The intricate world of marine propulsion systems involves various elements working in harmony to ensure optimal performance on the water. Familiarity with these components is essential for boat owners and enthusiasts alike, as it empowers them to maintain and enhance their vessels effectively. A comprehensive grasp of how each segment operates contributes significantly to the overall efficiency and longevity of the marine machinery.

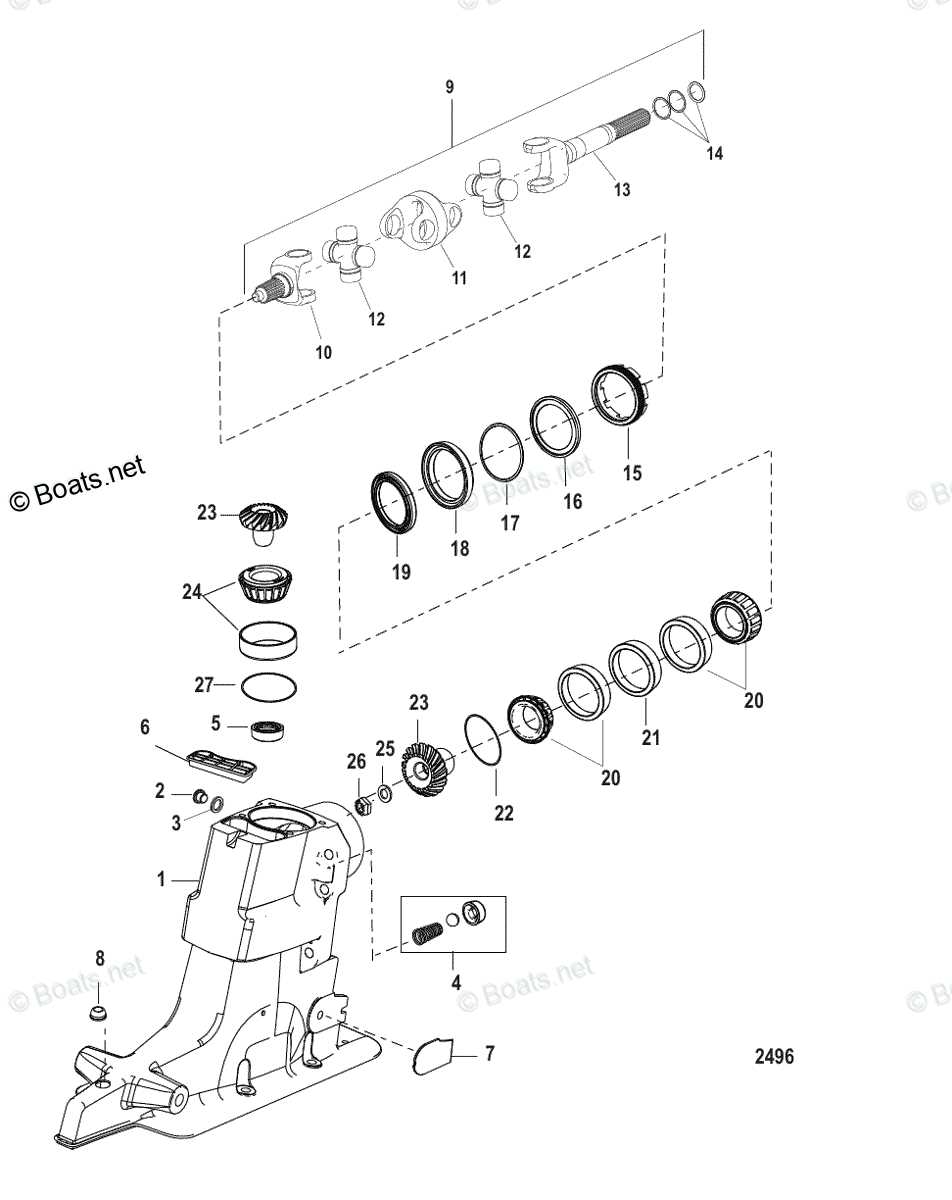

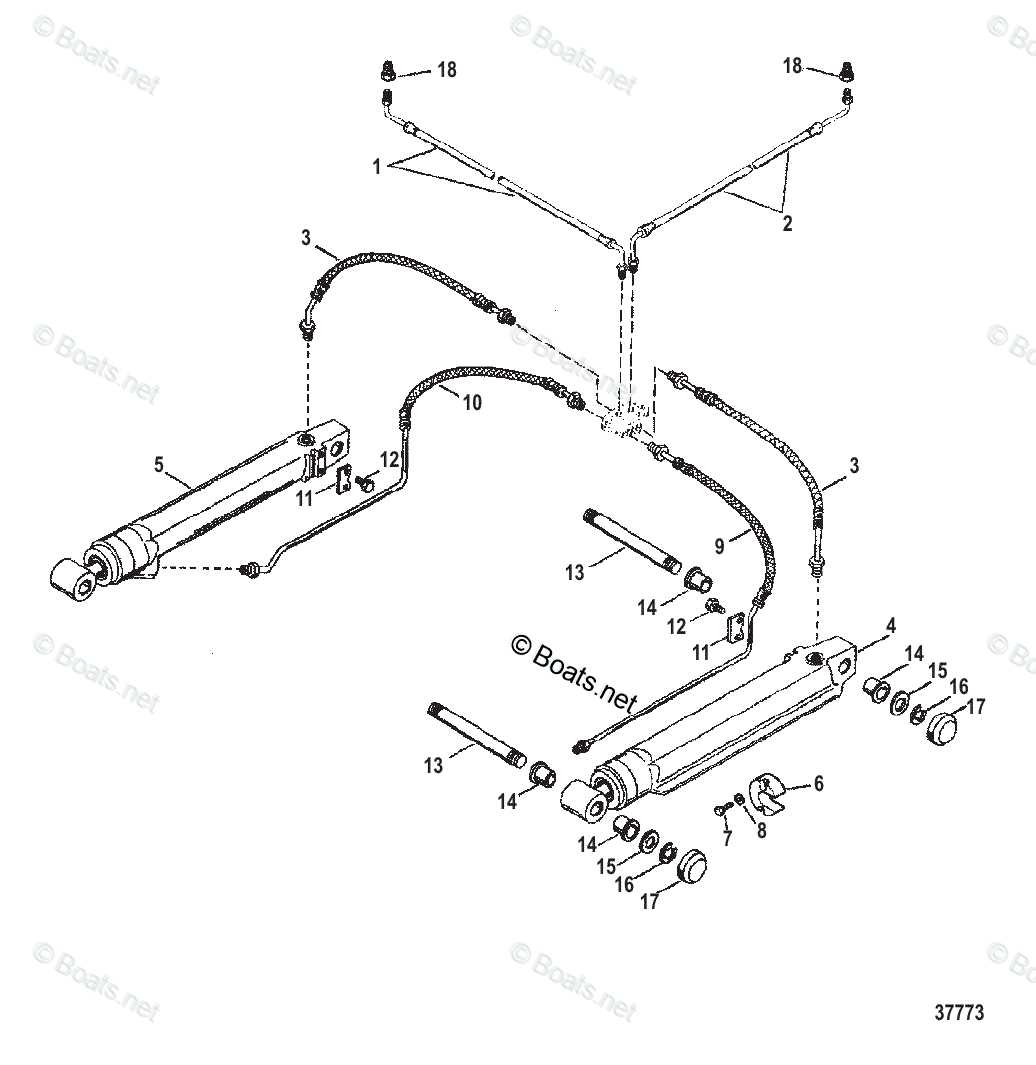

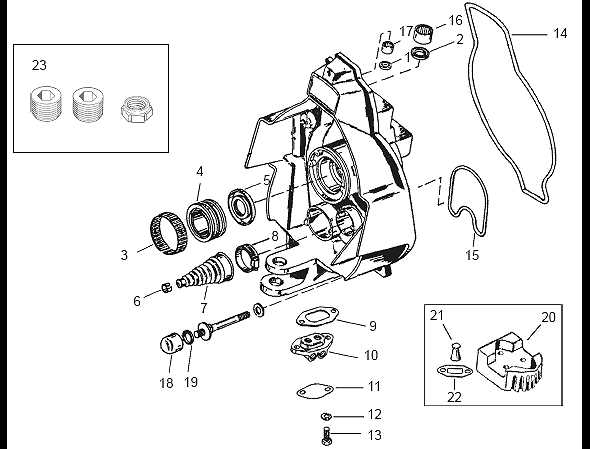

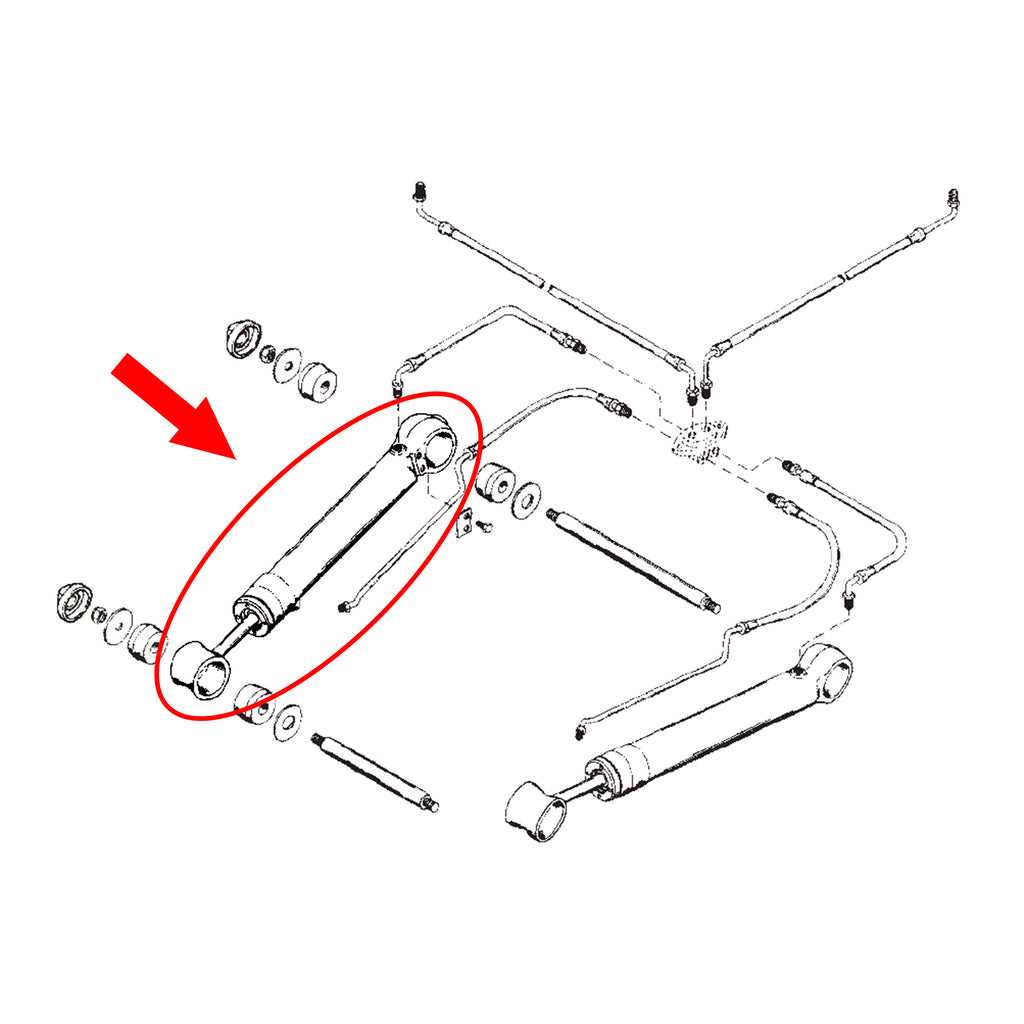

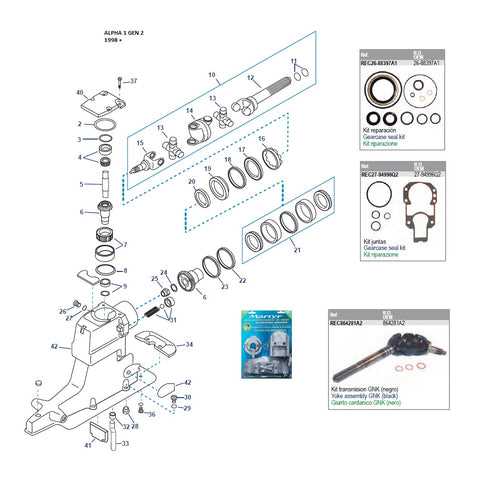

Delving into the specifics of drive mechanisms reveals a plethora of parts, each playing a critical role in the system’s functionality. From transmission units to the intricacies of steering devices, understanding their arrangement and interaction is paramount. By visualizing these elements, one can better appreciate their importance in facilitating smooth navigation and power transfer.

In this guide, we will explore the various components involved in marine drives, highlighting their interconnections and functions. Whether you’re looking to replace a worn-out piece or simply enhance your knowledge, having a detailed representation of these mechanisms can serve as an invaluable resource. Embracing this knowledge not only aids in maintenance but also enriches the overall boating experience.

Understanding Alpha One Outdrive Systems

Comprehending the mechanics of marine propulsion systems is crucial for both enthusiasts and professionals. These assemblies play a vital role in translating engine power into motion, enabling vessels to navigate waterways efficiently. An intricate interplay of components ensures smooth operation, requiring attention to detail during maintenance and repairs.

Familiarity with the various elements involved allows for better troubleshooting and enhancement of performance. Knowledge of assembly structure, operational principles, and maintenance practices equips users to make informed decisions. By delving into these systems, one can ultimately achieve greater reliability and longevity in marine adventures.

Key Components of Alpha One Outdrive

The efficient operation of marine propulsion systems relies on several essential elements. Each component plays a critical role in ensuring smooth performance and durability, contributing to the overall functionality of the unit. Understanding these key parts can help in maintenance and troubleshooting.

Essential Elements

Among the most vital elements are those that facilitate power transmission and steering control. Each of these components must work in harmony to provide reliable operation on the water.

| Component | Description |

|---|---|

| Gear Housing | Encloses and protects internal gears, ensuring efficient transfer of power. |

| Propeller | Converts engine power into thrust, enabling movement through the water. |

| Drive Shaft | Transmits rotational force from the engine to the propeller. |

| Trim Cylinder | Adjusts the angle of the unit for optimal performance and fuel efficiency. |

| Gimbal Bearing | Supports the drive shaft and allows for smooth rotation during operation. |

Maintenance Considerations

Regular inspections and maintenance of these components can significantly extend the lifespan of the system. Addressing wear and tear promptly ensures that each part functions as intended, preventing larger issues in the long run.

Benefits of Using Alpha One Outdrive

Utilizing advanced marine propulsion systems can greatly enhance your boating experience. These systems offer a range of advantages that contribute to both performance and durability.

- Improved Maneuverability: These units provide exceptional steering capabilities, allowing for easier navigation in tight spaces.

- Fuel Efficiency: Optimized design helps reduce fuel consumption, making long trips more economical.

- Durability: Constructed from high-quality materials, these systems are built to withstand harsh marine environments.

- Maintenance-Friendly: Easy access to components simplifies upkeep, saving time and effort.

- Enhanced Performance: These systems deliver superior acceleration and speed, enhancing overall boating enjoyment.

In summary, adopting such propulsion systems not only elevates performance but also ensures a more enjoyable and reliable boating experience.

Common Issues with Alpha One Parts

When it comes to marine propulsion systems, several challenges can arise that affect their overall performance and longevity. These concerns often stem from wear and tear, environmental factors, or improper maintenance. Understanding these common problems is essential for boat owners to ensure smooth operation and avoid costly repairs.

Wear and Tear: One of the most prevalent issues is the gradual degradation of components due to regular usage. Elements such as seals, bearings, and gears may experience friction-related damage, leading to inefficiencies in operation.

Corrosion: Exposure to saltwater can accelerate the deterioration of metal parts. Without proper protective measures, components may develop rust and corrosion, compromising their structural integrity and function.

Misalignment: Improper installation or adjustments can result in misalignment of the drive system. This can cause excessive vibration, leading to further damage and a reduction in overall performance.

Overheating: Insufficient lubrication or coolant flow can lead to overheating issues. When temperatures rise beyond acceptable levels, critical parts can warp or fail, necessitating immediate attention.

Clogged Filters: Debris and contaminants can obstruct filters, restricting fluid flow and causing additional strain on the system. Regular maintenance is key to preventing this issue and ensuring optimal operation.

Addressing these common challenges proactively can greatly enhance the reliability and lifespan of your marine propulsion system. Regular inspections and maintenance routines are vital for catching potential issues before they escalate.

Maintenance Tips for Outdrive Longevity

Ensuring the durability of your marine propulsion system requires regular attention and care. A proactive approach to maintenance can significantly extend the lifespan of your equipment, enhancing performance and reliability. Below are some essential guidelines to help you keep your mechanism in optimal condition.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Inspect Seals and Gaskets | Every season | Replace any damaged or worn components to prevent leaks. |

| Check Lubrication Levels | Before each use | Ensure proper fluid levels and use recommended lubricants. |

| Clean Cooling System | Every six months | Remove debris to maintain efficient operation and prevent overheating. |

| Examine Anodes | Quarterly | Replace corroded anodes to protect metal components from deterioration. |

| Test Electrical Connections | Every season | Inspect and tighten connections to ensure reliable performance. |

Adhering to these maintenance practices will not only enhance the longevity of your equipment but also ensure safe and enjoyable experiences on the water. Regular checks and timely interventions can make a significant difference in performance and efficiency.

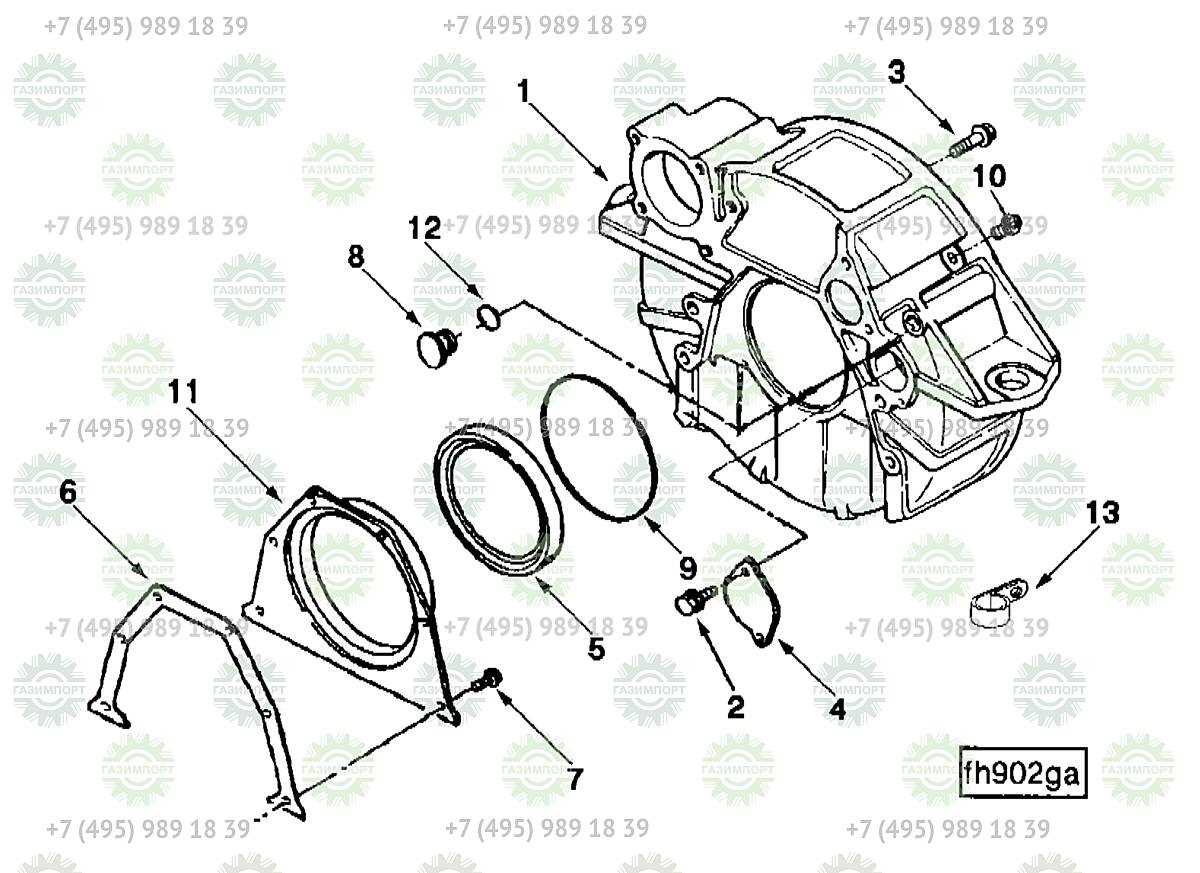

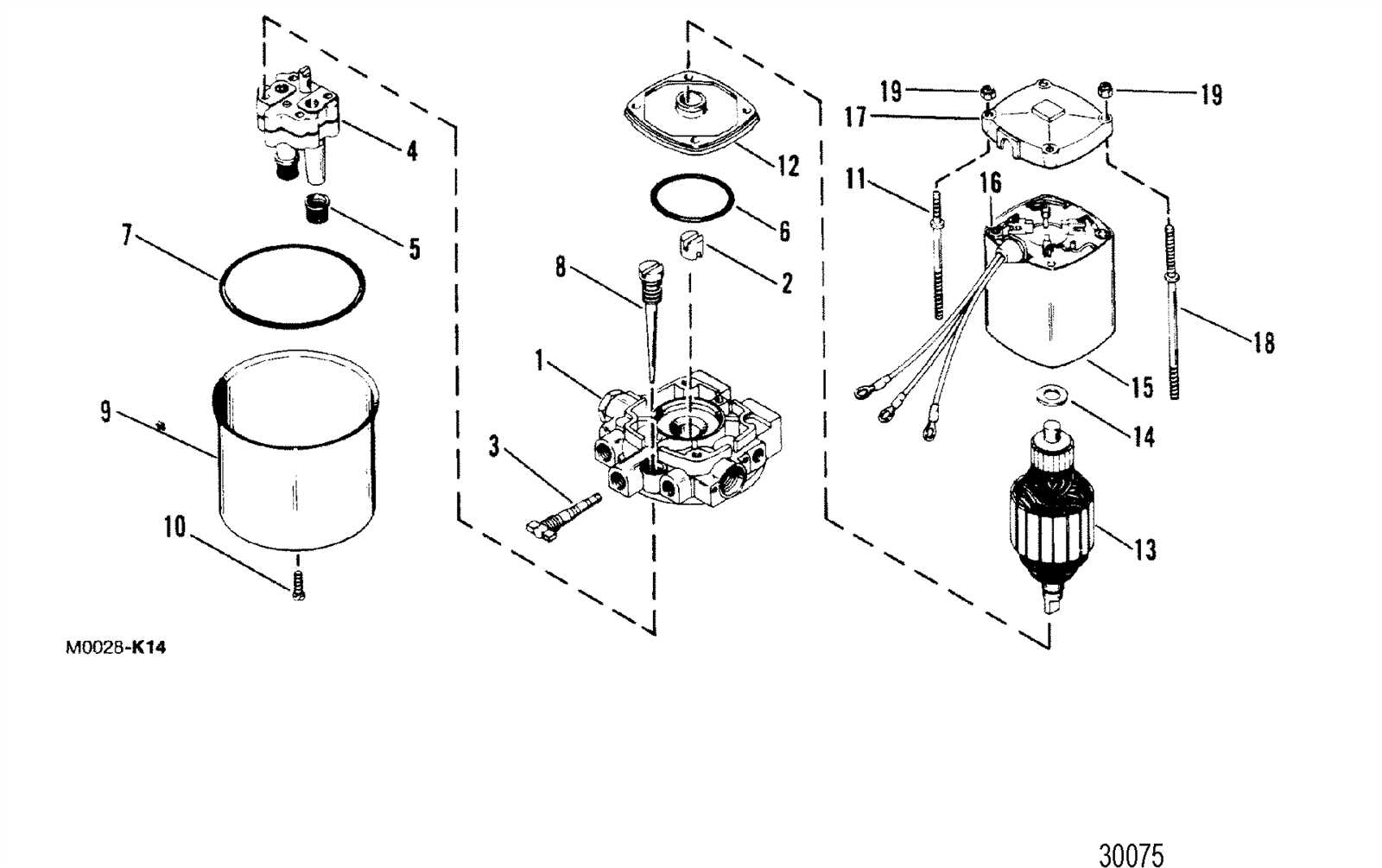

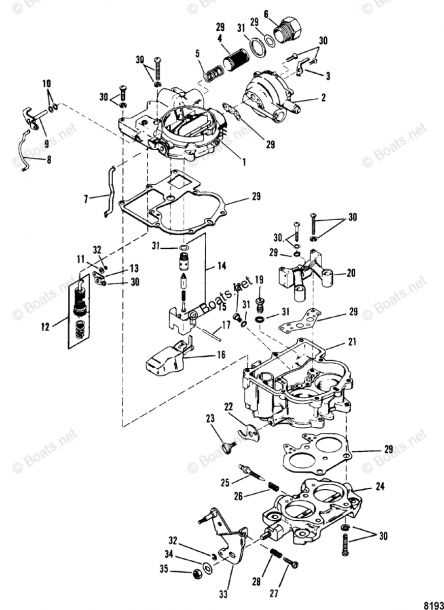

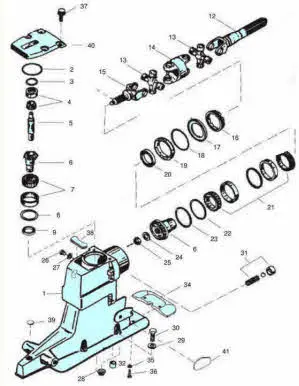

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual representations help identify components and their relationships within a system. By familiarizing yourself with how to interpret these drawings, you can streamline your troubleshooting processes and ensure proper assembly.

Key Elements of Technical Illustrations

- Labels: Each part is usually marked with a unique identifier, often a number or code. This helps correlate the visual with the corresponding list.

- Annotations: Additional notes may provide crucial information about each component, such as material specifications or installation tips.

- References: Look for reference points that indicate how parts fit together or relate to other sections of the system.

Steps to Effectively Interpret Illustrations

- Familiarize Yourself: Spend time understanding the layout and symbols used in the illustration. Each manufacturer may have its own conventions.

- Follow the Flow: Examine the connections and order of components. This can provide insights into how the entire system functions.

- Cross-Reference: Use the accompanying parts list or catalog to find additional details about each item, ensuring you have complete information.

- Practice: Regularly review different illustrations to build your proficiency in quickly identifying and understanding components.

Where to Buy Alpha One Parts

Finding the right components for your marine propulsion system is crucial for maintaining optimal performance. Various sources offer quality options for enthusiasts and professionals alike.

- Online Retailers: Websites specializing in marine equipment often provide a wide selection, allowing easy comparisons.

- Local Dealers: Visiting authorized vendors can give you access to expert advice and immediate availability.

- Second-Hand Markets: Platforms like eBay or local classifieds may have pre-owned items at competitive prices.

- Manufacturer’s Website: Purchasing directly from the original maker ensures authenticity and reliability.

Consider your needs and budget when choosing where to purchase these essential components for your vessel.

Upgrades for Enhanced Performance

Improving the efficiency and power of your marine propulsion system can significantly elevate your boating experience. By implementing certain enhancements, you can optimize speed, fuel economy, and overall handling.

Propeller Selection: Upgrading to a high-performance propeller can lead to better thrust and increased speed. Consider options with advanced materials and designs that reduce drag.

Transom Adjustments: Adjusting the transom height can enhance water flow and reduce turbulence, resulting in improved performance. Proper alignment is crucial for maximizing efficiency.

Engine Tuning: Regular maintenance and tuning of the engine can ensure it operates at peak efficiency. Upgrading ignition systems or fuel injectors can also provide noticeable improvements.

Hydraulic Systems: Investing in upgraded hydraulic components can enhance responsiveness and control. A high-quality steering system contributes to a smoother ride and better maneuverability.

Weight Distribution: Reassessing the weight distribution on your vessel can impact performance. Properly balancing the load will lead to improved stability and speed.

By choosing the right modifications, you can truly enhance the capabilities of your setup, ensuring an ultimate adventure on the water.

Installation Guide for Outdrive Components

This section provides essential instructions for the assembly and installation of various components related to marine propulsion systems. Understanding the proper sequence and technique is crucial for ensuring optimal performance and longevity.

Before starting, gather all necessary tools and components to streamline the installation process. Follow the steps outlined below for a successful setup:

| Step | Description |

|---|---|

| 1 | Inspect all components for any damage or wear before installation. |

| 2 | Begin by securing the main housing to the designated area on the vessel. |

| 3 | Attach the drive mechanism, ensuring all alignment markers are matched. |

| 4 | Connect hydraulic lines and electrical wiring as per the manufacturer’s guidelines. |

| 5 | Test all connections for leaks and functionality before finalizing the installation. |

By following these guidelines, you will ensure a robust and efficient installation process, ultimately enhancing the performance of your marine vessel.