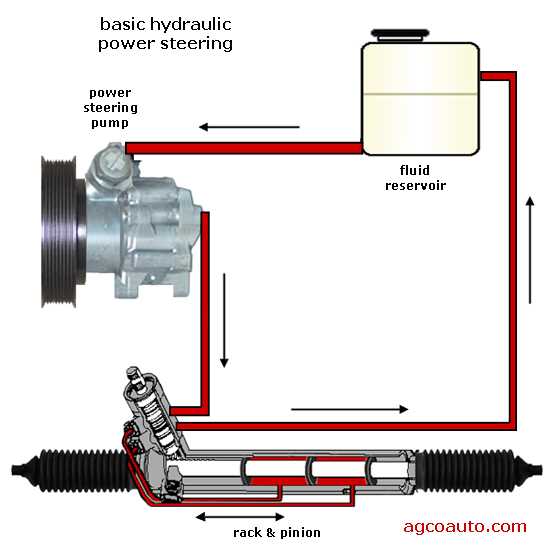

In modern vehicles, the ease of maneuvering is often attributed to intricate hydraulic assist mechanisms. These systems rely on a series of interconnected elements that work together to enhance driver control and reduce effort during navigation. A clear understanding of these components is essential for both enthusiasts and professionals involved in maintenance and repair.

By examining the various sections of these systems, one can gain insights into their functionality and importance. Each element plays a crucial role, contributing to the overall efficiency and responsiveness of vehicle handling. Recognizing how these pieces interact not only aids in troubleshooting but also fosters a deeper appreciation for automotive engineering.

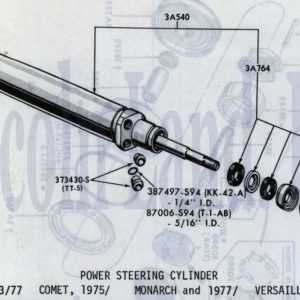

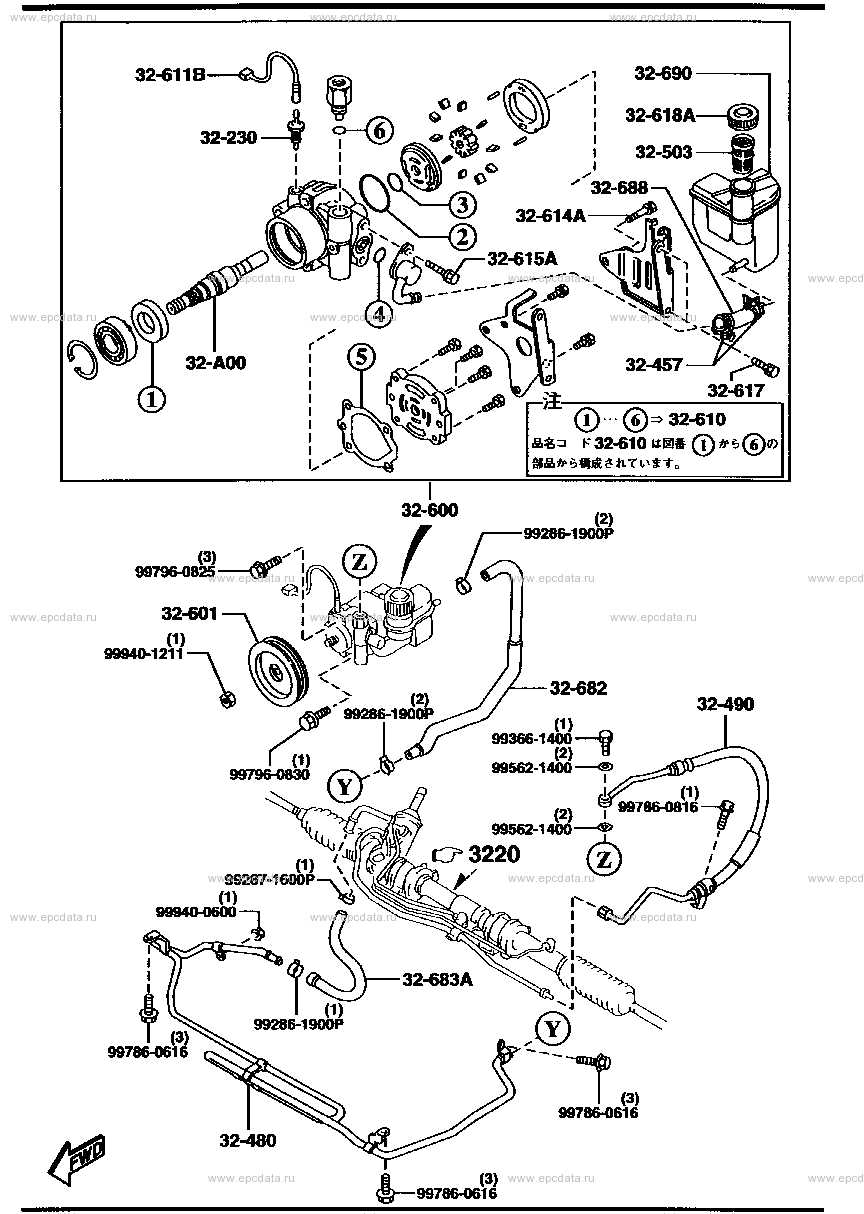

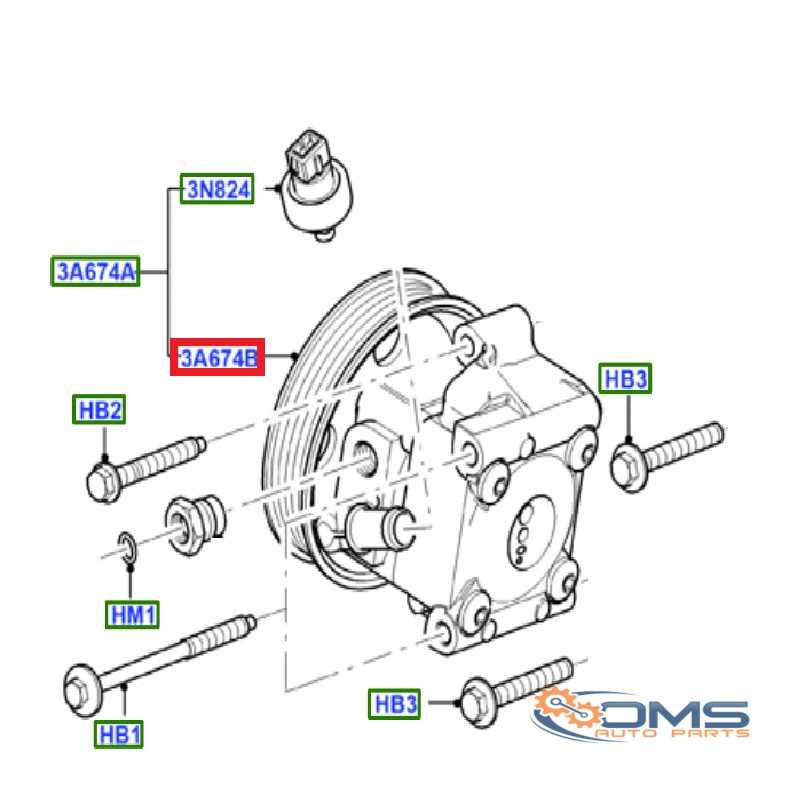

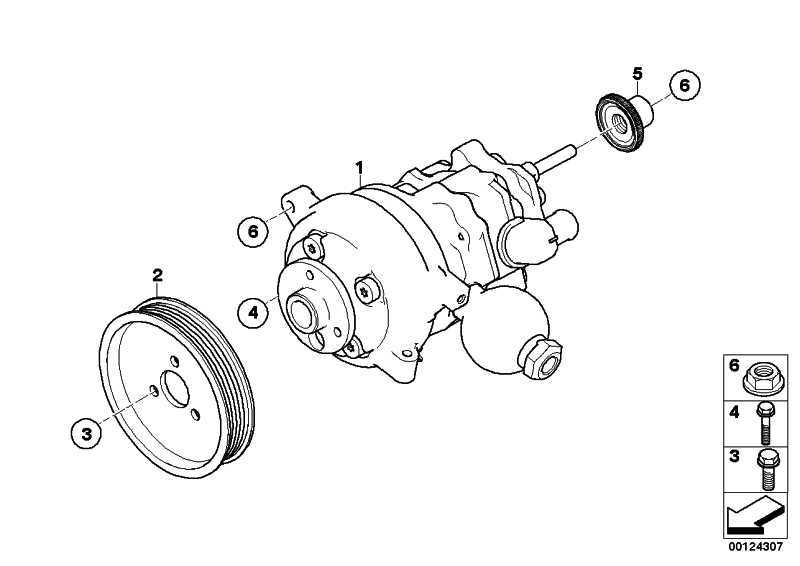

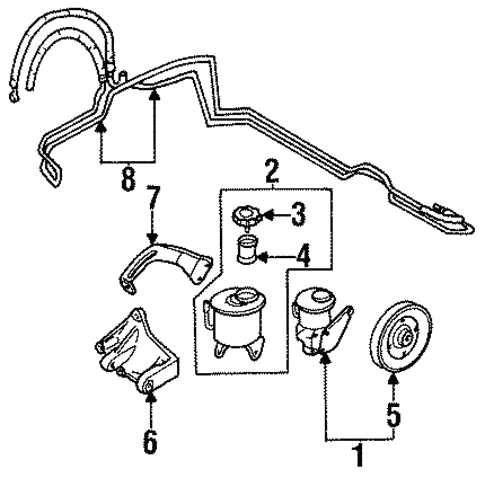

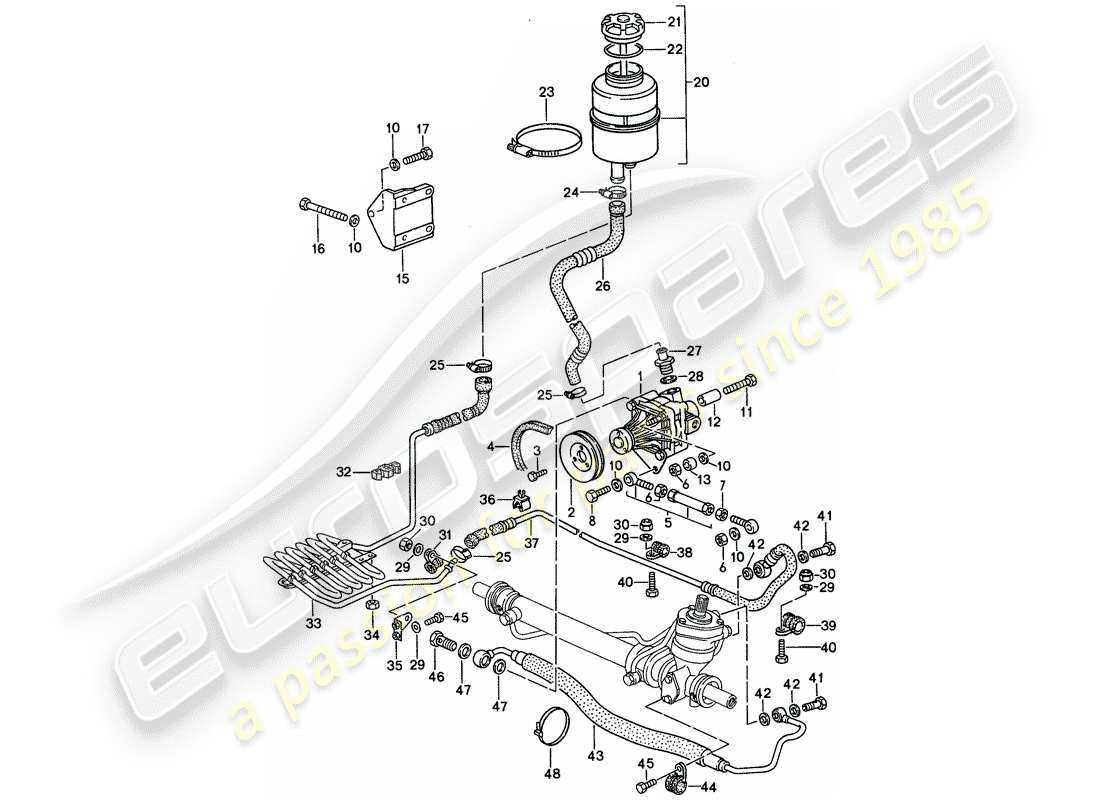

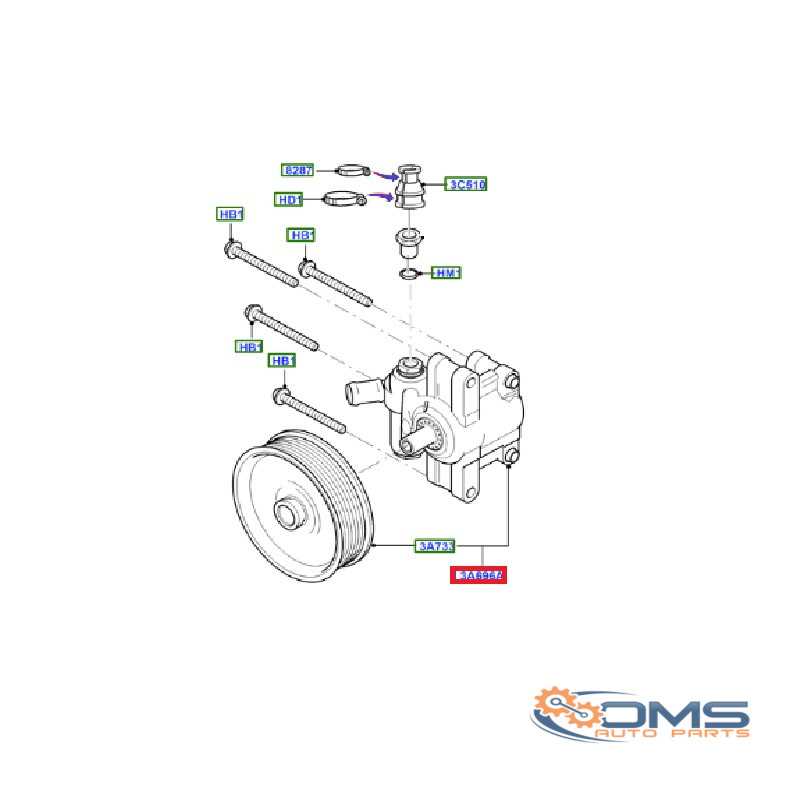

Moreover, having a visual representation of the configuration of these components can significantly simplify the learning process. It allows individuals to identify and comprehend each segment’s purpose and how it fits within the larger framework. This knowledge is invaluable for anyone looking to delve into the mechanics of hydraulic assist systems.

Understanding Power Steering System

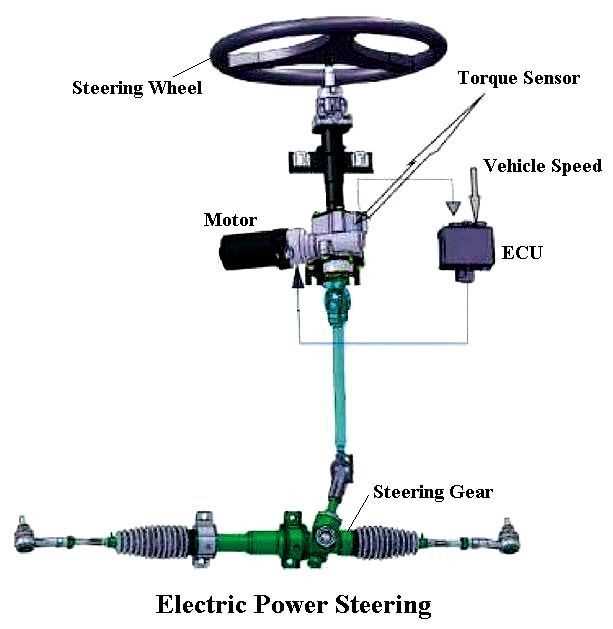

This section delves into the intricacies of a vital automotive component that enhances vehicle maneuverability. By utilizing hydraulic or electric assistance, this mechanism significantly reduces the effort needed for turning the vehicle, making it a crucial element for both comfort and safety while driving.

Key Components

- Hydraulic Fluid: The medium that transmits force within the system.

- Control Valve: Regulates the flow of fluid based on driver input.

- Motor or Actuator: Provides assistance in systems that use electric means.

- Reservoir: Stores the hydraulic fluid required for the operation.

- Hoses: Channels through which the fluid moves, connecting different parts.

Operation Mechanism

- Driver inputs force on the control device.

- The control valve directs fluid to assist in the intended direction.

- Fluid pressure enhances the force exerted by the driver.

- The system reacts, enabling smoother and easier navigation.

Understanding the components and mechanics behind this system is essential for diagnosing issues and ensuring optimal performance in any vehicle.

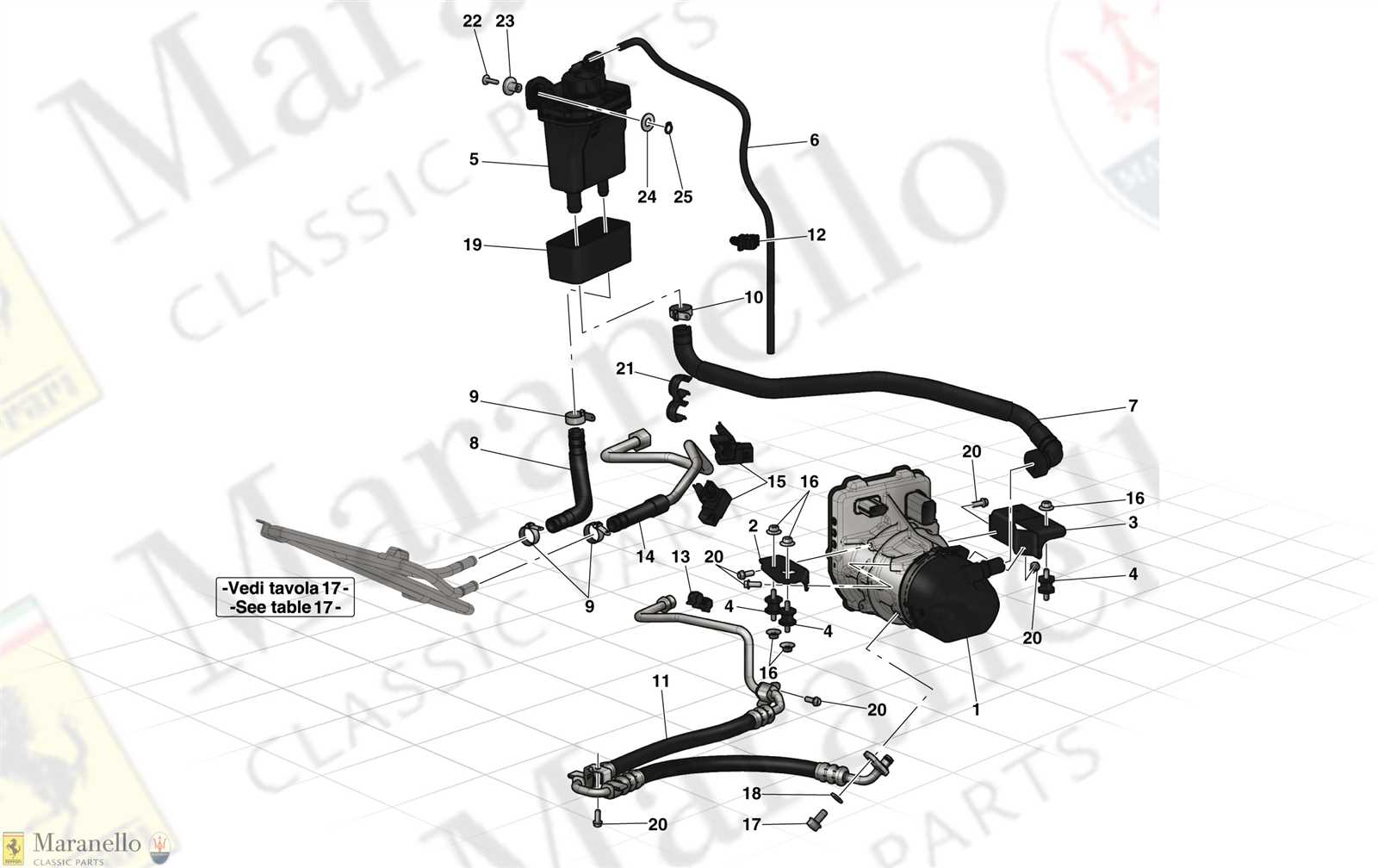

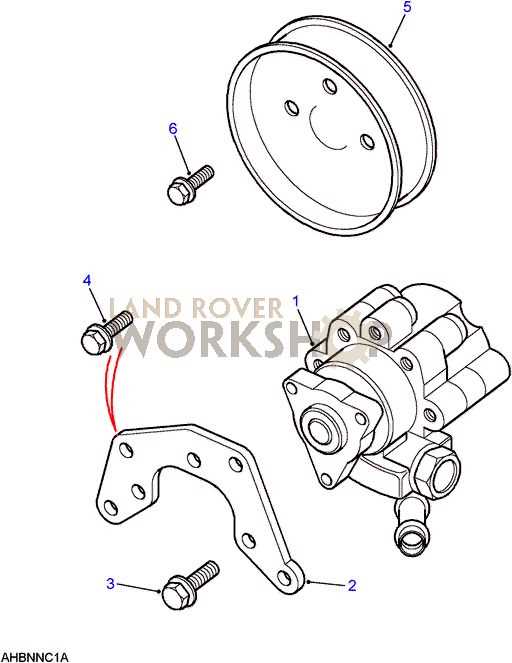

Key Components of Power Steering Pump

Understanding the essential elements of hydraulic assistance systems is crucial for both maintenance and troubleshooting. These systems consist of various intricate components that work together to enhance vehicle maneuverability and reduce driver effort.

Hydraulic Reservoir

The hydraulic reservoir serves as a storage unit for the fluid, ensuring an adequate supply for the entire mechanism. This component plays a vital role in maintaining optimal fluid levels, which directly impacts system performance. Regular checks are necessary to avoid leaks and ensure efficiency.

Control Valve

The control valve is responsible for regulating the flow of hydraulic fluid. This component allows for adjustments based on the driver’s input, enhancing responsiveness and handling. A malfunction in the control valve can lead to increased steering effort and reduced safety, highlighting its importance in the overall functionality of the system.

Function of Hydraulic Fluids

Hydraulic fluids play a crucial role in various mechanical systems, enabling the transfer of energy and facilitating smooth operation. Their properties and functions are essential for the efficiency and reliability of hydraulic mechanisms.

Key Functions

- Energy Transfer: These fluids transmit force from one component to another, allowing for effective operation of machinery.

- Lubrication: They reduce friction between moving parts, enhancing durability and performance.

- Temperature Regulation: Hydraulic fluids help dissipate heat generated during operation, maintaining optimal temperature levels.

- Corrosion Prevention: Many hydraulic fluids contain additives that protect internal surfaces from rust and wear.

Types of Hydraulic Fluids

- Mineral Oils: Derived from refining crude oil, these are the most common type of hydraulic fluids.

- Synthetic Fluids: Engineered for specific applications, these fluids offer superior performance under extreme conditions.

- Biodegradable Fluids: Made from renewable resources, they are designed to minimize environmental impact.

Common Issues in Power Steering Pumps

Various complications can arise in the hydraulic assistance systems of vehicles, leading to decreased efficiency and performance. Understanding these common problems can help in diagnosing issues promptly and ensuring the longevity of the system.

Common Symptoms

- Noisy operation, often described as whining or groaning.

- Difficulty in turning the wheel, especially at low speeds.

- Fluid leaks around the assembly.

- Overheating of the system, leading to potential failure.

Potential Causes

- Worn internal components due to prolonged use.

- Contaminated fluid that can impair functionality.

- Improper installation or alignment of the system.

- Insufficient fluid levels causing inadequate lubrication.

Addressing these issues early can save time and resources, ensuring optimal performance for the vehicle’s handling systems.

Maintenance Tips for Longevity

Ensuring the durability of your hydraulic system requires consistent care and attention. Implementing a few essential practices can significantly extend the lifespan of its components and enhance overall performance.

- Regular Fluid Checks: Frequently inspect and replenish the hydraulic fluid to maintain optimal levels.

- Leak Detection: Routinely examine connections and hoses for any signs of leakage.

- Clean Environment: Keep the surrounding area free from debris and contaminants to prevent potential damage.

- Monitor Noise Levels: Pay attention to unusual sounds during operation, which may indicate underlying issues.

- Scheduled Inspections: Conduct periodic assessments by professionals to identify wear and tear early.

By adhering to these guidelines, you can help ensure the continued functionality of your system and avoid costly repairs in the future.

Diagnosing Pump Failures

Identifying issues within hydraulic assist mechanisms is crucial for maintaining optimal vehicle performance. Recognizing the symptoms of malfunction can prevent further damage and costly repairs. By understanding common indicators and employing systematic evaluation, one can effectively address and resolve these challenges.

Common Symptoms

Look for signs such as unusual noises, fluctuating responsiveness, or fluid leaks. These symptoms may indicate underlying mechanical problems that require immediate attention. Pay special attention to any changes in the system’s efficiency, as these can serve as early warnings of potential failure.

Testing Methods

Utilize diagnostic tools to assess functionality. Checking fluid levels, inspecting for leaks, and evaluating pressure output are essential steps. Consistent monitoring can lead to timely interventions, ensuring the longevity of the hydraulic system. Remember, addressing issues promptly can save time and resources in the long run.

Replacement Procedures Explained

When it comes to maintaining the efficiency of your vehicle’s auxiliary components, understanding the process of replacing essential elements is crucial. This section provides a comprehensive overview of the necessary steps, tools, and considerations involved in the replacement procedure to ensure optimal functionality.

Essential Tools and Materials

Before beginning the replacement, gather all necessary tools and materials to streamline the process. Here’s a brief overview:

| Tool/Material | Purpose |

|---|---|

| Wrench Set | To loosen and tighten bolts |

| Screwdrivers | For removing clamps and securing components |

| Replacement Element | New unit for installation |

| Fluid | For replenishing system after replacement |

| Safety Goggles | To protect eyes during the process |

Step-by-Step Replacement Process

Follow these steps to ensure a successful installation:

- Begin by disconnecting the vehicle’s battery to prevent any electrical issues.

- Remove the necessary covers and components to access the unit that requires replacement.

- Carefully disconnect the hoses and wiring attached to the unit.

- Remove the old unit, taking note of its positioning for accurate installation of the new one.

- Install the new component, ensuring that all connections are secure and properly aligned.

- Reattach any hoses and wiring, followed by the vehicle’s covers.

- Reconnect the battery and check for any leaks or irregularities.

By following these procedures, you can effectively replace critical components, enhancing the overall performance of your vehicle.

Choosing the Right Parts for Repairs

When it comes to maintaining optimal functionality in your vehicle, selecting the appropriate components for repairs is crucial. The quality and compatibility of these elements significantly influence performance and longevity. Understanding the key factors in choosing the right components can save time and enhance reliability.

Factors to Consider

- Compatibility: Ensure that the components fit your specific vehicle model. Check the manufacturer’s recommendations for exact specifications.

- Quality: Opt for high-quality items to prevent premature wear and potential failures. Look for reputable brands or OEM parts.

- Cost: Balance cost with quality. Cheaper options may seem attractive but can lead to higher expenses over time due to replacements.

- Warranty: Choose items that come with a warranty. This can provide peace of mind and protection against defects.

Steps for Selection

- Research your vehicle’s specifications and recommended components.

- Compare different brands and read reviews from other users.

- Consult with a professional mechanic if uncertain about your choices.

- Purchase from reliable suppliers or retailers to ensure authenticity.

By considering these aspects, you can ensure that the components you select will effectively meet your vehicle’s needs, contributing to its overall performance and safety.