In any vehicle, the system responsible for handling and maneuverability is crucial for both safety and driving comfort. Understanding the structure and functionality of this system offers valuable insights, whether you’re maintaining an older model, upgrading specific elements, or simply curious about how each component interacts to provide stability and control on the road.

Each element in this setup contributes uniquely to the vehicle’s response, with individual parts working together to ensure a smooth, precise handling experience. Recognizing how these parts interconnect can help diagnose issues and enhance overall vehicle performance. Additionally, familiarizing yourself with the layout of each component is beneficial when selecting replacements or modifications, ensuring compatibility and optimizing vehicle balance.

This guide provides a comprehensive overview of these essential mechanisms. It offers a closer look at each component’s purpose and placement, detailing how they influence the handling, stability, and reliability of your vehicle’s driving experience.

Essential Components of 2nd Gen Dodge Ram Steering

This section covers key elements that contribute to precise control and handling. Understanding these elements can aid in maintenance, enhance driving performance, and ensure a smoother ride experience.

- Linkage Elements: These pieces connect the control mechanism to the wheels, allowing for effective direction changes. They also contribute to stability and help maintain alignment during turns.

- Hydraulic Support System: This mechanism provides fluid-based assistance, reducing the effort needed to maneuver. It is essential for ease of control, especially at low speeds or when parking.

- Joint and Pivot Points: These allow for flexibility in movement while maintaining strength and support. Proper care of these components ensures a responsive and durable connection, enhancing safety and comfort.

- Wheel Connector Arms: Attached directly to the wheels, these elements translate movements into changes in direction. They are crucial for accuracy and direct control.

- Control Box: Serving as the main hub, it directs forces from the wheel to the rest of the components, ensuring cohesive operation. A well-maintained control box is key to consistent and reliable handling.

Understanding the Steering Column Assembly

The column assembly plays a crucial role in the vehicle’s control system, connecting various components to ensure responsive handling. This section provides a breakdown of the parts involved and their roles in maintaining smooth, efficient operation.

Main Components and Their Functions

The column assembly contains multiple interconnected elements, each serving a specific purpose in the overall control system. Below is a list of essential parts:

- Column Shaft: The core section that transmits turning force from the wheel to the control mechanisms.

- Universal Joints: These parts enable smooth movement by connecting sections at various angles.

- Support Bearings: Positioned along the shaft, these reduce friction and enhance stability.

- Control Module: A central unit managing electronic controls and enhancing responsiveness.

Assembly and Adjustment Tips

Maintaining proper alignment and securing all connections are critical for optimal performance. Below are tips for assembly:

- Ensure all components are clean and free from obstructions before assembly.

- Use appropriate tools to fasten each connection firmly to avoid loose connections.

- Regularly inspect and adjust the column’s position to enhance handling precision.

Understanding the importance of each part in the column assembly helps maintain overall vehicle control

Identifying Key Suspension Elements

Understanding the primary components of a vehicle’s suspension system is essential for maintaining stability and control, especially on varied road surfaces. The suspension assembly is designed to absorb shocks, maintain wheel alignment, and provide overall comfort during drives.

- Control Arms: These components are crucial for connecting the wheel assembly to the frame, allowing for controlled movement and managing road impact. They help maintain alignment and ensure smooth rides over uneven terrain.

- Shock Absorbers: Responsible for dampening vibrations from the road, these parts keep the vehicle steady by controlling spring and suspension movement. Properly functioning shock absorbers are essential for reducing wear on other suspension parts.

- Ball Joints: These serve as pivotal connectors between various suspension elements, enabling smooth movement and contributing to the vehicle’s steering capabilities. They are designed to withstand significant stress while maintaining flexibility.

- Springs: Springs bear the vehicle’s weight and absorb shocks, making them foundational for maintaining a balanced ride. Coil and leaf springs are common types, each providing unique benefits based on load and driving

Common Signs of Steering Wear

As vehicle components age, the effects of regular use and environmental conditions can lead to noticeable changes in handling and control. Recognizing these early signs can prevent further wear and ensure a smoother, safer driving experience.

Unusual Noises

When handling turns or driving over uneven surfaces, drivers might notice unusual sounds, which can include squeaks, groans, or knocks. These sounds often indicate that certain parts may be wearing out or losing their original alignment.

- Squeaking: Often points to insufficient lubrication or components rubbing against each other.

- Groaning: Can signal metal-to-metal contact or a part that is strained under pressure.

- Knocking: May be a sign of loose connections or weakened joints.

Changes in Handling

Alterations in how a vehicle responds during driving can also be a key indicator of wear. Drivers might observe increased difficulty or decreased accuracy in maneuvering.

- Stiffness: Difficulty in moving certain directions can signal that parts may need inspection or replacement.

- Wandering: If a vehicle drifts or requires constant correction, alignment could be compromised

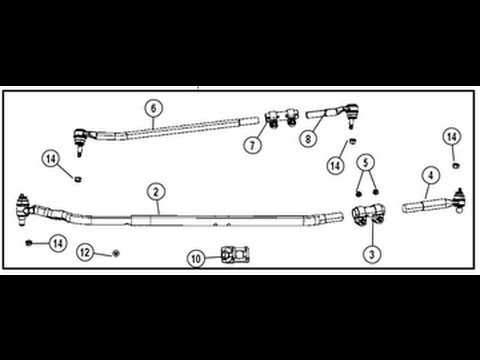

Role of Tie Rods in Steering

Tie rods are essential components in vehicle control, helping translate the driver’s input into movement. These links connect other key components within the front mechanism, enabling responsive handling and stability. Their position allows them to transmit force effectively, providing smoother alignment and precision while driving.

How Tie Rods Contribute to Control

The main function of tie rods is to keep the wheels aligned while adapting to turns, bumps, and road irregularities. This alignment not only ensures optimal road contact but also helps prevent uneven tire wear, maximizing longevity and performance. By working in conjunction with other parts, they maintain consistent movement that’s crucial for driver safety and comfort.

Comparing Inner and Outer Tie Rods

Typically, tie rods are divided into inner and outer sections, each playing distinct roles. The inner tie rod attaches closer to the vehicle’s central structure, transferring movement outward. Meanwhile, the outer tie rod connects to the wheel, making it the part directly responsible for turning. This partnership ensures a balanced and responsive system.

Component Primary Function Inner Tie Rod Transmits force from the central system to the outer rod Outer Tie Rod Directly influences wheel alignment and turning Power Steering Pump and Fluid Functions

The hydraulic mechanism responsible for assisting in the maneuverability of a vehicle plays a crucial role in ensuring a smooth driving experience. This section explores the essential functions of the hydraulic pump and the significance of the fluid within this system.

A hydraulic pump operates by generating pressure that facilitates the movement of fluid through the system, enhancing the driver’s ability to control the vehicle’s direction with minimal effort. The following are key functions of this component:

- Fluid Circulation: The pump circulates hydraulic fluid throughout the system, enabling seamless operation.

- Pressure Generation: By creating pressure, the pump assists in amplifying the driver’s input, making turns easier.

- Heat Dissipation: The movement of fluid aids in dissipating heat generated during operation, preventing overheating.

The fluid used in this mechanism serves several vital purposes:

- Lubrication: It reduces friction between moving components, prolonging their lifespan.

- Contamination Control: The fluid helps to carry away debris and contaminants, maintaining the system’s cleanliness.

- Temperature Regulation: It assists in managing the temperature within the system, ensuring optimal performance.

In summary, the hydraulic pump and its fluid are integral to the effective operation of a vehicle’s maneuverability system. Understanding their functions can enhance awareness of maintenance needs and contribute to a smoother driving experience.

Importance of Steering Linkages

The connections that facilitate the control of a vehicle’s direction are crucial for ensuring safe and effective maneuverability. These components serve as the bridge between the driver’s inputs and the wheels, translating movements into precise actions. Without well-designed linkages, a vehicle’s handling and stability could be compromised, leading to potential safety hazards.

Robustness and Responsiveness: The quality and construction of these connections significantly impact a vehicle’s overall performance. High-quality linkages contribute to a more responsive driving experience, allowing for quicker adjustments to the vehicle’s trajectory. This responsiveness is essential, particularly in dynamic driving conditions where precise control is necessary.

Safety Considerations: Properly functioning linkages are vital for maintaining safety on the road. Any wear or damage can lead to a loss of control, increasing the risk of accidents. Regular inspection and maintenance of these components ensure that they operate effectively, providing drivers with the confidence needed to navigate various terrains.

Long-term Durability: Investing in quality linkages can lead to extended service life and reduced maintenance costs. Components that are built to withstand the rigors of daily use tend to require less frequent replacement, making them a wise choice for vehicle longevity.

Maintaining Steering Stabilizers

Ensuring optimal performance of suspension components is crucial for vehicle safety and comfort. Proper upkeep of these essential elements helps enhance control and stability during operation, ultimately contributing to a smoother driving experience.

Importance of Regular Checks

Routine inspections are vital to identify wear and tear before they escalate into significant issues. Here are key aspects to focus on:

- Examine for signs of leakage, which can indicate fluid loss.

- Check for any unusual noises during operation, suggesting potential malfunctions.

- Inspect mounting points for corrosion or looseness.

Maintenance Tips

Implementing straightforward maintenance practices can prolong the lifespan of these components:

- Regularly clean the exterior to prevent dirt buildup that can lead to corrosion.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Replace damaged or worn components promptly to maintain performance and safety.

Choosing Quality Replacement Parts

When it comes to enhancing the functionality and reliability of your vehicle, selecting superior components is crucial. Opting for high-quality replacements not only ensures optimal performance but also contributes to the longevity of your vehicle. Understanding the importance of these choices can help you avoid frequent repairs and maintain the vehicle’s overall value.

Factors to Consider

There are several elements to consider when choosing replacements for automotive components. These include the reputation of the manufacturer, the materials used, and compatibility with your vehicle’s specifications. Quality components often feature durable materials that can withstand wear and tear, providing a better performance over time.

Cost vs. Quality

While it might be tempting to opt for the most affordable options available, investing in quality replacements can save you money in the long run. Cheaper alternatives may require frequent replacements, leading to higher overall costs. Balancing price with quality is essential for maintaining a reliable vehicle.

Feature Quality Parts Cheap Alternatives Durability High Low Performance Optimal Variable Warranty Often included Rarely offered Long-term Cost Lower Higher