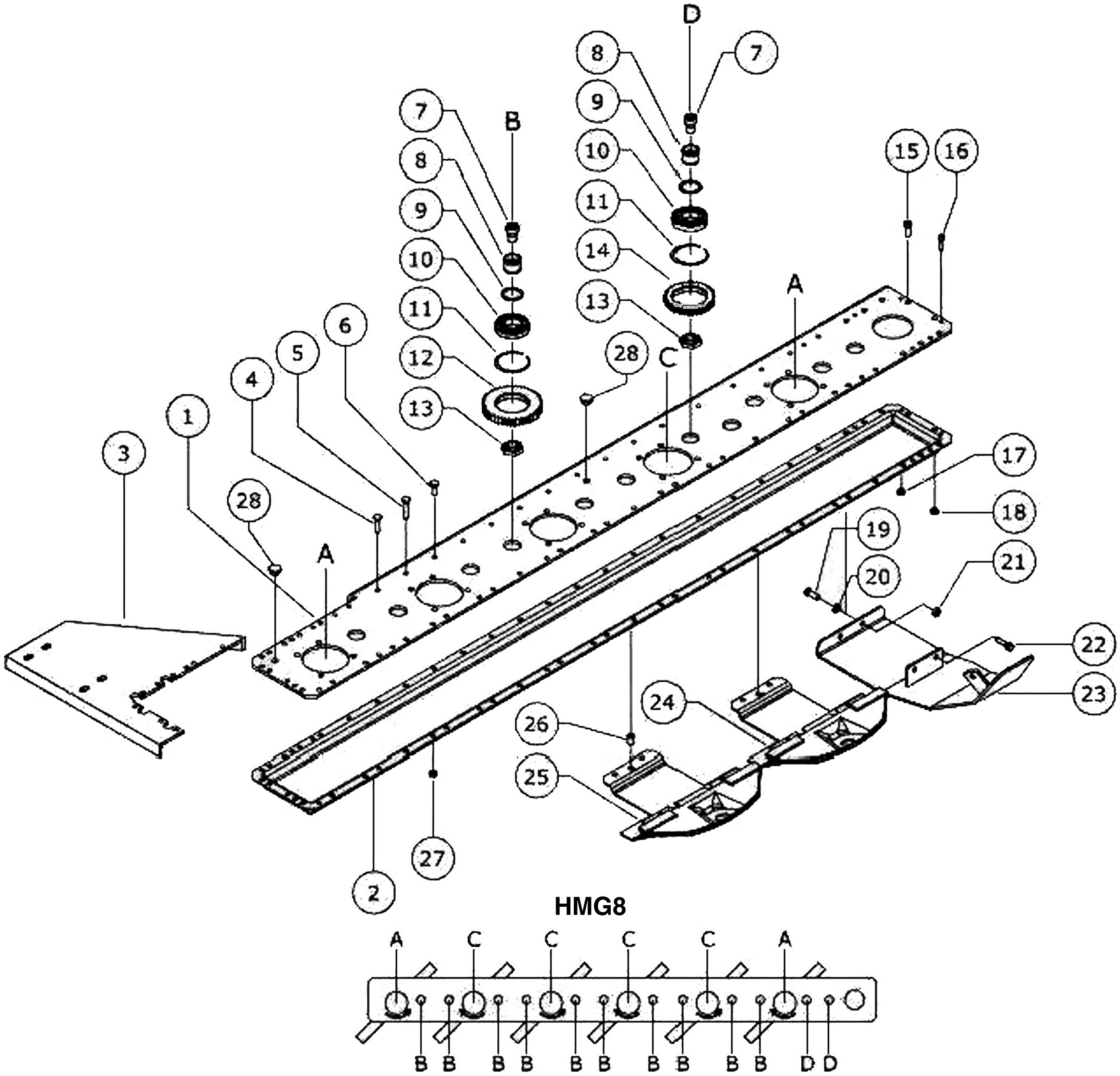

The intricate workings of machinery can often appear overwhelming, but a closer examination reveals a structured arrangement of components that work in harmony. A comprehensive representation of these elements not only aids in comprehension but also enhances maintenance and operational efficiency. By breaking down the various sections, users can better appreciate the functionality and interconnections within the system.

Having a clear visual representation of how each part fits together serves as an invaluable tool for both seasoned professionals and newcomers alike. It simplifies the troubleshooting process, allowing for quicker identification of issues and facilitating prompt repairs. Furthermore, this detailed layout can significantly improve the user’s ability to assemble or disassemble machinery, ensuring a smoother workflow.

In addition to practical applications, a thorough exploration of the configuration can lead to insights into optimizing performance. Understanding the relationships between different components can inform adjustments that may enhance efficiency or extend the lifespan of the equipment. Thus, a well-illustrated breakdown becomes more than just a reference; it transforms into a key resource for maximizing productivity and ensuring reliability.

Understanding Vermeer Parts Diagram

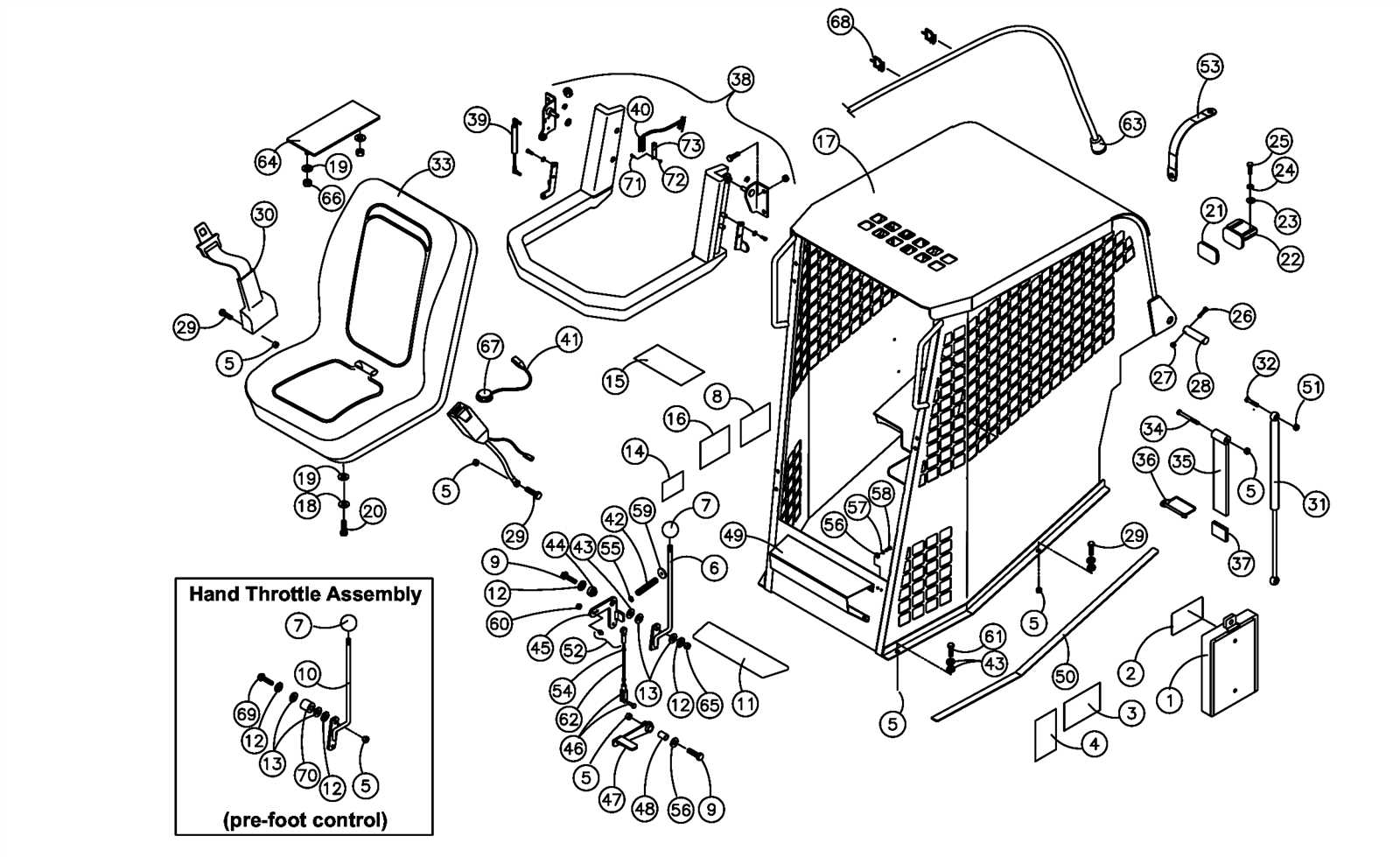

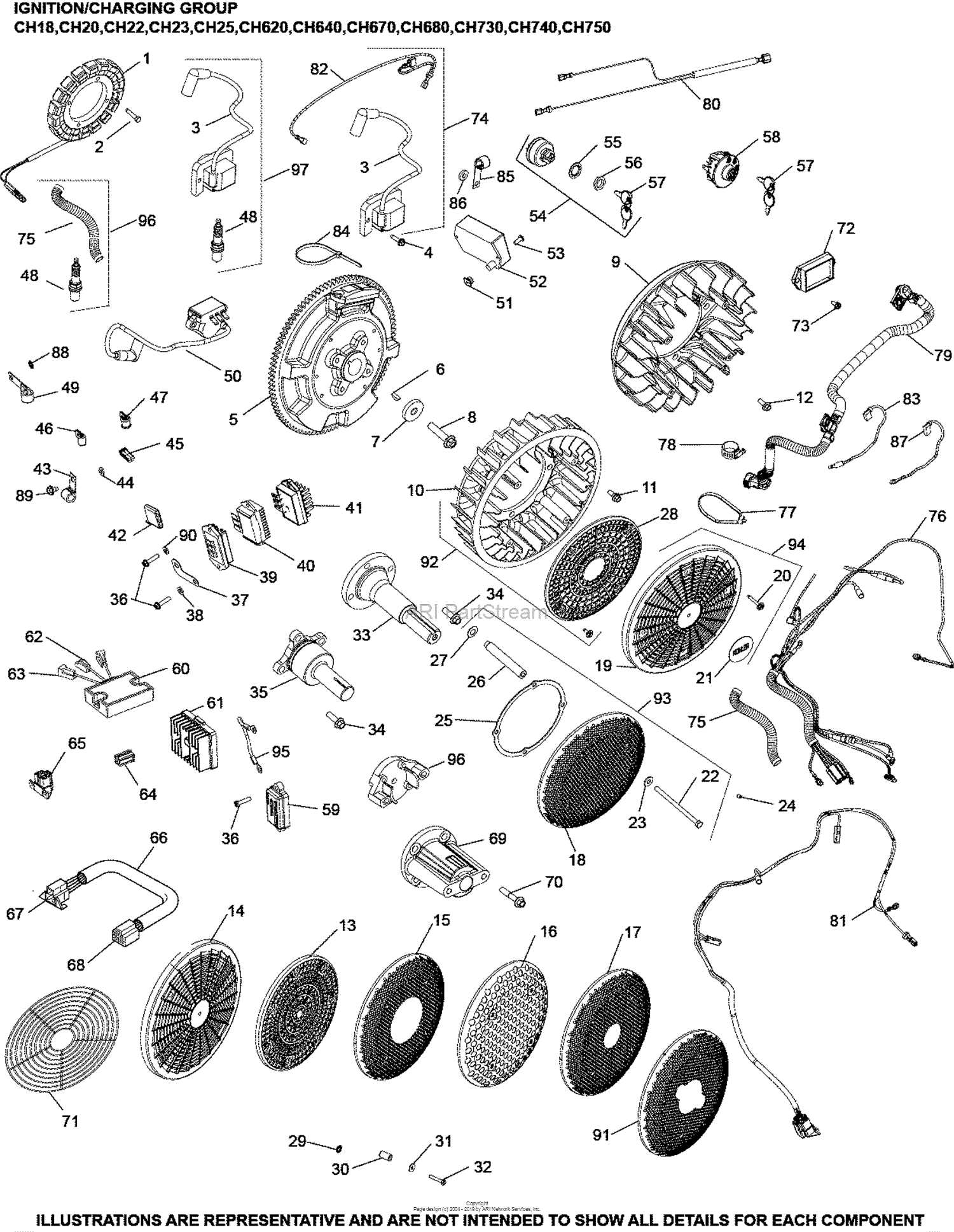

This section aims to provide insights into the intricate representations that illustrate the components of machinery. These visual guides serve as essential tools for anyone looking to comprehend the structure and functionality of various systems. By analyzing these detailed illustrations, users can gain a clearer understanding of how different elements interact and contribute to the overall performance.

Familiarizing oneself with these visual aids allows operators and technicians to efficiently identify and troubleshoot issues. Recognizing the significance of each component aids in maintaining optimal operation and enhances the longevity of the equipment. Moreover, these representations often include valuable information such as assembly instructions and part specifications, making them indispensable for effective maintenance.

In addition to aiding in repairs, these illustrations also play a crucial role in the training of new personnel. Understanding how the various sections fit together fosters a deeper appreciation of the machinery’s design and engineering. This foundational knowledge is vital for ensuring safe and proficient operation in diverse environments.

Importance of Accurate Parts Identification

Proper identification of components is crucial in ensuring the efficient operation and longevity of machinery. When each element is recognized and categorized correctly, maintenance and repairs can be conducted with precision, minimizing downtime and enhancing productivity. Misidentification can lead to inappropriate replacements, causing further complications and increased costs.

Enhancing Maintenance Efficiency

When technicians have a clear understanding of each individual component, they can streamline the maintenance process. Accurate identification allows for quicker troubleshooting and more effective solutions. By knowing exactly what is needed, teams can prepare the right tools and materials in advance, reducing the time spent on each task.

Reducing Operational Risks

Incorrect identification can result in using incompatible elements, which may compromise safety and operational integrity. This can lead to accidents, increased wear, and even catastrophic failures. Ensuring that each component is accurately recognized mitigates these risks and promotes a safer working environment.

| Benefit | Description |

|---|---|

| Efficiency | Faster troubleshooting and repairs. |

| Cost-Effectiveness | Reduces unnecessary expenditures on incorrect replacements. |

| Safety | Minimizes the risk of accidents and equipment failure. |

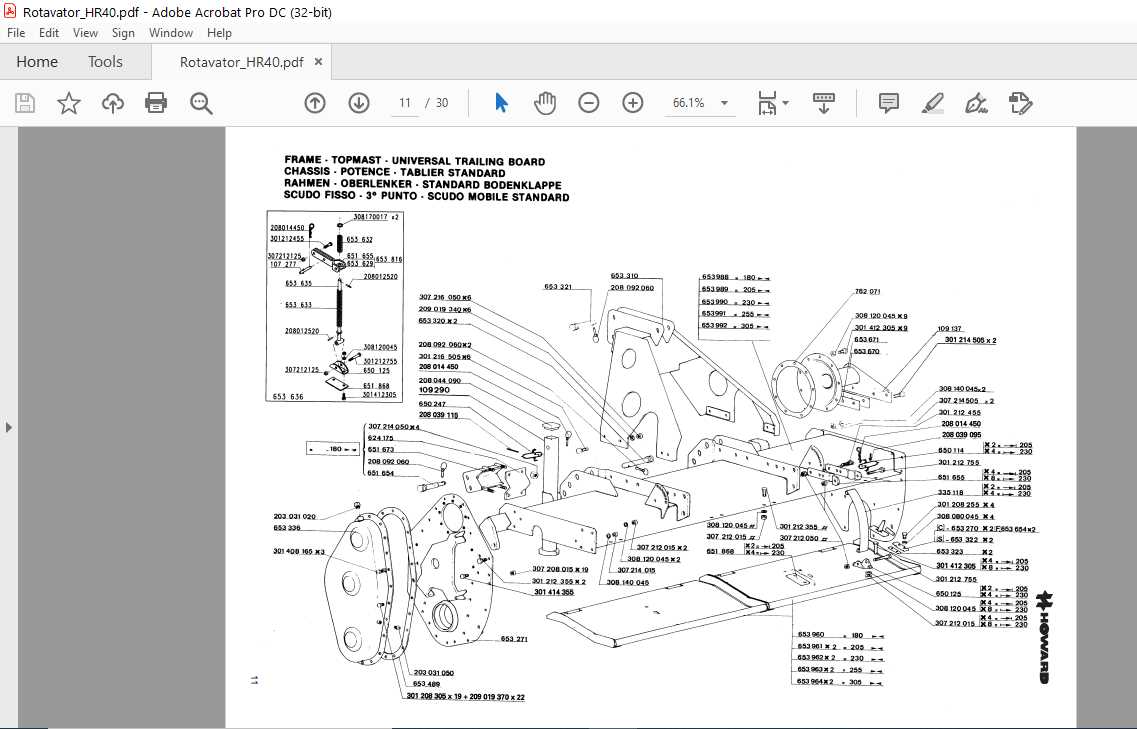

How to Read a Parts Diagram

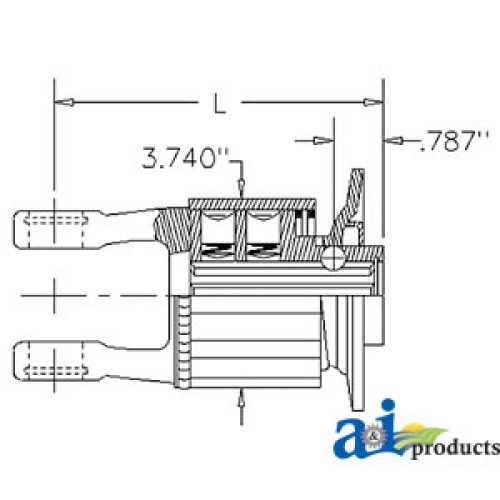

Understanding an assembly illustration is crucial for effective maintenance and repair tasks. These visual representations provide valuable information about components and their relationships, helping you navigate through the intricate details of machinery. By familiarizing yourself with the essential elements of these illustrations, you can streamline your repair process and ensure accurate replacements.

To effectively interpret these visual aids, consider the following steps:

- Familiarize Yourself with Symbols:

Each illustration may use specific symbols or icons to represent different components. Understanding these symbols is the first step in making sense of the overall layout.

- Identify the Components:

Look for labels or numbers associated with each part. These identifiers often correspond to a list, which can provide detailed information about each item.

- Analyze the Relationships:

Observe how the components are connected. Understanding how parts fit together is vital for disassembly and reassembly tasks.

- Refer to the Legend:

Most illustrations will include a legend or key that explains the symbols and labels used. This reference is essential for clarifying any ambiguities.

- Consult Additional Resources:

If you encounter unfamiliar components, refer to manuals or online resources for more in-depth information.

By following these guidelines, you can enhance your comprehension of assembly illustrations, leading to more efficient and accurate repair work.

Common Components in Vermeer Equipment

Understanding the essential elements that make up machinery is crucial for maintenance and operation. These components play a vital role in ensuring that equipment functions efficiently and reliably. A closer examination reveals a range of integral parts that contribute to the overall performance and durability of these machines.

Key Functional Elements

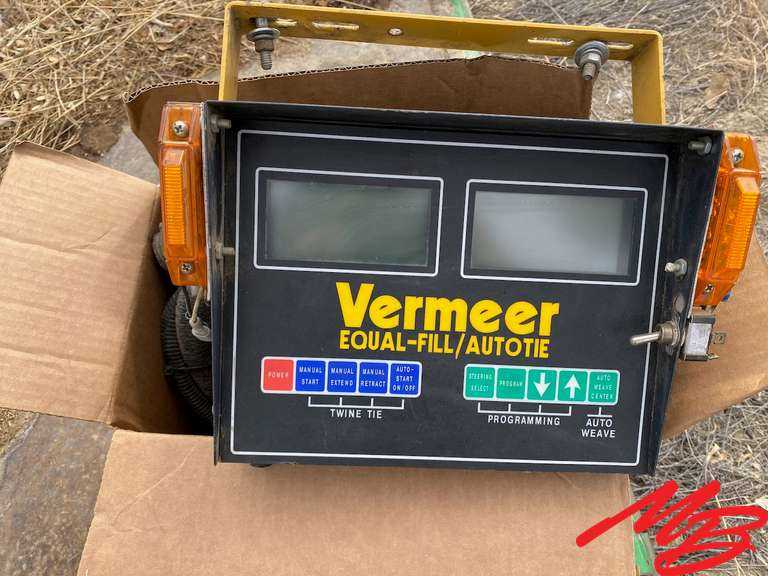

Among the primary components are the hydraulic systems, which facilitate movement and power transfer. These systems are essential for the operation of various attachments and functionalities. Additionally, the drivetrain, comprising the engine and transmission, is fundamental in converting power into motion, allowing for seamless operation across different terrains.

Supporting Structures

Support structures, such as frames and chassis, provide the necessary strength and stability to withstand demanding conditions. Furthermore, electrical systems, including wiring and control panels, enable operators to manage machine functions effectively. Each of these components works in harmony to ensure optimal performance and longevity of the equipment.

Finding Replacement Parts Efficiently

Locating suitable components for machinery can often be a daunting task, especially when faced with time constraints or specific requirements. A systematic approach is essential to streamline the process, ensuring that you obtain the correct items promptly and without unnecessary frustration.

Firstly, it is vital to understand the specific needs of your equipment. Familiarizing yourself with the model and its specifications will greatly enhance your search. Utilizing detailed manuals and resources can provide clarity on the essential elements required for maintenance or repair.

Moreover, leveraging online platforms can significantly expedite the quest for the right components. Numerous websites specialize in inventory listings, allowing users to filter options based on their criteria. It’s beneficial to read reviews and check ratings to ensure the reliability of suppliers.

Another effective strategy involves connecting with local distributors or authorized dealers. These professionals often possess invaluable insights and can assist in sourcing uncommon items that may not be readily available online. Building relationships with these experts can lead to quicker resolutions in the future.

Additionally, participating in forums and communities dedicated to your machinery type can yield useful recommendations. Engaging with other users can reveal alternative sources or innovative solutions to common challenges in obtaining the necessary items.

In conclusion, adopting a structured approach, utilizing online resources, collaborating with professionals, and engaging with the community can greatly enhance your efficiency in securing essential components. This proactive strategy not only saves time but also ensures the longevity and functionality of your machinery.

Maintenance Tips for Vermeer Machinery

Ensuring optimal performance of heavy equipment requires diligent upkeep and attention to detail. Regular maintenance not only prolongs the lifespan of the machinery but also enhances safety and efficiency during operation. Here are some essential guidelines to keep your equipment in prime condition.

- Routine Inspections: Schedule frequent checks to identify any signs of wear or damage. Pay close attention to hydraulic systems, electrical components, and moving parts.

- Fluid Levels: Regularly monitor and top off oil, coolant, and hydraulic fluid levels. This helps prevent overheating and ensures smooth operation.

- Filter Replacement: Change air, fuel, and hydraulic filters as per the manufacturer’s recommendations to maintain optimal performance and prevent contaminants from causing damage.

- Cleaning: Keep the exterior and interior of the equipment clean. Remove dirt, debris, and buildup that could impair functionality or lead to rust.

By adhering to these practices, operators can ensure that their machinery remains reliable and efficient, minimizing downtime and repair costs.

- Lubrication: Apply lubricant to all moving parts according to the maintenance schedule. Proper lubrication reduces friction and wear.

- Battery Care: Inspect and clean battery terminals regularly. Ensure connections are secure and that the battery is properly charged.

- Tire Maintenance: Check tire pressure and tread regularly. Proper inflation and good tread condition enhance traction and fuel efficiency.

- Operator Training: Ensure that all users are adequately trained in the operation and maintenance of the equipment to prevent misuse and accidents.

Implementing these maintenance tips will not only improve performance but also ensure safety and reliability in the long run.

Common Issues and Troubleshooting Guide

This section aims to address frequent challenges faced by operators and provide solutions to enhance operational efficiency. Understanding these common problems and their remedies can significantly reduce downtime and improve performance.

Frequent Problems

Operators may encounter various issues, from mechanical failures to performance inconsistencies. Recognizing the signs early can prevent more severe complications. Below are some typical problems and their potential causes.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Overheating | Insufficient lubrication or blocked cooling system | Check oil levels and clean cooling vents |

| Poor performance | Worn components or incorrect settings | Inspect parts and adjust settings accordingly |

| Strange noises | Loose components or damaged bearings | Tighten loose parts and replace damaged items |

Troubleshooting Steps

When facing any of the above issues, follow these steps for effective troubleshooting:

- Identify the problem by observing symptoms carefully.

- Refer to the maintenance manual for guidance.

- Perform a systematic check of all related systems.

- Make necessary adjustments or repairs.

- Test the equipment to ensure the issue is resolved.

Where to Source Genuine Parts

Finding authentic components for machinery is essential for maintaining performance and ensuring longevity. Relying on high-quality materials not only enhances the efficiency of the equipment but also safeguards the investment made in it. This section will guide you on where to obtain genuine replacements that meet industry standards.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These vendors have direct access to the manufacturer’s inventory and can provide assurance of quality. Always verify the dealer’s credentials and ensure they are officially recognized to avoid counterfeit items.

Manufacturer’s Website

Another excellent option is to visit the manufacturer’s official website. Many companies offer a dedicated section for ordering genuine components online. This ensures that you receive the correct items tailored specifically for your machinery. Additionally, customer support can assist with inquiries regarding compatibility and specifications.

In conclusion, sourcing authentic materials is crucial for effective machinery operation. Utilizing authorized dealers and the manufacturer’s website will help you secure quality components that uphold the integrity of your equipment.

Benefits of Using Official Diagrams

Utilizing authorized schematics offers numerous advantages that enhance both understanding and functionality. These detailed illustrations serve as reliable references, ensuring that users can accurately interpret the components and mechanisms involved. By adhering to standardized representations, individuals can improve their maintenance and repair processes, leading to greater efficiency and effectiveness.

Improved Accuracy

Official illustrations provide precise information, reducing the risk of errors during assembly or troubleshooting. Each element is clearly labeled, allowing users to identify parts quickly and accurately. This clarity minimizes misunderstandings and promotes correct installations, ultimately saving time and resources.

Enhanced Safety

Utilizing certified schematics significantly contributes to safety during operation and maintenance. These documents often include crucial safety guidelines and warnings, helping users avoid potentially hazardous situations. By following these official resources, individuals can ensure they are adhering to best practices and reducing the likelihood of accidents.