In modern heating solutions, a thorough understanding of the various elements involved is essential for efficient operation and maintenance. Each component plays a vital role in the overall functionality of the system, ensuring reliable performance throughout the colder months. Knowledge of these essential features not only aids in troubleshooting but also enhances the effectiveness of heating practices.

The intricate arrangement of these elements can be quite complex, but a clear overview allows users to grasp how each section contributes to the entire system. Recognizing the functions and interactions between different segments can significantly improve decision-making when it comes to repairs and upgrades.

For those looking to optimize their heating experience, familiarizing themselves with these key components is invaluable. Understanding their respective roles empowers users to maintain their systems efficiently and make informed choices regarding future enhancements.

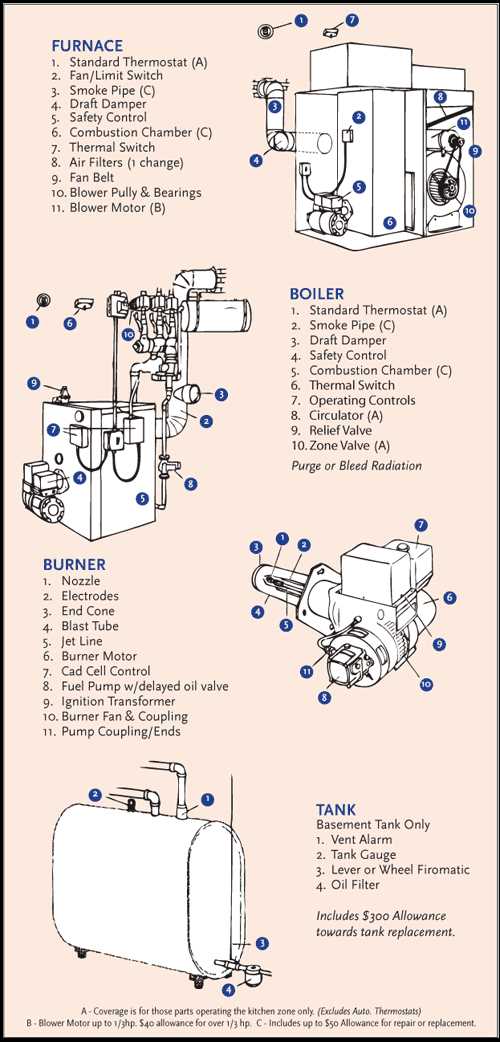

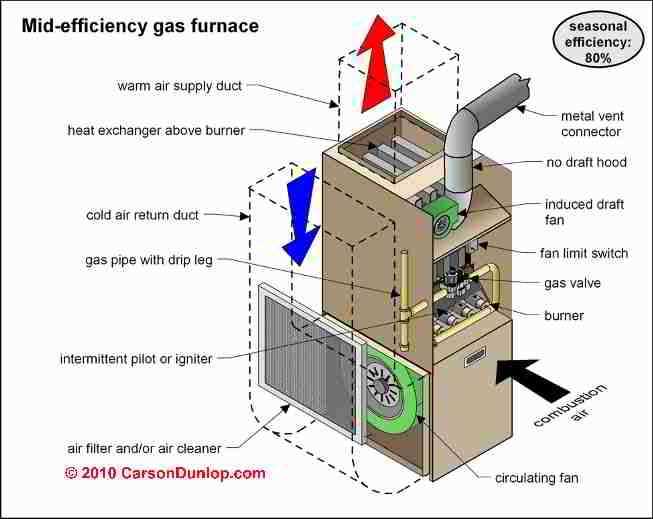

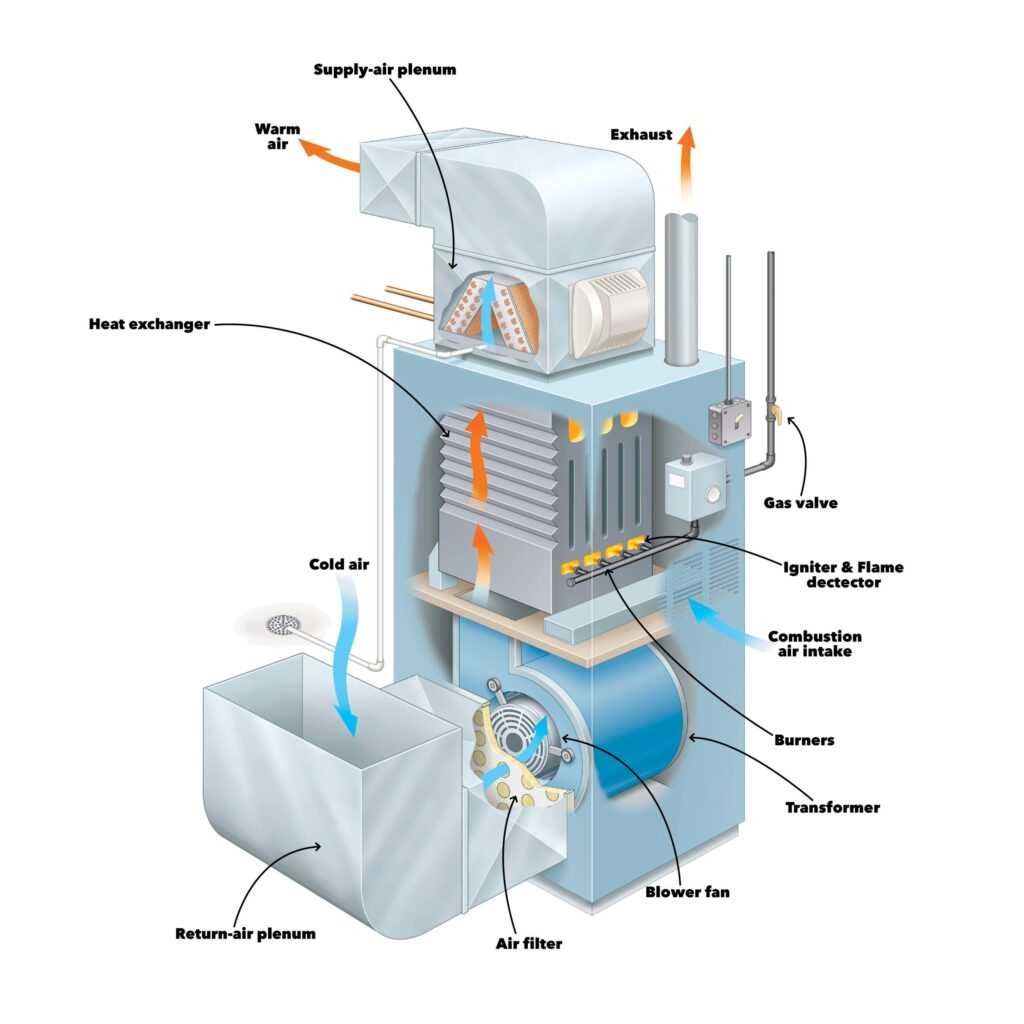

The functionality of heating systems relies on several crucial elements that work in unison to provide warmth and comfort. Understanding these components can help users maintain and troubleshoot their equipment effectively.

- Burner: This is the unit responsible for igniting the fuel to produce heat. It plays a vital role in the efficiency of the system.

- Heat Exchanger: This component transfers the generated heat to the air or water that circulates throughout the living space.

- Fuel Tank: A storage unit that holds the heating material, ensuring a continuous supply for the burner.

- Blower Motor: This motor powers the fan that circulates warm air throughout the building.

- Thermostat: A control device that regulates the temperature by turning the heating system on or off based on the desired settings.

- Flue Pipe: An exhaust system that vents combustion gases safely outside, preventing harmful buildup within the living area.

Each of these elements is integral to the overall operation of the heating mechanism, ensuring optimal performance and efficiency. Regular maintenance and understanding of these components can lead to improved longevity and functionality.

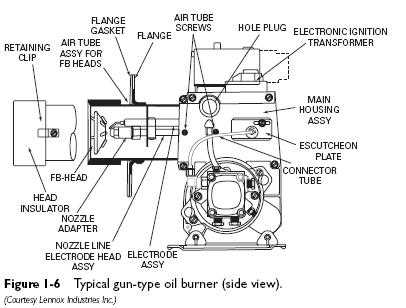

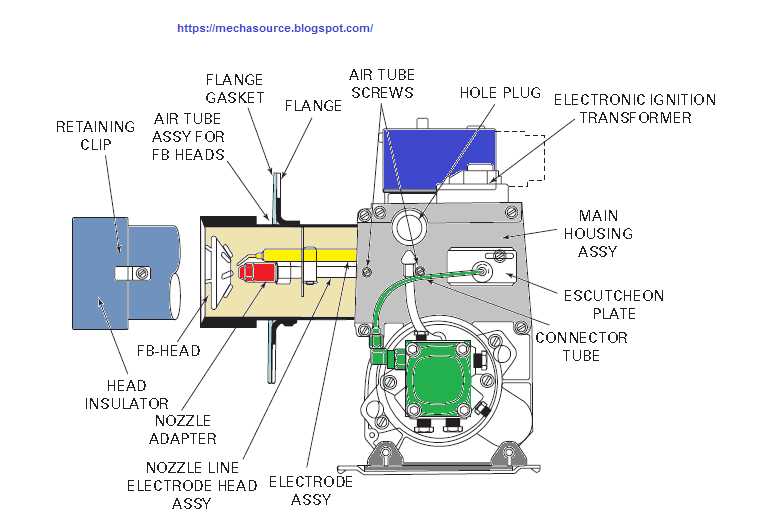

How Oil Burners Function

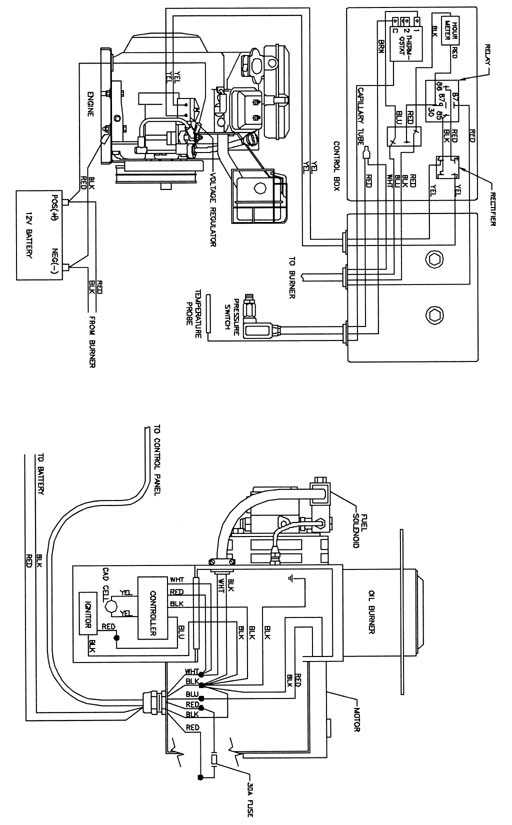

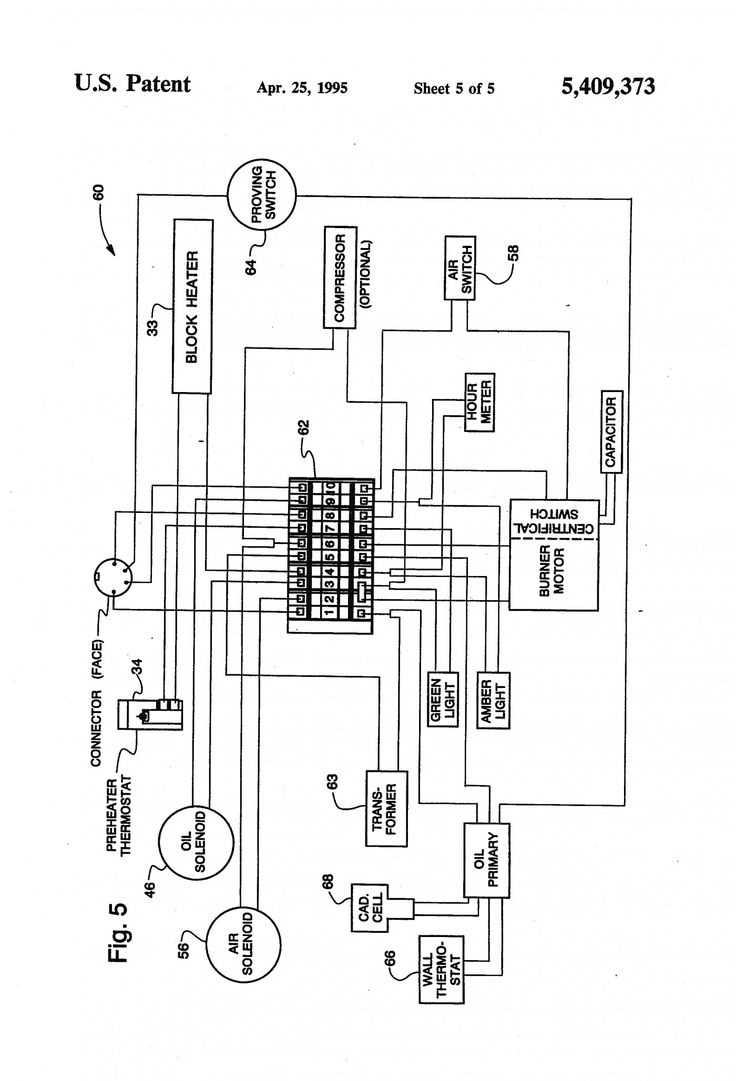

The process of converting liquid fuel into heat energy is vital for many heating systems. This mechanism involves a series of components that work in unison to ensure efficient combustion and optimal performance. Understanding the inner workings of this system helps in maintaining and troubleshooting it effectively.

Components Involved in the Process

At the core of this heating system is a device that atomizes the fuel, creating a fine mist that mixes with air for improved combustion. This atomization is crucial for achieving the right fuel-to-air ratio, allowing for a clean and efficient burn. Additionally, an ignition source ignites the mist, initiating the heating cycle.

Efficiency and Maintenance

To maximize energy output and reduce emissions, regular maintenance is essential. Ensuring that filters are clean and the atomization process is functioning correctly prevents buildup and inefficiencies. Monitoring these factors can lead to enhanced performance and longevity of the heating system.

Key Safety Features in Oil Furnaces

Ensuring the protection of users and property is paramount in heating systems. Various safety mechanisms are integrated to minimize risks and enhance reliability. Understanding these features is essential for effective operation and maintenance.

- Automatic Shut-off: This mechanism activates when irregularities are detected, preventing overheating or potential hazards.

- Flame Sensors: These components monitor the presence of a flame and will shut down the system if the flame is extinguished, ensuring safe operation.

- Pressure Relief Valves: These valves are designed to release excess pressure, protecting the system from damage and reducing the risk of explosions.

- Emergency Switch: A conveniently located switch allows for immediate shutdown in case of emergencies, providing quick access for users.

- Ventilation Controls: Proper ventilation is crucial; these controls ensure that exhaust gases are expelled safely, minimizing the risk of harmful emissions.

Regular maintenance and awareness of these critical safety features contribute to the overall efficiency and security of heating systems.

Maintenance Tips for Oil Furnace Parts

Regular upkeep of heating systems is essential for their efficiency and longevity. Proper maintenance helps identify potential issues before they escalate, ensuring a comfortable environment during colder months.

1. Regular Inspections: Schedule routine evaluations of your heating system to catch any signs of wear or damage early. Checking components such as filters, burners, and exhaust systems can prevent larger malfunctions.

2. Cleaning: Keep the interior of the system clean by removing dust and debris. This helps maintain optimal airflow and combustion efficiency. Pay special attention to the combustion chamber and surrounding areas.

3. Replace Filters: Changing air filters regularly is crucial for maintaining air quality and system performance. Dirty filters can restrict airflow and reduce efficiency, leading to increased energy consumption.

4. Monitor Fuel Levels: Keep an eye on fuel levels to avoid running out during peak usage times. Maintaining adequate fuel ensures consistent heating and reduces the risk of system strain.

5. Professional Servicing: Consider hiring a qualified technician for annual maintenance. Professionals can conduct comprehensive inspections and perform necessary repairs, ensuring the system operates safely and efficiently.

6. Safety Checks: Regularly test safety controls and emergency shut-off features. Ensuring these functions work correctly is vital for the safe operation of your heating system.

Identifying Common Oil Furnace Issues

Understanding the typical problems that can arise in heating systems is essential for maintaining optimal performance and efficiency. By recognizing these issues early, homeowners can prevent costly repairs and ensure a comfortable environment during colder months.

- Unusual Noises: Grinding, rattling, or squealing sounds may indicate loose components or worn-out parts that require attention.

- Inconsistent Heating: Fluctuating temperatures or cold spots in various rooms often suggest airflow problems or malfunctioning elements.

- Increased Energy Bills: A sudden rise in energy costs can be a sign of inefficiency, potentially due to dirt buildup or mechanical failures.

- Strange Odors: Unpleasant smells, particularly a strong burning or acrid scent, may indicate overheating or electrical issues.

- Frequent Cycling: If the system turns on and off excessively, it could be a sign of a faulty thermostat or other control problems.

Addressing these concerns promptly can help maintain system efficiency and prolong its lifespan. Regular maintenance and inspections are key to avoiding severe malfunctions.

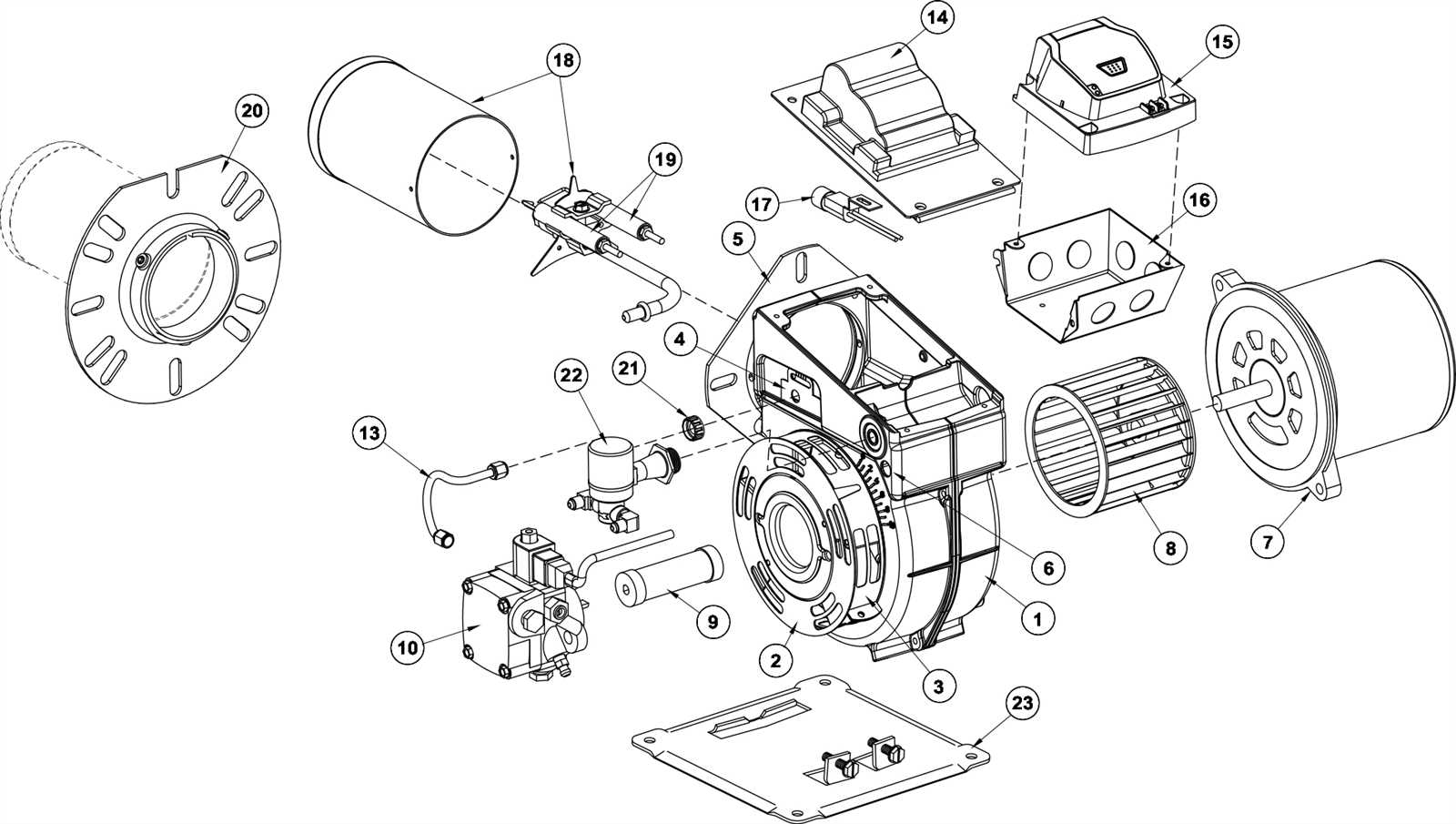

Replacement Parts for Oil Furnaces

When it comes to maintaining heating systems, having access to quality components is essential for optimal performance. Whether it’s for a repair or an upgrade, understanding the various elements involved can enhance efficiency and extend the lifespan of the equipment.

Key Components to Consider

- Burners: Responsible for igniting the fuel, ensuring proper combustion.

- Filters: Vital for maintaining clean airflow and preventing contaminants from entering the system.

- Blowers: Essential for circulating heated air throughout the space.

- Thermostats: Control the temperature settings, providing user convenience and energy efficiency.

Common Replacement Options

- Aftermarket alternatives: Often more affordable, but quality can vary.

- OEM components: Manufactured by the original company, ensuring compatibility and reliability.

- Upgraded models: Offer improved performance or energy efficiency compared to standard options.

Benefits of Upgrading Oil Furnace Components

Enhancing the individual elements of a heating system can lead to significant improvements in efficiency, comfort, and safety. Upgrading these components not only optimizes performance but also contributes to long-term savings and environmental sustainability. With advancements in technology, modern replacements offer numerous advantages over older versions.

Improved Efficiency

One of the primary benefits of updating these crucial elements is the increase in overall efficiency. Newer components are designed to maximize energy use, reducing fuel consumption and lowering utility bills. As a result, homeowners can enjoy consistent warmth without the burden of escalating costs.

Enhanced Safety Features

Modern upgrades often come with advanced safety mechanisms. By incorporating state-of-the-art technology, these innovations minimize risks associated with heating systems, providing peace of mind for users. Regularly updating components ensures that safety standards are met, further protecting the home and its occupants.

Comparing Oil Furnaces to Other Systems

When assessing different heating solutions, it is essential to understand how each system functions and what advantages or disadvantages they may present. Various heating methods can significantly impact efficiency, cost, and environmental considerations, making it crucial to evaluate their characteristics thoroughly.

| System Type | Efficiency | Initial Cost | Maintenance | Environmental Impact |

|---|---|---|---|---|

| Traditional Heating | Moderate | Low | Frequent | High emissions |

| Electric Heating | High | Moderate | Low | Low emissions |

| Gas Heating | High | Moderate | Moderate | Moderate emissions |

| Alternative Renewable Systems | Very High | High | Variable | Minimal emissions |

By comparing these heating systems, individuals can make informed decisions that align with their specific needs and preferences. Understanding the trade-offs involved allows homeowners to choose solutions that offer the best balance between cost-effectiveness and sustainability.