In the realm of machinery, the significance of directional control cannot be overstated. The functionality of these systems hinges on a variety of crucial elements that work in harmony to ensure smooth operation. A thorough comprehension of these components is essential for effective maintenance and repair.

Every operational unit comprises a network of interrelated pieces, each serving a distinct purpose. Recognizing how these elements interact allows for better troubleshooting and enhances the overall performance of the equipment. This knowledge is particularly valuable for those engaged in agricultural or industrial applications, where precision is vital.

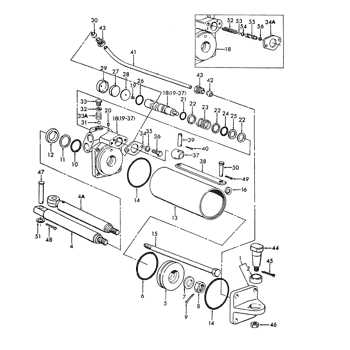

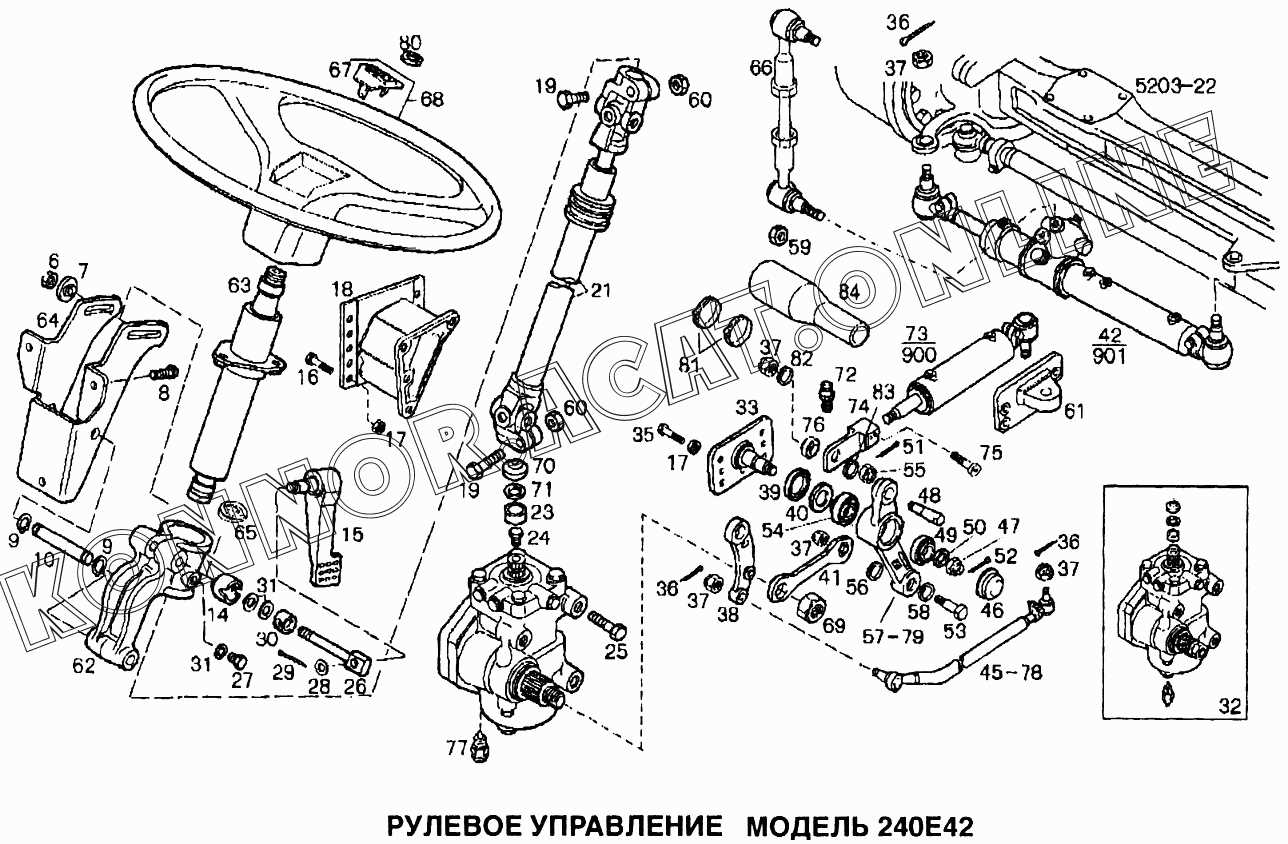

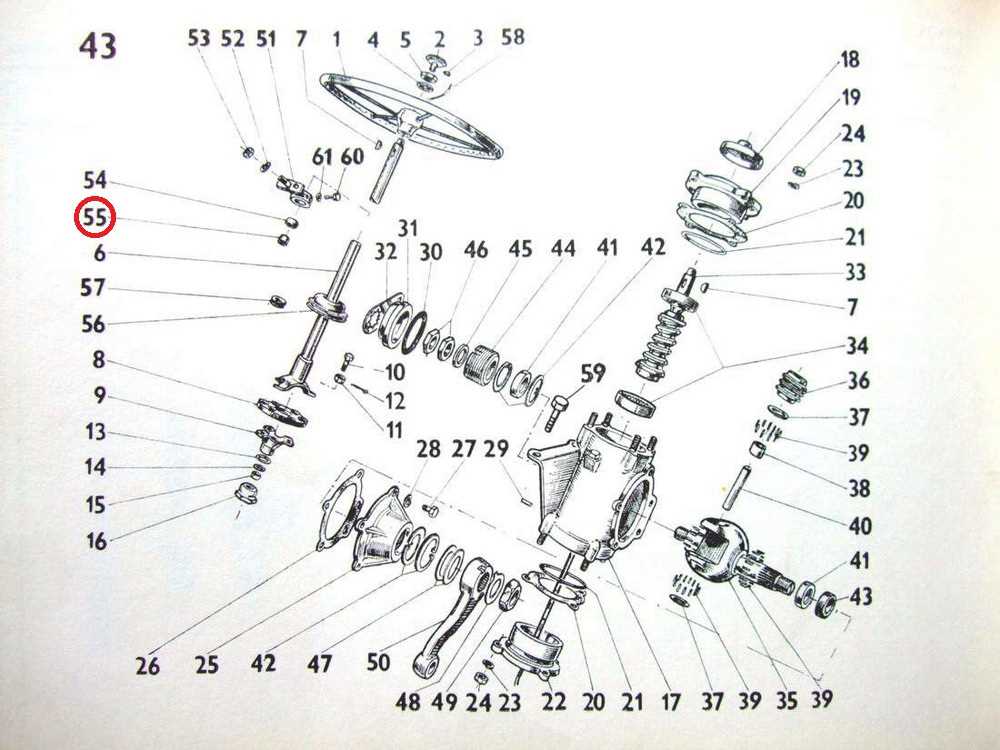

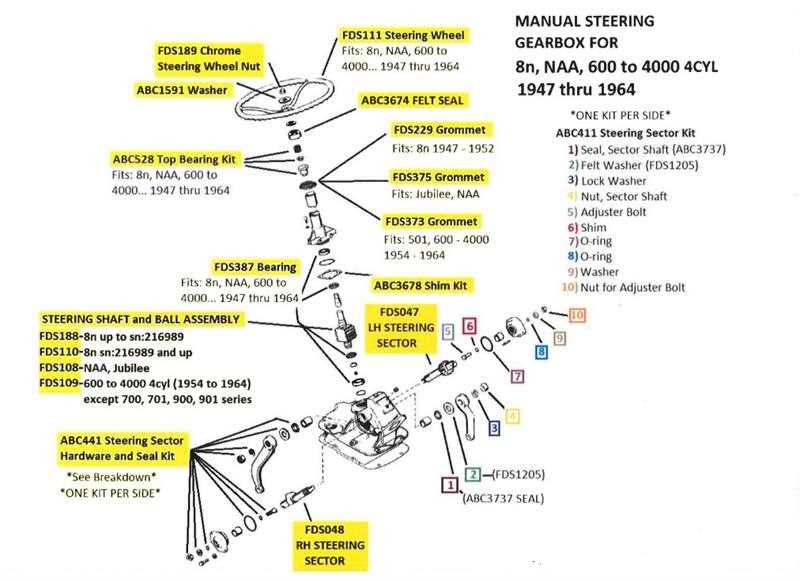

To facilitate a clearer understanding, a visual representation can be invaluable. Such illustrations not only highlight the layout of the components but also provide insights into their specific roles. This approach aids in grasping the intricacies involved in maintaining and enhancing the efficiency of the machinery.

Understanding Ford 5000 Steering Mechanics

The ability to maneuver a vehicle effectively relies on a complex system of components that work in unison. This system ensures that the operator maintains control and direction with precision, enhancing overall performance and safety.

Several key elements contribute to this intricate mechanism:

- Linkages: These connections transmit the operator’s input to the wheels, allowing for responsive adjustments.

- Hydraulic Systems: Utilizing fluid pressure, these systems provide assistance, making it easier to turn and navigate challenging terrains.

- Bearings: These reduce friction and ensure smooth movement, facilitating a seamless driving experience.

- Column Assembly: This central unit houses controls and connects to various components, linking the operator’s actions to the steering system.

Understanding how each of these elements interacts is crucial for maintaining functionality and addressing issues that may arise over time. Regular inspections and proper maintenance can significantly extend the lifespan of these vital components.

- Check fluid levels regularly to ensure optimal hydraulic performance.

- Inspect linkages for signs of wear and tear to prevent unexpected failures.

- Lubricate bearings periodically to maintain smooth operation.

- Examine the column assembly for loose connections or damage.

By comprehending the mechanics behind this system, operators can ensure better handling and increased reliability, leading to enhanced operational efficiency.

Key Components of the Steering System

The mechanism responsible for guiding a vehicle involves several crucial elements that work in harmony to ensure smooth navigation. Understanding these components is essential for maintaining optimal performance and achieving precise maneuverability. Each part plays a significant role in the overall functionality of the control mechanism.

Essential Elements

The following table outlines the primary components found in the guidance assembly:

| Component | Description |

|---|---|

| Column | Connects the wheel to the mechanism, allowing for driver input to be translated into movement. |

| Linkage | Transfers the motion from the column to the wheels, ensuring accurate direction change. |

| Box | Houses the gears that assist in converting rotational input into linear movement. |

| Rack | Moves side to side to turn the wheels as the driver maneuvers the vehicle. |

Importance of Maintenance

Regular inspection and upkeep of these elements are vital for ensuring safety and performance. Any wear or damage can significantly impact handling, making awareness of their condition imperative for any vehicle operator.

How to Read the Parts Diagram

Understanding a technical illustration can significantly enhance your ability to identify and source necessary components for repair or maintenance. These visual aids provide a structured representation of each element, allowing users to navigate through complex assemblies effectively.

Key Components of the Illustration

- Labels: Each part is usually accompanied by a label or number that corresponds to a list of items.

- Sections: The diagram is typically divided into sections, making it easier to focus on specific areas.

- References: Look for notes or reference markers that can guide you on how parts fit together.

Steps to Interpret the Illustration

- Start by locating the overall view to get a sense of the assembly.

- Identify the labeled components, matching them with the corresponding list.

- Focus on the sections relevant to your repair to avoid confusion.

- Use additional resources if needed to clarify complex parts or connections.

By familiarizing yourself with the structure and labeling of these technical illustrations, you can streamline your repair process and ensure you have all the necessary components on hand.

Common Issues with Steering Parts

Maintaining control over machinery is crucial for efficient operation. Several components play vital roles in ensuring smooth navigation. However, various problems can arise that may hinder performance and safety.

- Wear and Tear: Continuous usage leads to degradation of components, causing them to lose effectiveness.

- Loose Connections: Fasteners may become loose over time, resulting in instability and potential failure.

- Hydraulic Leaks: Fluid leaks can compromise the efficiency of the system, leading to decreased responsiveness.

- Corrosion: Exposure to elements can result in rust, which weakens structural integrity and performance.

- Misalignment: Improper installation or damage can cause parts to be out of alignment, affecting maneuverability.

Addressing these common challenges promptly is essential for ensuring longevity and optimal function of the equipment.

Maintenance Tips for Ford 5000

Proper upkeep of your machinery is essential for longevity and optimal performance. Regular attention to specific components can prevent wear and tear, ensuring smooth operation and reducing the risk of unexpected breakdowns.

1. Regular Inspection: Frequently check all critical areas for signs of wear or damage. Pay close attention to connections and fastenings to ensure everything is secure.

2. Lubrication: Consistent application of lubricant to moving parts reduces friction and prolongs the life of components. Follow the manufacturer’s guidelines for intervals and types of lubricants to use.

3. Fluid Levels: Regularly monitor and maintain proper levels of hydraulic fluids and oils. Low levels can lead to increased wear and potential failures.

4. Cleaning: Keep all surfaces free of dirt and debris. Regular cleaning prevents buildup that can affect functionality and aesthetics.

5. Tire Maintenance: Inspect tires for proper inflation and tread wear. Properly maintained tires enhance traction and improve overall handling.

6. Storage: When not in use, store the equipment in a dry, sheltered location to protect it from the elements. This practice helps avoid rust and other environmental damage.

By following these maintenance tips, you can ensure that your equipment remains reliable and efficient over time.

Where to Find Replacement Parts

Finding suitable components for your machinery can often be a daunting task, but with the right resources, it becomes much more manageable. Whether you are looking to repair or upgrade, understanding where to source these essential items is crucial for maintaining optimal performance.

Online Retailers are a convenient option, offering a vast selection of components. Websites specializing in machinery supplies often provide detailed descriptions and user reviews, helping you make informed decisions.

Local Dealerships can also be a valuable resource. They typically carry an inventory of original equipment and can offer expert advice. Building a relationship with your local dealer may lead to better support and availability of necessary items.

Salvage Yards are worth considering as well. These facilities often have a variety of used components at lower prices. While the condition of these items can vary, you may find high-quality parts that are just as effective as new ones.

Online Marketplaces like auction sites and classified ads can yield surprising finds. Many sellers list both new and used components, often at competitive prices. Always check the seller’s ratings and return policies to ensure a smooth transaction.

Finally, Specialty Forums and online communities dedicated to machinery enthusiasts can provide leads on hard-to-find components. Engaging with fellow users may also offer insights into alternative sources and recommendations based on their experiences.

Tools Needed for Steering Repairs

Proper maintenance and repair of the directional control system are crucial for ensuring safe and efficient operation. A variety of specialized instruments are required to effectively address any issues that may arise within the system. Having the right tools on hand not only facilitates the repair process but also enhances overall performance and longevity.

Essential Instruments

Below is a list of fundamental tools needed to carry out repairs efficiently:

| Tool | Description |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Pliers | Ideal for gripping and bending components as needed. |

| Screwdriver Set | Necessary for removing and installing screws in various sizes. |

| Ball Joint Separator | Facilitates the removal of ball joints without damage. |

| Grease Gun | Used for lubricating moving parts to reduce wear. |

Safety Equipment

In addition to the primary tools, safety equipment is vital for any repair job. Protective gear, such as gloves and safety glasses, should always be worn to prevent injuries. Additionally, using a sturdy jack and jack stands will provide stability and safety while working underneath vehicles.

Upgrading Your Ford 5000 Steering

Enhancing the maneuverability and responsiveness of your machinery can significantly improve your overall experience and efficiency. This section will guide you through various enhancements that can lead to a more refined driving experience. With the right adjustments and replacements, you can transform the way your vehicle handles on the field.

Benefits of Upgrading

Improving the control system can lead to several advantages, such as increased precision, reduced wear on components, and enhanced comfort during operation. These upgrades can make a notable difference in both performance and longevity.

Key Components to Consider

When planning an upgrade, focus on the essential elements that contribute to overall functionality. Below is a table outlining some critical components to evaluate:

| Component | Description | Upgrade Options |

|---|---|---|

| Control Wheel | Provides input for directional movement | Ergonomic designs, larger diameter |

| Linkage System | Connects the control wheel to the mechanisms | Heavy-duty materials, adjustable lengths |

| Hydraulic Cylinders | Facilitates movement with fluid pressure | High-performance models, better response rates |

| Mounting Brackets | Secures various components in place | Reinforced designs for durability |

By considering these elements, you can create a customized upgrade plan that enhances the handling and efficiency of your equipment, making your work more enjoyable and productive.