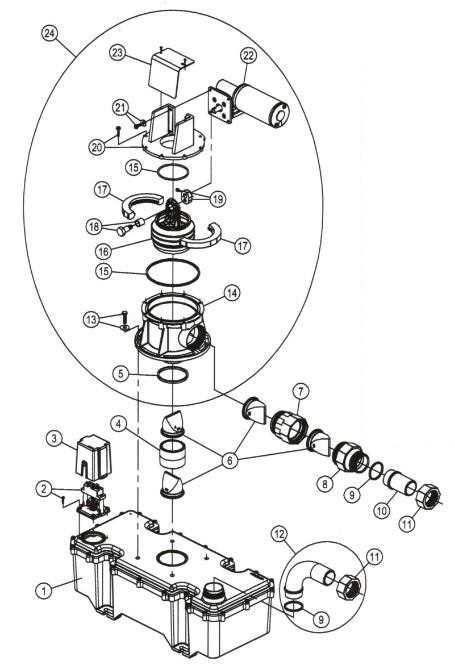

Every piece of equipment has its intricacies, and understanding the components is essential for optimal performance. When it comes to vacuum systems, familiarity with the internal and external elements can greatly enhance maintenance and troubleshooting efforts. A clear representation of these parts serves as a valuable resource for users, helping them identify and address any issues that may arise.

In this section, we delve into a detailed overview of the various components associated with a specific vacuum model. By breaking down the assembly into manageable sections, users can easily navigate through the essential parts, ensuring they have a solid grasp of how everything fits together. This knowledge not only facilitates efficient repairs but also contributes to the longevity of the device.

Moreover, having a visual guide at hand can significantly streamline the process of sourcing replacements or upgrades. Understanding the relationships between different components allows for better decision-making, whether it’s for routine maintenance or addressing unexpected malfunctions. With a thorough exploration of this topic, you’ll be better equipped to maximize the potential of your vacuum system.

Understanding Vacmaster VP112 Components

In order to optimize the performance of a specific vacuum system, it is crucial to comprehend its individual elements. Each component plays a significant role in the overall functionality, contributing to efficiency and reliability. By examining these parts, users can better appreciate how they work together to achieve the ultimate cleaning experience.

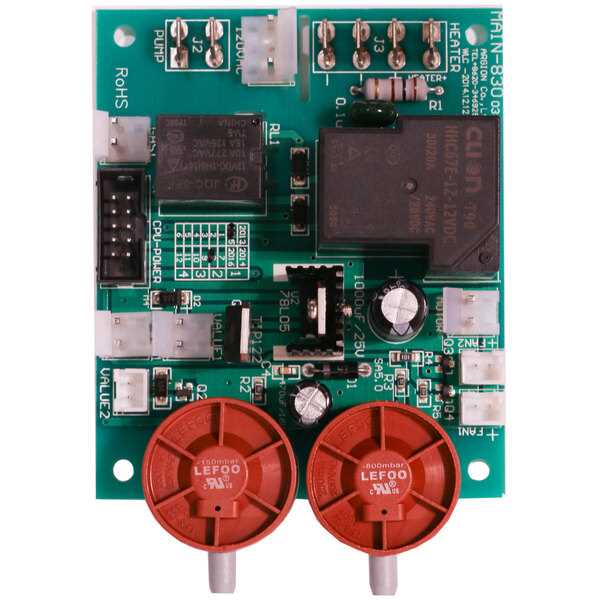

Power Unit: The core of any vacuum system, this element provides the necessary energy to drive the entire mechanism. Its efficiency directly influences the suction power and performance.

Collection Chamber: This component is responsible for gathering debris and dust. A well-designed chamber ensures easy disposal and maximum capacity, enhancing usability.

Filtration System: Effective filtration is essential for maintaining air quality. This system captures fine particles, preventing them from being released back into the environment.

Hoses and Attachments: These accessories are vital for versatility. They allow users to reach different surfaces and corners, making the vacuum suitable for various cleaning tasks.

Control Panel: The interface for operation, it provides users with the ability to adjust settings. A user-friendly design enhances the overall experience.

By delving into the specifics of each component, users can make informed decisions regarding maintenance, upgrades, and repairs, ultimately prolonging the life of their equipment.

Overview of Vacmaster VP112 Features

This section provides a comprehensive look at the key characteristics and functionalities of a popular vacuum sealing machine. Designed for efficiency and ease of use, it offers various features that enhance food preservation and storage solutions.

- Powerful Vacuum Pump: Ensures an airtight seal, prolonging the freshness of stored items.

- User-Friendly Control Panel: Simplifies the sealing process with intuitive buttons and indicators.

- Adjustable Seal Time: Allows customization based on the type of bags used, ensuring optimal sealing.

- Compact Design: Saves space in your kitchen or storage area while providing robust functionality.

- Durable Construction: Built with high-quality materials to withstand regular use and ensure longevity.

In addition to these features, this machine supports various bag sizes, accommodating different storage needs and allowing users to efficiently organize their food items.

- Convenient cleaning and maintenance options for hassle-free upkeep.

- Compatibility with a wide range of vacuum bags and rolls, enhancing versatility.

- Lightweight design for easy portability between kitchen and storage areas.

Overall, this sealing device combines functionality with practicality, making it a valuable addition for anyone looking to streamline their food preservation process.

Importance of a Parts Diagram

Understanding the layout of components in a device is crucial for effective maintenance and repair. A visual representation of these elements enhances clarity, helping users identify each part’s function and location. This knowledge empowers individuals to address issues confidently, ensuring proper handling and replacement of any faulty elements.

Moreover, having a clear schematic can significantly reduce the time spent on troubleshooting. It allows technicians to quickly locate the necessary pieces, making the repair process more efficient. With a comprehensive visual guide, users can better prepare for servicing tasks and minimize the risk of errors.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clarifies the function and placement of each element. |

| Time Efficiency | Reduces time spent on locating and identifying components. |

| Error Minimization | Helps prevent mistakes during repairs and replacements. |

| Informed Decision-Making | Enables users to make better choices regarding maintenance. |

In conclusion, a well-organized visual representation serves as an invaluable tool for anyone looking to maintain or repair their equipment effectively. It not only simplifies the process but also fosters a deeper understanding of the machinery involved.

Common Issues with Vacmaster Parts

When dealing with equipment that requires various components for optimal performance, it’s not uncommon to encounter certain challenges. Understanding these issues can significantly enhance the longevity and efficiency of the machine.

- Wear and Tear: Over time, certain components may degrade due to frequent use. This can lead to decreased efficiency and functionality.

- Clogs: Debris accumulation in hoses or filters can obstruct airflow, resulting in poor performance.

- Electrical Failures: Issues with wiring or motors can lead to operational failures, necessitating immediate attention.

- Seal Damage: Gaskets and seals can wear out, causing leaks and loss of suction, which affects the overall efficiency.

- Improper Assembly: Incorrectly assembled parts can lead to malfunctions. It’s crucial to follow guidelines for proper setup.

Addressing these common problems promptly can prevent further damage and ensure the equipment operates effectively. Regular maintenance and inspection play a vital role in mitigating these issues.

Where to Find Replacement Parts

Locating components for your equipment can be crucial for maintaining its performance. There are several reliable sources where you can obtain these essential items, ensuring that your device operates efficiently and effectively.

Online Retailers

- Visit major e-commerce platforms for a wide selection.

- Check specialized websites that focus on tools and equipment.

- Explore manufacturer websites for direct purchases.

Local Suppliers

- Search for hardware stores that stock various components.

- Consult local service centers that may offer compatible replacements.

- Look for trade shows or expos that feature vendors of tool accessories.

How to Read the Diagram

Understanding a visual representation of components is essential for efficient assembly, maintenance, or troubleshooting. By interpreting the illustration correctly, one can identify each segment and its function, leading to more effective handling of the equipment.

Identifying Components

Start by locating the key elements in the visual guide. Each part is typically labeled with a reference number or letter, which corresponds to a legend or list. This enables you to easily find specific items and understand their roles within the overall system.

Understanding Relationships

Pay attention to the connections and relationships between the different elements. Arrows or lines often indicate how components interact or fit together. This insight is crucial for grasping how the system operates as a whole and for ensuring that all pieces work in harmony.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your equipment. By implementing a few straightforward practices, you can ensure optimal performance and reduce the risk of unexpected breakdowns. Regular attention to detail can make a significant difference in durability and efficiency.

Regular Cleaning: Keep your device free from dust and debris. Cleaning the exterior and interior components helps prevent blockages and maintains airflow. Use a soft brush or cloth for sensitive areas to avoid damage.

Routine Inspections: Schedule periodic checks to identify any wear and tear. Look for signs of deterioration, such as cracks or frayed cords. Early detection can save you from costly repairs down the line.

Proper Storage: When not in use, store your equipment in a dry, cool place. Avoid exposure to extreme temperatures or humidity, as these conditions can negatively affect performance and longevity.

Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule and procedures outlined in the user manual. This ensures that your equipment remains in optimal condition and complies with warranty requirements.

Use Quality Supplies: When replacing any consumable items, opt for high-quality products. Substandard materials can lead to premature failures and compromise the functionality of your device.

By incorporating these practices into your routine, you can significantly enhance the lifespan of your equipment, ensuring it operates efficiently for years to come.

Customer Reviews on Vacmaster Parts

When it comes to assessing the quality and reliability of various components, user feedback plays a crucial role. Customers often share their experiences, highlighting strengths and weaknesses that can guide potential buyers. This section focuses on what users are saying about their recent purchases, offering valuable insights into performance and durability.

Overall Satisfaction: Many users express high levels of satisfaction with the functionality of these items. They appreciate the seamless integration and enhanced efficiency that these components bring to their equipment.

Durability: A recurring theme in reviews is the robustness of the products. Customers frequently mention that the longevity of these components exceeds their expectations, making them a worthwhile investment.

Customer Support: In addition to product quality, support services receive commendations. Users report prompt responses and effective solutions to any issues they encounter, enhancing their overall experience.

In summary, user reviews reflect a positive consensus regarding these items, underscoring their value in achieving optimal performance.

Comparison with Other Models

When evaluating different vacuum sealing machines, it’s essential to understand how each model stacks up against its competitors. This analysis highlights key features, performance metrics, and overall user satisfaction, helping you make an informed decision.

Several alternatives on the market offer similar functionalities, yet each has unique aspects that may cater to specific needs. Here are some notable comparisons:

- Performance:

- Some devices provide higher suction power, making them more efficient for bulk sealing.

- Others might focus on quieter operation, appealing to users prioritizing noise reduction.

- Design:

- Compact models save counter space, ideal for small kitchens.

- Heavier-duty options may offer more durability for frequent use.

- Versatility:

- Some units come with a variety of sealing settings for different types of foods.

- Others might include additional features, such as built-in cutters for bags.

- Price Range:

- Budget-friendly models provide essential features without frills.

- Higher-end options offer advanced technology and additional accessories.

In conclusion, evaluating these factors allows users to select a machine that best aligns with their specific requirements and preferences, ensuring optimal performance and satisfaction.