The functionality of lawn machinery greatly relies on the efficiency of its maneuvering system. Proper navigation is essential for achieving precise cutting and optimal performance in various terrains. This section delves into the intricate assembly of elements that govern directional control, ensuring that users can maintain their equipment effectively.

In any lawn tractor, comprehending the various components that contribute to its guiding mechanism is vital for both maintenance and troubleshooting. Each element plays a crucial role, from the connection points to the pivoting mechanisms, and understanding these relationships can significantly enhance the operational longevity of the equipment.

This exploration will provide insights into the layout and interaction of these crucial elements. By familiarizing yourself with the configuration, you will be better equipped to identify issues, perform repairs, and ultimately improve your machine’s handling capabilities.

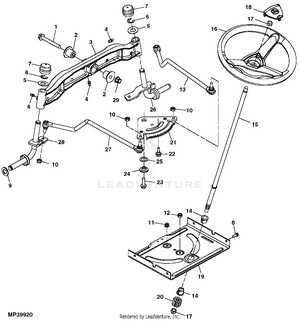

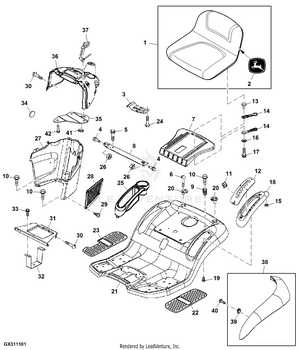

John Deere LA145 Steering Parts Diagram Information

This section provides essential details regarding the components involved in the directional control system of a popular lawn tractor model. Understanding the arrangement and function of these elements is crucial for maintenance and troubleshooting. Knowledge of these components can significantly enhance the performance and longevity of the machine.

Key Components Overview

The directional mechanism consists of various crucial elements that work in harmony to ensure smooth operation. Key items include the control wheel, connecting rods, and pivot points. Each of these parts plays a vital role in facilitating responsive maneuverability, allowing for precise navigation across different terrains.

Maintenance Tips

Regular inspection of the directional components is important to prevent wear and tear. It is advisable to check for any signs of damage or looseness and to apply appropriate lubrication where necessary. Keeping these elements in good condition ensures that the machine operates efficiently and reduces the risk of costly repairs.

Understanding the Steering System Components

The navigation mechanism of any vehicle is crucial for its maneuverability and overall functionality. This intricate assembly consists of several key elements that work together to ensure precise control and stability while in motion. Each component plays a vital role, contributing to the seamless operation of the entire system.

The primary element is the control wheel, which allows the operator to direct the machine’s path. Attached to this wheel are various linkages that transmit motion to the front wheels, enabling responsive turning. Additionally, the framework housing these components is designed to absorb shocks and vibrations, enhancing the overall driving experience.

Moreover, additional fittings such as bushings and connectors ensure smooth movement and reduce wear over time. Regular maintenance and inspection of these elements are essential for maintaining optimal performance and safety. Understanding these components will aid users in troubleshooting and effectively managing their machinery.

Identifying Key Parts in the Steering Assembly

Understanding the essential components of a directional control system is crucial for effective maintenance and repair. Each element plays a significant role in ensuring smooth navigation and maneuverability, contributing to the overall performance of the equipment.

Key components typically found in such systems include:

- Wheel Mechanism: The primary interface for user input, allowing for directional changes.

- Linkage System: Connects the wheel to other components, transmitting motion and force.

- Pivot Points: Enable rotation and flexibility within the assembly, facilitating smoother turns.

- Control Column: Houses the mechanism for input, often including grips or levers.

- Bearings: Reduce friction between moving parts, ensuring efficient operation.

To maintain optimal functionality, it’s vital to regularly inspect these components for wear and damage. Recognizing each part’s role will aid in troubleshooting and performing necessary adjustments or replacements.

Exploring the Function of Each Steering Component

Understanding the individual elements that contribute to directional control is essential for optimal operation and maintenance. Each component plays a specific role, working in harmony to ensure precise maneuverability. By examining these integral parts, one can appreciate their contributions to the overall performance and reliability of the vehicle.

The control mechanism serves as the interface between the operator and the machinery, allowing for adjustments in direction. This element directly influences responsiveness, translating user inputs into movement. Coupled with this are linkages, which transmit force and motion, ensuring that commands result in accurate alterations in trajectory.

The pivot points are critical, facilitating smooth rotations and enabling sharp turns. They minimize friction, ensuring longevity and reducing wear. Additionally, the framework that supports these components must be robust, providing stability and durability throughout various operating conditions.

Finally, any system of this nature benefits from regular inspection and maintenance. Understanding the functionality of each element not only aids in troubleshooting but also enhances the overall effectiveness, ensuring a seamless experience in operation.

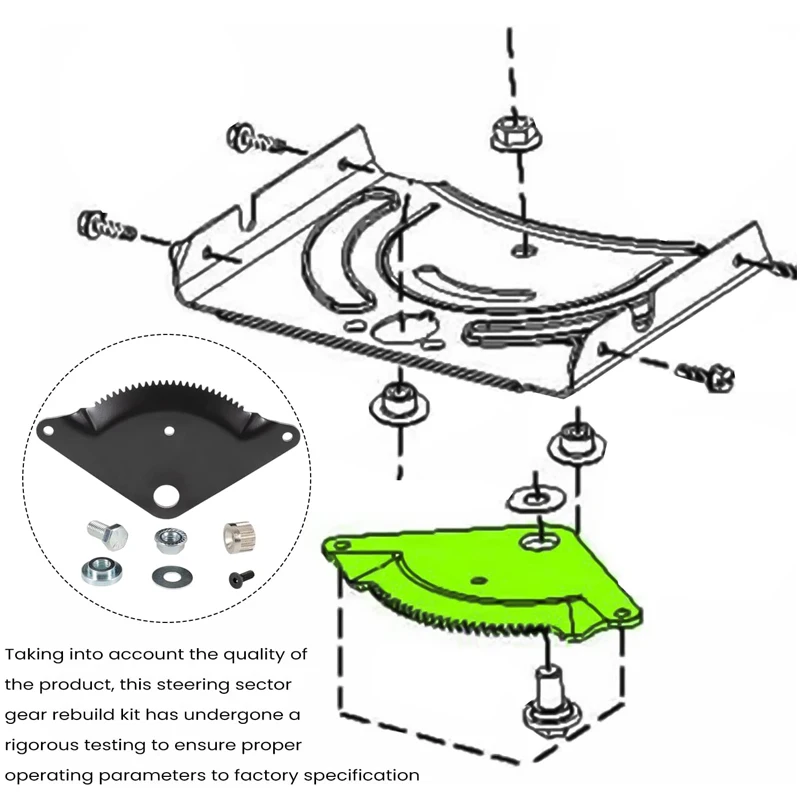

Steps to Replace or Maintain Steering Parts

Ensuring optimal performance of your vehicle’s directional control system is essential for a smooth and safe operation. This section outlines the key actions required to effectively replace or maintain these crucial components, helping you achieve ultimate reliability and functionality.

Preparation and Tools Required

Before beginning the process, gather the necessary tools and materials. This preparation will streamline your work and enhance efficiency.

| Tool/Material | Purpose |

|---|---|

| Wrench Set | Loosening and tightening bolts |

| Screwdriver | Removing covers and components |

| Replacement Components | Substituting worn parts |

| Lubricant | Ensuring smooth operation |

Step-by-Step Process

Begin by safely elevating the vehicle and ensuring stability. Next, systematically remove the necessary coverings and identify components for inspection. Replace any damaged elements and apply lubricant where needed. Finally, reassemble all parts carefully, ensuring everything is securely in place for optimal functionality.

Common Issues and Troubleshooting Tips

Maintaining optimal functionality in outdoor equipment is crucial for efficient operation. Understanding potential challenges and knowing how to address them can save time and enhance performance. This section outlines typical problems encountered with control mechanisms and offers practical solutions for troubleshooting.

1. Misalignment Problems: One frequent issue involves misalignment, which can lead to erratic handling. Regularly inspect the connection points for wear and ensure everything is properly aligned. If misalignment is detected, adjustments may be necessary to restore proper functionality.

2. Excessive Play: Over time, wear and tear can result in excess play within the control system. If you notice a lack of responsiveness, check for any loose components. Tightening bolts or replacing worn parts can help restore stability.

3. Difficulty in Operation: If the mechanism feels stiff or resistant, it may indicate a lack of lubrication or accumulated debris. Cleaning the components and applying appropriate lubricants can significantly improve movement.

4. Noisy Operation: Unusual noises during use can be a sign of underlying issues. Inspect for any loose or damaged parts, and replace as necessary to reduce noise and improve overall performance.

5. Fluid Leaks: If fluid is leaking from the system, it’s essential to identify the source quickly. Regularly check seals and hoses for any signs of wear. Replacing damaged components can prevent further issues and maintain efficiency.

By proactively addressing these common issues, users can ensure their equipment operates smoothly and efficiently, leading to a more productive experience.

Where to Find Genuine John Deere Parts

Locating authentic components for your equipment is essential for ensuring optimal performance and longevity. Reliable sources offer high-quality alternatives that maintain the integrity of your machinery. Understanding where to acquire these essential elements can save time and enhance functionality.

Authorized Dealerships

Visiting certified retailers is one of the most effective ways to procure original components. These establishments provide assurance regarding the authenticity and compatibility of their offerings. Additionally, their knowledgeable staff can assist with any queries and help identify the exact elements required for your machine.

Online Marketplaces

The internet is a valuable resource for sourcing genuine components. Numerous platforms specialize in providing access to original equipment, often featuring detailed descriptions and user reviews. However, it’s crucial to verify the credibility of the seller to ensure that you are receiving genuine products.

DIY Maintenance Tips for Your LA145 Steering System

Proper upkeep of your mower’s maneuvering mechanism can enhance its performance and longevity. Regular attention to this system can prevent wear and tear, ensuring smooth operation and improved handling. Here are some essential tips to keep your equipment in top condition.

| Task | Frequency | Description |

|---|---|---|

| Check Lubrication | Every 25 hours | Inspect and apply lubricant to moving parts to minimize friction and wear. |

| Tighten Fasteners | Monthly | Ensure that all bolts and screws are secure to maintain stability during operation. |

| Inspect Belts | Every season | Examine for signs of wear, cracking, or fraying; replace if necessary. |

| Clean Components | After each use | Remove debris and dirt from the mechanism to prevent obstruction and ensure smooth operation. |

| Test Alignment | Seasonally | Check that all components are correctly aligned to prevent uneven wear and steering issues. |

Following these simple steps can greatly enhance the functionality of your mower’s navigation system. Regular maintenance not only prolongs its lifespan but also ensures a safe and enjoyable mowing experience.

Resources for Further Information and Support

This section provides a collection of valuable resources for anyone seeking additional insights or assistance related to equipment maintenance and repair. Whether you are a novice or an experienced user, these tools can enhance your understanding and aid in troubleshooting.

Online Communities

- Forums dedicated to machinery enthusiasts

- Social media groups focused on equipment support

- Dedicated websites for sharing tips and experiences

Official Support Channels

- Manufacturer’s customer service for direct inquiries

- Authorized dealers for specialized assistance

- Official manuals and guides for in-depth knowledge