The intricate network of machinery that supports various agricultural tasks requires a comprehensive grasp of its essential elements. Each segment plays a crucial role in ensuring seamless operation, contributing to overall efficiency and productivity. Recognizing how these components interconnect is vital for anyone involved in the maintenance or enhancement of such systems.

By delving into the structure and functionality of each individual element, operators can make informed decisions regarding upkeep and troubleshooting. This knowledge not only fosters better performance but also prolongs the lifespan of the machinery. Familiarity with the arrangement and specifications of these units allows for timely interventions and optimal usage.

Whether you are a seasoned expert or a newcomer in the field, understanding the layout and function of the machinery’s components will empower you to manage your equipment more effectively. Embracing this knowledge can lead to enhanced operational efficiency and reduced downtime, ensuring that tasks are completed smoothly and effectively.

Understanding LS Tractor Components

Gaining insight into the various elements of LS machinery is essential for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency, durability, and productivity. By familiarizing yourself with these elements, you can enhance your operational skills and troubleshoot issues effectively.

Key components include:

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Transmission: This element facilitates the transfer of power from the engine to the wheels, allowing for speed adjustments and movement control.

- Hydraulics: Critical for powering attachments and implements, enabling lifting and maneuvering tasks.

- Chassis: The structural framework that supports all other components, ensuring stability and strength.

- Electrical System: Responsible for powering lights, instruments, and other electronic features.

Understanding the function of each component allows operators to make informed decisions regarding maintenance and repairs. This knowledge can also contribute to improved performance and longevity of the machinery.

Regular inspection and awareness of potential wear and tear can lead to better upkeep and functionality. Familiarizing yourself with the layout and role of these elements is beneficial for both novice and experienced users.

Importance of Tractor Parts Diagrams

Understanding the intricate components of agricultural machinery is crucial for efficient maintenance and operation. Visual representations play a vital role in comprehending how each element interacts and functions within the system.

Utilizing such visuals offers several advantages:

- Facilitates quick identification of specific components.

- Enhances troubleshooting by highlighting potential issues.

- Improves communication among technicians and operators.

- Assists in ensuring proper assembly and disassembly procedures.

Moreover, these representations serve as valuable resources for training new personnel. They provide clear guidance, allowing individuals to familiarize themselves with complex machinery efficiently.

In summary, leveraging visual aids significantly enhances understanding, promotes effective maintenance practices, and ensures optimal performance of agricultural equipment.

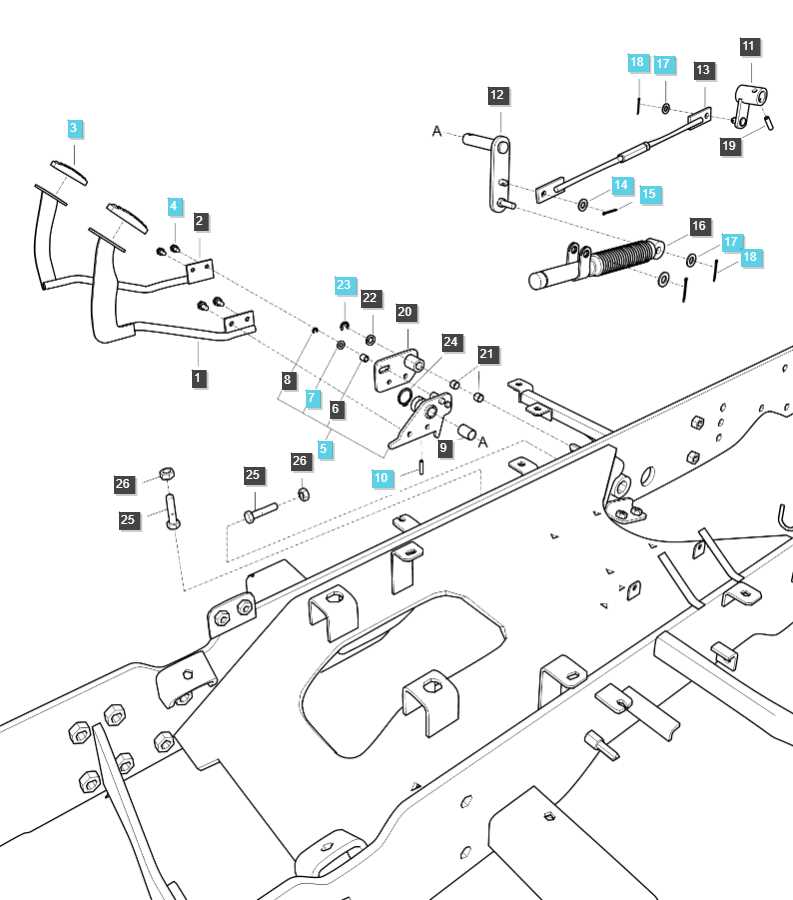

How to Read LS Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide insights into the arrangement and functionality of various elements within a machine, allowing users to identify specific sections and their interconnections.

Familiarizing Yourself with Symbols

Each visual representation uses specific symbols to denote different components. Familiarizing yourself with these can greatly enhance your comprehension. Common symbols include:

- Circles for connectors

- Squares for structural elements

- Arrows indicating flow or movement

Interpreting Layouts

The layout often reflects the order and relationship between components. To interpret effectively:

- Start from the main unit and work outward.

- Follow the arrows to understand movement or assembly order.

- Cross-reference with a list for clarification on specific parts.

Common LS Tractor Issues and Solutions

Every agricultural machine can encounter difficulties, leading to decreased efficiency and performance. Understanding frequent problems and their remedies is essential for maintaining optimal functionality. This section highlights some typical challenges faced by users of LS equipment and provides effective solutions to address them.

Engine Performance Problems

A common issue involves engine inefficiency, which may manifest as reduced power output or irregular operation. Clogged filters or fuel quality can significantly impact performance. Regularly checking and replacing filters, as well as using high-quality fuel, can alleviate these issues. Additionally, ensuring proper maintenance of the ignition system can help keep the engine running smoothly.

Hydraulic System Failures

Hydraulic system malfunctions can lead to poor performance of attachments and implements. Signs of trouble include slow or unresponsive movements. Leaks in hoses or connections are often the culprits. Conducting routine inspections and replacing damaged components promptly can prevent further complications. Maintaining the hydraulic fluid at the recommended levels also contributes to the longevity of the system.

Where to Find LS Parts Diagrams

Finding the necessary visuals for your LS equipment can greatly enhance your understanding of its components and assembly. Various resources are available that cater to both enthusiasts and professionals alike, ensuring you have access to comprehensive illustrations and information.

Online Resources

- Manufacturer’s Website: Official sites often provide detailed visuals and manuals.

- Dedicated Forums: Community-driven platforms can offer insights and shared resources.

- YouTube Tutorials: Visual guides that can simplify complex processes.

Local Dealerships

- Authorized Dealers: They typically have access to official documentation.

- Workshops: Local mechanics may provide helpful insights and visual aids.

Benefits of Using Original Parts

Choosing genuine components for machinery maintenance offers numerous advantages that enhance performance and longevity. Authentic items are designed specifically to meet the unique specifications of the equipment, ensuring optimal functionality and reliability. Utilizing original components can lead to fewer operational issues, reduced downtime, and overall better efficiency.

Enhanced Reliability

Original components undergo rigorous testing to guarantee their durability and effectiveness. This reliability translates into consistent performance, allowing operators to complete tasks without unexpected interruptions. When equipment functions as intended, it minimizes the risk of breakdowns and maintenance costs.

Long-Term Cost Efficiency

Investing in authentic items may appear more expensive initially, but it often proves cost-effective over time. High-quality components tend to have a longer lifespan, reducing the need for frequent replacements. Additionally, they contribute to maintaining the value of the machinery, making it a wise choice for those seeking long-term savings.

Maintenance Tips for LS Tractors

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By adhering to specific maintenance practices, you can prevent issues and enhance efficiency. Below are key strategies to help you maintain your equipment effectively.

Regular Inspections

Conduct frequent assessments of critical components. Check for signs of wear, leaks, or unusual noises. This proactive approach allows you to identify potential problems before they escalate, saving time and resources.

Fluid Management

Ensure that all necessary fluids, such as oil and coolant, are at appropriate levels. Change them as recommended by the manufacturer to prevent overheating and ensure smooth operation. Proper fluid management is vital for the overall health of your machinery.

Upgrades and Modifications for Efficiency

Enhancing performance and productivity is a key objective for many operators. By implementing strategic improvements and customizations, users can optimize functionality, reduce operational costs, and extend the lifespan of their equipment. This section explores various enhancements that can lead to greater efficiency in daily tasks.

Performance Enhancements

Upgrading engine components can significantly boost power output and fuel efficiency. High-performance filters and advanced fuel systems allow for better air and fuel mixture, resulting in smoother operation. Additionally, integrating electronic control systems can provide precise monitoring and adjustments, ensuring that the machinery operates at its peak.

Ergonomic Modifications

Improving operator comfort and accessibility can lead to more effective work. Modifications such as adjustable seating and enhanced visibility through better cab designs can reduce fatigue during long hours of operation. Furthermore, incorporating user-friendly controls allows for quicker response times and improved handling, ultimately contributing to a more productive experience.