This section provides an in-depth look at the essential components of agricultural machinery. Understanding the intricate parts that make up these machines is crucial for maintaining their efficiency and performance. Each element plays a vital role in the overall functionality, ensuring seamless operation in various farming tasks.

Visual aids serve as valuable resources for mechanics and operators alike, offering clarity in identifying specific elements and their respective locations. These resources enhance knowledge, making it easier to perform maintenance and repairs effectively.

By familiarizing oneself with the individual components, users can improve their ability to troubleshoot issues and implement necessary solutions. This knowledge not only boosts confidence but also contributes to extending the lifespan of the equipment.

This section aims to provide a comprehensive understanding of a specific agricultural machine known for its efficiency and reliability. By exploring the various components and their functions, readers will gain valuable insights into the operation and maintenance of this equipment.

General Features

Highlighting the essential attributes of the machinery, this part will cover:

- Type and classification of the machine

- Primary functions and capabilities

- Design innovations and improvements

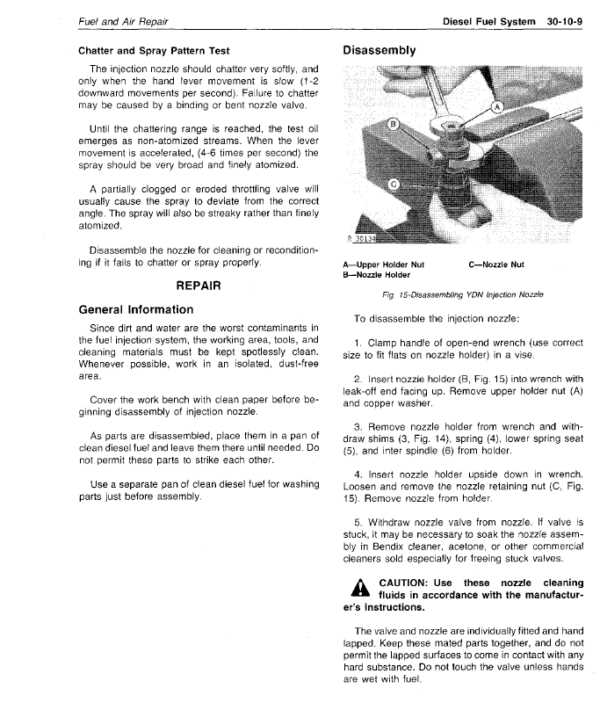

Maintenance Essentials

Discussing the importance of upkeep, this section will detail:

- Regular service intervals

- Common issues and troubleshooting techniques

- Best practices for longevity and performance

Key Components of the 950 Model

The essential elements of this agricultural machinery are designed to work in harmony, ensuring optimal performance and efficiency. Each component plays a significant role in the overall functionality, contributing to the effectiveness of various tasks.

Engine: The heart of the machine, the engine provides the necessary power for operation. It is crucial for driving all other systems, from hydraulic mechanisms to electrical components.

Transmission: This component facilitates the transfer of power from the engine to the wheels, allowing for seamless movement across diverse terrains. It is vital for maintaining control and efficiency during operation.

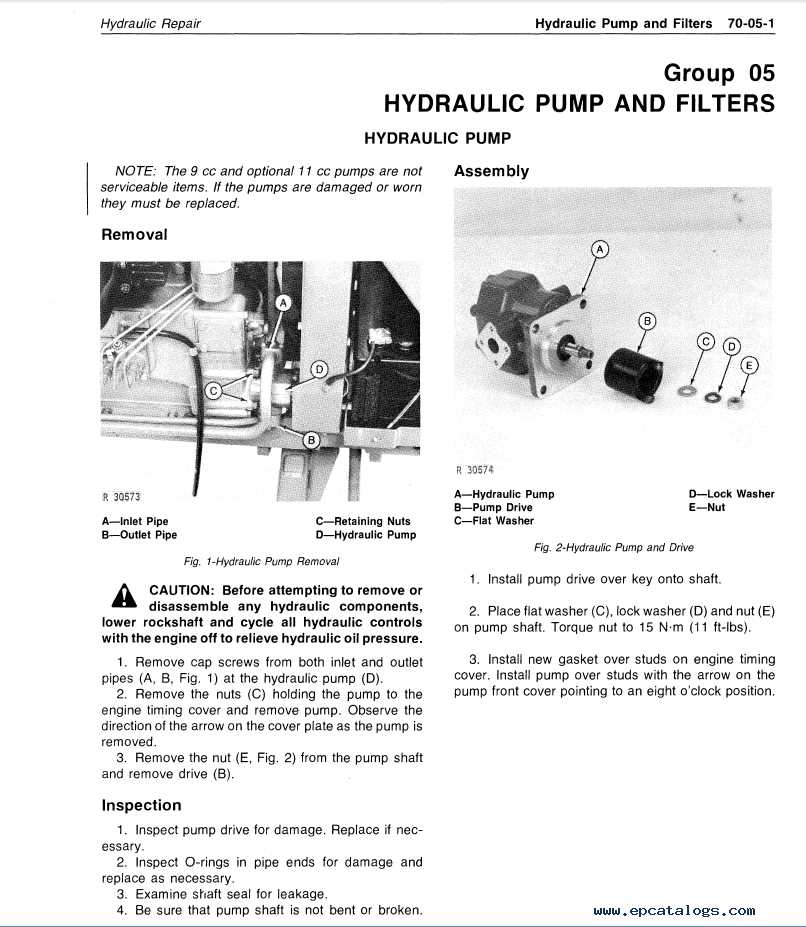

Hydraulic System: This system enables various attachments and implements to operate effectively. It provides the necessary force for lifting, lowering, and maneuvering equipment, enhancing the versatility of the machinery.

Chassis: The framework supports all other components, ensuring durability and stability. A robust chassis contributes to the longevity of the machine, allowing it to withstand demanding agricultural tasks.

Electrical System: This system powers essential functions, including lighting and instrument panels. It ensures reliable operation and communication between various parts, enhancing the user experience.

Understanding these fundamental components allows operators to appreciate the intricate design and engineering behind this agricultural workhorse, ultimately leading to more effective usage and maintenance.

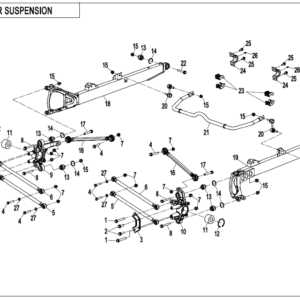

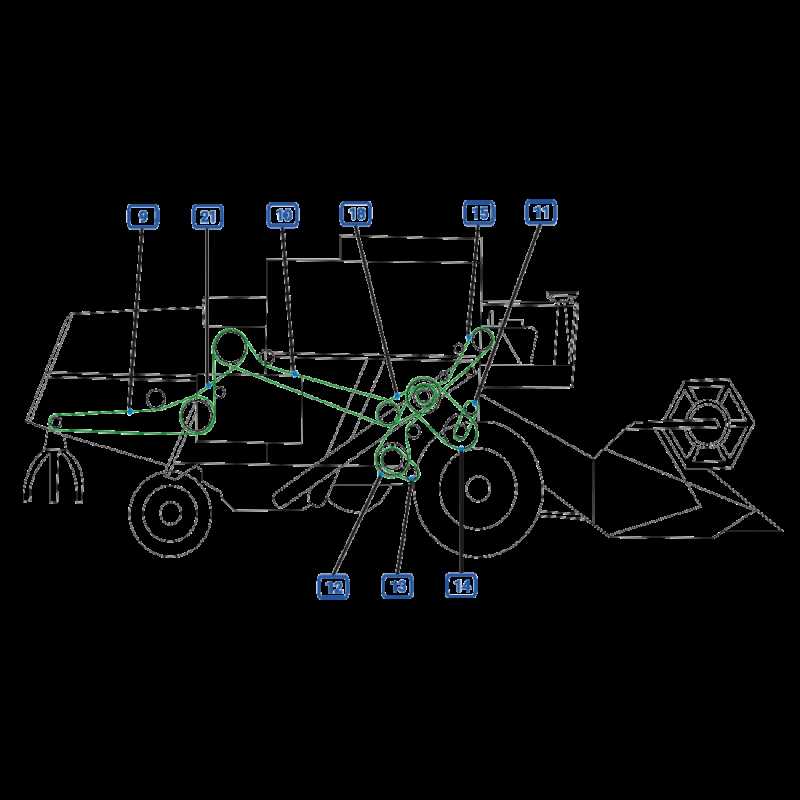

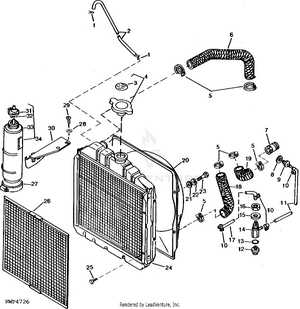

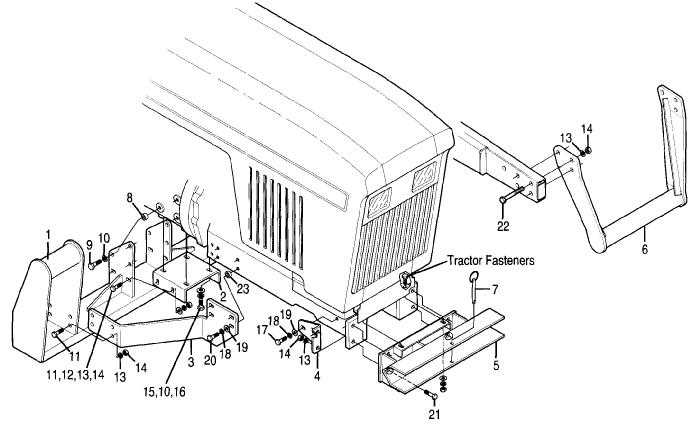

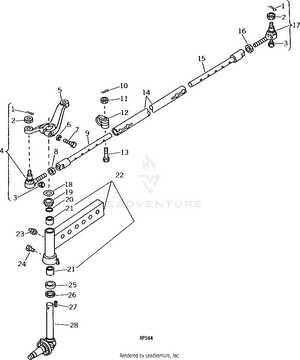

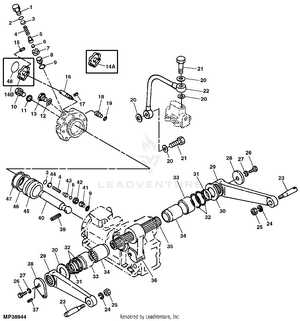

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components play a crucial role in helping users identify and locate individual elements within a complex system. Such illustrations not only enhance comprehension but also streamline the troubleshooting process.

Clear communication is vital when it comes to working on machinery. Well-structured visuals facilitate dialogue among technicians and engineers, ensuring that everyone is on the same page. These illustrations provide a common language, reducing the likelihood of misunderstandings and errors during repairs.

Furthermore, utilizing schematics contributes to improved efficiency. When users can quickly reference a visual guide, they save time during maintenance tasks. This efficiency not only benefits individual technicians but also enhances overall productivity in a workshop environment.

Ultimately, having access to comprehensive visual guides supports better decision-making. Users can assess the condition of various components and determine necessary replacements or repairs more effectively. This proactive approach helps to extend the lifespan of machinery and ensures optimal performance.

How to Read the Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repair of machinery. This guide will provide insights into interpreting such illustrations effectively, ensuring users can identify and locate the necessary elements within their equipment.

Familiarize Yourself with the Layout

The first step in mastering the illustration is to become acquainted with its structure. Typically, these visuals will include various sections, each labeled with specific identifiers. Pay attention to how these areas are organized, as they often correspond to particular assemblies or systems within the machine.

Identify Key Components

Once you have a grasp of the layout, focus on recognizing the major elements depicted. Each item will be accompanied by a unique reference number or code, making it easier to cross-reference with the accompanying list. This will facilitate quicker ordering and replacement, enhancing your operational efficiency.

Common Replacement Parts for 950

When it comes to maintaining agricultural machinery, understanding the essential components that may require periodic replacement is crucial. Regularly assessing these elements can ensure optimal performance and longevity of the equipment.

Among the frequently replaced components are filters, which help maintain clean fluids and enhance the overall efficiency of the machine. Belts are also vital, as they play a significant role in the functioning of various systems by facilitating movement. Additionally, seals and gaskets are essential for preventing leaks, thereby safeguarding the internal mechanisms from contamination.

Another critical category includes bearings and bushings, which are integral for smooth operation and minimizing friction in moving parts. Moreover, electrical components, such as batteries and switches, often need to be replaced to ensure reliable starting and operation. Keeping an eye on these commonly used elements will aid in maintaining the machinery in peak condition.

Maintenance Tips for John Deere 950

Regular upkeep is essential for the longevity and efficiency of your machinery. Implementing effective maintenance practices not only enhances performance but also prevents costly repairs. Below are some crucial recommendations to consider for optimal functioning.

- Check Fluid Levels: Regularly inspect and replenish essential fluids such as oil, coolant, and hydraulic fluid to ensure smooth operation.

- Inspect Filters: Clean or replace air and fuel filters at recommended intervals to maintain engine performance and fuel efficiency.

- Tire Maintenance: Regularly check tire pressure and tread depth. Properly inflated tires improve traction and reduce wear.

- Battery Care: Examine the battery for corrosion and ensure connections are tight. A clean, well-maintained battery is vital for reliable starts.

Adopting these maintenance strategies will help extend the lifespan of your equipment and ensure it operates at peak performance.

Where to Find Authentic Parts

When it comes to maintaining machinery, ensuring the use of genuine components is crucial for optimal performance and longevity. Authentic components not only enhance the reliability of the equipment but also prevent potential issues that may arise from using substandard alternatives. Here are some reliable sources for acquiring original components.

Authorized Dealers

Visiting authorized dealerships is one of the best ways to find genuine components. These dealerships are officially recognized and provide a wide range of original items. Benefits of shopping here include:

- Expert advice from trained staff.

- Access to the latest inventory.

- Warranty on products purchased.

Online Retailers

Another convenient option is to search for reputable online retailers. Many websites specialize in high-quality components for various machinery. When choosing an online platform, consider the following:

- Check customer reviews and ratings.

- Ensure the website offers secure payment options.

- Look for return policies and customer support services.

Benefits of Using Original Components

Utilizing authentic components for machinery is essential for ensuring optimal performance and longevity. These components are specifically designed to fit seamlessly within the system, providing enhanced reliability and efficiency. By opting for original parts, users can experience a range of advantages that contribute to the overall functionality of their equipment.

Enhanced Durability

Original components are manufactured with high-quality materials and advanced engineering standards. This results in:

- Increased resistance to wear and tear.

- Better performance under extreme conditions.

- Extended lifespan of the equipment.

Improved Compatibility

Authentic components ensure perfect compatibility with existing systems, which leads to:

- Reduced risk of malfunction or breakdown.

- Streamlined installation processes.

- Optimal operational efficiency.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and components of specific machinery. It aims to provide clarity and assistance for users seeking information on essential elements and their functionality.

What should I do if I can’t find a specific component?

If you are unable to locate a particular element, consider checking online resources or consulting with local suppliers who specialize in equipment accessories. Additionally, referring to manuals can be beneficial for identifying the correct item.

How can I ensure proper installation of the components?

To guarantee accurate installation, always follow the manufacturer’s guidelines and recommendations. Utilize the appropriate tools and take your time to ensure that each element is securely fitted. If unsure, seek professional assistance.