When it comes to maintaining outdoor machinery, having a clear understanding of each component is essential for optimal performance. This guide aims to shed light on the intricate elements that contribute to the overall functionality of high-pressure cleaning devices. By exploring the various sections of the equipment, users can gain valuable insights into how each part interacts within the system.

In this exploration, we will delve into the specific roles that different components play, highlighting their importance and interconnectivity. A thorough grasp of these elements not only facilitates better upkeep but also empowers users to troubleshoot potential issues effectively. Whether you’re a seasoned technician or a novice user, comprehending the layout of the machinery can enhance your maintenance routine.

Moreover, familiarity with the assembly of these devices can significantly reduce downtime and improve efficiency. By identifying each section and understanding its function, users can ensure their equipment remains in top condition, ready to tackle any cleaning task with ease. Let’s embark on this journey to unravel the essential components that make up these powerful machines.

Understanding Craftsman Power Washers

Cleaning equipment plays a vital role in maintaining the appearance and longevity of various surfaces. This machinery is designed to deliver high-pressure streams of water to remove dirt, grime, and other debris effectively. Knowing the components and functionality of this type of apparatus can enhance its use and prolong its lifespan.

Key Features of the Equipment

- Efficiency: The high-pressure mechanism allows for quicker and more thorough cleaning compared to manual methods.

- Versatility: Suitable for a wide range of applications, from driveways to decks.

- Adjustable Settings: Users can modify pressure levels based on the cleaning task.

Essential Components

- Motor: Powers the unit, generating the necessary force for cleaning.

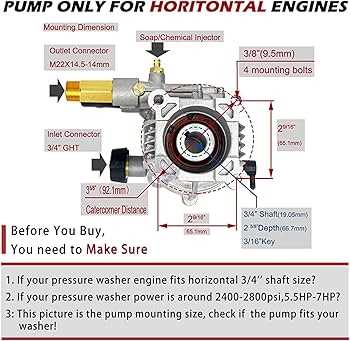

- Pump: Increases water pressure, enabling effective removal of stubborn stains.

- Hoses: Deliver water to the nozzle, available in various lengths for convenience.

- Nozzles: Different types provide varying spray patterns for specific tasks.

Understanding the functionality and design of this equipment can lead to more efficient cleaning practices and better maintenance, ensuring optimal performance over time.

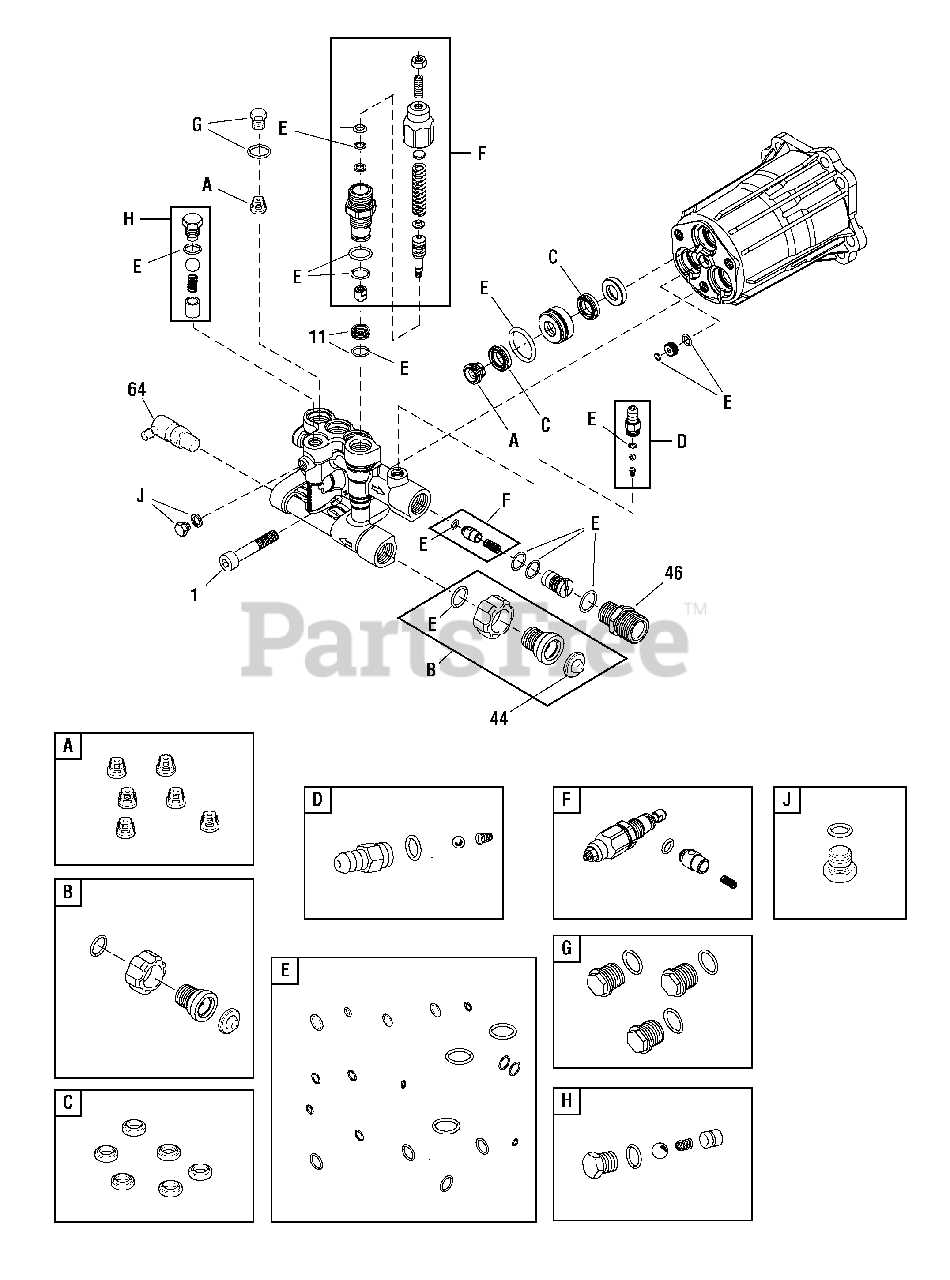

Key Components of Power Washers

Understanding the essential elements of high-pressure cleaning machines is crucial for efficient use and maintenance. Each component plays a vital role in ensuring optimal performance, enhancing both effectiveness and durability. Familiarity with these elements allows users to troubleshoot issues and perform necessary repairs with ease.

Motor and Pump

The motor serves as the heart of the machine, converting electrical or gasoline energy into mechanical energy. This energy powers the pump, which pressurizes the water, creating the force needed for cleaning. A well-functioning motor and pump are essential for achieving the desired pressure and flow rate.

Hose and Nozzle

The hose transports the high-pressure water from the pump to the cleaning surface, while the nozzle directs the flow. Different nozzle types allow for various spray patterns, enabling users to tackle a range of surfaces and dirt types. Proper care of these components is necessary to maintain efficiency and prevent leaks.

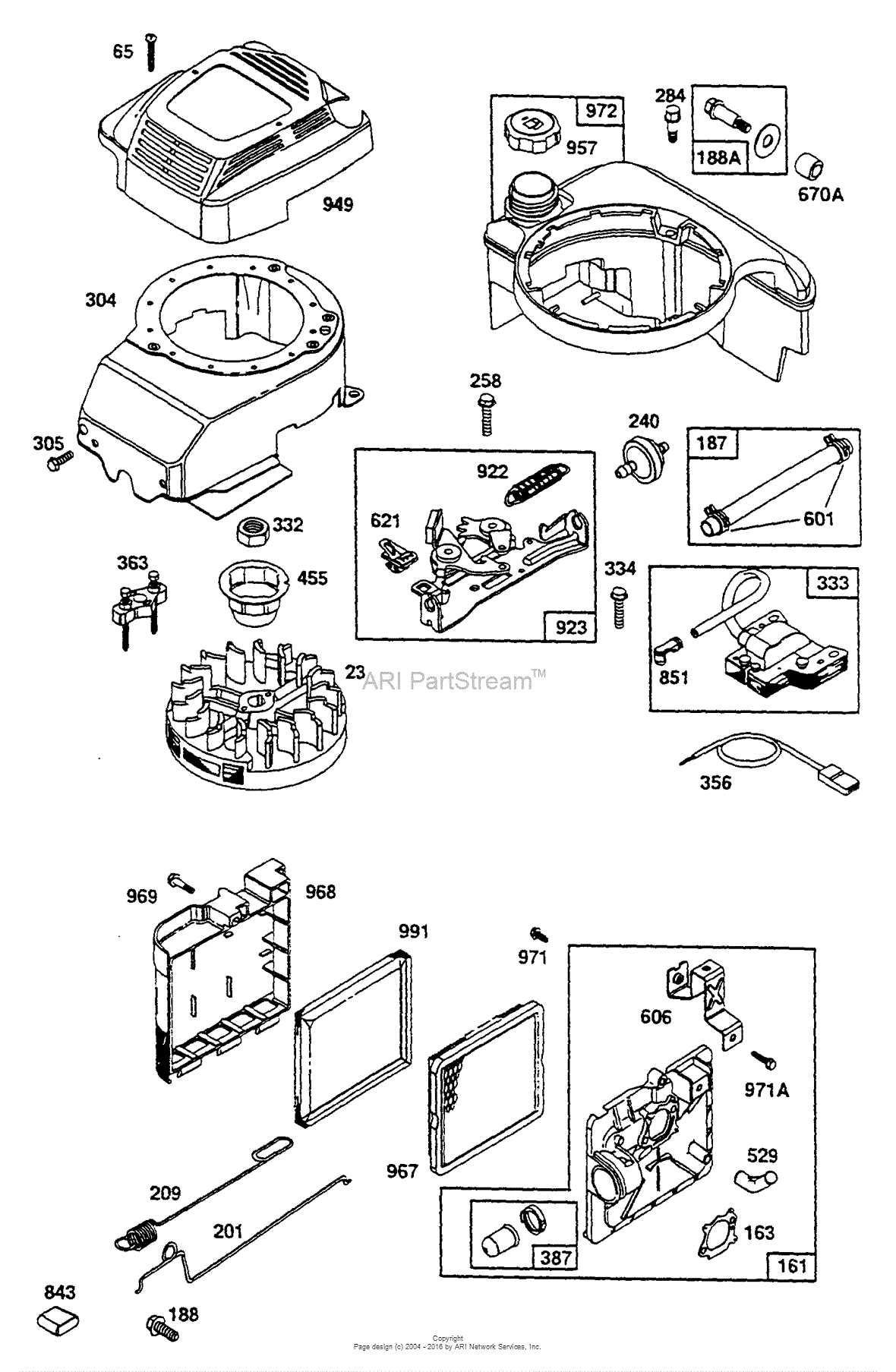

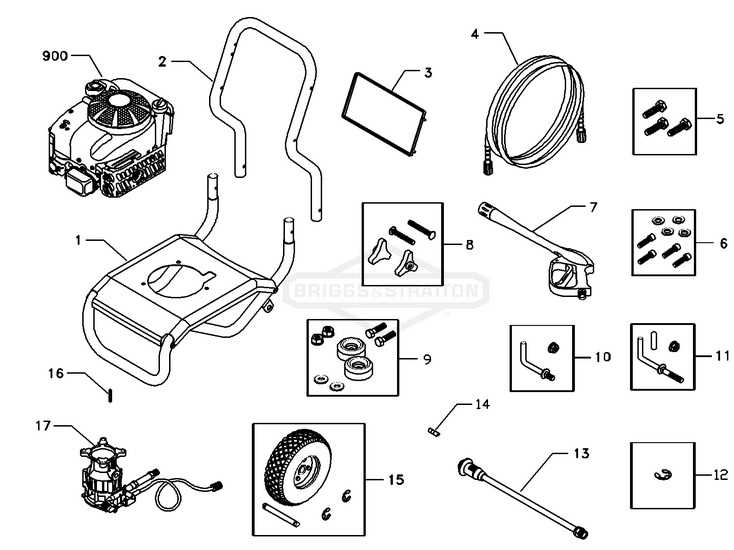

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations of these elements facilitate quicker identification and troubleshooting, allowing users to address issues with confidence. By clearly illustrating how different components interconnect, these illustrations serve as essential guides for both novice and experienced users.

Enhanced Troubleshooting

Visual aids simplify the process of diagnosing problems. When individuals can see the arrangement of various elements, they can more easily pinpoint malfunctions. This clarity reduces downtime and helps maintain the equipment’s performance.

Streamlined Repairs

Having access to detailed representations allows for more efficient repair processes. Users can refer to the visuals to ensure they have all necessary components before starting work, thus minimizing the likelihood of missed or misplaced items. Additionally, these guides often highlight specific assembly instructions, making the repair process smoother.

| Benefits | Description |

|---|---|

| Quick Identification | Facilitates the fast recognition of components and issues. |

| Improved Accuracy | Ensures precise reassembly and replacement of parts. |

| Reduced Errors | Minimizes mistakes by providing clear visual guidance. |

Common Parts and Their Functions

Understanding the essential components of a high-pressure cleaning device is crucial for effective maintenance and optimal performance. Each element plays a specific role, contributing to the overall efficiency and functionality of the equipment. Below is a detailed overview of these vital components and their respective functions.

| Component | Function |

|---|---|

| Motor | Powers the unit, converting electrical energy into mechanical energy to create pressure. |

| Pump | Increases water pressure, essential for generating the force needed for effective cleaning. |

| Trigger Gun | Controls the flow of water; users can start and stop the spray easily. |

| Pressure Hose | Transmits pressurized water from the pump to the nozzle, designed to withstand high pressure. |

| Spray Nozzle | Regulates the spray pattern and pressure, allowing for versatility in cleaning tasks. |

| Water Inlet | Connects to the water supply, ensuring a steady flow of water to the system. |

| Filter | Prevents debris from entering the system, protecting internal components from damage. |

| Frame | Provides structural support and stability, often equipped with wheels for mobility. |

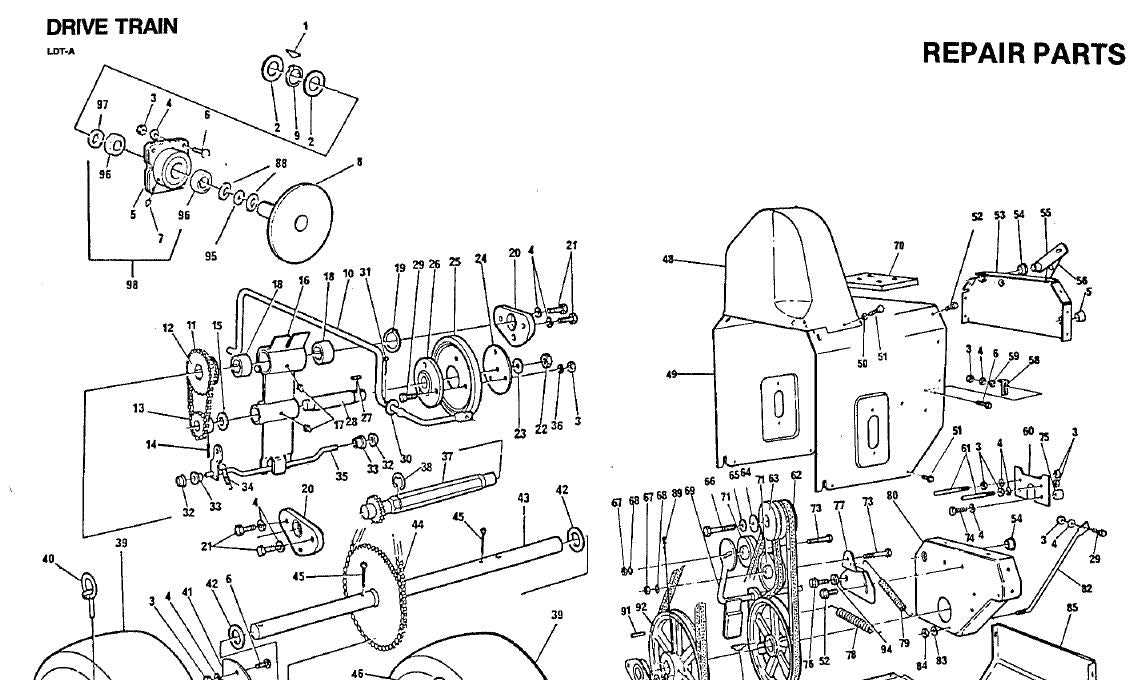

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair of machinery. These visuals provide a clear representation of the components and their relationships, enabling users to identify the necessary elements for a specific task. By familiarizing yourself with the layout and symbols used, you can streamline the repair process and ensure accuracy.

Familiarize Yourself with the Symbols

Most illustrations use standardized symbols to represent various components. Recognizing these symbols is crucial, as they convey important information about each part’s function and placement. Pay close attention to any legends or keys included, as they will guide you in interpreting the illustration correctly.

Follow the Sequence of Assembly

Typically, assembly visuals are arranged in a logical order, reflecting the sequence in which parts should be connected or disassembled. Taking note of this arrangement can help you avoid mistakes and ensure a smooth assembly process. Start from the base components and work your way to the outer elements, following the flow indicated in the illustration.

Maintenance Tips for Power Washer Parts

Proper upkeep of your cleaning equipment is essential for ensuring longevity and optimal performance. By regularly attending to key components, you can prevent wear and tear, enhance efficiency, and avoid costly repairs. Here are some effective strategies to keep your machine in excellent shape.

Regular Inspection: Frequently examine all essential components for any signs of damage or wear. Look for cracks, corrosion, or loose fittings that may compromise performance. Timely identification of issues can help in addressing them before they escalate.

Cleaning: After each use, rinse off any debris or grime that may have accumulated on the exterior and within internal mechanisms. A clean unit operates more efficiently and reduces the risk of clogs or malfunctions.

Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This reduces friction, helping to maintain smooth operation and prevent premature failure.

Storage: Store your equipment in a dry, sheltered environment to protect it from the elements. Use protective covers if available, and ensure that the machine is drained of any liquids to avoid damage during freezing temperatures.

Periodic Maintenance: Follow a scheduled maintenance routine, including checking filters and hoses, tightening connections, and replacing worn-out seals. Keeping a checklist can help ensure that no critical step is overlooked.

Professional Servicing: Consider having a qualified technician perform an annual inspection. They can identify potential issues that may not be apparent during regular checks, ensuring your equipment remains in peak condition.

By incorporating these practices into your routine, you can significantly extend the lifespan of your cleaning apparatus while ensuring it functions effectively whenever you need it.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often seem daunting. However, with the right approach and resources, you can streamline the process and ensure your tools remain in optimal condition. This section will guide you through effective strategies for sourcing the necessary items quickly and efficiently.

Utilizing Online Resources

The internet offers a wealth of information for those seeking specific components. Numerous websites provide catalogs and searchable databases, making it easy to find what you need. Additionally, many online retailers offer detailed specifications and user reviews to assist in your decision-making process.

Local Retailers and Repair Shops

Don’t overlook the value of local shops. Hardware stores and specialized repair centers often stock essential components. Building a relationship with staff can lead to helpful recommendations and insights on the best options available for your needs.

| Resource Type | Benefits |

|---|---|

| Online Retailers | Wide selection, user reviews, easy comparisons |

| Local Hardware Stores | Immediate access, personal assistance, supporting local businesses |

| Repair Shops | Expert advice, installation help, often carry hard-to-find items |

Common Issues and Troubleshooting

When operating high-pressure cleaning equipment, users may encounter various challenges that can hinder performance. Identifying and resolving these problems promptly can enhance efficiency and extend the lifespan of the machine. This section outlines frequent complications and offers practical solutions to ensure smooth operation.

Performance Drops

A significant decrease in cleaning efficiency is a common complaint. This issue may stem from several factors, such as clogged filters, worn-out seals, or incorrect nozzle types. To address this, first check for blockages in the intake or discharge areas. Clean or replace filters as necessary and inspect seals for wear. Ensuring the correct nozzle is used for the specific task can also make a substantial difference.

Engine Starting Issues

Difficulty in starting the engine can be frustrating. Possible causes include fuel supply problems, faulty spark plugs, or air intake blockages. Begin troubleshooting by verifying that the fuel is fresh and the tank is filled. Inspect the spark plug for signs of damage or wear, and replace it if needed. Additionally, ensure that the air filter is clean to allow for proper airflow, which is crucial for starting the engine smoothly.

Upgrading Your Power Washer Parts

Enhancing the efficiency and performance of your cleaning equipment can significantly improve your experience and results. Whether you’re looking to replace worn-out components or seeking to elevate the overall functionality, considering upgrades is a wise investment.

First and foremost, assess the current state of your device. Identify which components are underperforming or no longer meet your needs. This evaluation will help you prioritize upgrades, ensuring that your budget is spent wisely.

Next, explore compatible alternatives that offer improved durability and effectiveness. Options like high-performance nozzles or advanced hoses can lead to better water flow and pressure, making your cleaning tasks faster and more efficient.

Lastly, consider the benefits of quality over cost. Investing in premium components may initially seem like a higher expenditure, but the long-term gains in reliability and performance can outweigh the upfront costs. By upgrading strategically, you can extend the lifespan of your equipment while achieving outstanding cleaning results.