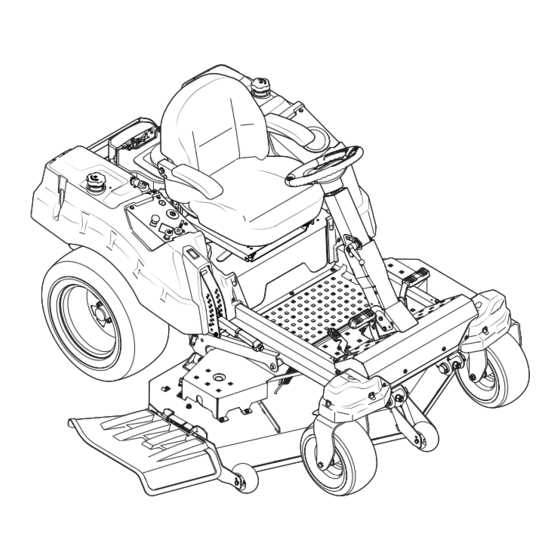

Maintaining an efficient control mechanism in various machines is crucial for ensuring both precision and reliability during operation. The proper alignment and function of certain elements can significantly impact performance, making it essential to understand how these mechanisms interact and work together. This section explores the essential elements responsible for ensuring seamless control, offering insights into their function and importance.

Each component plays a vital role in maintaining stability and control, and ensuring these parts are in top condition is key to avoiding operational issues. From linkages to other essential connectors, understanding the function of these elements helps identify potential areas for maintenance or replacement. By learning more about their roles, users can ensure optimal performance and longevity for the entire system.

This guide delves into the most critical elements involved in effective control systems, providing a clear and detailed overview. By following this information, users can gain a deeper understanding of how to maintain and repair essential parts, ensuring a smooth and reliable experience.

Understanding the Cub Cadet Steering System

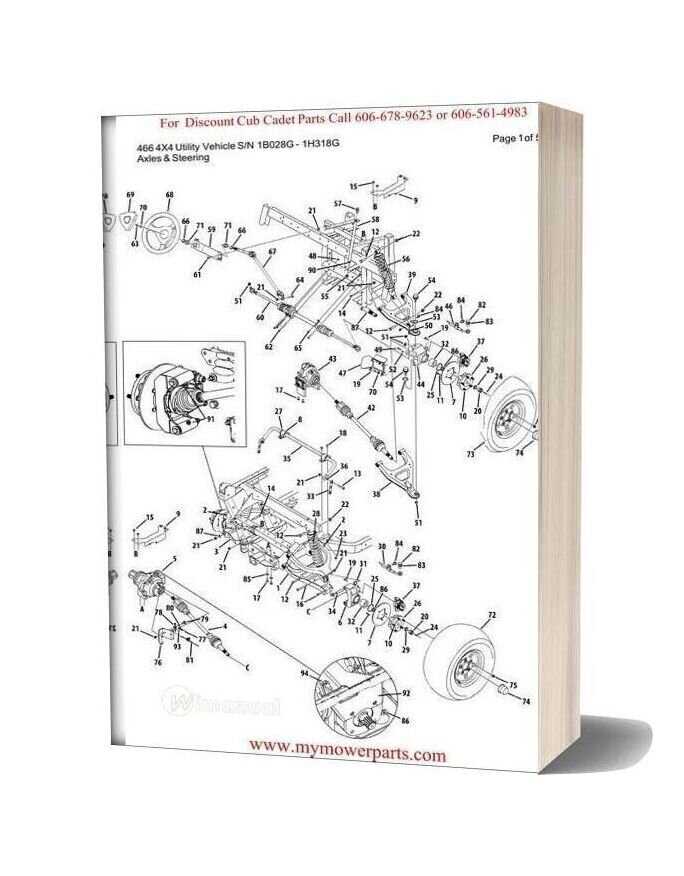

Maintaining proper control of your equipment depends heavily on the precise functionality of its maneuvering mechanism. The various interconnected components work together to ensure smooth and responsive direction changes during operation. Without a well-maintained system, handling can become unpredictable, leading to potential issues in the field.

Key Elements and Their Roles

At the heart of this system are several critical elements that contribute to its overall performance. These include connectors responsible for transferring motion from the controls to the wheels, as well as various shafts and linkages that ensure every turn is executed smoothly. Proper alignment and condition of these elements are essential for safe and efficient operation.

Common Issues and Maintenance Tips

Over time, natural wear and tear can cause certain components to become less effective. Regular inspections are crucial to identify any loosening, corrosion, or misalignment within the system. Lubrication and timely replacement of worn-out parts are simple yet effective ways to extend the lifespan of your equipment and maintain optimal performance.

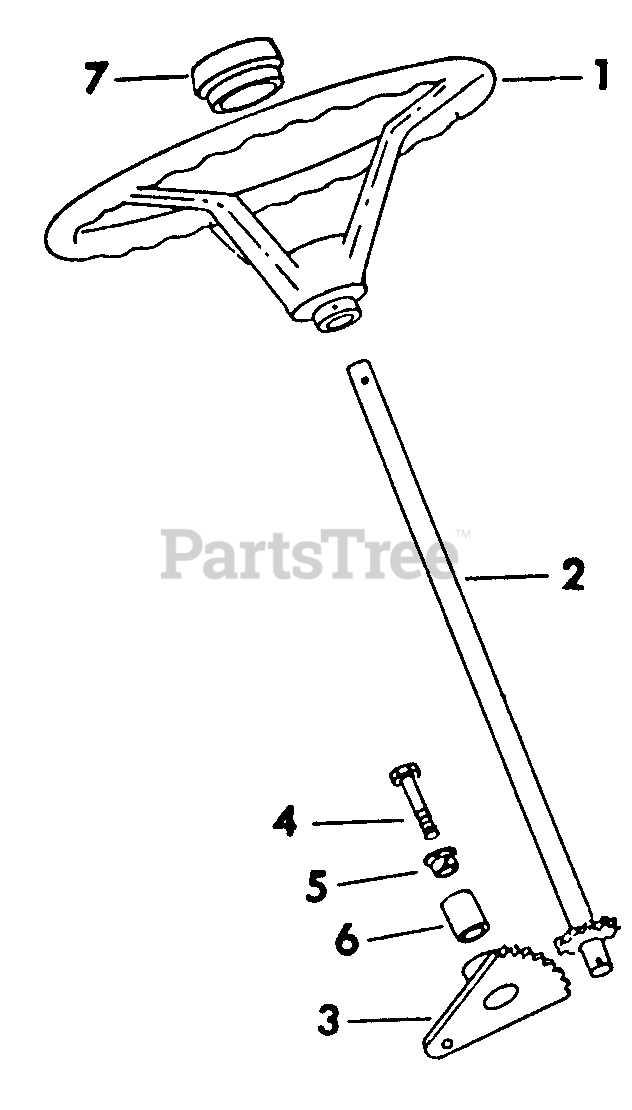

Common Components of Steering Assemblies

Mechanisms responsible for turning and maneuvering machinery often consist of various interconnected elements. These components work together to ensure smooth directional control and provide stability during operation. Understanding the individual elements involved can help in maintaining functionality and ensuring efficient performance over time.

Key Linkage Elements

The system relies on specific linkage elements that transfer motion from the control interface to the moving parts. Components such as tie rods, joints, and shafts are crucial in ensuring precise movement. These parts allow for seamless coordination between input and output motions, enabling effective turns and adjustments in various terrains.

Support and Stabilization Components

Several components provide necessary support and stabilization to the entire mechanism. Bearings, bushings, and mounts help reduce friction and wear, ensuring a longer lifespan for the assembly. These elements also help absorb shocks and vibrations, contributing to a smoother overall experience.

Proper maintenance and timely inspection of these components ensure optimal performance and longevity.

How to Identify Steering Issues

One of the key indicators of mechanical problems in your vehicle’s handling system is a noticeable change in its maneuverability. Whether you’re experiencing difficulty turning or hearing unusual noises, recognizing these early signs can help prevent larger issues down the road. It’s important to pay close attention to how your equipment reacts during operation, as even slight differences in performance can signal underlying issues.

Unresponsive Controls: If you find that the controls are not as reactive as they once were, it could indicate a problem within the control mechanisms. This is often the first sign that something isn’t functioning correctly, making it essential to address before it worsens.

Strange Sounds: Another warning sign is unusual noises when maneuvering. These could range from grinding to squeaking, often hinting at worn-out or misaligned components within the control system. Early detection can save you from more extensive repairs.

Unusual Vibrations: If you feel vibrations while navigating, this may be

Maintenance Tips for Steering Parts

Regular care of your vehicle’s navigation mechanism is essential for ensuring smooth operation and extending the lifespan of its components. A well-maintained system allows for better handling and reduces the risk of breakdowns. Below are practical recommendations for keeping everything in good working order.

Inspection and Cleaning

Routine visual checks can help identify early signs of wear and tear. Examine connections and joints for any looseness or corrosion. It’s also important to clean moving elements to prevent dirt build-up, which can hinder movement and cause premature wear.

- Check for rust on metallic parts

- Ensure no debris or grime is obstructing movement

- Tighten loose connections as necessary

Lubrication and Adjustment

Applying appropriate lubrication is critical to maintain smooth performance. Regularly oil key areas where friction occurs, ensuring all components move freely. Adjustments may also be necessary to maintain proper alignment, which contributes to precise control.

- Use recommended lubricants to minimize friction

- Adjust alignment for optimal performance

- Test after each adjustment to ensure accuracy

Replacing Worn Steering Components

Over time, various elements responsible for maneuvering can wear out due to regular use and exposure to tough conditions. These components are crucial for maintaining proper control and ensuring smooth directional changes. Regular inspection and timely replacement of these elements can help prevent unexpected failures and maintain the reliability of your equipment.

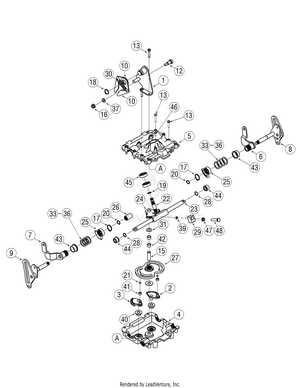

Identifying the Key Components for Replacement

To ensure a successful replacement process, it is important to identify the critical elements that may require attention. Look for signs of wear such as loose connections, unusual noises, or difficulty in making turns. Key elements may include linkages, joints, and bearings that help facilitate movement. Regular maintenance can prevent excessive wear, but replacement becomes necessary when components start to fail.

Step-by-Step Replacement Process

Once worn components have been identified, replacing them is a relatively straightforward process that requires the right tools and parts. Make sure to follow the manufacturer’s recommendations for installation, torque specifications, and alignment to ensure that the new components perform correctly.

Component Upgrading the Steering Mechanism for Better Control

Improving the directional system of your machine can significantly enhance its maneuverability and overall performance. A well-functioning control setup not only ensures a smoother ride but also allows for greater precision during operation. Upgrading components can lead to a more responsive and enjoyable experience, whether you’re navigating tight corners or tackling uneven terrain.

Several key elements can be addressed to elevate the handling capabilities of your equipment. Consider enhancing the following components:

Component Upgrade Options Benefits Control Rods High-performance rods Increased durability and responsiveness Linkage System Precision-engineered linkages Improved accuracy and reduced play Wheel Assembly Advanced wheel designs Enhanced traction and stability Bearings Upgraded bearings Smoother operation and reduced friction By investing in these enhancements, operators can expect a noticeable difference in their equipment’s handling characteristics. A focus on quality components not only improves efficiency but also contributes to a more enjoyable operating experience.

Locating Genuine Replacement Steering Parts

Finding authentic components for your machine can significantly enhance its performance and longevity. It is essential to identify reliable sources that offer high-quality replacements, ensuring that your equipment operates smoothly and efficiently. Whether you are a hobbyist or a professional, securing the right items will contribute to the overall functionality of your vehicle.

Identifying Authorized Dealers

One of the most effective ways to locate genuine components is by visiting authorized dealers. These retailers typically stock a wide range of original items, providing you with the assurance that you are purchasing high-quality replacements. Additionally, authorized sellers often have knowledgeable staff who can assist you in selecting the appropriate components for your specific model.

Exploring Online Resources

The internet offers a wealth of information when searching for authentic components. Many manufacturers maintain websites where you can browse available items and make purchases directly. It is advisable to verify the credibility of online retailers by reading reviews and checking their return policies. This diligence will help ensure that you receive the right replacements that meet the required standards.

Improving Steering Performance with Lubrication

Effective maintenance of the guiding mechanism is crucial for enhancing overall maneuverability and responsiveness. Proper lubrication not only reduces friction but also prevents wear and tear, ensuring a smoother operation. By regularly applying suitable lubricants, users can significantly extend the lifespan of components, while simultaneously improving their functionality.

Choosing the Right Lubricant

Selecting an appropriate lubricant is essential for optimal performance. Different formulations are designed for specific applications, so it’s important to consider the manufacturer’s recommendations. Grease is often favored for its ability to remain in place and resist being washed away, while oil can be beneficial in areas that require fluidity and penetration.

Application Techniques

To achieve the best results, it’s important to follow proper application techniques. Begin by cleaning the areas to be lubricated to remove any dirt or debris. Then, apply the lubricant evenly to ensure full coverage. Regular checks and timely reapplication can greatly improve performance, allowing for more precise control and a more enjoyable experience.

Troubleshooting Steering Problems on Cub Cadet Models

Addressing issues related to maneuverability in various mower models is essential for maintaining performance and safety. Understanding common symptoms and their underlying causes can help users effectively resolve these concerns, ensuring smooth operation.

Common Symptoms

- Difficulty in turning the machine.

- Unusual noises during operation.

- Vibrations felt in the control mechanisms.

- Inconsistent response to directional changes.

Potential Causes and Solutions

- Worn or Damaged Components: Inspect the links and joints for wear. Replace any damaged parts to restore functionality.

- Improper Alignment: Check the alignment of the drive system. Adjust if necessary to ensure all components are properly aligned.

- Fluid Levels: Ensure that any hydraulic fluid is at the correct level. Refill or replace fluids if they are low or contaminated.

- Loose Connections: Examine all connections and fasteners. Tighten any loose parts to enhance stability and performance.