The efficient upkeep of farming tools is essential for ensuring smooth and uninterrupted work in the field. Understanding the key components and their interconnections can make a significant difference in maintaining performance. Regular attention to each part of the machinery helps to prevent breakdowns and extends its overall lifespan.

Whether dealing with older or newer agricultural models, detailed knowledge of how different mechanical elements operate together is crucial. This understanding allows for better troubleshooting, minimizing downtime during critical working periods. By familiarizing oneself with the arrangement of various components, it becomes easier to carry out maintenance tasks effectively.

Ih 100 Sickle Mower Overview

This agricultural machine offers a reliable and efficient way to manage vegetation in fields and pastures. With a sturdy design, it ensures smooth operation even in challenging environments. Its cutting mechanism provides precision, making it ideal for both small-scale and extensive operations.

The system is engineered to handle a variety of terrains, offering flexibility for different field conditions. Its durable construction and user-friendly interface allow for easy maintenance and operation, minimizing downtime and increasing productivity.

- Durable build suitable for rough conditions

- Efficient cutting mechanism for precise results

- Easy to maintain and operate

- Adaptable to various terrain types

Overall, this machinery provides a balanced combination of power and versatility, making it a valuable tool in maintaining agricultural lands efficiently and effectively.

Key Components of the Mower

The equipment consists of various essential elements that work together to ensure efficient operation. Each part has a specific role in maintaining smooth functionality and performance, contributing to the overall reliability of the machine.

Frame and Structure: The base provides stability and support for the entire system. Its design allows for durability and resilience during use.

Cutting Mechanism: This section handles the primary task, which is crucial for achieving precise results. Proper maintenance of this area ensures long-lasting efficiency.

Drive System: The power transmission is responsible for controlling the movement and force distribution, allowing seamless operation across different terrains.

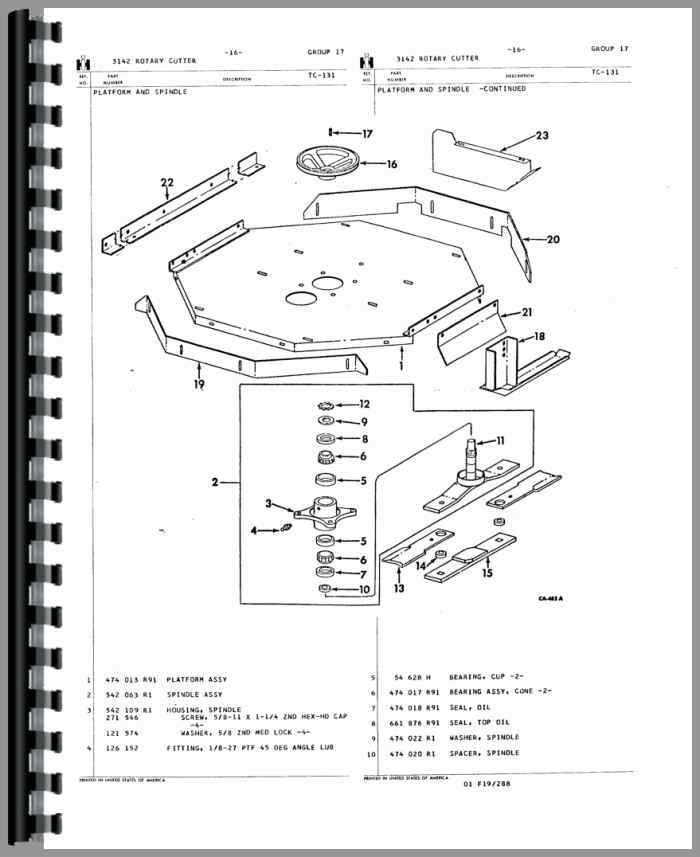

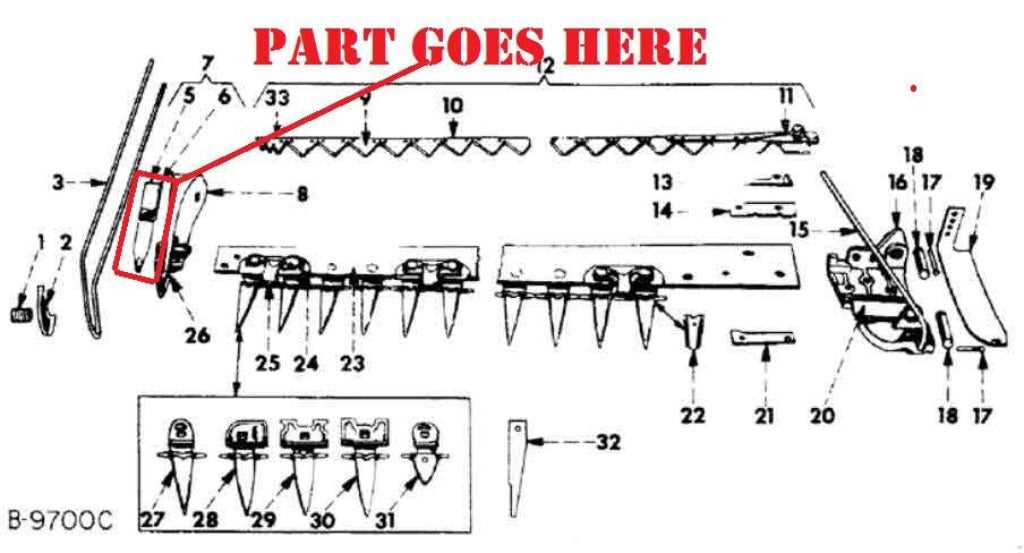

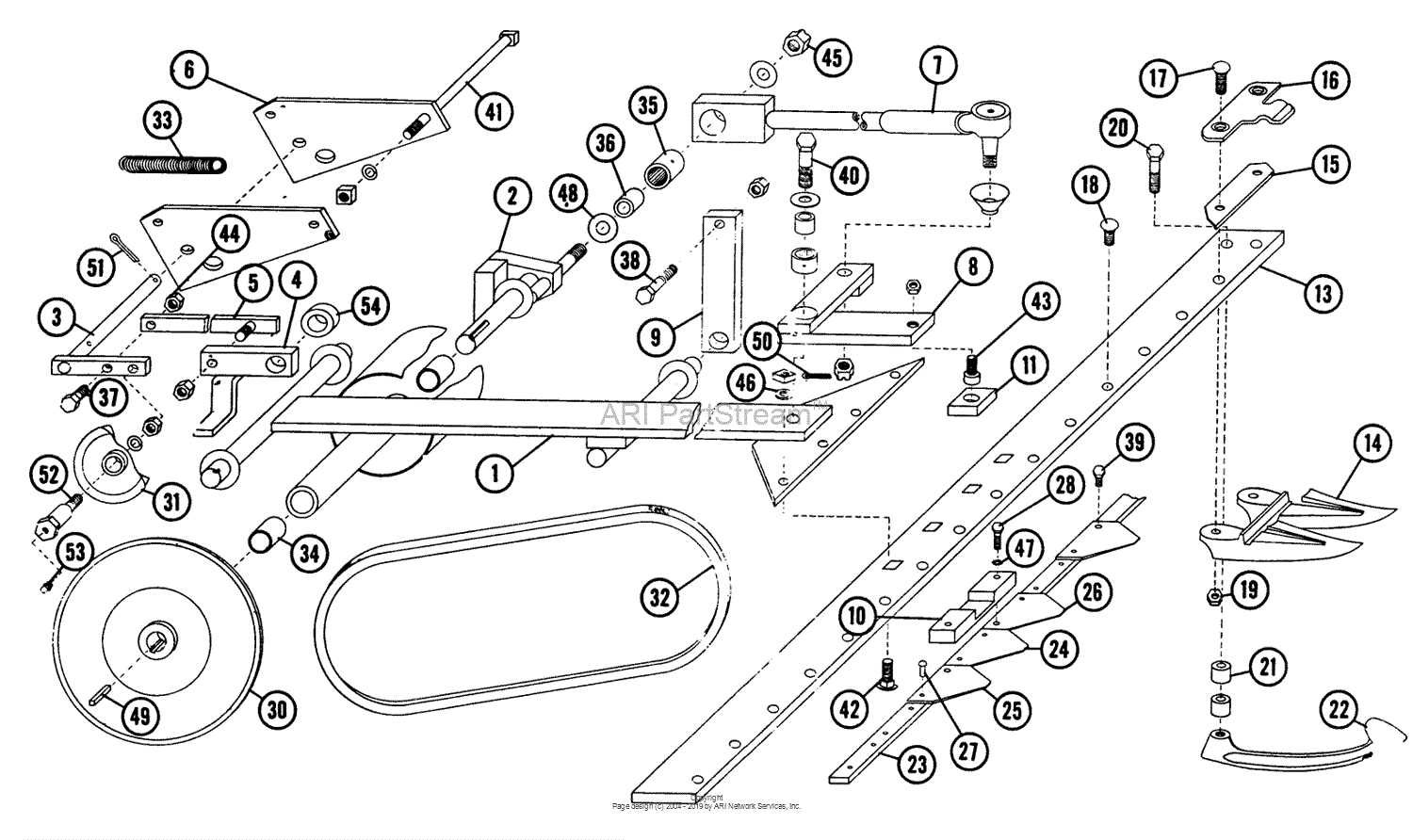

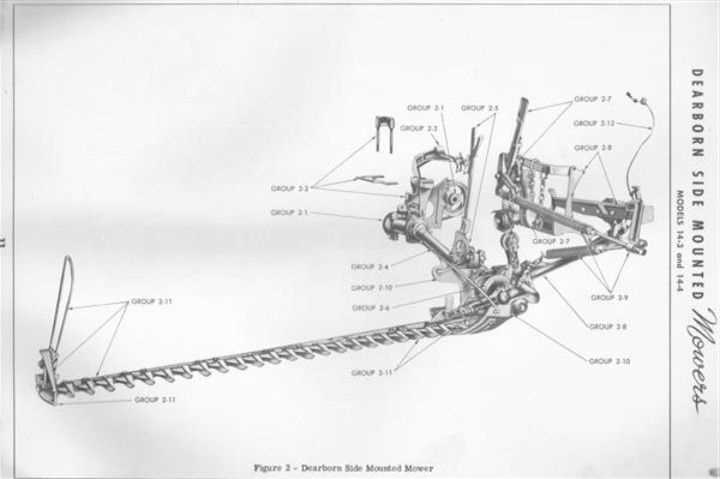

Understanding the Parts Diagram

To effectively maintain and repair complex equipment, it’s crucial to familiarize yourself with the visual representation of its components. This illustration helps to identify various elements and their arrangement, providing a clear overview of how each part interacts within the system. Understanding this layout is essential for troubleshooting and ensuring proper assembly during repairs.

Each section of the equipment is designed with specific functionality in mind. By analyzing the layout, you can trace how different mechanisms work together and pinpoint any potential issues that may arise during operation. The diagram also serves as a guide for identifying replacements and ensuring compatibility between various components.

Maintenance Tips for Longevity

Proper care and routine upkeep of machinery are crucial to ensuring long-term performance and preventing unexpected malfunctions. By following simple yet effective practices, you can significantly extend the lifespan of your equipment and avoid costly repairs.

Regular Cleaning

- Remove debris and dirt after each use to prevent build-up that could affect functionality.

- Check hidden areas and corners where dust or residues might accumulate over time.

- Use appropriate cleaning tools and avoid harsh chemicals that may damage sensitive components.

Lubrication

- Apply lubricant to moving parts regularly to reduce friction and wear.

- Use the manufacturer-recommended type of lubricant for best results.

- Inspect lubricated areas for excess grease build-up, which may attract dirt.

By incorporating these maintenance habits into your routine, you’ll be able to enhance the efficiency and durability of your equipment, ensuring reliable operation for years to come.

Common Issues and Solutions

When working with mechanical equipment, users may occasionally encounter problems that can affect performance. These issues can often be addressed with basic troubleshooting and regular maintenance, ensuring smooth and efficient operation. Below are some of the most common problems along with suggested solutions to help restore functionality quickly and efficiently.

Operational Problems

- Check for any obstructions or debris that may have built up over time and clear the area to ensure smooth movement.

- Inspect the mechanical components for signs of wear or damage, replacing any parts as necessary to maintain optimal performance.

- Ensure that all moving parts are adequately lubricated to reduce friction and prevent overheating during operation.

Maintenance Tips

- Regularly tighten any loose bolts or fasteners to prevent structural issues during use.

- Periodically inspect the equipment for rust or corrosion and clean it properly to extend its lifespan.

- Store the machinery in a dry place to avoid moisture-related damage that can affect its functionality.

How to Order Replacement Parts

When it comes to maintaining the efficiency of your equipment, timely replacement of worn components is essential. Knowing how to properly order new elements can help avoid unnecessary delays and ensure that the machine continues to function smoothly.

Here is a simple guide to assist you in ordering replacement components:

- Identify the needed component: Carefully examine the equipment and consult the manual or other resources to determine exactly what you need to replace.

- Gather essential details: Make sure to have information such as the model of the machine, serial number, and specifications of the component to ensure accuracy when ordering.

- Choose a reliable supplier: Look for authorized sellers or trusted platforms that offer original or compatible replacement parts to maintain the quality and performance of your equipment.

- Place your order: Contact the supplier via phone, email, or their online store. Be clear and precise when sharing the details to avoid any errors in your order.

By following these steps, you can ensure that the replacement process is quick and efficient, keeping your equipment running without prolonged downtime.

Comparative Analysis with Other Models

The performance and features of agricultural equipment vary greatly between different types of machinery. By comparing several models, we can identify significant distinctions in design, efficiency, and functionality. This section explores how various machines excel in specific tasks and where their limitations might lie, offering a broader perspective on their practical applications in diverse farming scenarios.

Efficiency and Performance

One of the key differences between machines lies in their efficiency. Some models are designed to handle larger workloads and are ideal for extensive use, while others offer better precision and are suited for more delicate operations. Understanding these differences helps in choosing the right equipment for specific agricultural tasks.

Durability and Maintenance

Durability is another important factor in comparing these machines. Some models require frequent maintenance but provide excellent performance, while others are built to last longer with minimal upkeep. Evaluating these aspects can lead to more informed decisions when selecting equipment for long-term use.

User Experiences and Reviews

Feedback from individuals who have utilized this equipment highlights its practicality in various tasks. Users often appreciate the reliability and efficiency it offers, noting how well it performs under different conditions. Many have shared insights on its ease of use, emphasizing the convenience of handling and maintaining the machinery over time.

Several users also point out the durability of the device, with some praising its long-lasting performance even after extended periods of use. Reviews frequently mention that the machine’s structure allows for smooth operation, contributing to overall satisfaction among owners.

In addition to functionality, many reviews reflect on the tool’s versatility, with users reporting its ability to adapt to a range of applications. Overall, experiences tend to be positive, with a strong focus on the practical benefits and long-term reliability of the equipment.

Tips for Efficient Operation

For optimal performance, it’s important to follow some basic practices that enhance both effectiveness and longevity. By keeping a regular maintenance routine and adjusting settings appropriately, you can ensure smooth functioning and avoid unnecessary downtime.

Regular Inspection

Conducting a thorough inspection before each use is crucial. Check for any signs of wear or potential issues that might affect the equipment’s performance. Identifying and addressing problems early can prevent bigger issues later on.

Proper Adjustments

Make sure that all components are correctly aligned and functioning as intended. Adjustments, such as setting the correct tension or ensuring smooth motion, will improve efficiency and minimize the risk of breakdowns.