In any vehicle, the system responsible for controlling movement plays a critical role in ensuring smooth operation and safety. Understanding how each element works together allows for better maintenance and troubleshooting. By examining the various mechanisms and connections, drivers and mechanics alike can gain insights into how to keep everything running efficiently.

This guide delves into the intricate network of elements that form the foundation of control for directional movement. Each part serves a specific function, and together they create a reliable system for maintaining balance and precision. Proper knowledge of these interconnected components can aid in enhancing performance and extending the life of the vehicle.

Whether for repairs or upgrades, knowing how these mechanisms interact can be invaluable. With detailed insights into their functions, you’ll be better prepared to address any issues that may arise, ensuring optimal handling and control on the road.

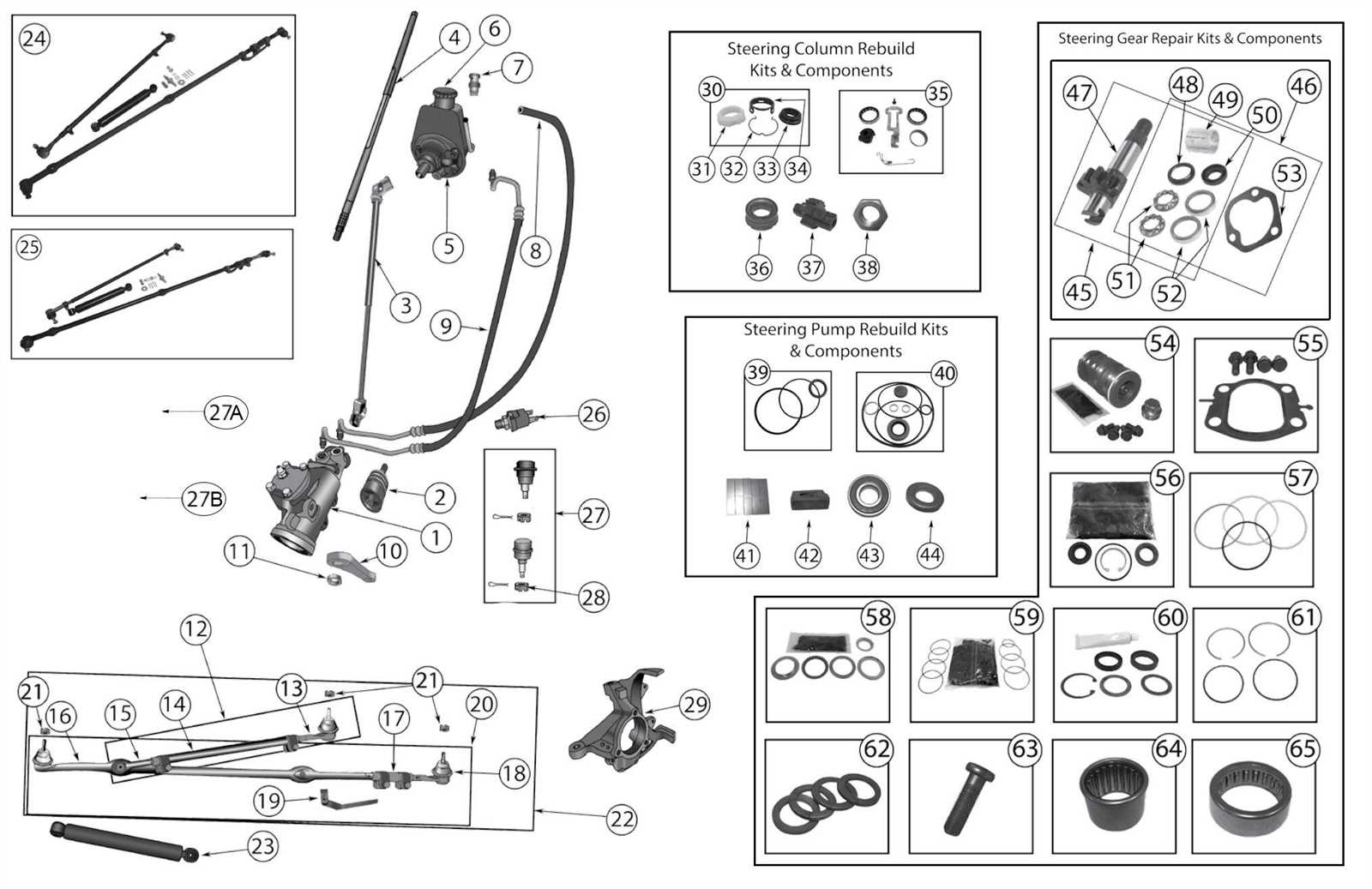

Overview of Key Steering Components

The mechanisms responsible for ensuring smooth control and navigation of a vehicle are composed of several critical elements. Each of these components plays a vital role in delivering a reliable and responsive driving experience, working together to ensure precise handling under various conditions.

- Control Mechanism: This component translates driver input into action, allowing for effective changes in direction.

- Linkage System: Connecting various elements, this system helps distribute the effort and ensures synchronized movement across the system.

- Rotational Assist: Supporting ease of use, this part reduces the amount of force required to maneuver.

- Movement Stabilizers: These ensure that the overall system remains balanced and stable, especially during turns or uneven surfaces.

Together, these elements form an essential network that contributes to vehicle safety and performance.

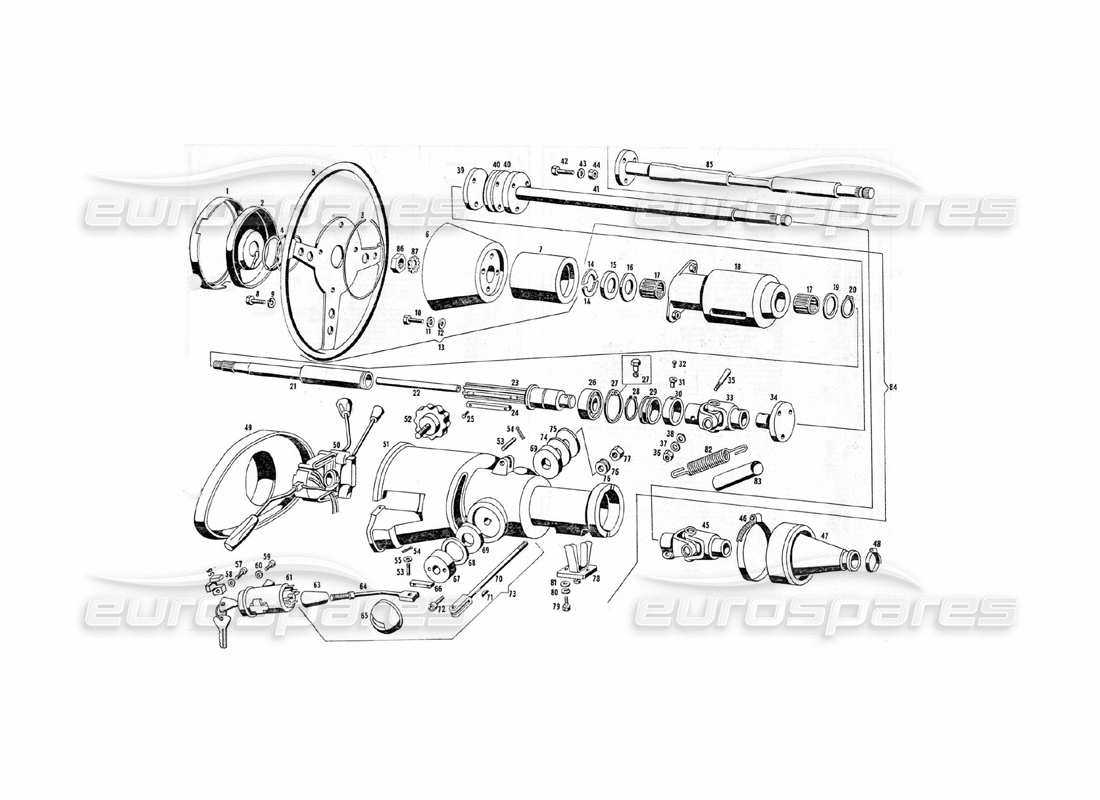

Functions of Steering Wheel Systems

The system responsible for controlling the vehicle’s direction plays a crucial role in ensuring safety and maneuverability. This complex setup allows drivers to maintain control during different driving conditions, enhancing the overall experience on the road. Its primary purpose is to offer precise handling and responsiveness, adapting to both high and low speeds.

Key Components and Their Roles

The components involved in the directional control system are designed to work together seamlessly. Below are the essential elements and their respective functions:

- Control mechanism: Ensures accurate responses to the driver’s input, converting movements into appropriate actions.

- Connection system: Links various parts of the vehicle, allowing for efficient transfer of forces and commands.

- Support structure: Maintains stability and helps absorb shocks, improving comfort and control during use.

Benefits of Efficient Systems

A well-designed directional control system offers several advantages

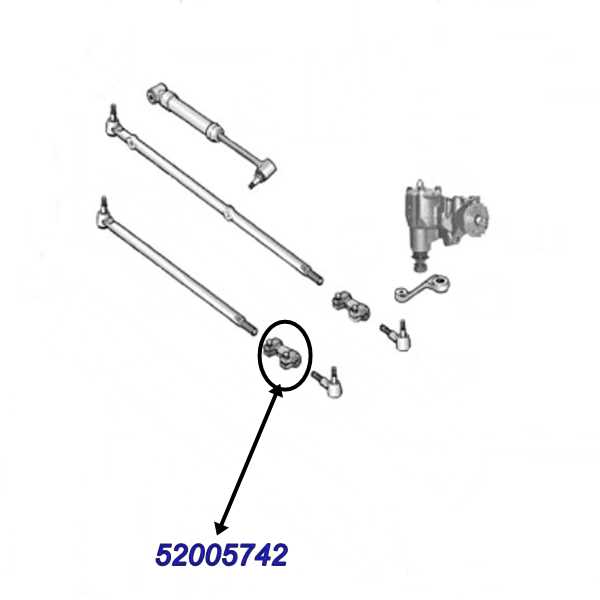

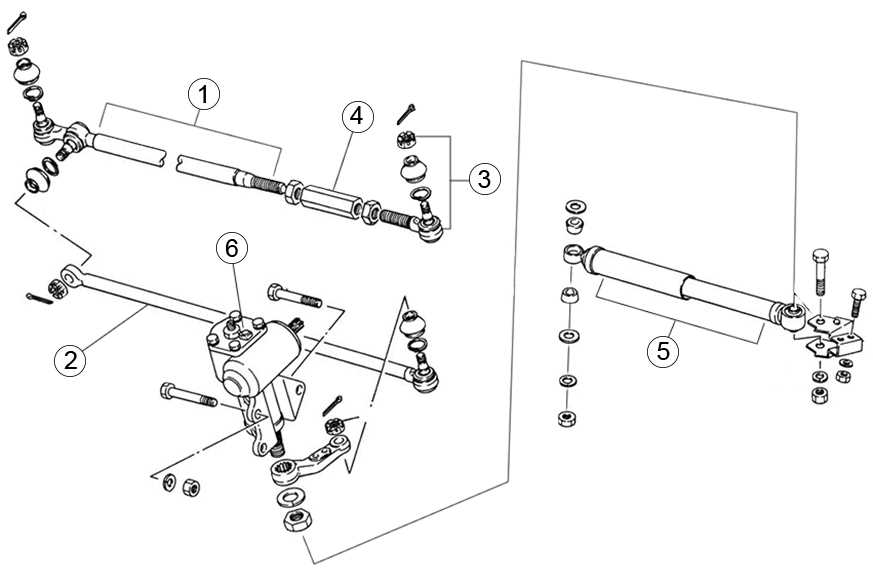

Understanding the Steering Linkage Mechanism

The movement of a vehicle is highly dependent on how well the connection between the control system and the wheels is organized. This mechanism allows for precise turns and ensures stability, making the entire driving experience more fluid. The way various components work together to translate user input into actual wheel movement is critical for safe operation.

Key Elements of the Linkage

At the core of this setup, several important parts contribute to seamless functioning. Each element is responsible for transmitting forces and ensuring the vehicle reacts accurately to the driver’s actions. From the central rod to the attached connectors, these parts are vital for translating rotational movement into responsive handling.

How the Components Work Together

Every element in the linkage mechanism must be synchronized for smooth operation. The central rod interacts with other components, which in turn adjust the angle of the wheels. This synchronized movement ensures efficient performance and prevents any lag or instability during use.

The Role of the Power Steering Pump

The power steering pump plays a vital function in providing smooth and effortless vehicle control. It helps reduce the effort required to maneuver, making driving more comfortable and responsive. The pump ensures that hydraulic fluid is circulated efficiently, allowing the system to assist in directional changes without extra force.

| Key Function | Description |

|---|---|

| Hydraulic Pressure Generation | The pump generates pressure needed to circulate fluid, which assists in moving components that control direction. |

| Fluid Regulation | Ensures the hydraulic fluid flow is consistent, maintaining smooth operation and responsive handling. |

| Effort Reduction | Minimizes the physical effort required, allowing the driver to steer with minimal force. |

| Adjustment Type | Description |

|---|---|

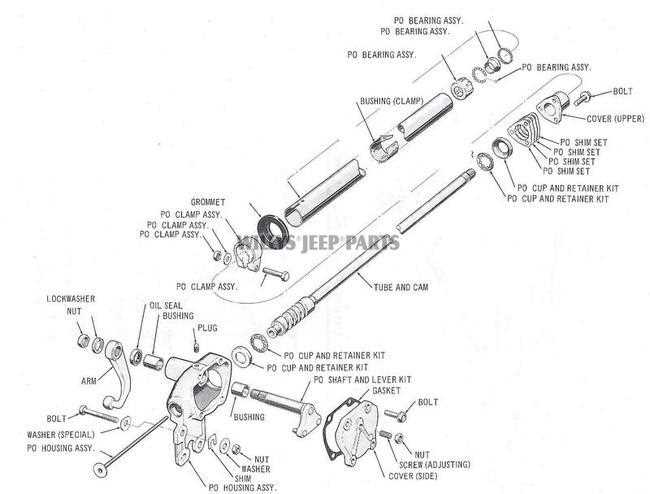

| End Play Adjustment | Ensures minimal movement within the unit, enhancing responsiveness. |

| Preload Adjustment | Modifies the tension on the internal components to reduce wear. |

| Alignment Check | Verifies that the mechanism is correctly aligned to improve handling. |

| Lubrication Maintenance | Ensures that all moving parts are adequately lubricated for smooth operation. |

Implementing these adjustments can lead to a noticeable improvement in driving experience. Regular maintenance and attention to this assembly contribute significantly to vehicle reliability and performance.

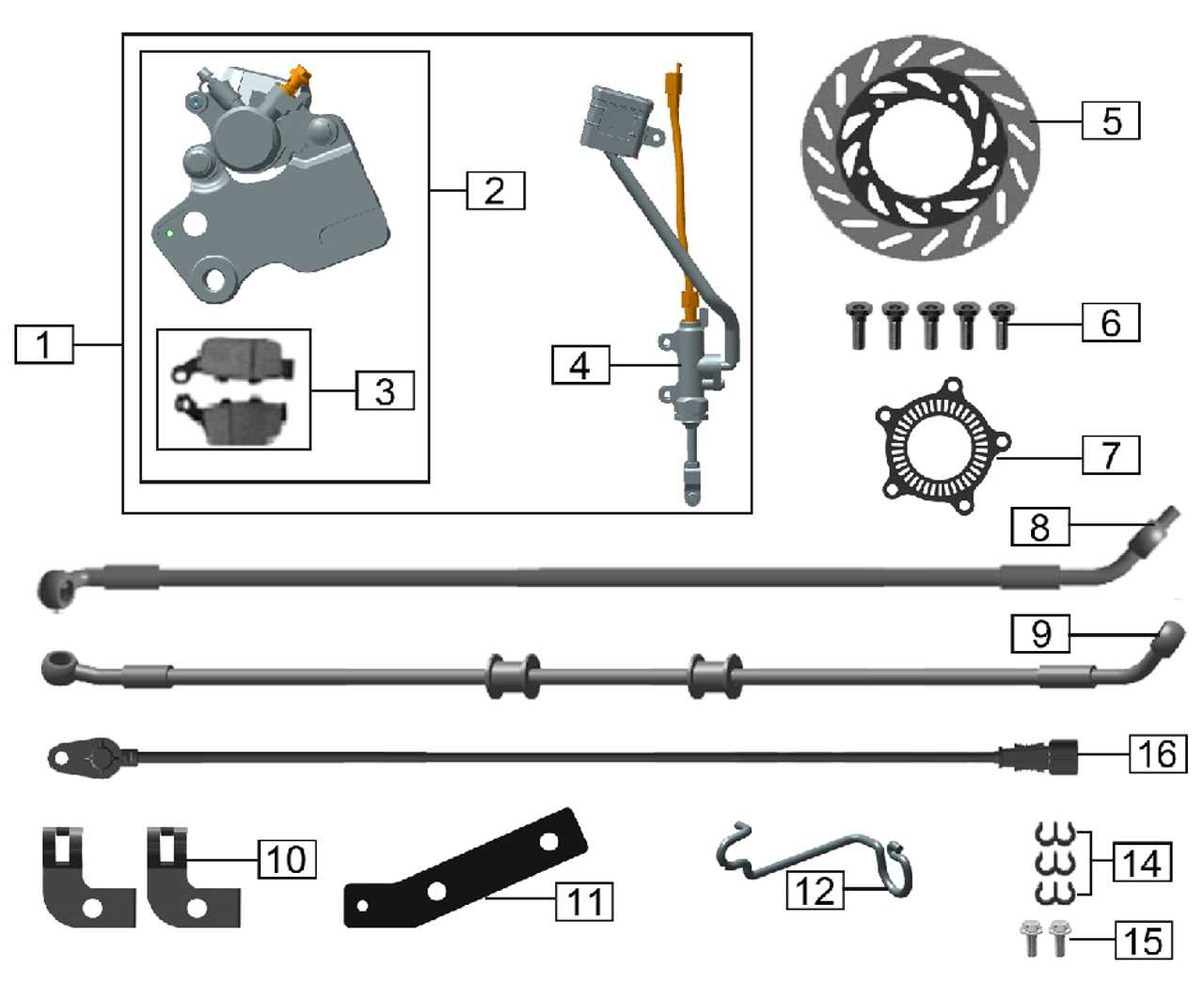

Ball Joints and Their Maintenance

Ball joints are critical components in the suspension system, allowing for smooth movement and flexibility in the vehicle’s handling. Proper maintenance of these joints is essential for ensuring optimal performance and extending their lifespan. Regular inspection and timely servicing can prevent excessive wear and tear, contributing to safer driving experiences.

Signs of Wear

Identifying signs of deterioration in ball joints is crucial for maintaining overall vehicle stability. Common indicators include:

| Indicator | Description |

|---|---|

| Noise | Clunking or popping sounds when turning or going over bumps. |

| Excessive Play | Looseness in the steering wheel or abnormal movement of the suspension. |

| Visual Damage | Cracks or signs of wear on the rubber boot surrounding the joint. |

Maintenance Tips

To ensure the longevity of ball joints, consider the following maintenance practices:

- Regularly inspect for signs of wear and damage.

- Keep the joints lubricated according to the manufacturer’s recommendations.

- Replace any worn or damaged components promptly to avoid further issues.

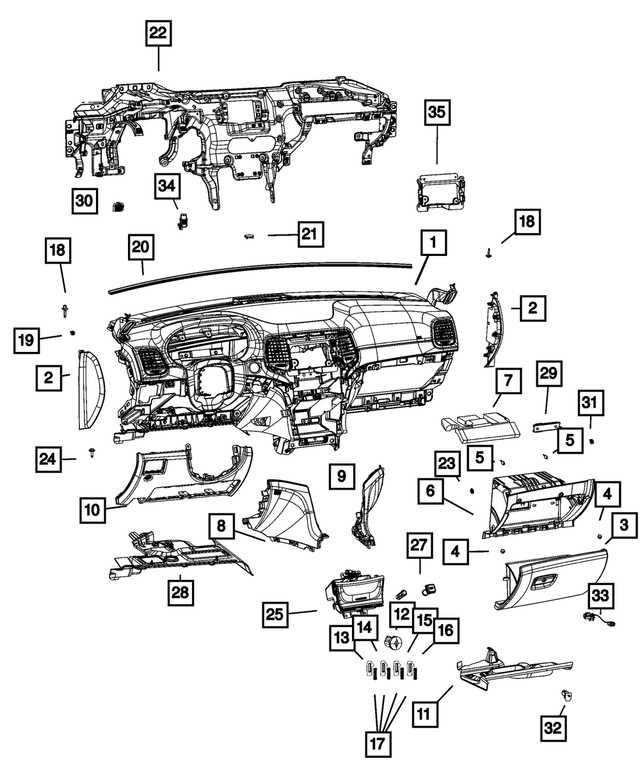

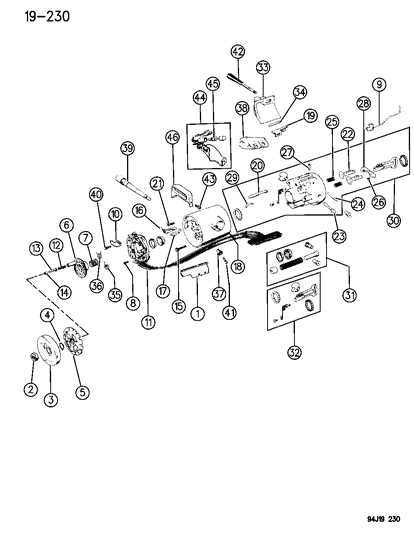

Steering Shaft and Couplings Explained

The mechanism responsible for directing a vehicle involves several key components that work in harmony to ensure optimal control and maneuverability. Among these components, the transmission link and its connecting elements play a critical role in facilitating the driver’s input into the vehicle’s navigation system. Understanding these components is essential for both maintenance and performance enhancement.

Functionality of the Transmission Link

The transmission link serves as the crucial intermediary between the driver’s actions and the vehicle’s directional response. This component transmits rotational motion from the control interface to the wheels, ensuring that the vehicle follows the intended path. It is designed to accommodate various angles and distances, allowing for smooth operation even under challenging conditions.

Connecting Elements and Their Importance

Connecting elements, often referred to as couplings, are designed to join different sections of the transmission link. They play a vital role in absorbing vibrations and accommodating misalignments, which helps maintain a seamless connection during operation. The quality and design of these couplings directly influence the overall responsiveness and reliability of the vehicle’s navigation system.