When it comes to the maintenance and functionality of compact digging machinery, having a comprehensive grasp of its internal structure is crucial. Each element plays a vital role in the overall performance, making it imperative for operators and technicians to familiarize themselves with these intricacies.

In this section, we will explore the various segments that constitute a specific model of a compact excavator. By delving into the relationship between these components, users can better appreciate how they interact to enhance productivity and ensure longevity.

Understanding these elements not only aids in effective troubleshooting but also empowers operators to make informed decisions regarding repairs and upgrades. Equipped with this knowledge, you can optimize your equipment’s capabilities and reduce downtime significantly.

Kubota KX040 Overview

This compact machine exemplifies versatility and power, designed to tackle a variety of tasks efficiently. Its robust engineering allows for exceptional performance in confined spaces, making it an ideal choice for construction and landscaping projects.

Equipped with advanced technology, this model ensures optimal productivity and ease of use. The user-friendly controls and ergonomic design enhance operator comfort, reducing fatigue during long working hours.

Notably, the durability of this machine stands out, offering reliability in challenging conditions. With a focus on performance, it effectively balances strength and agility, making it a valuable asset for any professional operation.

Key Features of KX040

This section explores the essential attributes of a popular compact excavator, highlighting its capabilities and advantages for various applications in construction and landscaping.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that ensures high performance and efficiency. |

| Compact Design | Designed to navigate tight spaces while maintaining stability and power. |

| Versatile Attachments | Compatible with a range of tools for diverse tasks, enhancing productivity. |

| User-Friendly Controls | Intuitive controls that allow for ease of operation and quick learning. |

| Durable Build | Constructed with high-quality materials to withstand rigorous work environments. |

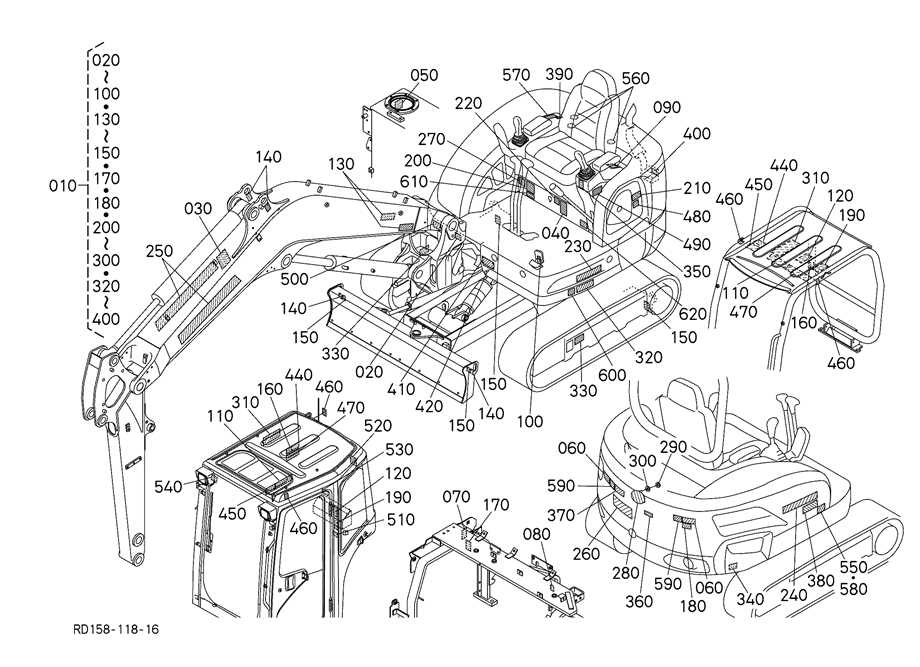

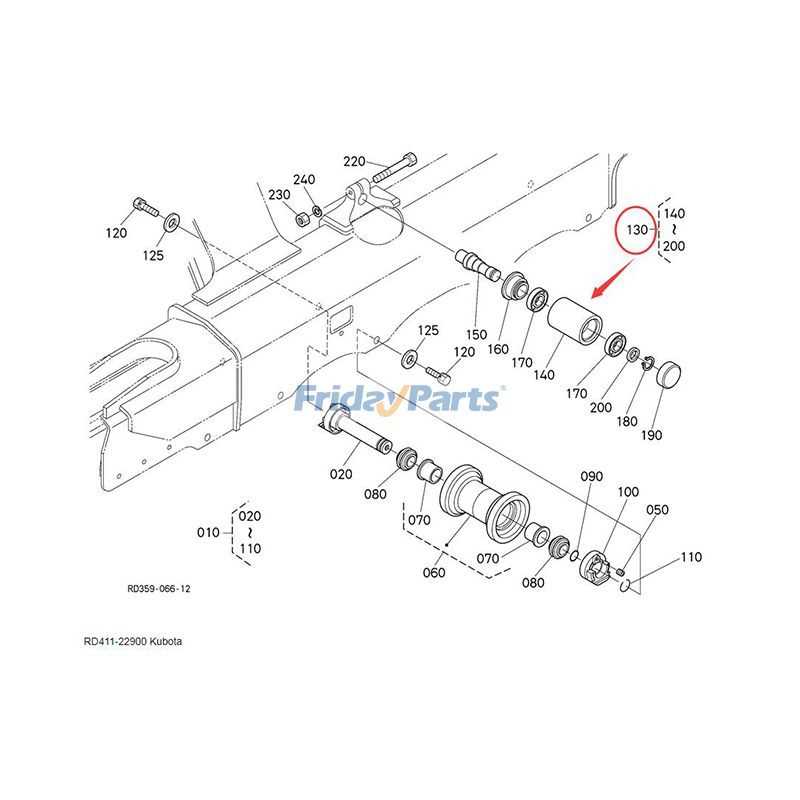

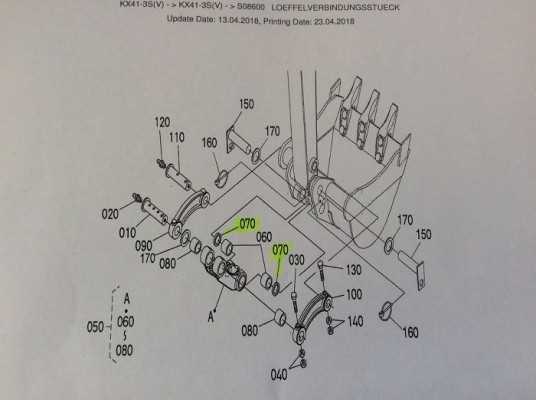

Understanding the Parts Diagram

Comprehending the schematic representation of machinery components is essential for effective maintenance and repair. This visual guide helps users identify each segment and understand its function within the larger system.

- Identification: Recognizing different elements aids in troubleshooting issues.

- Organization: A well-structured layout facilitates easier access to information.

- Communication: Clear labels and symbols enhance understanding among technicians.

By mastering this graphical tool, operators can enhance their skills and ensure optimal performance of their equipment.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the effective maintenance and operation of machinery. They provide essential guidance, ensuring that users can easily identify components and understand their relationships, leading to improved performance and safety.

Benefits of Detailed Illustrations

- Enhance understanding of complex systems.

- Facilitate quicker repairs and troubleshooting.

- Reduce the risk of errors during assembly or disassembly.

Impact on Efficiency

- Streamlined workflows due to clear visual guidance.

- Minimized downtime with accurate information at hand.

- Improved training for new operators through accessible resources.

Common Components in KX040

The efficient functioning of any machinery relies on a variety of essential elements that work together seamlessly. Understanding these components can greatly enhance maintenance practices and overall performance. This section delves into the key parts that are integral to the operation of this particular excavator model.

Engine: The heart of the machine, responsible for generating power. It ensures that all other systems operate smoothly and effectively.

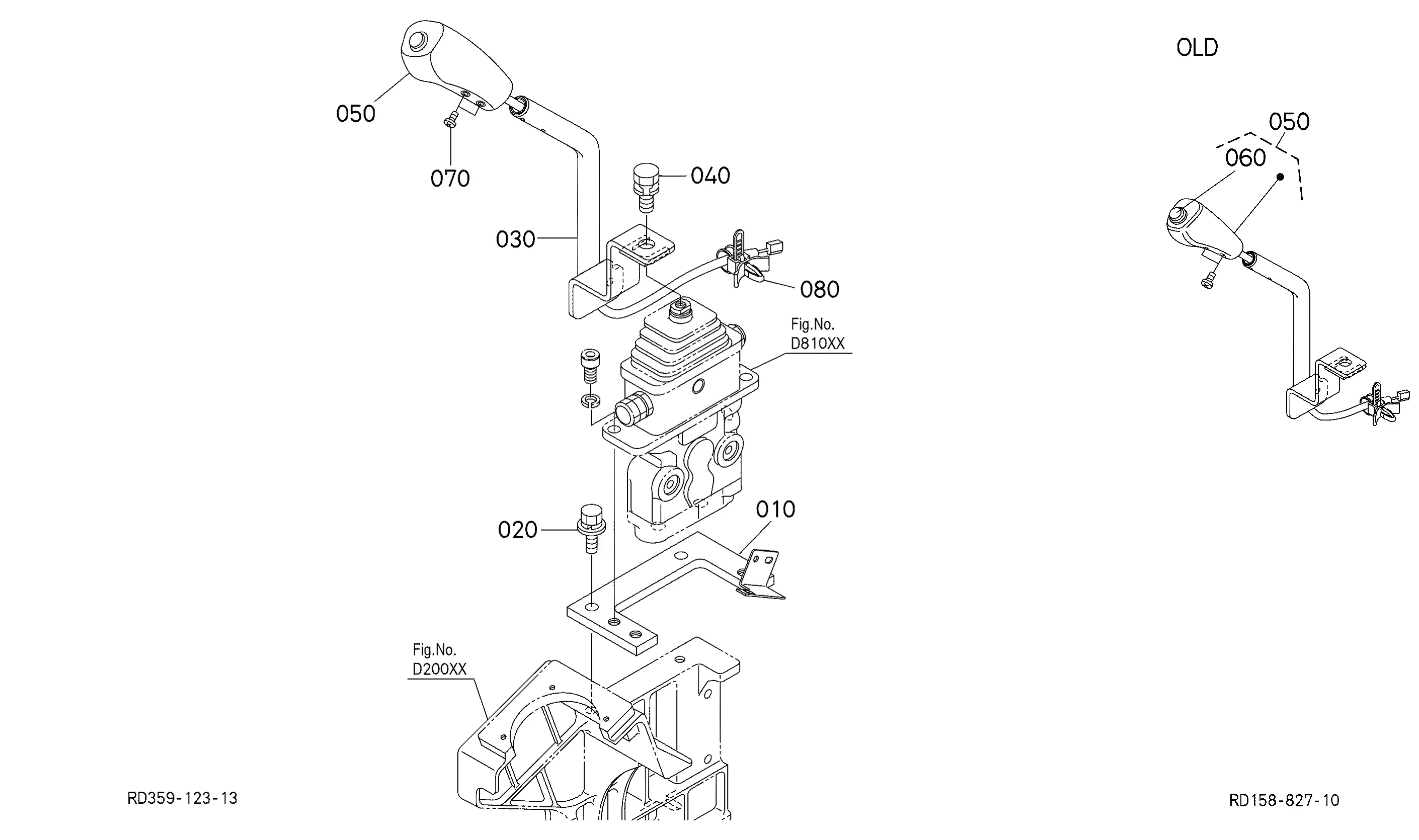

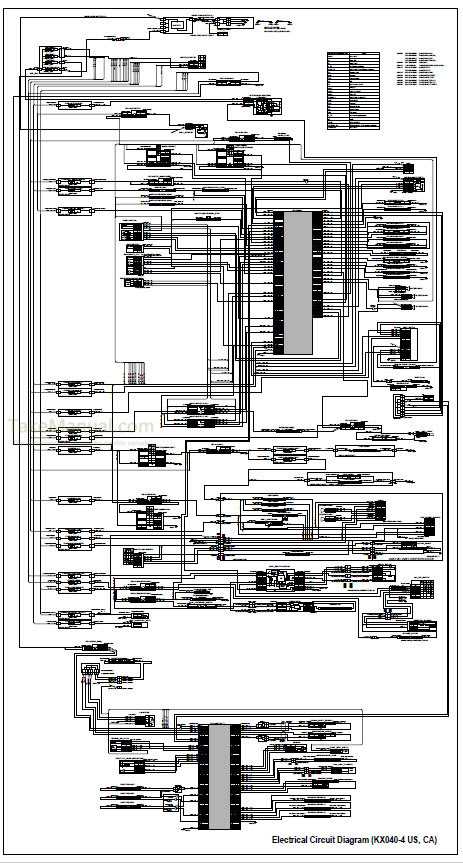

Hydraulic System: A crucial assembly that facilitates movement and operation of attachments. It converts engine power into hydraulic energy, enabling various functions such as lifting and digging.

Undercarriage: This assembly provides stability and mobility. It supports the entire structure and is designed to withstand rigorous terrains, ensuring the machine can navigate various job sites.

Cabin: The operator’s workspace, equipped with controls and visibility enhancements. A well-designed cabin improves operator comfort and efficiency, contributing to safer operations.

Attachments: Versatile tools that can be swapped depending on the task at hand. They enhance the machine’s functionality, allowing it to perform a wide range of activities, from digging to grading.

By familiarizing oneself with these components, operators can better understand their machine’s capabilities and ensure optimal performance through proper care and maintenance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires a systematic approach to upkeep and care. Regular maintenance not only enhances performance but also prevents costly breakdowns. By adhering to a few essential practices, you can keep your equipment operating efficiently and reliably over time.

Start with routine inspections to identify any signs of wear and tear. Check fluid levels, filters, and belts, making necessary adjustments or replacements promptly. Clean components regularly to prevent debris buildup that can hinder functionality.

Following the manufacturer’s guidelines for servicing is crucial. Adhering to recommended schedules for oil changes and system checks ensures that your machinery remains in peak condition.

Investing in quality parts during repairs can significantly impact durability. Using original or high-grade replacements minimizes the risk of failure and enhances overall performance.

Lastly, maintaining a proper operating environment contributes to longevity. Keep the equipment sheltered from extreme weather conditions and ensure it is stored in a clean, dry area when not in use.

How to Read the Diagram

Understanding a technical illustration can greatly enhance your ability to maintain and repair machinery. These visuals provide a comprehensive overview of the components and their interrelations, making it easier to identify parts and troubleshoot issues. Familiarity with the layout and symbols used is essential for effective interpretation.

Begin by examining the legend or key, which explains the symbols and annotations. This will give you insight into the specific elements represented in the visual. Next, follow the flow of connections and relationships between components, as this will help you grasp how the system operates as a whole. Pay close attention to any highlighted sections or notes that might indicate critical points or special instructions.

Finally, practice by cross-referencing the illustration with the physical unit. This hands-on approach will solidify your understanding and enhance your skills in navigating similar visuals in the future. With time and experience, you will find that these resources are invaluable in mastering equipment maintenance.

Resources for Parts Replacement

Finding the right components for machinery maintenance can be a challenging task. It is essential to have access to reliable sources that provide accurate information and quality products. Whether you are a professional technician or a DIY enthusiast, knowing where to look can significantly simplify the replacement process.

Here are some valuable resources to consider:

- Official Manufacturer Websites: These platforms often have detailed catalogs and guides that can help you identify the necessary items.

- Online Retailers: Numerous e-commerce sites specialize in machinery components, offering competitive prices and customer reviews.

- Local Dealers: Authorized dealers can provide original parts and expert advice tailored to your specific needs.

- Forums and Community Groups: Engaging with online communities can yield practical insights and recommendations from fellow users.

- Repair Manuals: These documents often contain extensive information on replacement procedures and compatible components.

Utilizing these resources can ensure that you find the correct items needed for effective maintenance and repair, ultimately enhancing the performance and longevity of your equipment.