Maintaining optimal functionality of winter machinery is crucial for effective snow removal. This section explores the essential components that contribute to the overall performance of your equipment during harsh weather conditions.

Familiarizing yourself with the various elements and their configurations enhances operational efficiency and extends the lifespan of your gear. By examining the intricate layout of these components, users can better address any issues that may arise.

Furthermore, knowing how each section interacts within the system provides a deeper insight into troubleshooting and repair. This knowledge empowers operators to take proactive measures, ensuring their tools are always ready for the ultimate challenge of winter weather.

Understanding John Deere Snowblower Design

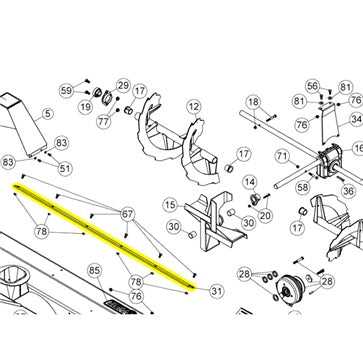

Effective winter equipment relies on a thoughtful arrangement of components and engineering principles that ensure optimal performance in challenging conditions. This section explores the intricacies of a specific model, focusing on how its construction contributes to efficiency and reliability.

- Core Mechanism: The primary assembly is designed to efficiently gather and discharge accumulated snow, utilizing rotational force and aerodynamic shapes.

- Durability: High-quality materials are selected to withstand harsh weather and resist wear over time, ensuring longevity.

- Ergonomics: User-friendly features are incorporated to enhance ease of operation, minimizing physical strain during use.

The engineering behind this machine exemplifies the balance between functionality and user experience, providing a reliable solution for winter maintenance tasks.

- Components are precisely calibrated for effective interaction.

- Modular design allows for easy maintenance and repairs.

- Advanced technology is utilized for optimal power management.

By understanding these design elements, users can appreciate the performance and reliability that this equipment offers during winter months.

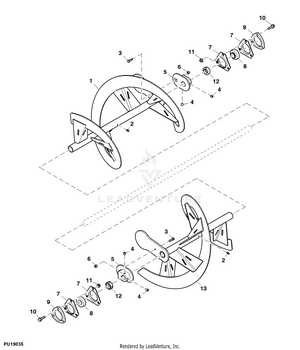

Key Components of the 54 Snowblower

The efficient operation of a winter clearing machine relies on several crucial elements that work in harmony to ensure optimal performance. Understanding these components is essential for proper maintenance and troubleshooting.

- Auger: This rotating mechanism collects and breaks up snow, enabling efficient movement through the chute.

- Impeller: Positioned behind the auger, this component helps to propel the snow out of the chute, enhancing discharge distance.

- Chassis: The frame serves as the foundation, supporting all other parts and providing stability during operation.

- Skid Shoes: These adjustable elements determine the height of the cutting edge, allowing for effective snow removal on various surfaces.

- Drive System: This assembly transfers power from the engine to the auger and impeller, ensuring smooth operation.

- Controls: The levers and switches enable the operator to manage speed, direction, and other essential functions with ease.

Each of these elements plays a vital role in the overall functionality of the unit, and understanding their purpose can greatly enhance the user experience during the winter season.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring the longevity and efficiency of any machinery. Neglecting this essential aspect can lead to performance issues, increased wear, and costly repairs. By committing to a routine maintenance schedule, users can optimize functionality and reduce the likelihood of unexpected breakdowns.

Benefits of Routine Care

Regular maintenance offers numerous advantages that contribute to the overall health of equipment. Key benefits include:

| Benefit | Description |

|---|---|

| Enhanced Performance | Regular checks and adjustments help maintain optimal operation, ensuring machinery runs smoothly. |

| Increased Lifespan | Proper care prevents excessive wear and tear, extending the useful life of components. |

| Cost Savings | Preventative measures can save money by reducing the need for major repairs or replacements. |

Best Practices for Maintenance

To achieve the best results, following recommended practices is essential. This includes regular inspections, cleaning, and timely replacements of worn parts. Additionally, maintaining proper lubrication and addressing minor issues before they escalate can significantly enhance reliability.

Identifying Common Wear Parts

Understanding the components that experience regular wear is crucial for maintaining optimal performance in your equipment. These elements are essential for effective operation and can significantly impact efficiency when they start to degrade. Recognizing these items can help ensure timely replacements and prevent potential issues during use.

Blades are among the most frequently replaced components. Over time, exposure to ice and abrasive materials can dull their edges, leading to reduced performance. Regularly checking and sharpening or replacing these implements can enhance functionality.

Belts also play a vital role in the machinery’s operation. They can wear out due to constant friction and tension. Signs of wear may include cracking or fraying, which necessitates replacement to maintain proper power transfer.

Bearings support the moving parts and can suffer from wear due to prolonged use. If you notice unusual noises or vibrations, it might be time to inspect and potentially replace these essential components to avoid further damage.

Lastly, housings can also experience wear, especially if subjected to harsh conditions. Regular inspections can help identify cracks or corrosion, ensuring that the structural integrity is maintained and that the equipment remains safe to operate.

By being vigilant and proactive about these common components, you can extend the life of your machinery and enhance its performance throughout the winter season.

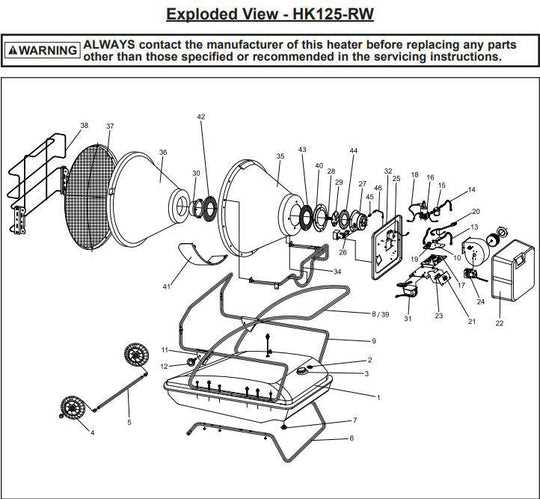

How to Access the Parts Diagram

Finding the right visual reference for your equipment’s components is essential for maintenance and repairs. Accessing a schematic can greatly assist in understanding the assembly and organization of various elements, ensuring efficient troubleshooting and part replacement.

Online Resources

The internet is a valuable tool for locating detailed schematics. Many manufacturers offer digital manuals that can be easily downloaded. You can visit official websites or reputable third-party platforms dedicated to machinery resources. Ensure you have the model number at hand for precise results.

Local Dealers and Service Centers

Another effective method is to contact local dealers or service centers. They often have physical copies of schematics available and can provide expert advice on maintenance. Visiting these locations can also facilitate direct communication with knowledgeable staff who can assist you in finding the necessary information.

| Method | Description |

|---|---|

| Online Resources | Visit official sites or trusted platforms for downloadable manuals. |

| Local Dealers | Contact nearby dealers for physical copies and expert advice. |

Tips for Ordering Replacement Parts

When it comes to maintaining outdoor equipment, ensuring you have the correct components is crucial for optimal performance. Whether you’re tackling winter challenges or preparing for seasonal tasks, knowing how to efficiently acquire the necessary items can save you time and frustration.

1. Identify Your Model: Before placing an order, make sure you know the specific model of your equipment. This information is vital for selecting compatible components.

2. Refer to Manufacturer Resources: Utilize official manuals or online resources provided by the manufacturer. These documents often include detailed listings and specifications that can guide your selection.

3. Check Compatibility: Always verify that the items you intend to purchase are suitable for your model. Cross-referencing part numbers can prevent costly mistakes.

4. Compare Prices: Don’t settle for the first option you find. Shopping around can lead to better deals and help you avoid overpaying for essential items.

5. Read Customer Reviews: Insights from other users can offer valuable information regarding the quality and performance of specific components. Take note of their experiences to make informed decisions.

6. Order in Advance: Anticipating your needs can prevent delays during critical times. Stocking up on essential items before the season starts ensures you’re prepared for any situation.

7. Keep Records: Maintaining a log of previous purchases and replacements can assist in future ordering. This information helps track when components may need replacing again.

By following these tips, you can enhance your ability to effectively source the necessary items, ensuring your equipment remains reliable and efficient.

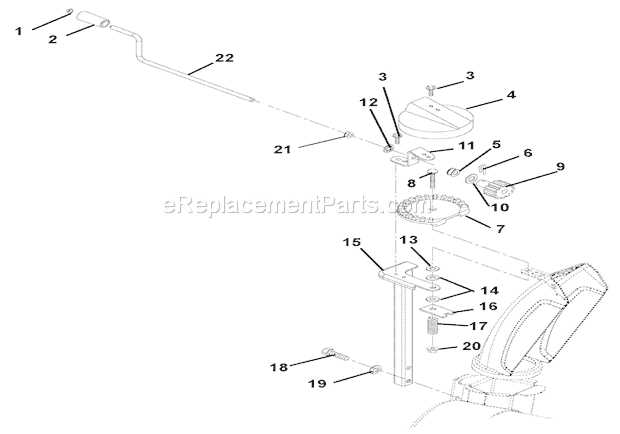

Installation Guide for New Components

This section provides essential guidance for the proper installation of new elements in your equipment. Following these instructions will ensure optimal performance and longevity of the machine. Careful attention to detail during the installation process can prevent future issues and enhance efficiency.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure that your workspace is clean and organized to facilitate an efficient workflow. It is also crucial to consult the specific manual for your model, as it will contain vital information regarding compatibility and specific installation procedures.

Installation Procedure

Start by removing any existing components that may obstruct the installation of new elements. Use appropriate tools to detach parts safely, minimizing the risk of damage. Once the old components are removed, position the new elements carefully, ensuring they align correctly with the designated fittings. Tighten all fasteners securely, but avoid over-tightening, which may lead to unnecessary wear or damage. After installation, perform a thorough inspection to confirm that everything is properly secured and aligned.

Once the installation is complete, it is recommended to run a brief test to verify the functionality of the newly installed components. Regular maintenance checks will help identify potential issues early, ensuring your equipment remains in peak condition.

Enhancing Performance with Upgrades

Improving functionality and efficiency is essential for any machinery enthusiast. By incorporating specific enhancements, users can experience significant advancements in operation and reliability.

- Engine Modifications: Upgrading the engine can boost power output and efficiency.

- Auger Enhancements: Advanced auger designs can improve snow management and flow.

- Transmission Upgrades: Enhanced transmission systems provide smoother operation and better speed control.

- Blades and Scrapers: Investing in high-quality blades ensures effective clearing and durability.

Implementing these modifications not only optimizes performance but also prolongs the lifespan of the equipment.