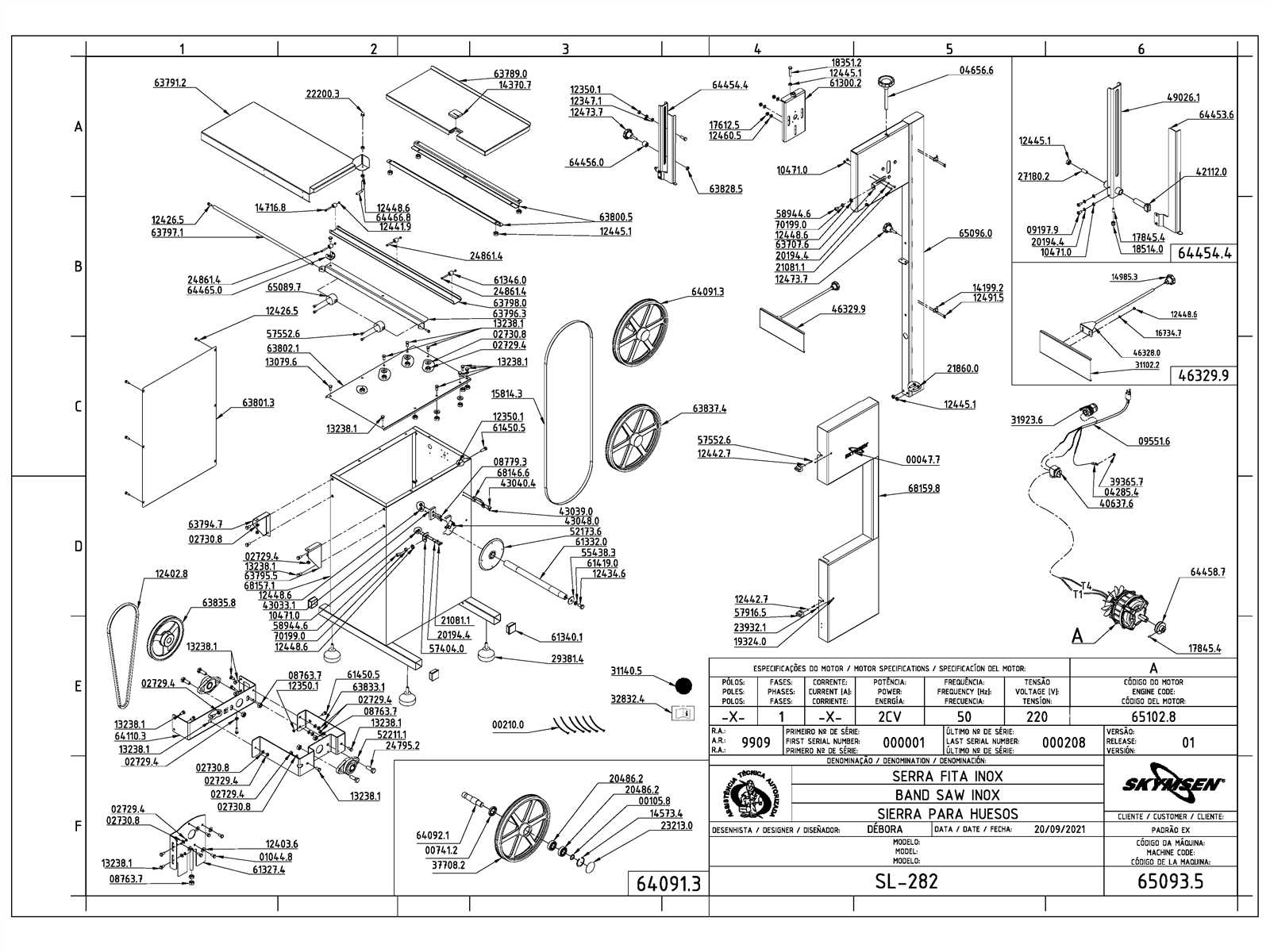

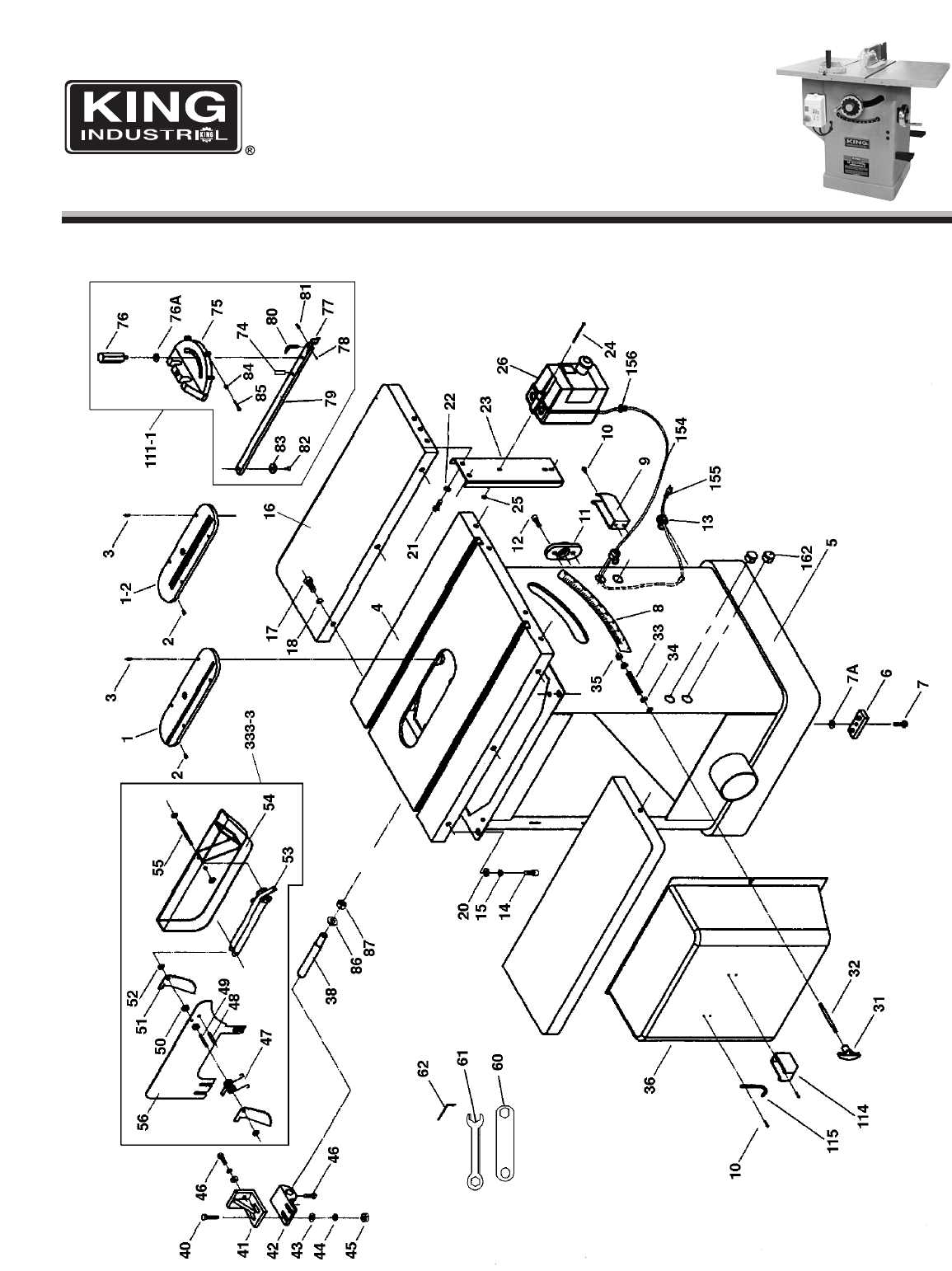

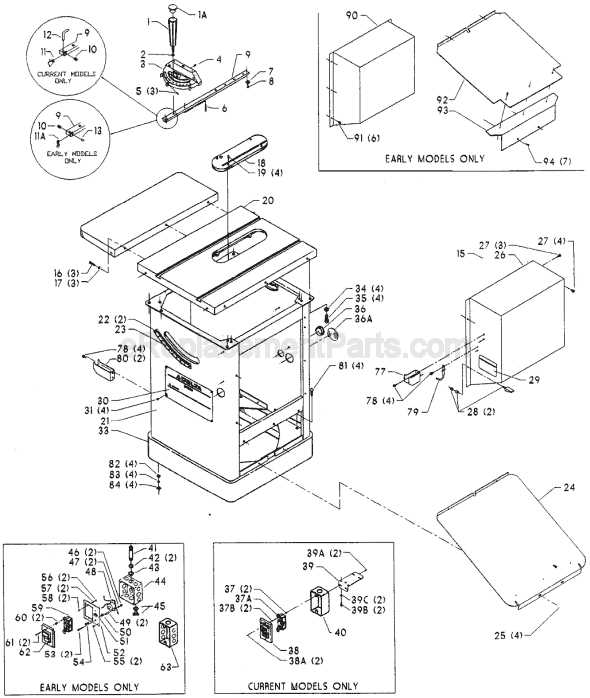

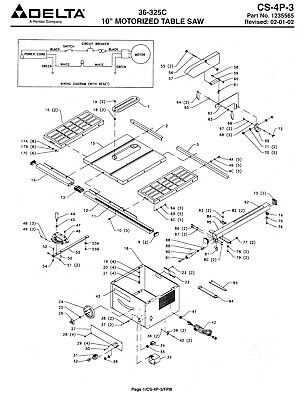

Understanding the structure of your equipment is essential for maintaining its efficiency and ensuring long-lasting performance. A well-organized breakdown of the various elements within a cutting device provides clarity on how each section works together to deliver precise results. By studying the arrangement of these mechanical components, you can better identify potential issues and optimize functionality.

In this guide, we explore the internal configuration of a widely-used cutting machine, giving attention to each individual mechanism. We will highlight how different segments connect, function, and contribute to the overall operation. This information is crucial for anyone looking to fine-tune or repair their equipment, ensuring it continues to operate smoothly and efficiently over

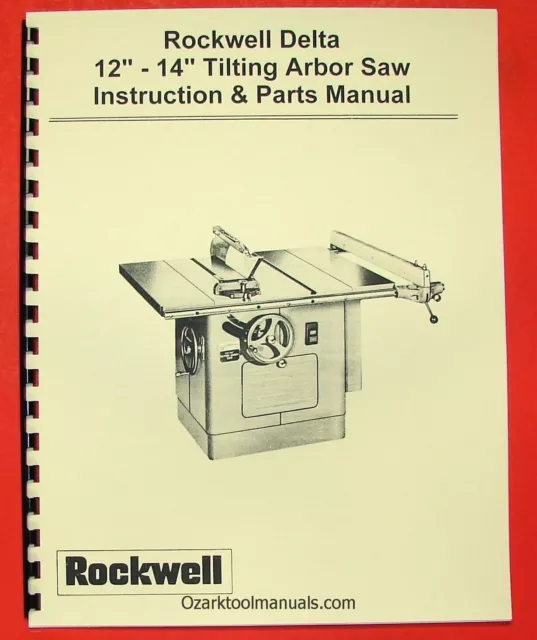

Understanding the Components of a Precision Cutting Machine

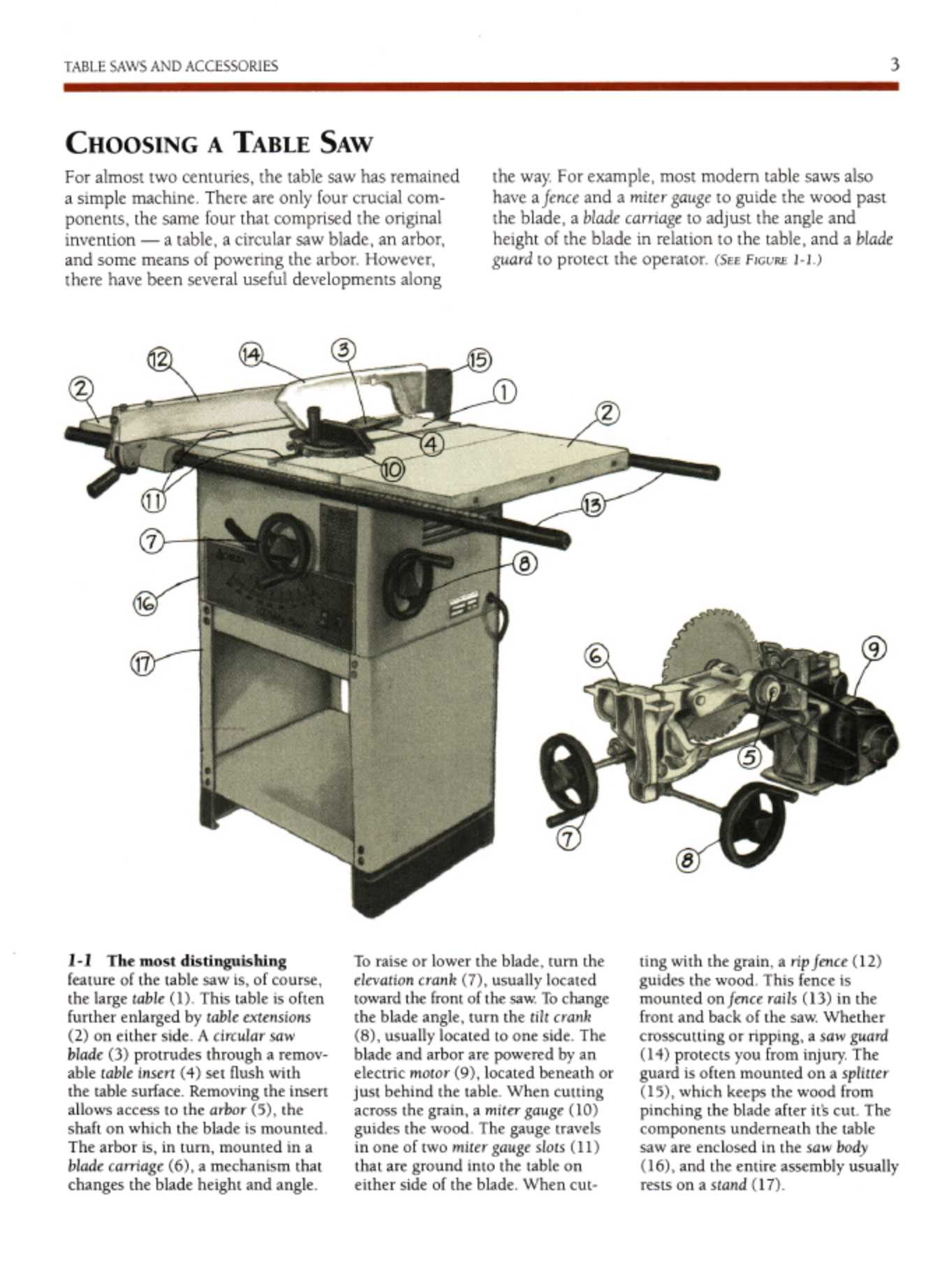

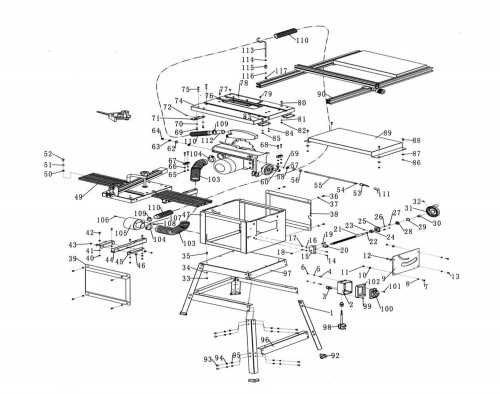

The structure of a precision cutting machine consists of various key elements that work together to deliver accurate and efficient results. By examining the different mechanisms involved, users can better appreciate how each piece contributes to the overall functionality. This knowledge can be helpful for both maintenance and optimization of the equipment’s performance.

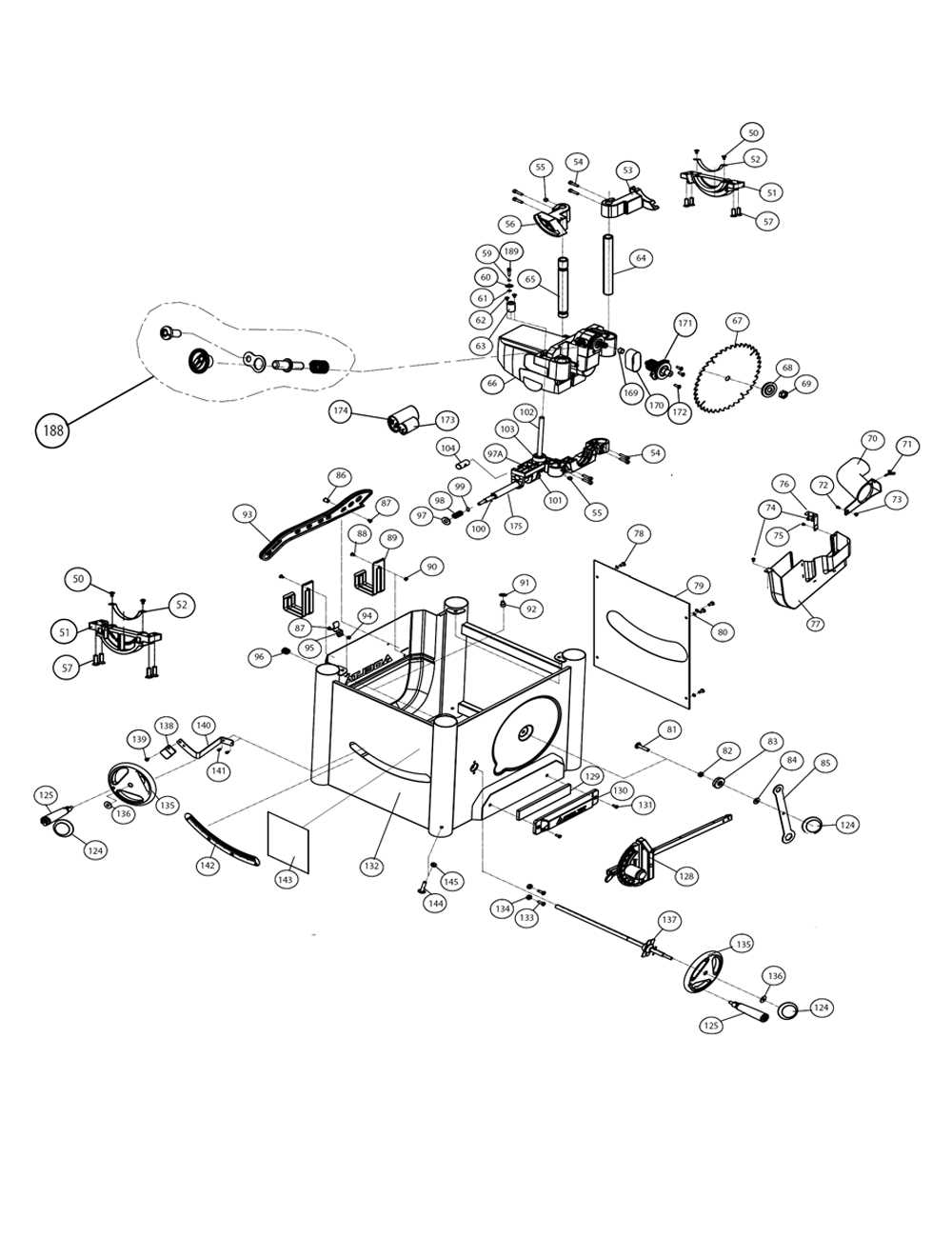

Motor Assembly: The central driving force behind the machine, the motor powers the entire system, ensuring smooth operation and consistent cutting power. Regular maintenance of this element is crucial for long-term reliability.

Blade Mechanism: The rotating blade is the primary tool for cutting, and its sharpness and alignment are vital for precision. Proper adjustment of the blade enhances both the accuracy and safety of the operation.

Fence System:

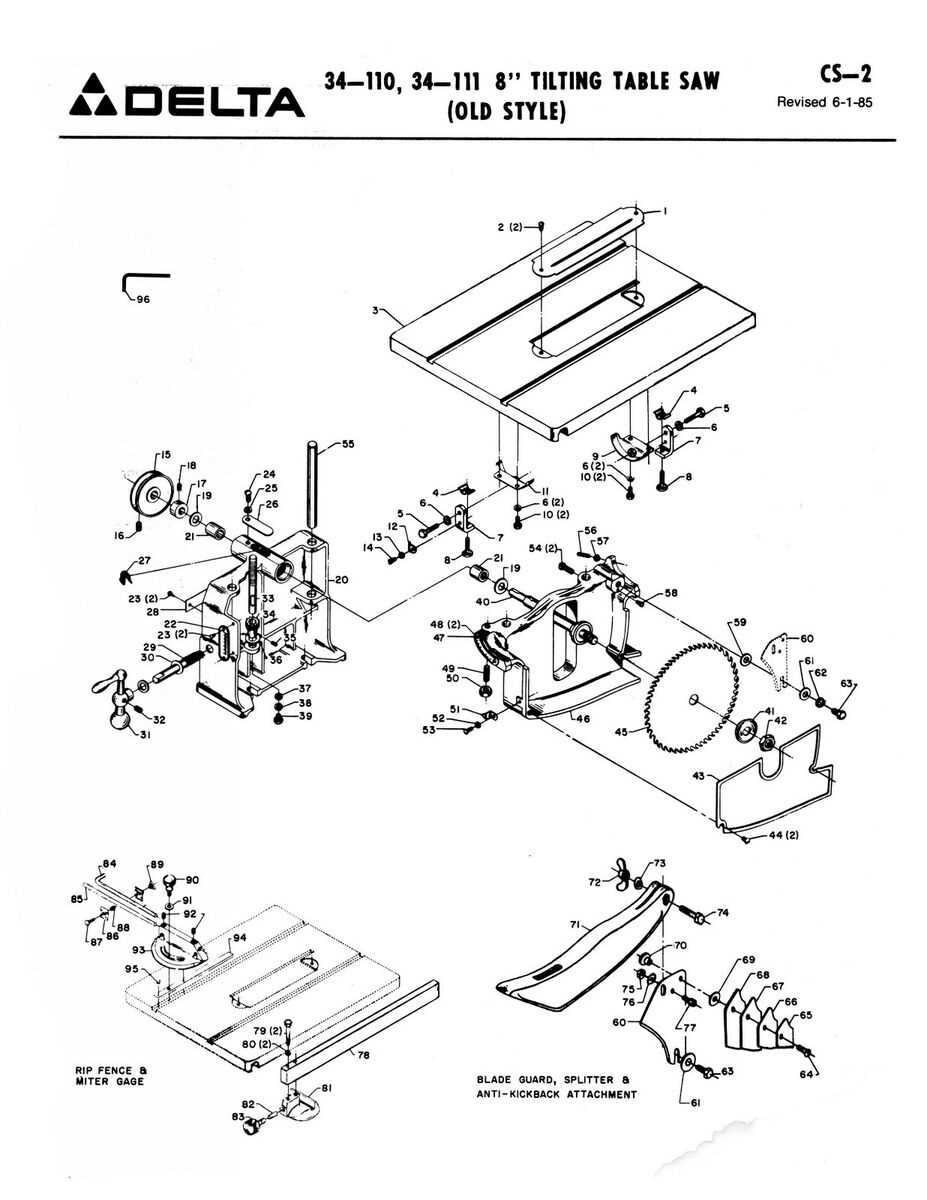

Exploring the Blade Assembly

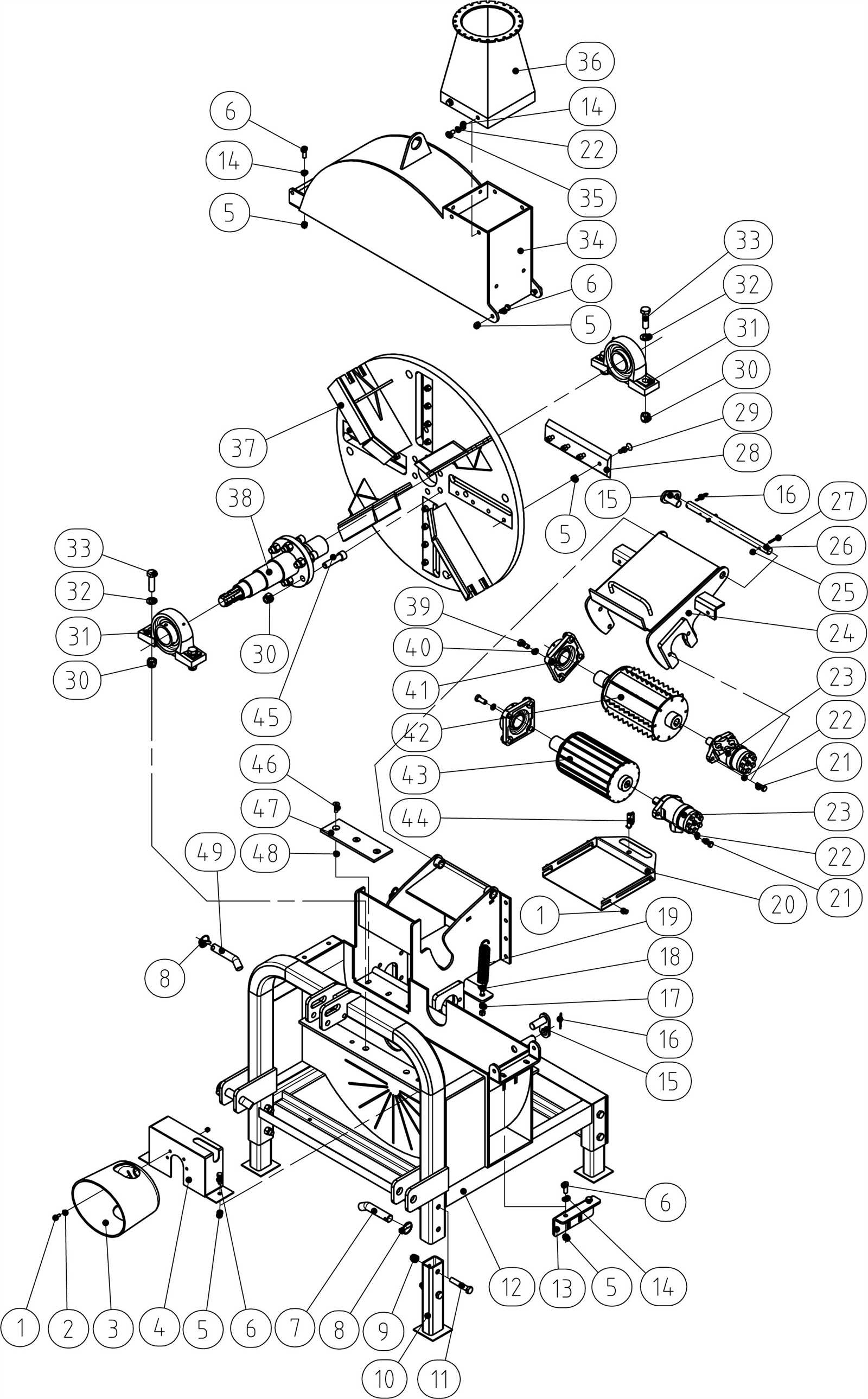

The blade assembly is a critical component in ensuring the efficiency and precision of woodworking operations. Understanding the individual elements that form this system can help maintain its functionality and enhance performance during use. Each part plays a significant role in providing stability, accuracy, and safety during cutting tasks.

At the heart of the assembly is the cutting disc itself, which is mounted securely and designed to rotate at high speeds. Surrounding components, such as the arbor and its locking mechanisms, ensure the blade remains stable while in motion. Other parts, including the guard system and height adjustment mechanisms, provide additional safety and flexibility for various types of cuts.

Regular maintenance of these elements not only extends their lifespan but also ensures that cutting operations remain smooth and efficient. Proper care, such as regular cleaning and alignment, is essential to keep the entire assembly functioning optimally, reducing wear and potential damage over time.

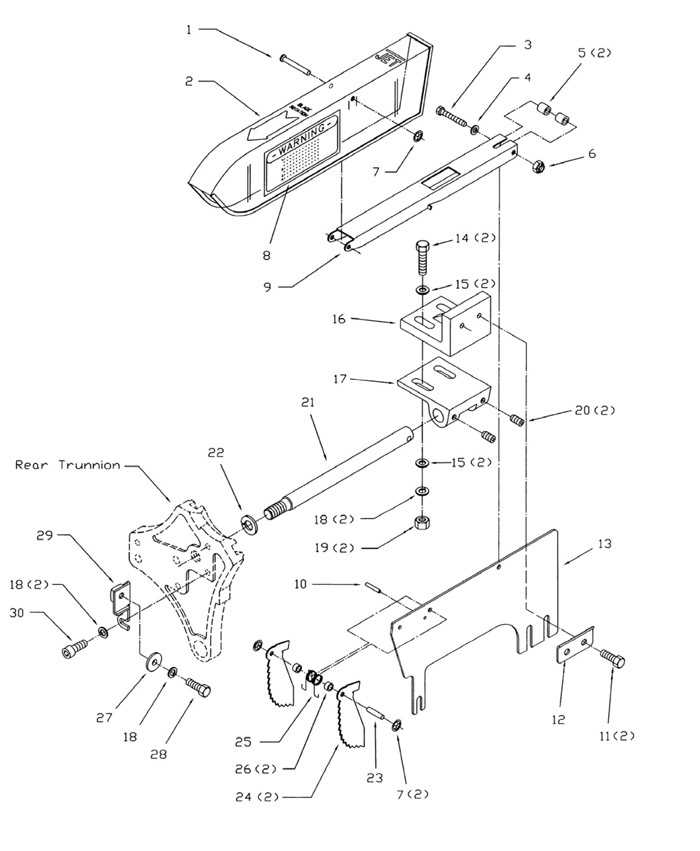

Guide to the Motor System

The motor system plays a crucial role in ensuring the efficiency and performance of machinery. Understanding its components and functionality is essential for proper maintenance and optimal operation. This section will provide an overview of the key elements that make up this vital system, offering insights into their interaction and importance in the overall mechanism.

| Component | Function | Maintenance Tip |

|---|

| Component | Function | Importance |

|---|---|---|

| Arbor | Holds the cutting blade | Ensures stability and alignment |

| Bearings | Reduces friction | Enhances smooth operation |

Regular inspection and maintenance of these components are vital to prevent potential issues such as misalignment or excessive wear. Ensuring that the arbor is securely fastened and the bearings are well-lubricated will significantly improve the cutting tool’s performance and lifespan.

The Role of the Dust Collection Port

Efficient debris management is crucial for maintaining a clean and safe workspace when working with power tools. A well-designed dust extraction system plays a significant role in ensuring that particles generated during operation are effectively removed. This not only enhances visibility but also promotes a healthier environment for users.

Improving Air Quality

The presence of a dedicated extraction outlet helps to minimize airborne contaminants. By connecting a vacuum or filtration system, the tool can significantly reduce the amount of sawdust and wood shavings in the air, leading to improved respiratory conditions for users. This is particularly important in enclosed areas where ventilation may be limited.

Enhancing Tool Performance

Effective dust management also contributes to optimal tool functionality. By reducing the accumulation of debris around the working area, the device can operate more smoothly, leading to better precision and reduced wear on components. A clean workspace ensures that users can focus on their tasks without the distraction of clutter.

Identifying Common Switch Mechanisms

Understanding the various control devices is crucial for effective operation and safety of woodworking equipment. These components enable users to start, stop, and control the machinery, ensuring a smooth workflow. This section will explore different types of mechanisms commonly found in these tools, providing insights into their functionality and features.

Types of Control Devices

- Toggle Switches: These are simple on/off devices that provide a straightforward means of operation. They are often used for basic control tasks.

- Push Button Switches: Designed for ease of use, these mechanisms allow users to activate the tool with a simple press, often incorporating safety features to prevent accidental activation.

- Rotary Switches: These allow users to select from multiple settings by rotating a knob. They are beneficial for adjusting various speeds or operational modes.

- Foot Switches: Ideal for hands-free operation, these devices enable users to control the equipment with their feet, enhancing safety and convenience during work.

Key Features to Consider

- Durability: Look for mechanisms made from robust materials to withstand frequent use and wear.

- Ergonomics: Consider the design that promotes ease of use, allowing for quick and comfortable operation.

- Safety Features: Check for built-in safety mechanisms, such as emergency stop buttons or protective covers, to minimize risk during operation.

Maintenance Tips for Moving Parts

Ensuring the smooth operation of components that undergo regular motion is vital for the longevity and efficiency of your equipment. Proper upkeep helps in preventing wear and tear, reducing the risk of malfunction, and enhancing overall performance. Implementing a routine maintenance schedule can significantly improve the reliability of these mechanisms.

Here are some essential maintenance tips to consider:

- Regular Cleaning: Keep all moving components free of dust and debris. Use a soft brush or compressed air to remove particles that can cause friction or blockage.

- Lubrication: Apply appropriate lubricants to moving surfaces to minimize friction. Follow the manufacturer’s recommendations for types and frequencies of lubrication.

- Inspection: Periodically check for signs of wear or damage. Look for cracks, chips, or deformation that could affect performance.

- Alignment Checks: Ensure that all components are properly aligned. Misalignment can lead to uneven wear and operational inefficiencies.

- Adjustment of Tension: Make sure that any belts or chains are correctly tensioned. Improper tension can lead to slippage or excessive strain on components.

By following these guidelines, you can enhance the performance and lifespan of the moving elements within your machinery, ensuring consistent and reliable operation.