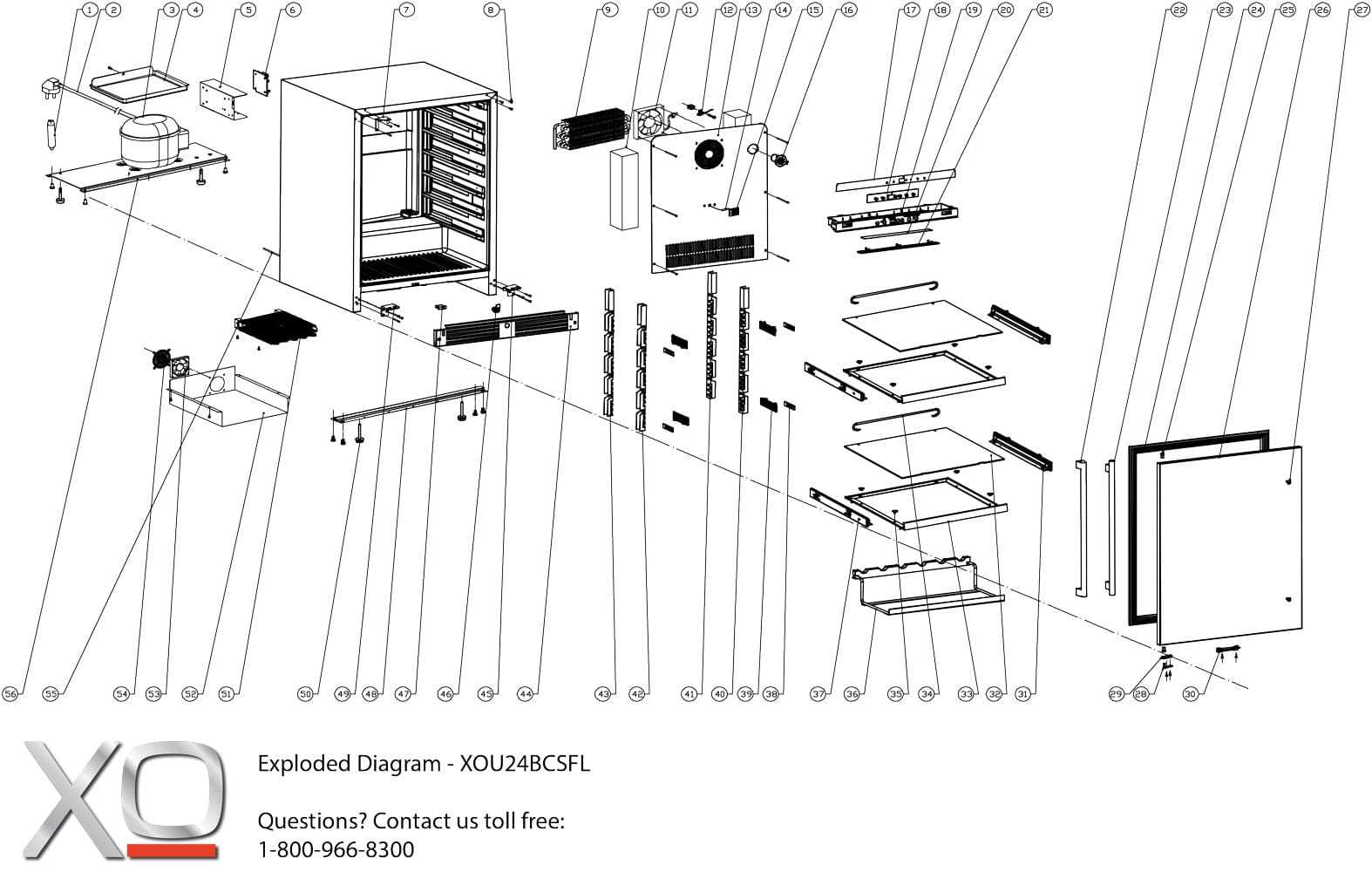

The operational efficiency of refrigeration devices relies on the seamless interaction between various elements. These units are carefully designed with a network of interconnected sections, each contributing to the overall functionality. To ensure long-term performance, it’s essential to have a clear overview of how these sections come together, forming a cohesive system that powers cooling processes.

Each element plays a specific role, from maintaining temperature stability to managing water flow. By analyzing the individual components and their functions, one can gain a deeper understanding of how the equipment operates. This knowledge is crucial for troubleshooting and ensuring smooth performance.

Examining a detailed layout of these components provides insight into the technical intricacies of the system. It allows users to identify key areas of maintenance, ensuring that each section is functioning correctly to avoid disruptions in

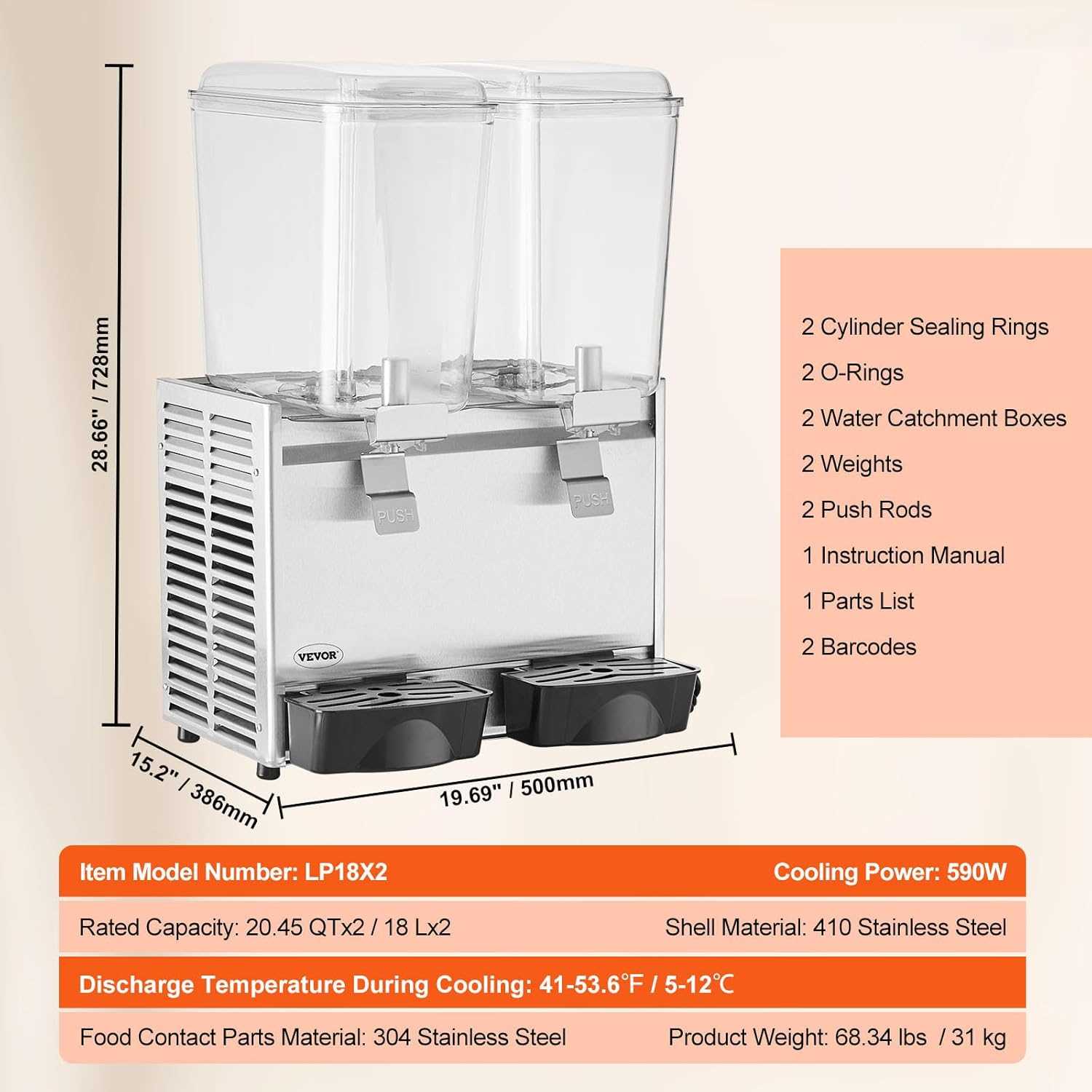

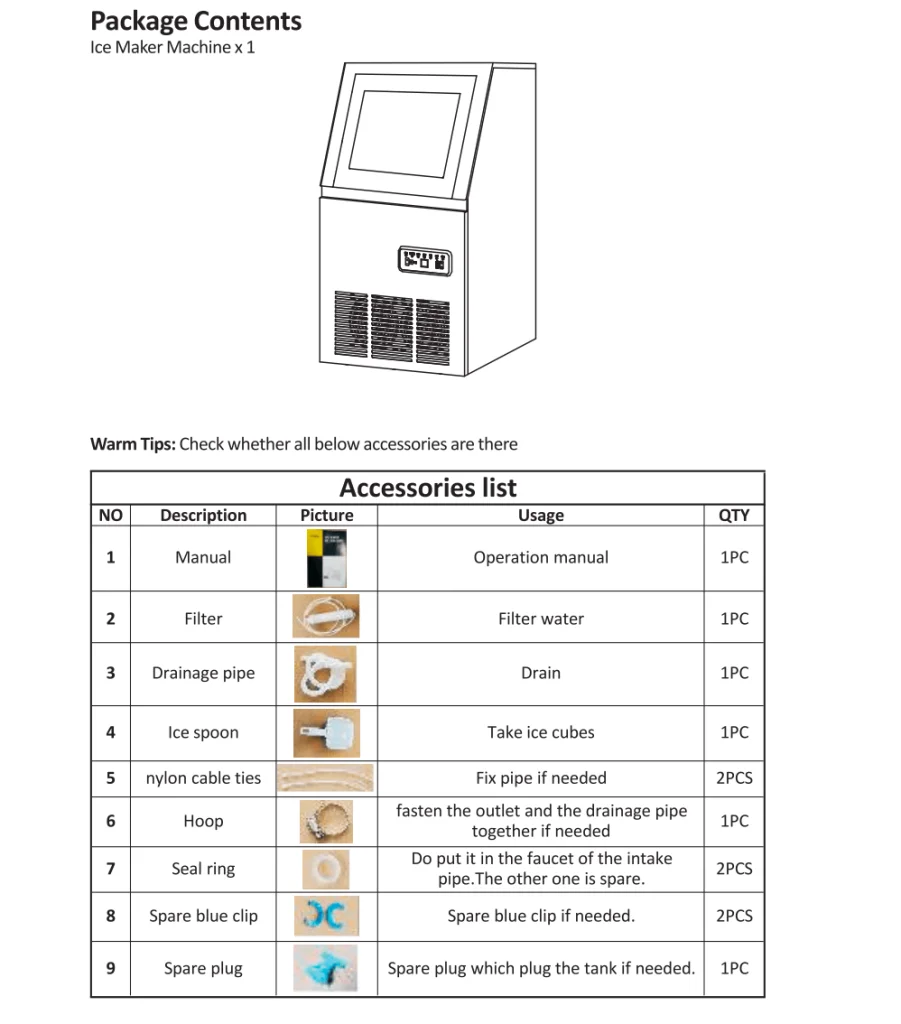

Overview of Components in Ice Makers

Understanding the key elements of a cooling system that produces frozen cubes is crucial for maintaining and troubleshooting these devices. Each component plays a specific role in the overall function, contributing to the efficient production of the frozen material. By familiarizing yourself with these elements, you can better manage performance and ensure optimal operation.

Main Elements of Cooling Systems

The core of the system includes a mechanism for controlling the cooling process, responsible for reducing temperatures to create the desired outcome. This process is supported by a compressor, which circulates refrigerant to remove heat. A set of coils, commonly called evaporators, absorbs this heat, aiding the freezing process.

Water System and Its Functions

The water system plays a crucial role in ensuring smooth and efficient operation of various mechanisms. It is responsible for maintaining the necessary flow and distribution of liquids within the unit, ensuring optimal performance across all connected components. A well-designed system helps maintain balance and prevents overheating, blockages, or interruptions.

Flow Regulation: One of the key functions is to control the movement of liquid through a series of channels and valves, ensuring that each part receives the required amount at the right time. This regulation helps maintain proper operation and reduces wear and tear on the components.

Filtration and Purification: The system often includes filters that remove impurities and ensure that only clean liquid circulates. This prevents contamination and

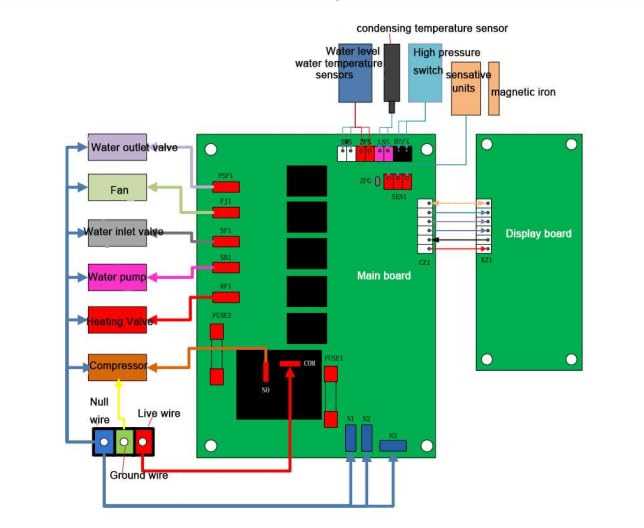

Electrical Parts and Their Roles

The electrical system within cooling and dispensing equipment is responsible for the operation and coordination of various components. Each element plays a vital role in ensuring efficient performance, from powering the unit to managing specific functions. Understanding how these elements contribute to overall functionality is key to troubleshooting and maintaining the system effectively.

Control Unit

The control unit serves as the central hub, regulating the activity of various elements in the system. It monitors inputs and sends signals to activate or deactivate certain components based on operational needs. This ensures that processes are executed in the correct sequence, maintaining proper functioning.

Power Supply and Wiring

The power supply provides the necessary energy to run the system. Wiring connects all components, allowing the safe and efficient transfer of electricity. Proper insulation and connection

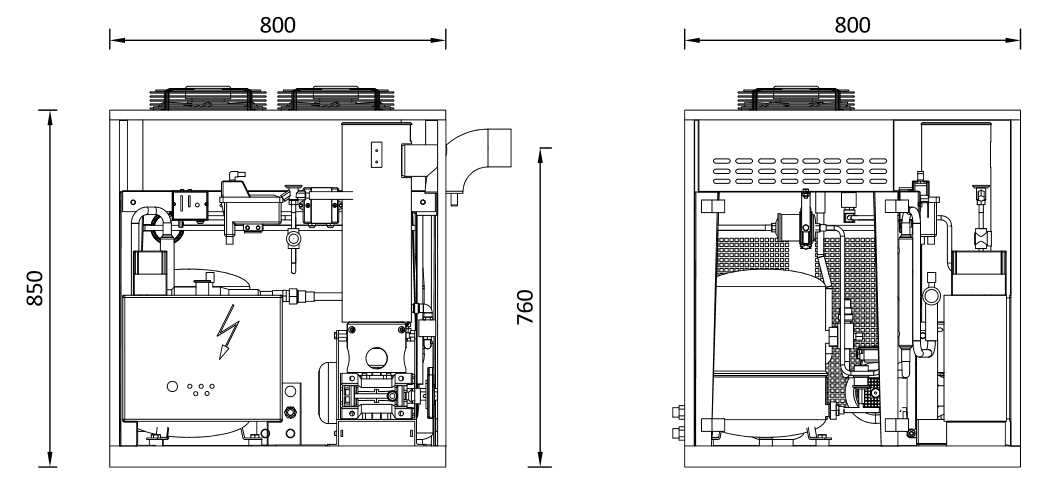

Cooling Mechanism Breakdown

The system responsible for temperature regulation operates through a series of interconnected components designed to control and reduce heat effectively. By understanding how each part works together, we can gain insight into the core processes that enable efficient cooling. This breakdown will explain the individual functions of the key elements and their roles in maintaining the desired temperature within the system.

Heat Exchange Process

The main goal of the cooling setup is to remove heat from a specific area. This is achieved through a heat exchange process that utilizes refrigerants to absorb and transfer thermal energy. As the refrigerant flows through the system, it passes through various stages where it undergoes compression, condensation, and evaporation. These transitions allow the system to effectively reduce temperature and expel excess heat.

Compressor and Condenser Functions

The compressor plays a crucial role by pressurizing the refrigerant, raising its

Ice Production Process Elements

The system responsible for forming solid, frozen water cubes involves a series of coordinated steps, each with a specific role in transforming liquid into a crystalline structure. Various components collaborate in this process, ensuring efficient performance and consistent output. Understanding these key stages helps to grasp how water transitions from liquid to solid form.

Water Inflow and Preparation

The journey begins with the flow of water into the system. At this point, filters and regulators ensure the liquid is clean and at an appropriate temperature. The water is then directed into the forming area where its state will undergo a transformation. The precision in this step is crucial for producing uniform results.

Cooling and Solidification

Once in the forming section, the liquid encounters surfaces that gradually lower its temperature. As cooling intensifies, a change in the molecular structure occurs, leading to solid formation. This transformation is closely monitored to ensure the consistency and clarity of each frozen block. The

Control System and Sensors in Machines

The operational efficiency of various industrial systems hinges on their control frameworks and sensor technologies. These components work in unison to monitor, regulate, and optimize processes, ensuring that systems function smoothly and meet desired performance criteria. By integrating sophisticated controls with precise detection mechanisms, industries can enhance productivity and reliability.

Role of Control Systems

Control systems serve as the brain of operational setups, making critical decisions based on input from sensors. They analyze data, execute commands, and adjust settings in real-time to maintain optimal functionality. This dynamic interaction not only enhances system responsiveness but also minimizes the risk of operational failures, leading to improved safety and efficiency.

Importance of Sensors

Sensors are essential for gathering data from the environment and providing valuable feedback to control systems. These devices can measure various parameters such as temperature, pressure, and humidity, facilitating informed decision-making. By deploying high-quality sensors, industries can achieve greater accuracy in monitoring and controlling their processes, ultimately resulting in enhanced performance and energy efficiency.

Cleaning and Maintenance Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your appliance. This involves not only routine cleaning but also replacing specific components that may wear out over time. Understanding the various elements involved in maintenance helps users maintain peak functionality and hygiene standards.

Essential Components for Upkeep

Several crucial elements contribute to the effective care of the device. Filters, for example, play a vital role in ensuring clean operation by trapping impurities and debris. Regular replacement of these filters helps in maintaining performance and efficiency. Additionally, seals and gaskets must be routinely checked for wear and tear, as compromised seals can lead to inefficiency and leaks.

Cleaning Techniques

Proper cleaning techniques are imperative for sustaining hygiene and functionality. Utilizing mild detergents and warm water can effectively remove residues without damaging sensitive components. It’s important to avoid abrasive materials that could scratch surfaces. Furthermore, ensuring all removable parts are thoroughly cleaned and dried before reassembly will prevent the buildup of mold or mildew.

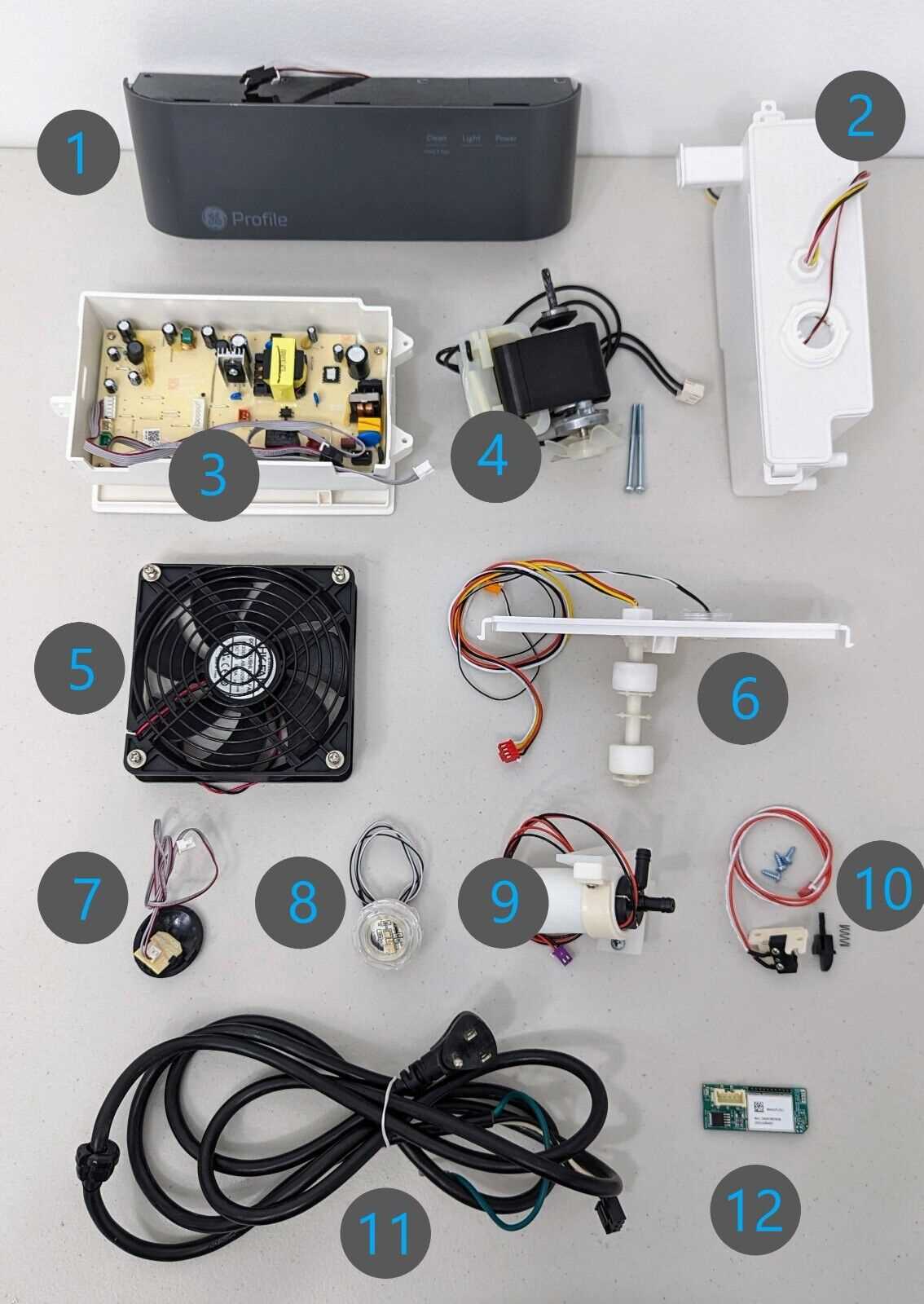

Common Replacement Parts and Their Uses

In any appliance designed for freezing and cooling, certain components may require periodic replacement due to wear and tear or operational inefficiencies. Understanding these elements can help users maintain optimal performance and extend the lifespan of their units. This section outlines the most frequently replaced components and highlights their specific functions within the overall system.

One of the essential elements is the compressor, which is responsible for circulating refrigerant and maintaining low temperatures. A malfunctioning compressor can lead to inadequate cooling, making it crucial to address issues promptly. Another significant component is the condenser coil, which dissipates heat generated during the cooling process. When this part becomes clogged or damaged, it can hinder the unit’s efficiency, leading to higher energy consumption and reduced cooling capacity.

The water inlet valve also plays a vital role, controlling the flow of water into the unit for freezing. If this valve fails, it may result in inadequate water supply, impacting the overall functionality. Additionally, the evaporator coil is essential for the freezing process, as it absorbs heat from the surrounding environment. Damage or blockage in this component can lead to inefficient freezing and increased operational costs.

Lastly, seals and gaskets are critical for maintaining proper insulation and preventing leaks. Worn or damaged seals can lead to energy loss and reduced efficiency, making their replacement essential for optimal performance. By understanding these common components and their functions, users can ensure their appliances operate effectively and efficiently.

How to Identify Faulty Components

Determining malfunctioning elements within a unit is essential for maintaining optimal performance. Recognizing signs of wear or dysfunction can prevent further damage and ensure efficient operation. By systematically examining each component, users can quickly pinpoint issues and decide on appropriate actions.

Here are some common indicators that can help in identifying problematic components:

- Unusual Noises: Listen for any strange sounds such as grinding, rattling, or buzzing that may indicate a mechanical issue.

- Inconsistent Performance: If the unit fails to operate consistently or shows fluctuations in output, it may signal a deeper problem.

- Leaks: Inspect for any fluid leaks, which can suggest issues with seals or connections.

- Increased Energy Consumption: A rise in energy bills without a clear reason can be a sign of inefficiency caused by failing elements.

- Error Codes: Pay attention to any displayed error codes, which often provide clues about the specific malfunction.

To effectively diagnose issues, follow these steps:

- Turn off the unit and disconnect it from the power supply for safety.

- Carefully inspect each component for visible damage or wear.

- Test electrical connections and sensors with appropriate tools to ensure they are functioning correctly.

- Consult the user manual for troubleshooting tips specific to your model.

- Consider reaching out to a professional technician if the issue remains unresolved.

Regular maintenance and timely identification of faulty elements will extend the lifespan of your unit and enhance overall efficiency.