In modern agriculture, effective machinery plays a crucial role in optimizing fieldwork. One of the key tools used by farmers involves a complex system of rotating elements designed for soil preparation. This equipment aids in breaking up the soil, ensuring it is ready for planting, while also helping to manage crop residue efficiently. Without these essential tools, the process of preparing the land would be far more labor-intensive and time-consuming.

Each part of this machinery is carefully engineered to perform a specific function. From the rotating elements that interact directly with the soil, to the frame that holds everything together, every component must work in harmony for the equipment to function effectively. Understanding how these elements are arranged and how they contribute to the overall process can provide valuable insights into both the operation and maintenance of the machinery.

Maintaining the different components is vital for ensuring long-term performance. Regular checks and replacements, when necessary, can prevent breakdowns and improve efficiency. Knowing the layout of the various elements can also make it easier to troubleshoot potential

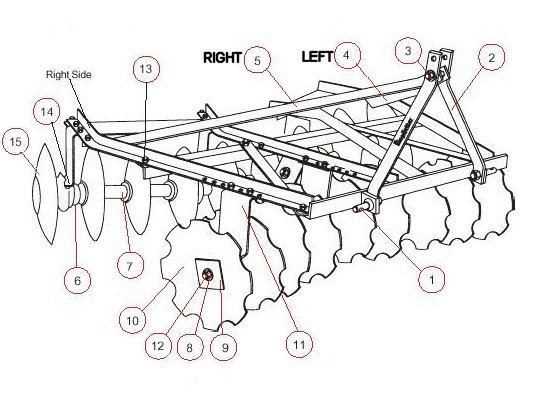

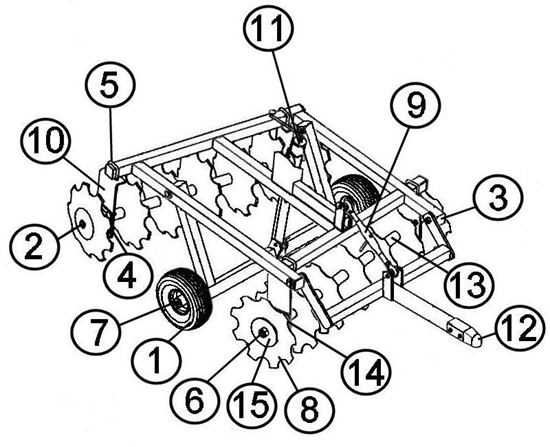

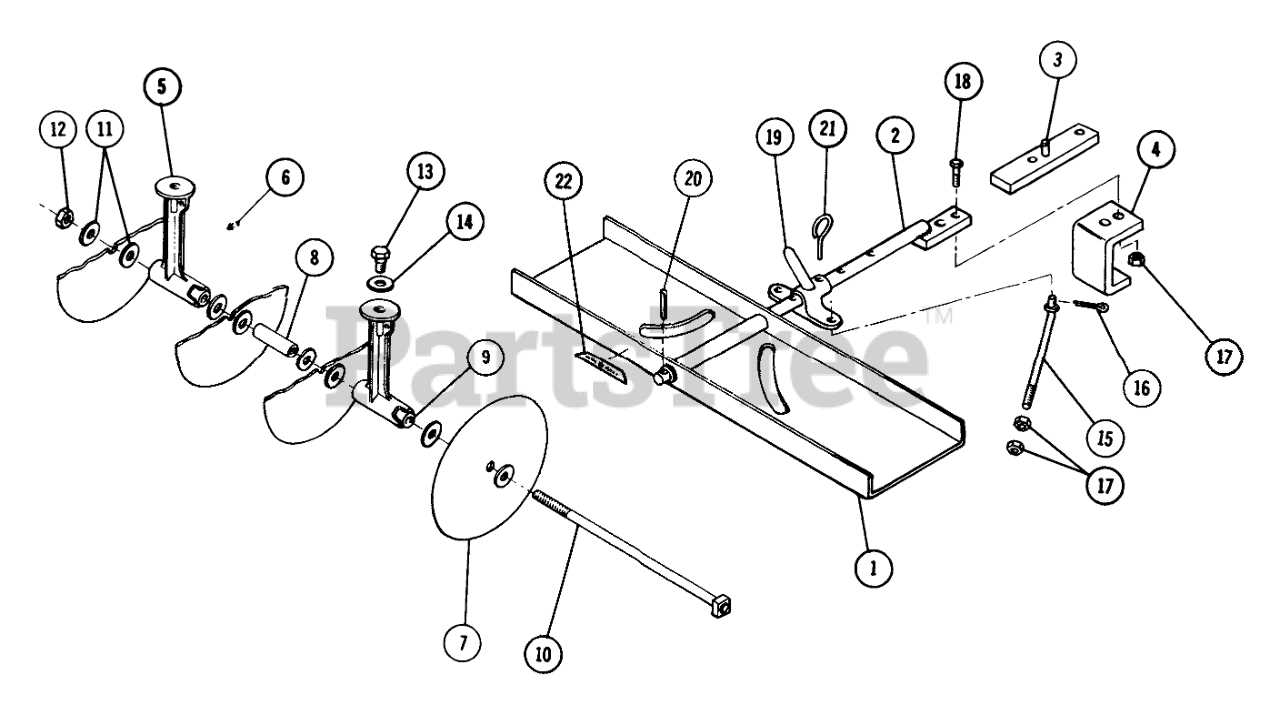

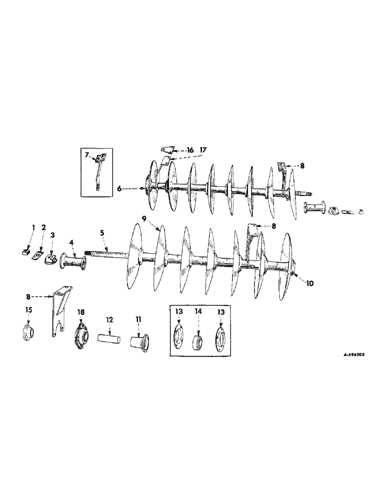

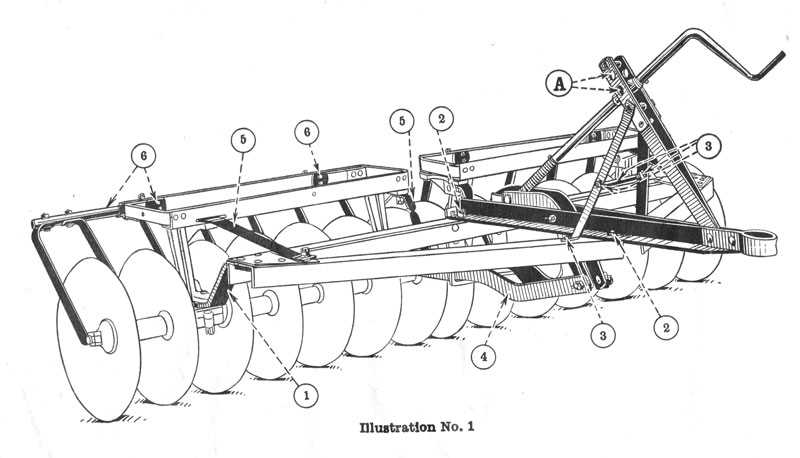

Disc Harrow Parts Diagram Overview

This section provides a detailed insight into the structure and components of a common agricultural tool designed for soil preparation. Understanding the arrangement and purpose of each element is crucial for effective operation and maintenance.

- Main Frame: The backbone that holds all elements together, ensuring stability and support during fieldwork.

- Rotating Blades: These sharpened metal disks are responsible for breaking up the soil and preparing it for planting.

- Axle Assembly: Connects the rotating elements and allows for smooth turning during movement.

- Adjustable Settings: These mechanisms allow users to control depth and pressure based on the terrain.

- Connection Points: Links the implement to a tractor or other vehicle, facilitating easy towing and maneuvering.

The proper alignment and upkeep of each component ensure

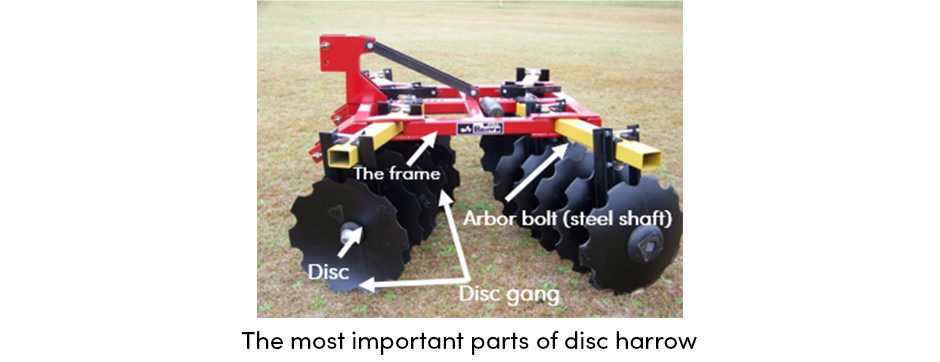

Essential Components of a Disc Harrow

The agricultural tool consists of several key elements that work together to improve soil conditions. These components are vital for ensuring the equipment operates efficiently and effectively, making it an essential part of the cultivation process.

One of the primary parts is the frame, which provides structural support and stability. It holds other parts in place and helps distribute weight evenly. Coupled with this is the axle system, which ensures smooth movement and alignment during operation.

Another crucial component is the set of rotatable blades, responsible for penetrating the soil surface and preparing it for further processes. These blades are mounted at precise angles to optimize performance. Additionally, the bearings play a pivotal role by reducing friction and wear, extending the tool’s lifespan.

Finally, the hitch mechanism connects the equipment to the

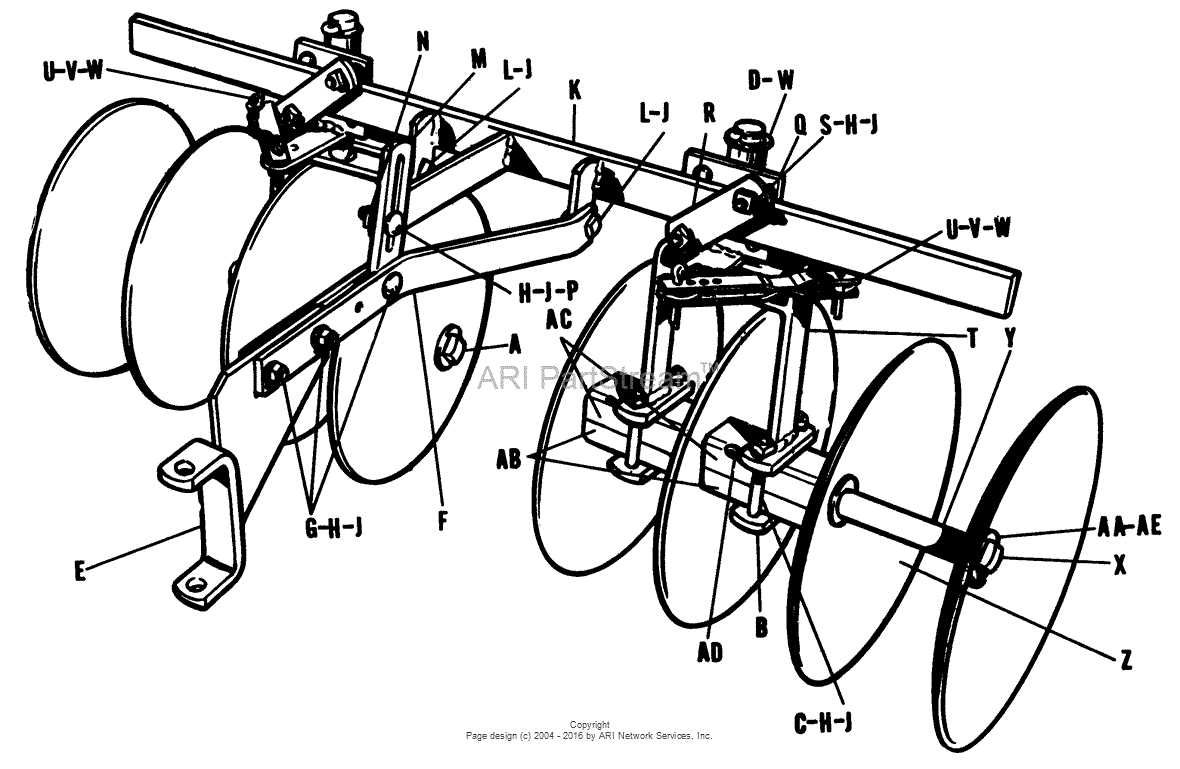

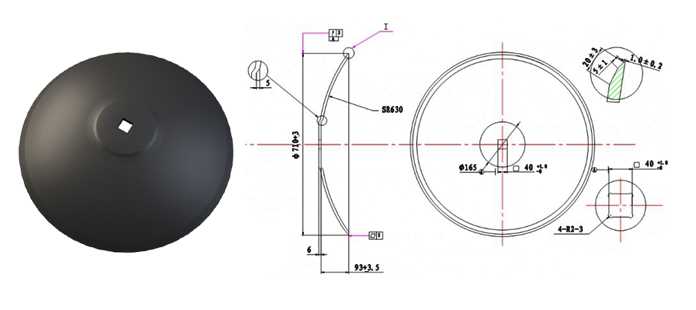

Blade Types and Their Functions

Different blade variations serve specific purposes based on their design and structure. Understanding these differences helps in selecting the right tools for various soil conditions and agricultural needs.

- Serrated Blades: These blades are designed to cut through tough terrain and vegetation. The notched edges allow for better grip and penetration, making them ideal for breaking hard ground or cutting through roots.

- Smooth Blades: Known for their clean, even edges, these blades are effective in soft soil conditions. They offer less resistance, ensuring smooth operation while leveling or mixing the soil.

- Fluted Blades: With ridges along the surface, fluted blades are built to enhance soil movement and improve aeration. They are particularly useful in scenarios requiring thorough mixing or turning of the earth.

- Flat Blades: These blades provide precision when it comes to shallow cutting or finishing work. Their straight edges

Frame Construction and Durability

The structure and strength of agricultural tools are critical factors in ensuring long-term performance in the field. A well-engineered framework provides stability, supports all components, and withstands demanding work conditions. Robust materials and careful design choices contribute to a longer lifespan and reliable functionality.

Material Selection

The choice of materials is vital for enhancing the endurance of the tool’s foundation. High-quality steel or reinforced alloys are often used to prevent bending or warping under pressure. This approach not only increases the longevity of the equipment but also minimizes the need for frequent repairs or replacements.

Design Considerations

Attention to the design of the framework is essential in maintaining its strength and efficiency. Reinforced joints and strategically placed supports improve weight distribution, ensuring the tool can handle various workloads without compromising its structural integrity. Such features make it adaptable to different terrains and farming operations.

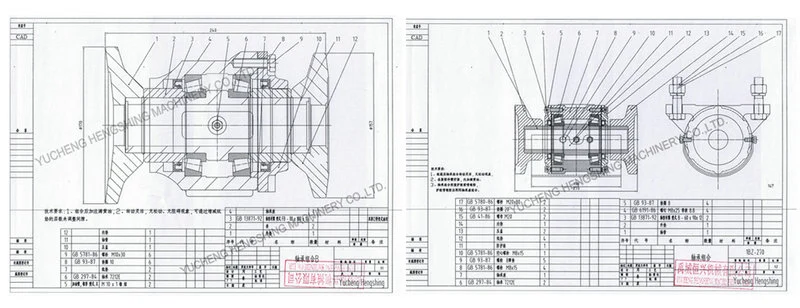

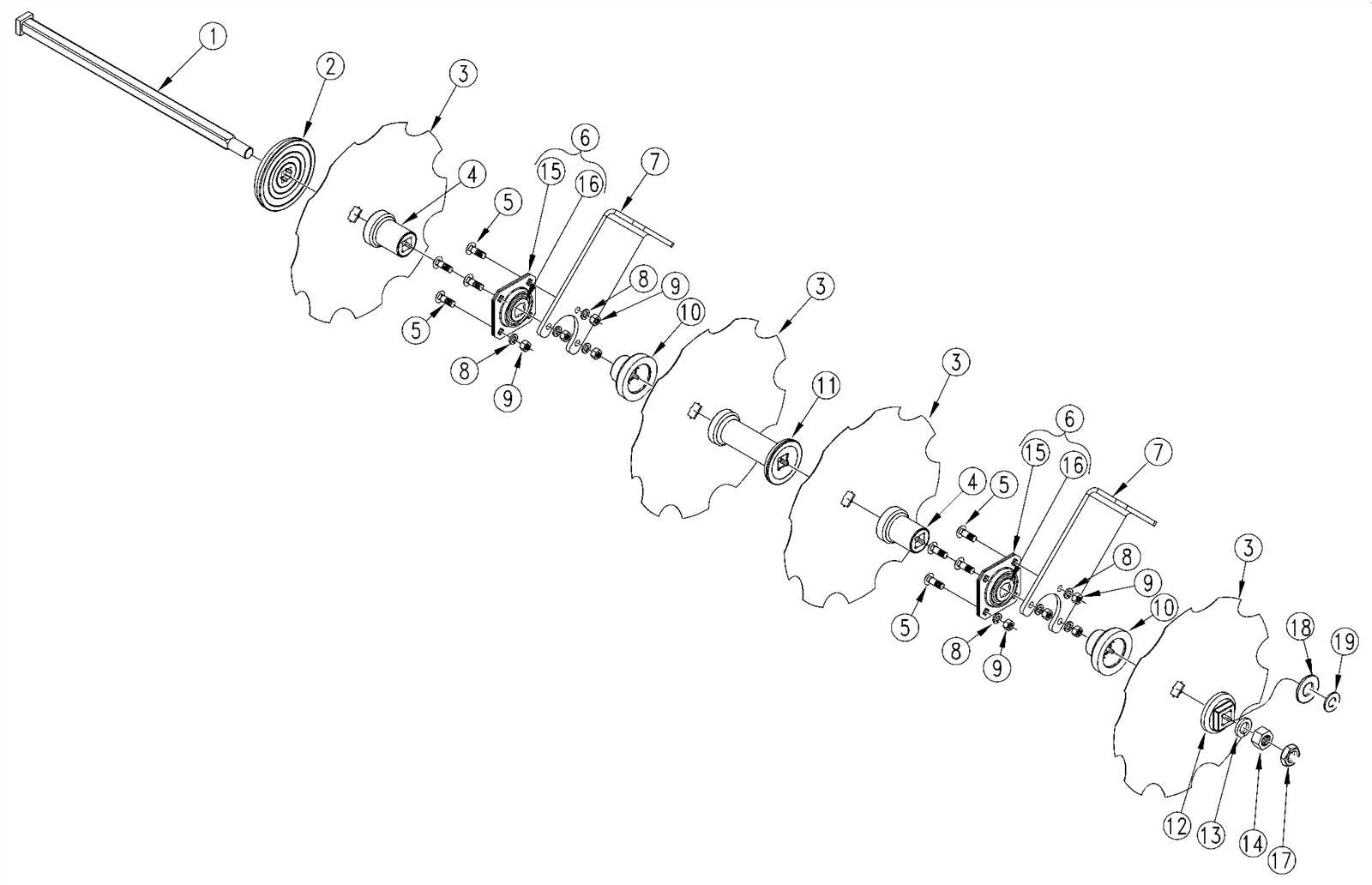

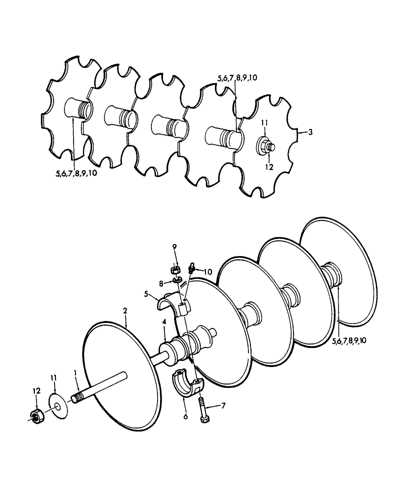

Axles and Bearings in Tillage Implements

The core of the smooth and efficient operation of agricultural equipment relies on its axles and bearings. These components are essential in ensuring the overall stability and rotational motion during soil preparation activities. Their strength, durability, and proper maintenance are key factors for long-lasting performance and reduced downtime in the field.

Axle Functionality and Maintenance

Axles serve as the structural backbone, responsible for supporting and distributing the load across the rotating components. Proper lubrication and regular inspections are necessary to prevent wear and avoid costly replacements. Signs of wear include unusual vibrations or noises during operation, which may indicate misalignment or damage.

Bearings: Ensuring Smooth Operation

Bearings facilitate the rotational movement, minimizing friction and reducing the stress on other components. Choosing the right type of bearing is crucial, as it directly impacts efficiency and longevity. Se

Maintenance Tips for Harrow Blades

Ensuring the longevity and efficiency of soil tilling implements is crucial for optimal agricultural performance. Regular upkeep not only enhances their functionality but also prevents costly replacements. Implementing effective maintenance strategies can significantly improve the lifespan of these tools.

Regular Inspection

Conducting frequent inspections is vital to identify wear and tear early. Look for signs of damage, such as cracks or dullness, that can affect performance. Addressing minor issues promptly can prevent more significant problems down the line.

Sharpening Techniques

Keeping the cutting edges sharp is essential for achieving efficient soil penetration. Use appropriate sharpening tools to maintain the blades’ edge. Regular sharpening minimizes strain on the equipment and improves overall performance.

Adjusting the Disc Gang for Efficiency

Proper alignment and calibration of the cutting elements are crucial for optimizing performance during soil preparation. Fine-tuning these components can significantly enhance their effectiveness, leading to improved soil structure and better crop yields. The adjustments should take into account various factors, including soil type, moisture content, and the desired depth of tillage.

Understanding Angle and Spacing

Adjusting the angle and spacing between the cutting elements allows for tailored operation to specific soil conditions. Increasing the angle can enhance penetration in tougher soils, while a more horizontal setting is ideal for lighter, more cultivated earth. Similarly, the spacing between the elements affects the coverage area and the overall efficiency of the tillage process. Narrow spacing may provide a smoother finish, while wider spacing can be effective for breaking up compacted layers.

Regular Maintenance and Inspection

To maintain optimal performance, routine maintenance and inspection of the cutting components are essential. Regularly checking for wear and damage ensures that adjustments can be made promptly, preventing inefficiencies. Proper lubrication and tightening of connections contribute to a longer lifespan and consistent operation, enabling the equipment to function at its best.

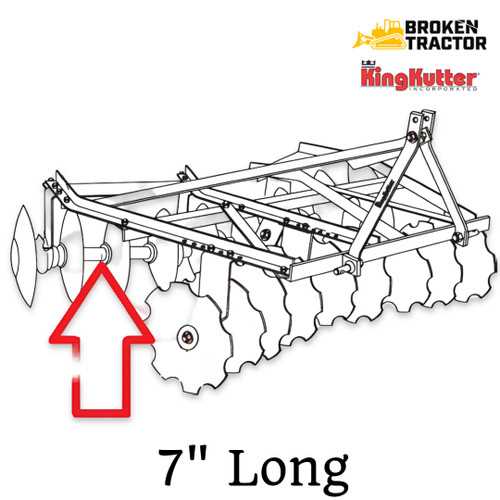

Common Wear Points and Replacement Parts

When working with tillage equipment, understanding areas prone to wear is crucial for maintaining optimal performance. Identifying components that frequently require servicing can help ensure the machinery operates efficiently and reduces downtime. This section highlights common locations susceptible to wear and suggests suitable replacements for each.

Component Common Issues Recommended Replacement Blade Worn edges, cracking New blades of the same size and type Scraper Deformation, loss of effectiveness Replacement scrapers with compatible dimensions Bearings Excessive play, noise High-quality bearings suited for the model Frame Cracks, bends Reinforced frame parts or new sections Hitch Wear and tear, misalignment Replacement hitches designed for compatibility Improving Performance with Quality Parts

Enhancing the efficiency and effectiveness of agricultural equipment hinges on the use of high-quality components. When machinery operates with superior elements, it not only boosts productivity but also ensures longevity and reliability. The selection of top-tier materials can significantly impact the overall functionality of the equipment.

Investing in durable and reliable components leads to smoother operations, reducing the likelihood of unexpected breakdowns. Quality elements minimize maintenance requirements, allowing farmers to focus on their core activities rather than frequent repairs. Furthermore, superior components can enhance the precision and effectiveness of soil cultivation, ensuring optimal conditions for crop growth.

Ultimately, prioritizing the acquisition of high-standard components is a crucial strategy for improving operational outcomes. By doing so, agricultural professionals can achieve greater efficiency, reduce costs in the long run, and foster a more sustainable farming practice.