In the intricate world of automotive design, the components responsible for directing a vehicle play a crucial role in ensuring safety and functionality. These mechanisms not only influence handling but also contribute to the overall driving experience.

To fully grasp the layout and function of these elements, it is essential to explore their various sections and how they interconnect. A clear visualization aids in understanding their individual roles and the importance of each component in achieving seamless navigation.

By delving into the specifics of these assemblies, enthusiasts and professionals alike can appreciate the complexity and ultimate efficiency of modern vehicle engineering. This knowledge empowers users to maintain and repair their systems effectively, enhancing both performance and safety on the road.

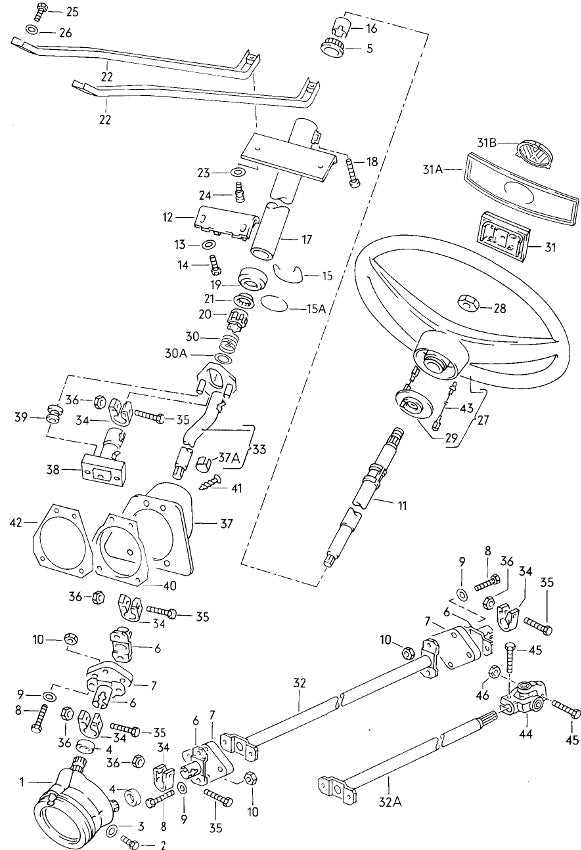

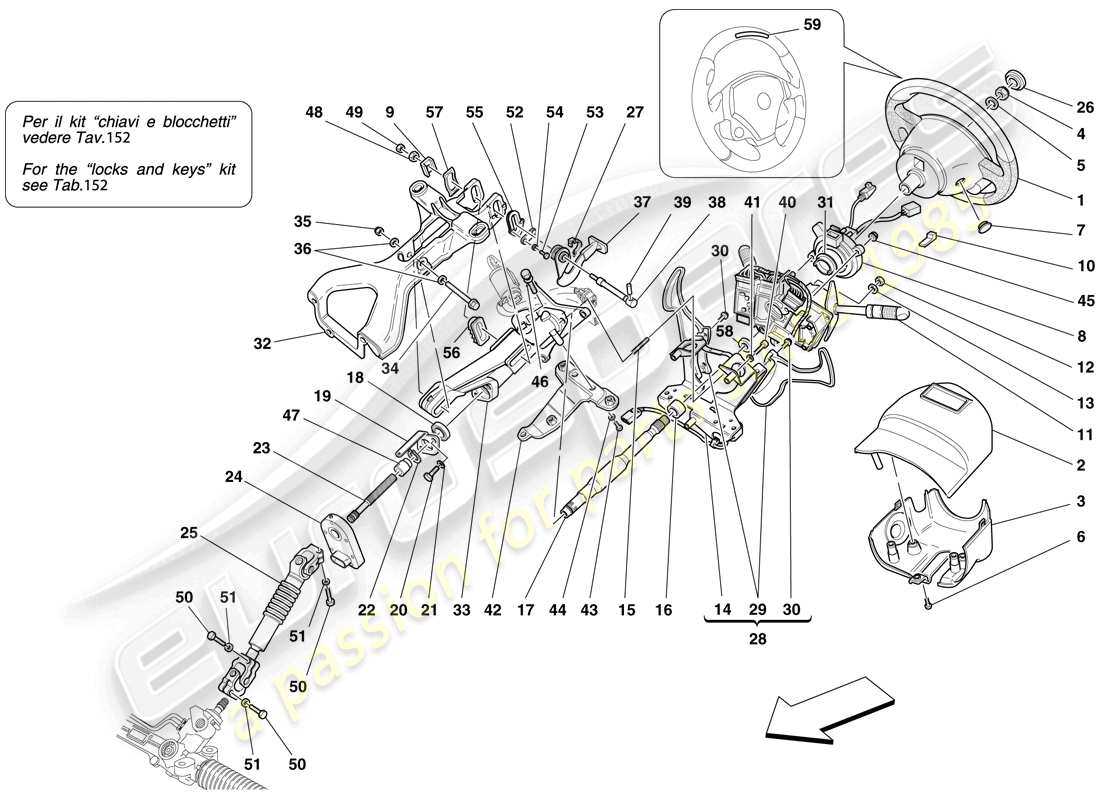

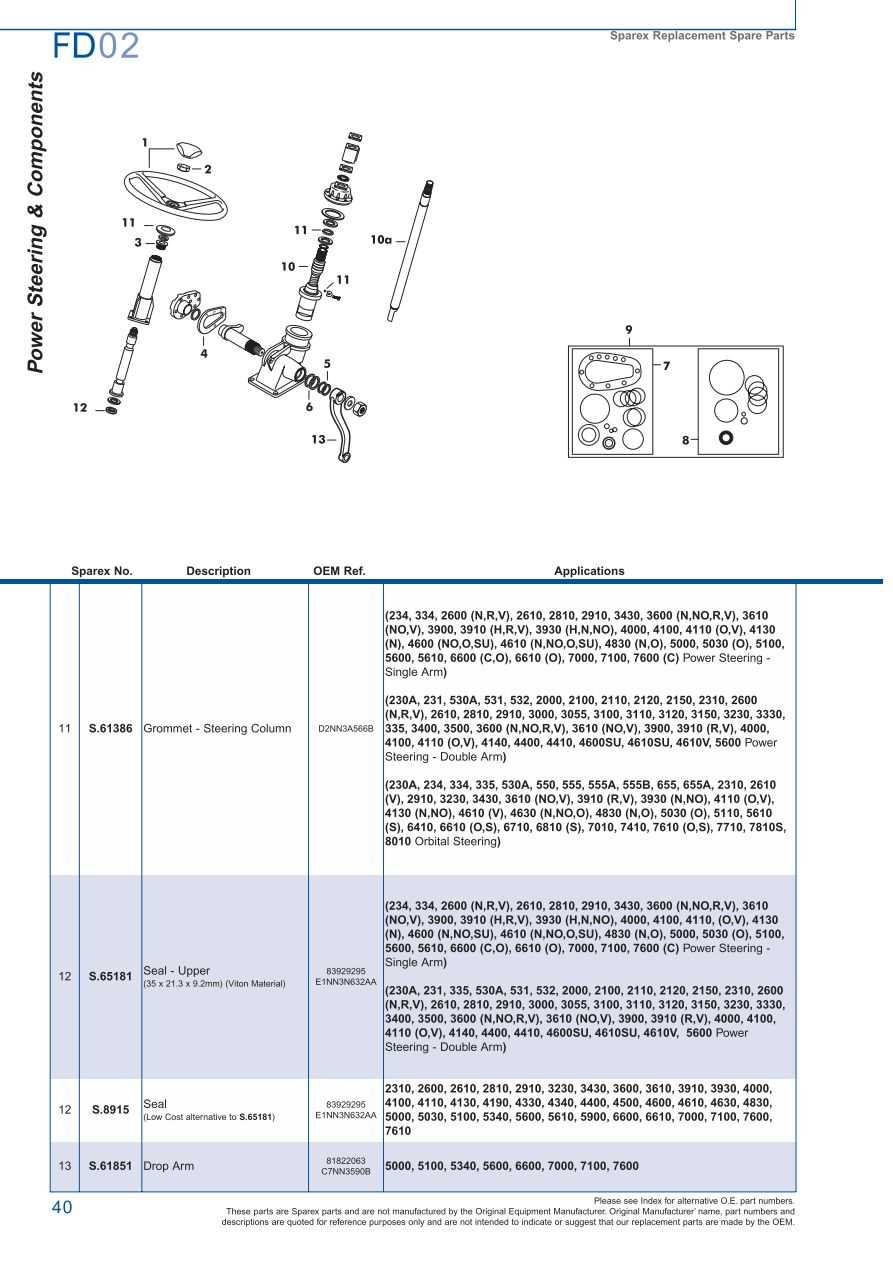

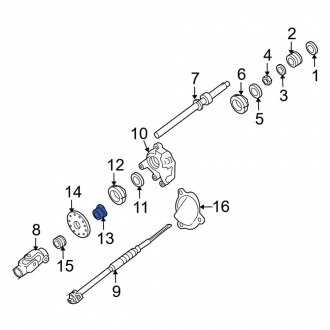

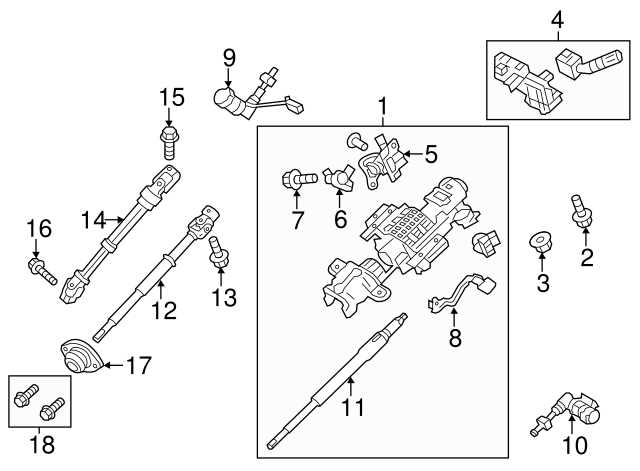

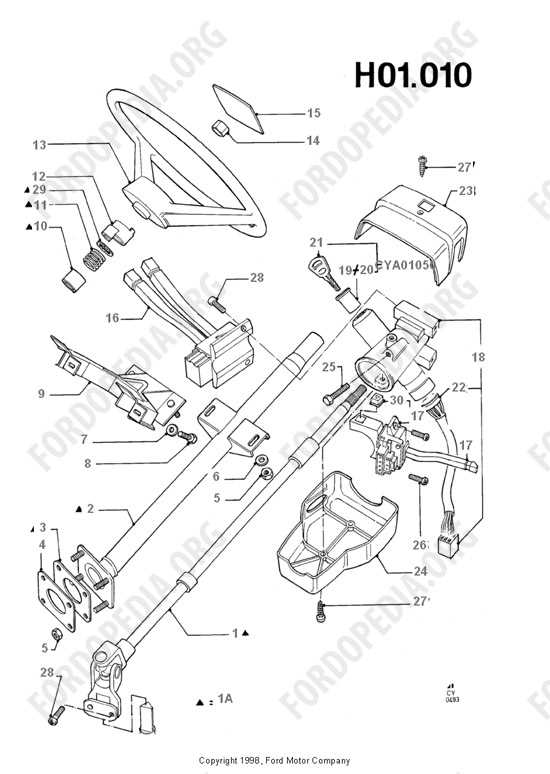

Understanding Ford Steering Column Components

When examining the assembly responsible for vehicle navigation, it’s crucial to comprehend its various elements and their interrelationships. This intricate system plays a pivotal role in ensuring safe and responsive maneuvering, encompassing numerous components that work harmoniously together.

Central to this assembly is the main shaft, which facilitates the transfer of input from the driver to the mechanism that alters direction. Coupled with this are the numerous supports and housings that provide stability and protection for internal mechanisms.

Additionally, control interfaces such as levers and switches allow the operator to engage various functionalities, enhancing the overall driving experience. The integration of safety features, including ignition locks and collapsible elements, further emphasizes the importance of each component in maintaining both functionality and protection.

Understanding these individual elements and their roles provides valuable insights into the operation of the navigation system, ultimately contributing to improved vehicle performance and safety.

Importance of Steering Column Diagrams

Visual representations of critical components play a significant role in understanding complex mechanical systems. These illustrations serve as essential tools for both professionals and enthusiasts, allowing them to grasp the intricate relationships and functions of various elements within a vehicle’s control system.

Benefits of Visual Representations

- Enhances comprehension of assembly and disassembly processes.

- Aids in troubleshooting issues effectively and efficiently.

- Facilitates training for new technicians and mechanics.

- Streamlines maintenance tasks, reducing the likelihood of errors.

Key Elements to Consider

- Clear labeling of components for easy identification.

- Detailed annotations explaining functions and interactions.

- Accurate scaling to represent true dimensions.

- Inclusion of safety precautions and best practices.

Overall, these visual aids not only promote understanding but also foster a safer and more efficient work environment in the automotive field.

Common Parts in Ford Steering Columns

Understanding the essential components that make up the mechanism responsible for vehicle navigation is crucial for maintenance and repair. These elements work in unison to ensure precise control and safety while driving.

Key Elements

Among the most critical components are the ignition switch, which activates the electrical systems, and the tilt mechanism, allowing for customizable positioning. Additionally, the shifter assembly enables smooth transition between gears.

Additional Components

Other notable features include the wiring harness, which connects electrical circuits, and the bearing support that provides stability. Each of these elements plays a vital role in the overall functionality and reliability of the navigation system.

How to Read a Steering Diagram

Understanding a schematic representation of the directional control system is crucial for effective maintenance and repair. This visual guide provides essential information about the various components and their interconnections. By familiarizing yourself with the layout and symbols used, you can easily interpret the functionalities and troubleshoot any issues.

Components Overview

Each element in the schematic serves a specific role, contributing to the overall operation of the control mechanism. Common symbols represent various components, such as switches, levers, and connectors. Recognizing these symbols is the first step in decoding the schematic.

Interpreting Connections

Lines and arrows illustrate how different parts interact. Solid lines typically indicate physical connections, while dashed lines may represent electrical pathways. Understanding these relationships allows you to trace circuits and diagnose problems effectively.

| Symbol | Description |

|---|---|

| Electrical Connector | |

| ⚙️ | Mechanical Component |

| Rotational Movement | |

| Adjustment Mechanism |

By mastering these fundamentals, you will enhance your ability to work with the schematic effectively, ensuring a thorough understanding of the system’s architecture.

Identifying Issues in Steering Systems

Recognizing problems in the directional control mechanism of a vehicle is crucial for maintaining safety and performance. Several symptoms can indicate underlying complications, which, if left unaddressed, may lead to more severe consequences. Awareness of these signs is the first step in ensuring reliable handling and preventing further damage.

Common indicators of dysfunction may include unusual noises, such as grinding or clicking, when turning the wheel. These sounds often suggest wear or damage within the assembly. Additionally, if the mechanism feels loose or unresponsive, it could signify issues with the connections or components responsible for precision control. Vibrations felt through the steering interface can also point to imbalances or misalignments that require immediate attention.

Another critical aspect to consider is fluid leakage. Any visible signs of fluid pooling beneath the vehicle can indicate a compromised hydraulic system, leading to decreased efficiency. Regularly checking fluid levels and inspecting for leaks can help detect problems early. Unusual tire wear may also reflect alignment or suspension issues, affecting the overall handling and stability.

In conclusion, being proactive in identifying these potential issues can lead to safer driving experiences and extended vehicle longevity. Regular maintenance and inspections are essential practices for any vehicle owner aiming to preserve the integrity of the steering mechanism.

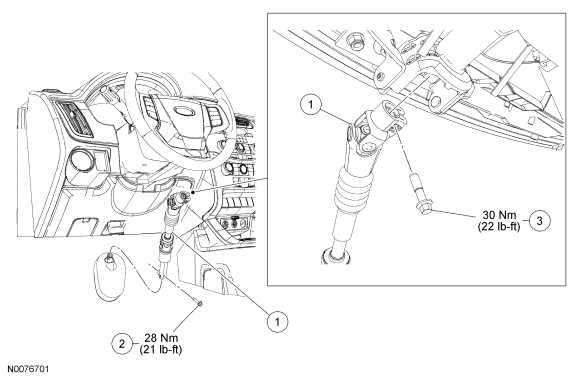

Tools Needed for Steering Column Repair

Repairing the mechanism that controls direction requires a variety of tools to ensure the process is efficient and effective. Having the right equipment not only simplifies the task but also helps prevent damage to components. Below is a list of essential tools you will need for this repair.

- Socket Set: A comprehensive set of sockets will help you tackle various fasteners easily.

- Wrench Set: Adjustable and fixed wrenches are vital for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing screws from different assemblies.

- Pliers: Needle-nose and regular pliers assist in gripping and manipulating small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Trim Removal Tools: These help in safely removing covers and trims without causing damage.

- Multimeter: Useful for diagnosing electrical issues within the system.

- Work Light: Provides visibility in tight spaces during the repair process.

Having these tools on hand will prepare you for a successful repair job, allowing you to address any issues effectively and efficiently.

Steps for Disassembling Steering Columns

Disassembling the control assembly requires a methodical approach to ensure all components are handled with care. Proper preparation and understanding of the structure will facilitate a smoother process.

1. Safety First: Before starting, disconnect the battery to prevent any electrical hazards. Always wear safety gear, including gloves and goggles.

2. Remove the Covers: Begin by carefully taking off the outer casings. This may involve unscrewing or unclipping various fasteners, ensuring no pieces are damaged during removal.

3. Disconnect Wiring: Identify and detach any electrical connections linked to the assembly. Take note of their placement for reassembly.

4. Unscrew Fasteners: Locate and remove screws or bolts securing the internal components. Keep these fasteners organized to simplify reinstallation.

5. Extract Internal Components: Gently pull out the inner mechanisms, being mindful of any springs or small parts that may spring out unexpectedly. Document the arrangement for future reference.

6. Clean and Inspect: Once disassembled, clean each component and inspect for wear or damage, which may need addressing before reassembly.

Replacement Parts for Ford Models

Maintaining the performance and safety of your vehicle often requires sourcing quality components. Whether you’re undertaking repairs or enhancements, understanding the essential elements is crucial for ensuring longevity and reliability. Each model may have unique specifications, so familiarity with the various replacements available is key.

Quality Options: When looking for components, it’s important to prioritize quality over cost. Original equipment manufacturer (OEM) replacements typically provide the best fit and durability, ensuring that your vehicle operates as intended. Aftermarket alternatives can also be viable, but researching the manufacturer’s reputation is advisable.

Common Components: Typical elements that may need replacement include control mechanisms, linkages, and associated fixtures. Each plays a vital role in overall functionality. Regular inspections can help identify wear and tear before issues escalate.

Purchasing Tips: Always verify compatibility with your specific model year and type. Consulting with a knowledgeable supplier can provide insights into the best options available. Additionally, consider warranties or return policies to safeguard your investment.

Investing in the right components not only enhances performance but also contributes to a safer driving experience.

Maintaining Your Steering System Effectively

Regular upkeep of your guidance mechanism is crucial for ensuring optimal performance and safety. By addressing potential issues early, you can extend the lifespan of your system and enhance driving experience. This section outlines essential practices for effective maintenance.

Key Maintenance Practices

- Inspect for leaks regularly to prevent fluid loss.

- Check all connections and fasteners to ensure stability.

- Lubricate moving components to reduce wear and tear.

Signs of Wear

- Unusual noises during operation.

- Difficulty in maneuvering the vehicle.

- Vibrations felt through the handling system.

By keeping an eye on these signs and following maintenance guidelines, you can ensure a reliable and safe driving experience.