In the realm of farming equipment, a comprehensive grasp of machinery components is essential for optimal performance and maintenance. The intricate assembly of elements plays a pivotal role in ensuring that these powerful machines operate efficiently and effectively in the field.

Identifying individual components allows operators and enthusiasts alike to enhance their knowledge, ensuring that every part contributes to the overall functionality. By delving into the specifics, one can better appreciate the engineering behind these robust machines.

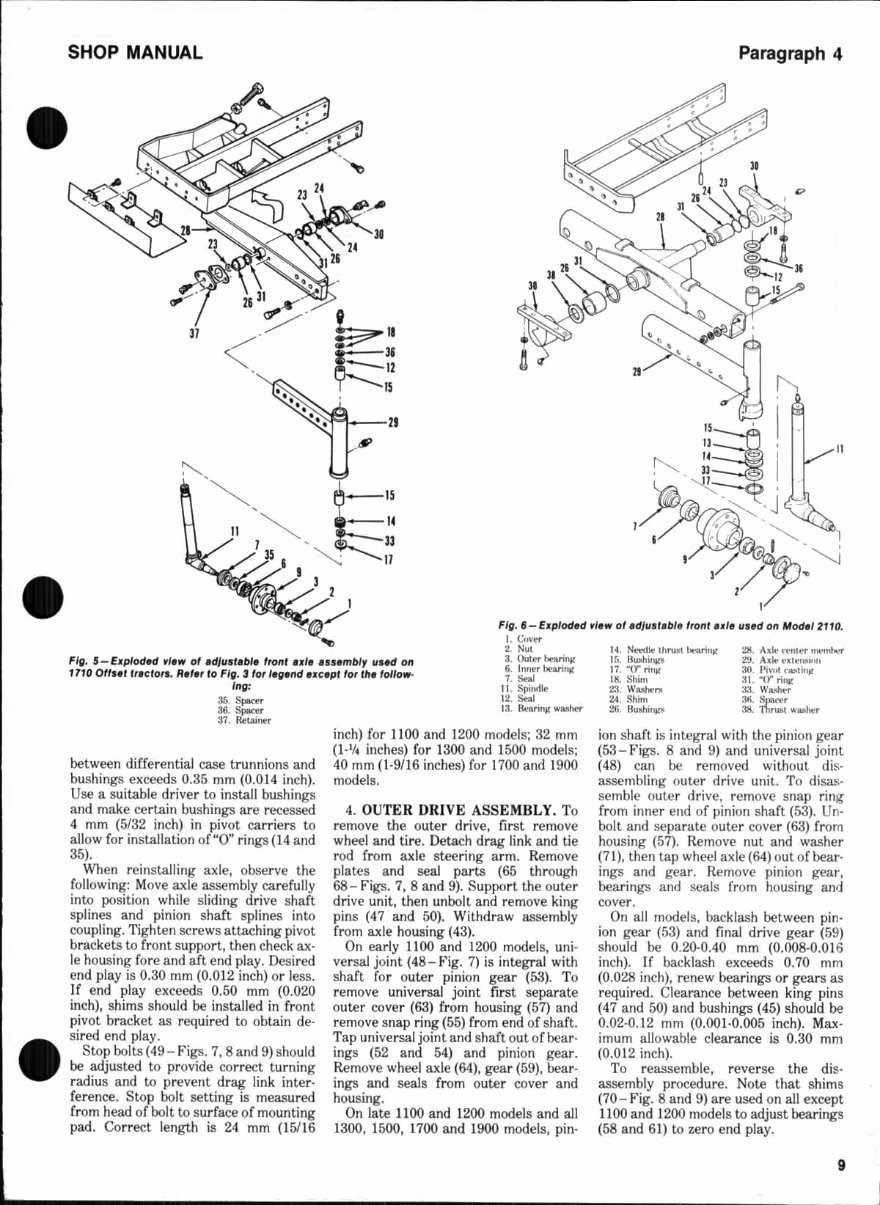

Moreover, a clear visual representation of the arrangement and function of each element provides valuable insights for troubleshooting and repairs. This understanding leads to the ultimate goal of maximizing productivity and extending the lifespan of agricultural equipment.

Overview of Components in the Ford 1700 Agricultural Machine

In this section, we delve into the fundamental components that make up the structure and functionality of the renowned Ford 1700 agricultural vehicle. Exploring the intricate mechanisms that drive its operation, we uncover the essential elements that contribute to its robust performance and enduring reliability.

Primary Mechanisms

- Core mechanical elements

- Key operational systems

- Foundational assemblies

Integral Features

- Essential features

- Key structural components

- Vital functional units

This exploration provides a comprehensive insight into the intricate design and engineering of this agricultural vehicle, shedding light on its critical components and their interdependent roles within the machinery.

Understanding the Tractor’s Main Components

Familiarity with the essential elements of agricultural machinery is crucial for optimal performance and maintenance. Each segment plays a pivotal role in the overall functionality, ensuring efficiency during operation.

- Engine: The powerhouse that provides the necessary energy for all tasks.

- Transmission: This component facilitates speed regulation and torque transfer to the wheels.

- Hydraulics: A system that enables the lifting and moving of heavy implements with ease.

- Chassis: The structural framework that supports various parts and maintains stability.

- Electrical System: Essential for starting, lighting, and powering auxiliary equipment.

Understanding these components can enhance maintenance practices and prolong machinery life.

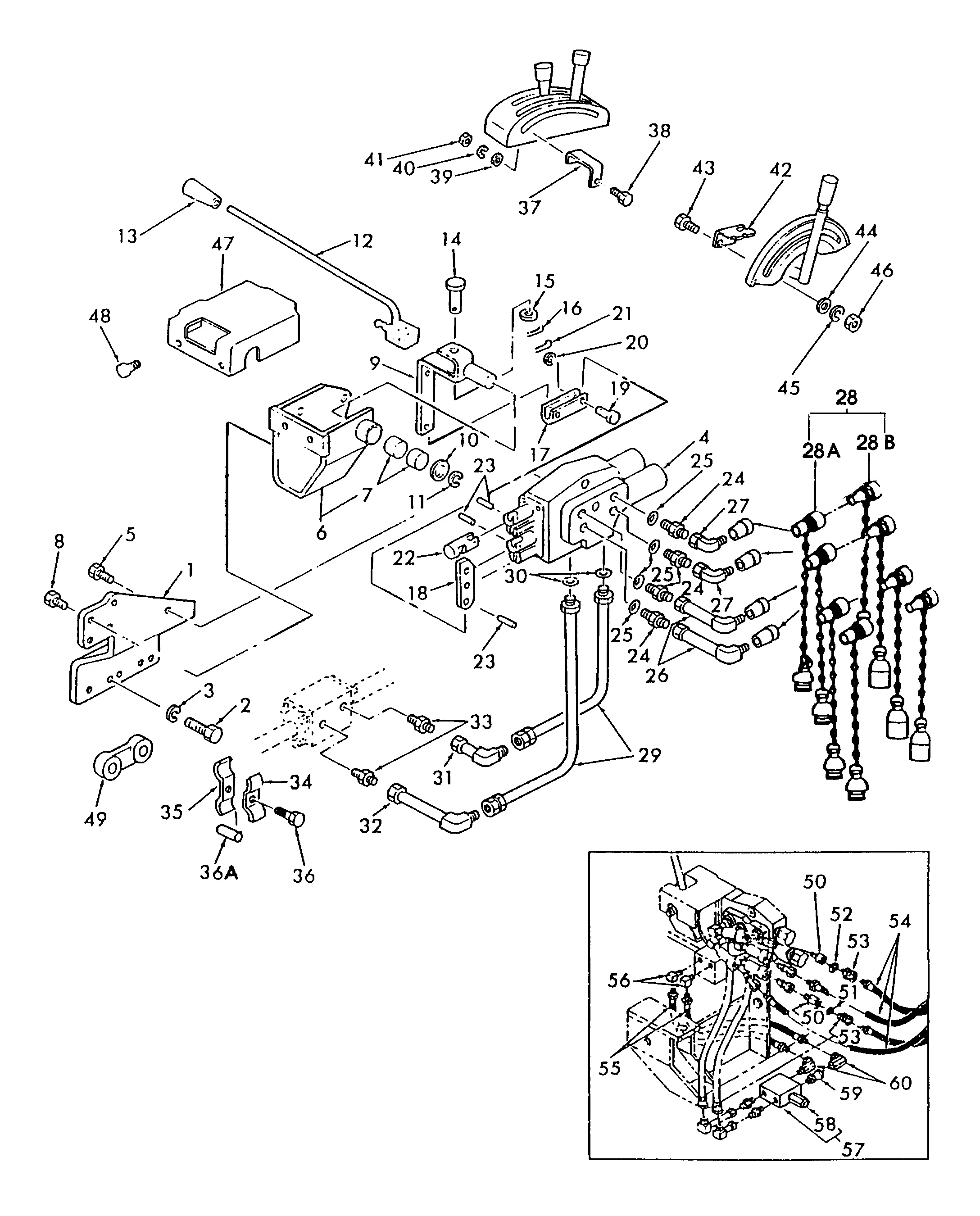

Importance of a Detailed Parts Diagram

A comprehensive visual representation of components is essential for efficient maintenance and repair tasks. Such illustrations provide users with clarity and insight, ensuring that each element is properly identified and understood. This ultimately enhances the overall functionality and longevity of the machinery.

Understanding the significance of these illustrations can be outlined in several key points:

- Identification: Clear visuals help in recognizing individual elements, reducing the chances of confusion during repairs.

- Efficiency: Quick reference aids in streamlining maintenance tasks, allowing for faster identification of required components.

- Reduction of Errors: Accurate representations minimize the likelihood of mistakes during assembly or disassembly.

- Guidance: Step-by-step visuals can serve as a helpful guide for those less experienced in mechanical work.

- Inventory Management: Knowing the specific components helps in tracking inventory and ensuring the availability of necessary parts.

In conclusion, a well-structured visual guide is invaluable for anyone involved in the upkeep of machinery, promoting efficiency and reducing the potential for errors.

How Diagrams Help in Tractor Maintenance

Visual representations serve as crucial tools in the upkeep of machinery. They provide clear guidance, allowing operators to identify components, understand their functions, and execute necessary maintenance tasks efficiently. By translating complex structures into accessible visuals, these illustrations enhance both comprehension and execution.

Improving Understanding of Components

Detailed visuals break down intricate systems into manageable sections. Each element can be labeled clearly, making it easier for users to recognize and differentiate between various parts. This clarity reduces confusion and ensures that maintenance is conducted correctly, minimizing the risk of errors.

Streamlining Repair Processes

When faced with a malfunction, having a visual guide can significantly expedite troubleshooting. Users can refer to these representations to pinpoint issues quickly, leading to more efficient repairs. By following the outlined steps, operators can work methodically, ensuring that no detail is overlooked.

In summary, visual aids are invaluable in the maintenance of heavy machinery. They enhance understanding, streamline repairs, and ultimately contribute to the longevity and efficiency of the equipment.

Engine Components of Ford 1700

The heart of any machine is its power unit, where various elements work in harmony to ensure optimal performance. Understanding the components that make up this unit is essential for maintenance and repairs. This section delves into the crucial elements that contribute to the efficient functioning of the engine.

Main Components

- Cylinder Block: The foundational structure housing the cylinders.

- Pistons: Moving components that compress the fuel-air mixture.

- Crankshaft: Converts linear motion of the pistons into rotational motion.

- Camshaft: Operates the intake and exhaust valves, regulating airflow.

- Valves: Control the entry of air and exit of exhaust gases.

Supporting Systems

- Cooling System: Maintains optimal operating temperatures.

- Lubrication System: Ensures smooth operation of moving parts.

- Fuel System: Delivers the necessary fuel for combustion.

- Ignition System: Initiates the combustion process efficiently.

Each of these components plays a pivotal role in ensuring reliability and performance. Regular checks and maintenance of these elements can significantly extend the lifespan of the engine.

Key Parts for Engine Performance

Ensuring optimal functionality of an engine relies heavily on several essential components that work in harmony. These critical elements contribute to the efficiency, power output, and overall durability of the system. Understanding their roles can help in maintaining peak performance and addressing potential issues before they escalate.

Fuel System Components

The fuel delivery mechanism is vital for providing the right mixture to the combustion chamber. Key elements such as the fuel pump, injectors, and fuel filter play significant roles in ensuring the engine receives a consistent and clean supply of fuel. Proper maintenance of these components is crucial for preventing blockages and ensuring smooth operation.

Ignition System Essentials

The ignition system ignites the fuel-air mixture, setting the stage for combustion. Important parts like spark plugs, ignition coils, and distributors must function effectively to ensure reliable starts and efficient fuel use. Regular checks and replacements of these components can lead to enhanced performance and improved fuel economy.

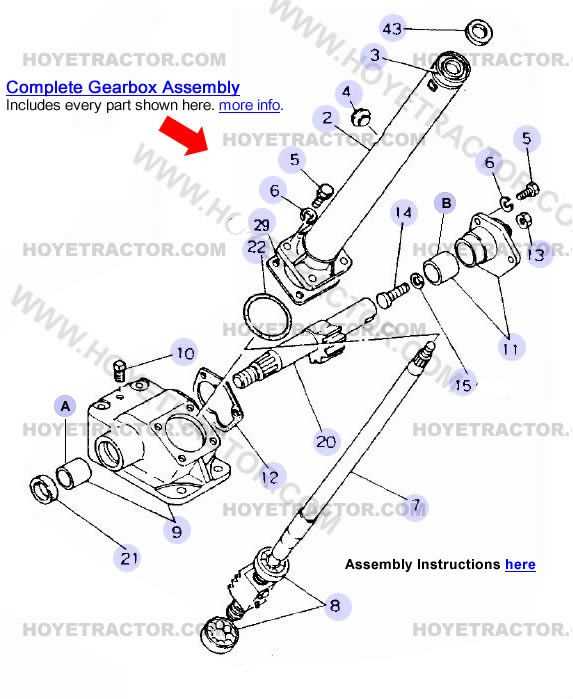

Transmission System Breakdown

The transmission system plays a crucial role in ensuring efficient power transfer within machinery. Understanding its components and their functions allows for better maintenance and troubleshooting, ultimately enhancing performance and longevity.

Key Components

At the heart of the transmission system are several essential elements, including gears, shafts, and clutches. Each component interacts seamlessly, enabling smooth gear shifts and optimal torque distribution. Regular inspection of these parts can prevent costly repairs and downtime.

Maintenance Tips

To keep the transmission system functioning at its best, regular lubrication is vital. Additionally, checking fluid levels and ensuring no leaks are present can significantly improve reliability. Following a routine maintenance schedule helps in identifying potential issues early.

Essential Parts for Gear Operation

The smooth functioning of any mechanical system heavily relies on the proper interaction of key components. In gear-driven systems, there are several crucial elements that ensure power is transmitted efficiently and reliably. Each part plays a distinct role, from initiating motion to maintaining consistent performance under varying loads and conditions.

Gears are the core components that engage with one another to transfer rotational motion. The size, tooth design, and material composition of each gear determine the efficiency and durability of the system. Without properly designed gears, achieving the desired output would be impossible.

Bearings are vital in reducing friction between rotating parts. They support the shafts and ensure smooth movement, preventing excessive wear that could lead to mechanical failure. The quality of bearings significantly influences the overall performance and longevity of the machinery.

Clutches are used to engage and disengage gears, allowing for smooth transitions between different power settings. A well-functioning clutch system is essential for controlling speed and torque, particularly during gear shifting.

Shafts act as the connectors between gears and other system components, transmitting rotational force from one part to another. Proper alignment and balance of shafts are critical for preventing undue strain and ensuring synchronized operation.

Lubricants reduce wear and tear by minimizing friction between moving parts. They help in maintaining optimal temperatures and prevent overheating, which could otherwise lead to breakdowns.

Each of these components plays a pivotal role in the seamless operation of gear mechanisms, ensuring that power is transferred efficiently and reliably across the system.

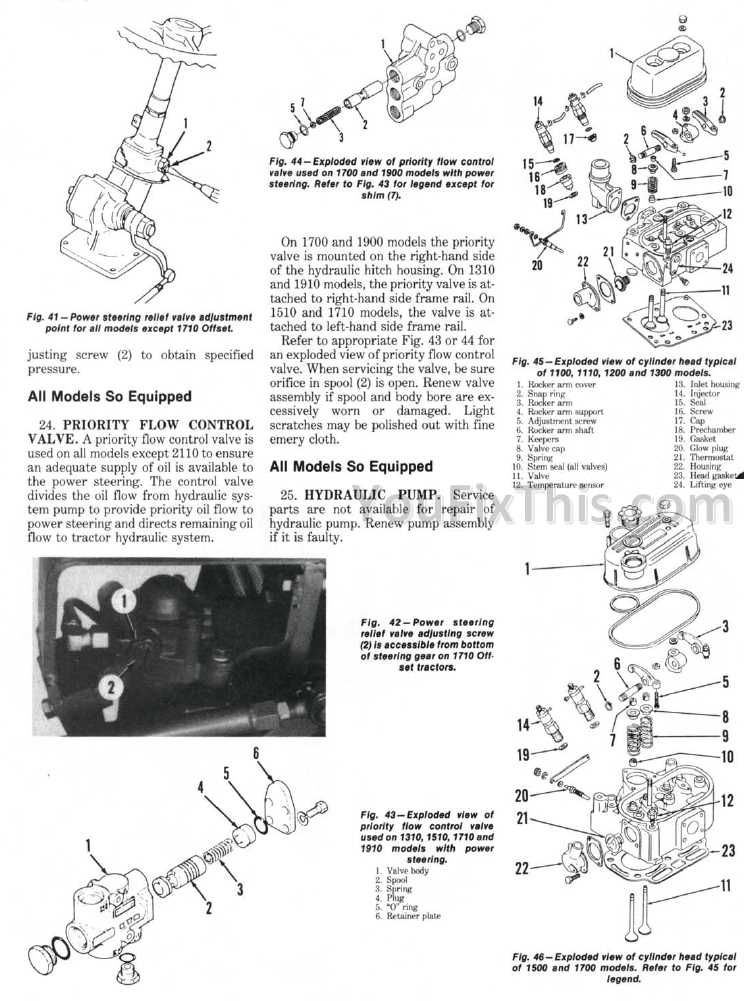

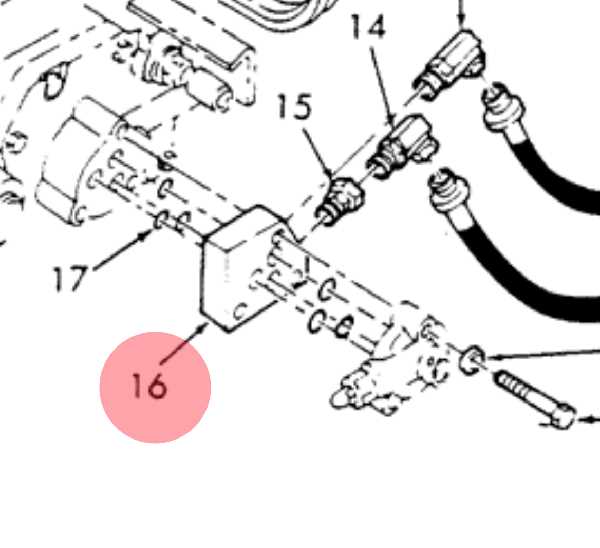

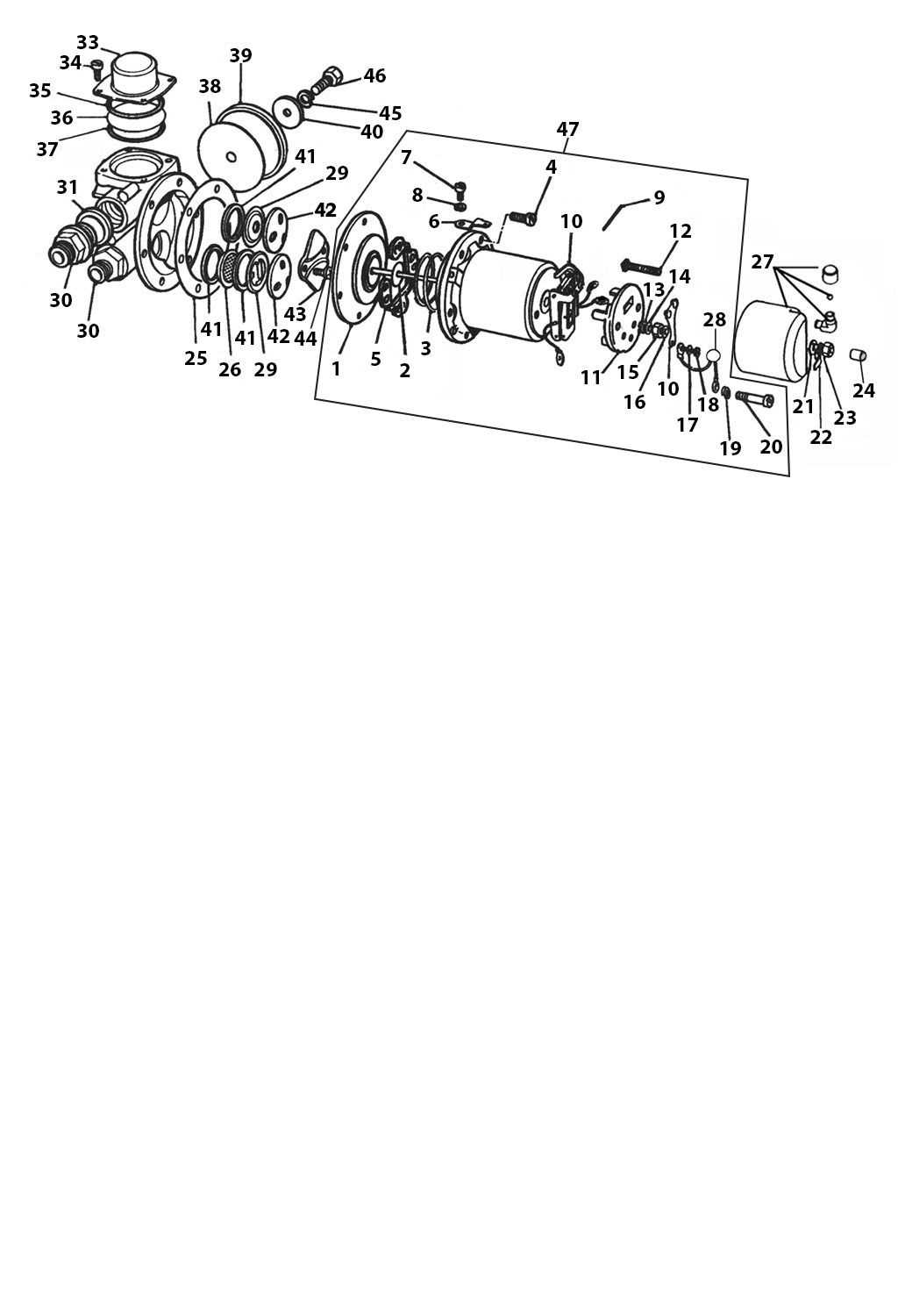

Hydraulic System and Its Functionality

The hydraulic system is a crucial component in machinery, enabling the transmission of power through fluid movement. This technology is fundamental for various applications, providing efficiency and control in operations that require lifting, pushing, or pulling heavy loads.

At its core, the hydraulic system operates by utilizing pressurized fluid to transmit energy. This mechanism allows for the transformation of small forces into larger, more effective forces, making it ideal for tasks that demand significant strength. Components such as pumps, cylinders, and valves work in harmony to create a seamless flow of fluid, facilitating precise movements and enhancing overall functionality.

Understanding the essential elements of a hydraulic system reveals its importance in enhancing productivity. The pump draws fluid from a reservoir and pressurizes it, while valves regulate the flow and direction of the fluid. Cylinders then convert hydraulic energy back into mechanical energy, enabling machinery to perform specific tasks with remarkable efficiency.

In summary, the hydraulic system exemplifies a powerful engineering solution that significantly improves operational capabilities in various industries. Its design ensures that heavy lifting and precise maneuvers can be executed with minimal effort, showcasing the elegance of hydraulic technology.

Parts That Drive the Hydraulics

The hydraulic system in any heavy machinery is a crucial component that enables various mechanical functions, from lifting to steering. The system relies on a network of specialized components that convert mechanical energy into fluid power, creating the force necessary for different operations. These elements work in tandem, with each one contributing to the overall efficiency and performance of the system. Understanding the individual components that make up this system is essential for proper maintenance and troubleshooting.

Hydraulic Pump

The hydraulic pump is the heart of the system, responsible for circulating fluid under pressure to the rest of the components. It converts mechanical energy from the engine into hydraulic energy, providing the force needed for various functions like lifting or pushing. A properly functioning pump is essential for maintaining optimal fluid flow and pressure throughout the system.

Control Valve and Cylinders

The control valve regulates the flow of hydraulic fluid to different parts of the system, directing it to the appropriate cylinders or actuators. These cylinders, in turn, convert the fluid’s pressure into linear motion, allowing for tasks such as raising and lowering implements. Without precise control of fluid distribution, the entire system’s efficiency can be compromised.