Maintaining outdoor spaces often requires specialized tools designed to handle grass and vegetation effectively. A thorough understanding of these tools can greatly enhance their performance and longevity. By exploring the various components of this essential equipment, users can ensure optimal functionality and address potential issues before they escalate.

Each segment of the device plays a crucial role in its overall operation. From the cutting mechanism to the power source, familiarizing yourself with these elements not only aids in routine maintenance but also empowers users to undertake minor repairs. By delving into the intricacies of these components, one can gain insights into how to keep their trimming tool in peak condition.

In this guide, we will break down the structure of your trimming apparatus, highlighting the significance of each element. Understanding how these components work together can provide valuable knowledge for both novice and experienced users alike, making outdoor maintenance tasks more efficient and manageable.

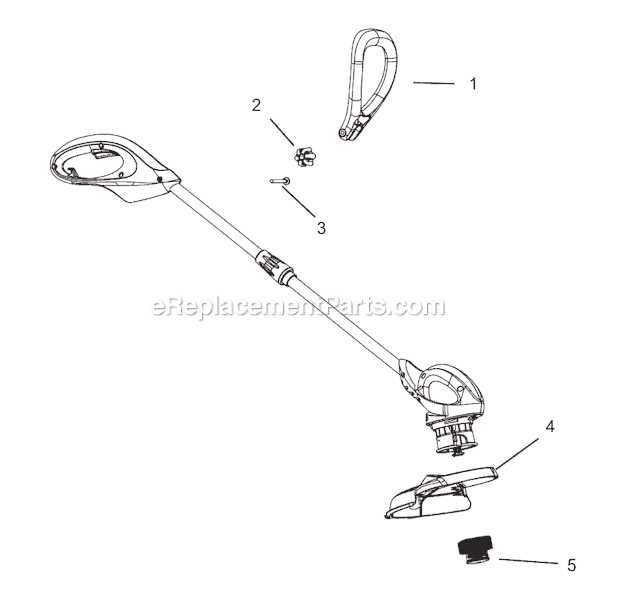

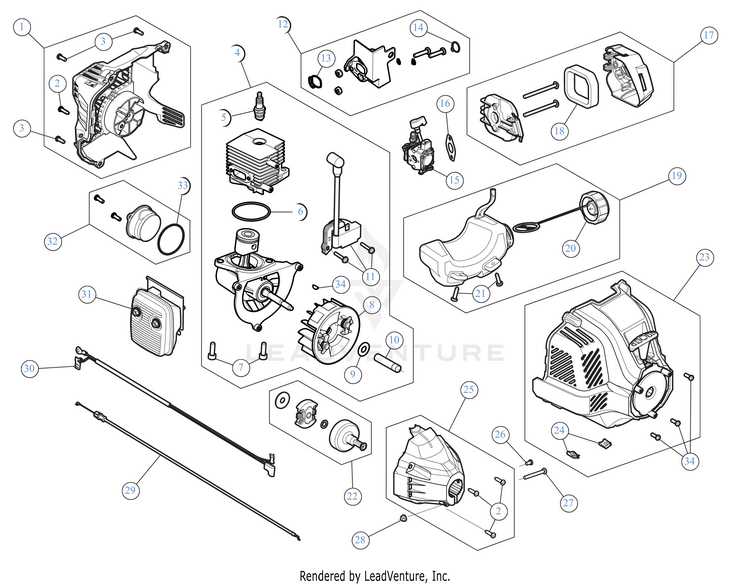

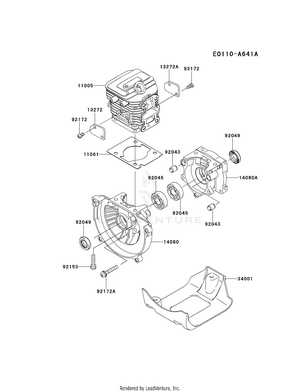

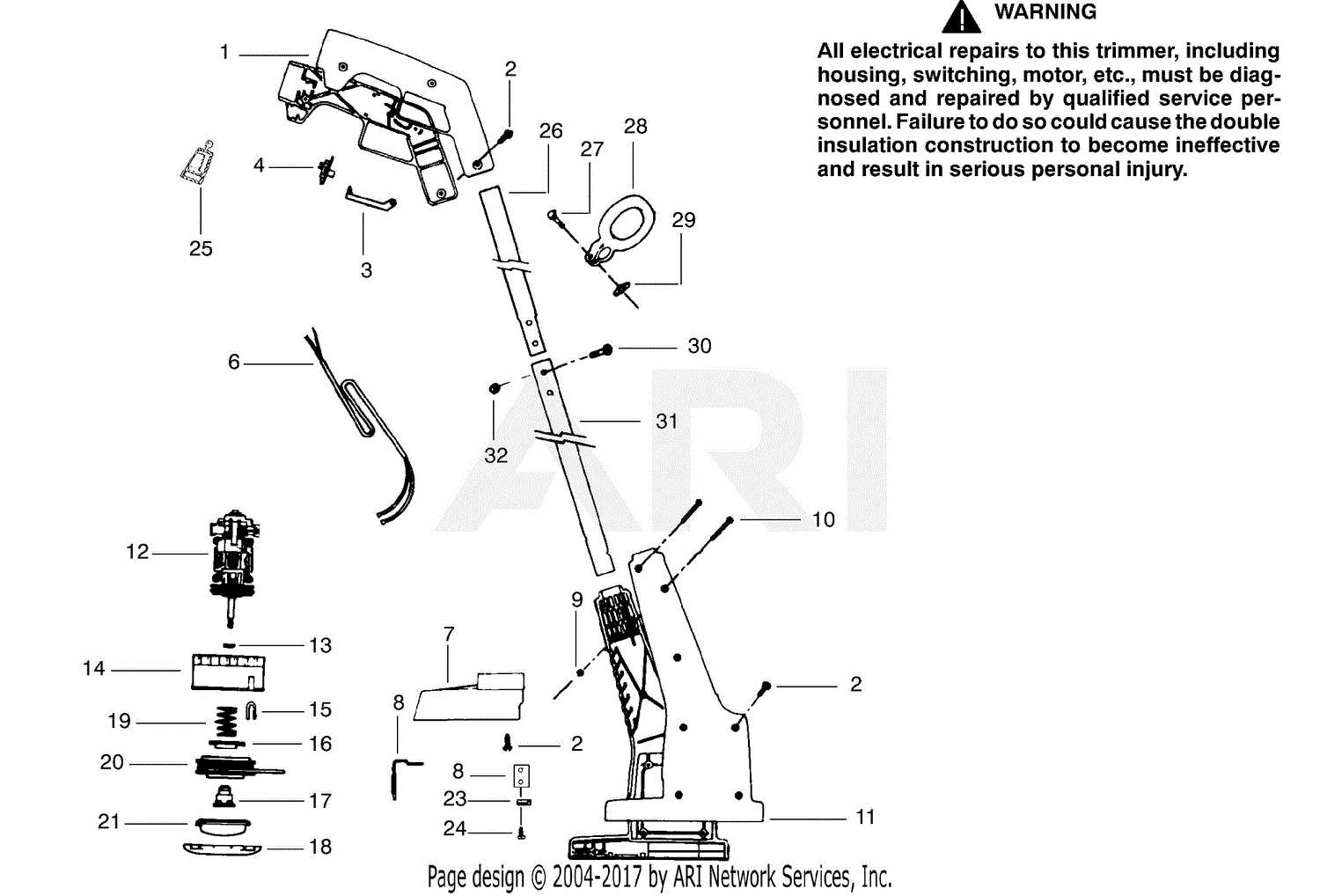

Understanding Weed Wacker Components

Familiarizing oneself with the essential elements of a cutting tool is crucial for effective maintenance and operation. Each component plays a vital role in the overall functionality, ensuring efficient performance during landscaping tasks. By grasping the intricacies of these elements, users can enhance their experience and prolong the life of their equipment.

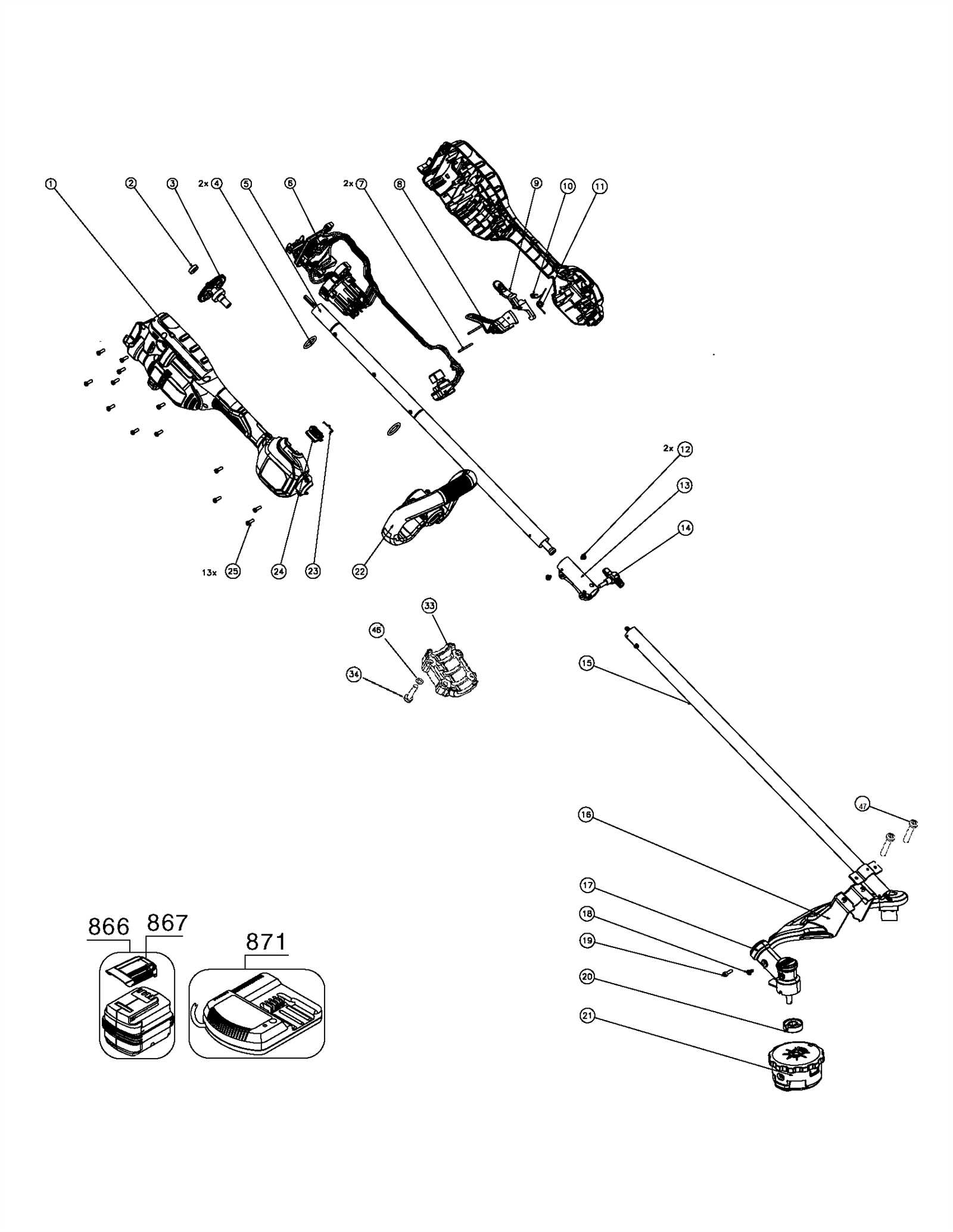

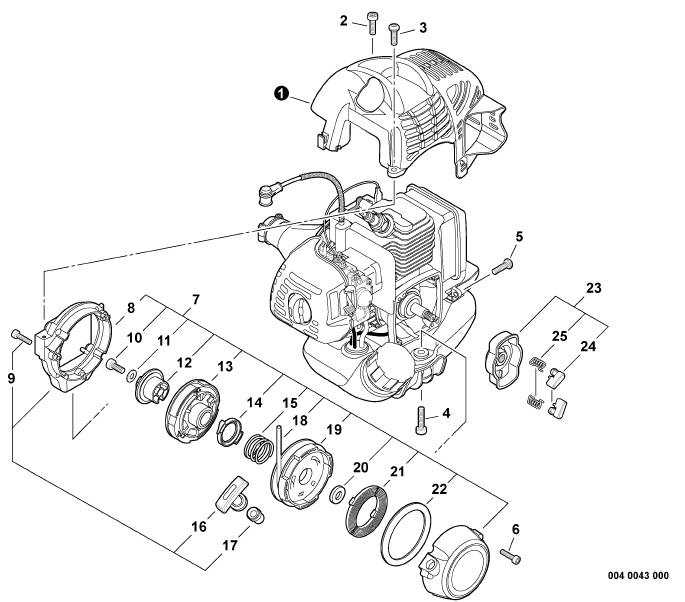

The engine serves as the powerhouse, converting fuel into mechanical energy. This energy drives the cutting mechanism, allowing for precision in trimming and edging. Understanding how to maintain this core component can significantly impact performance.

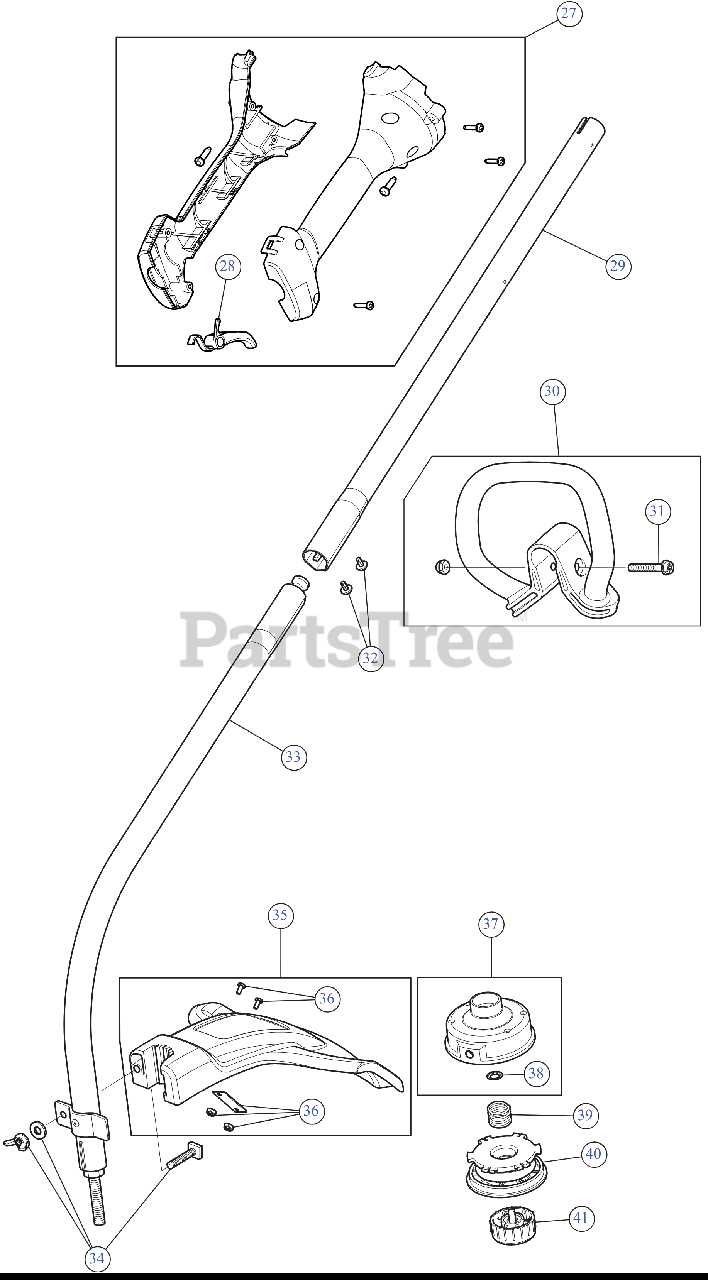

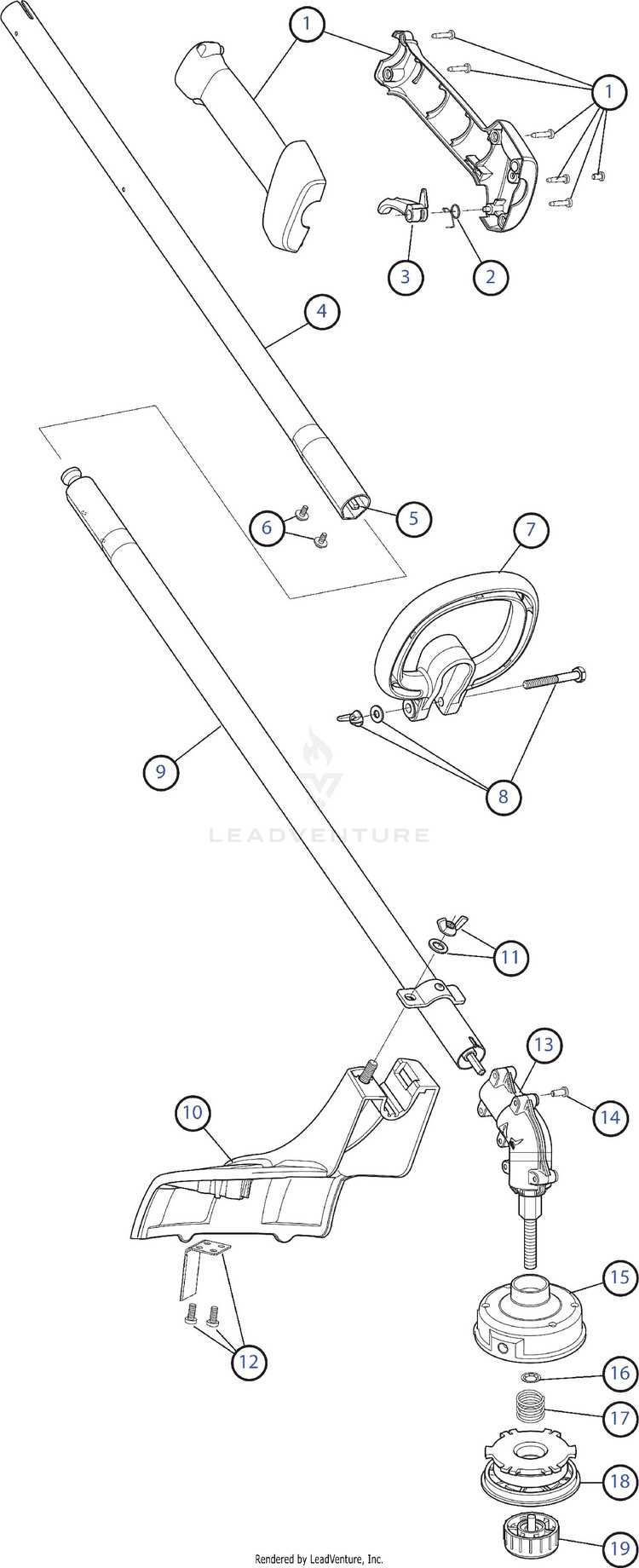

The cutting head is where the action happens. Equipped with various line types or blades, it is responsible for executing the actual cutting. Knowing how to properly replace or adjust this part can make a noticeable difference in effectiveness.

Additionally, the handle and shaft provide stability and control, allowing users to maneuver the tool with ease. Their ergonomic design is essential for reducing fatigue during prolonged use.

Lastly, the throttle and trigger mechanisms are crucial for regulating power and speed. Mastering these controls enables precise handling and adaptability to different tasks, from light trimming to heavy-duty clearing.

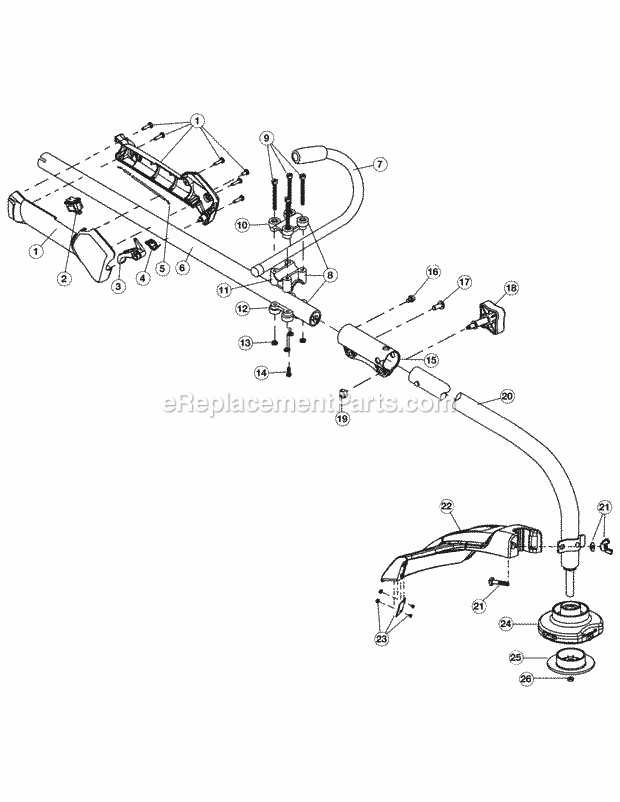

Essential Parts of a Weed Wacker

Understanding the crucial components of a trimming device is vital for maintaining its efficiency and longevity. Each element plays a significant role in the overall functionality, ensuring that the machine operates smoothly and effectively. Familiarity with these elements can enhance both performance and user experience.

Power Source: The engine or motor is the heart of the equipment, providing the necessary energy for operation. Options include gas-powered or electric models, each with its advantages and drawbacks.

Cutting Head: This is where the magic happens, as it houses the mechanism responsible for cutting grass and weeds. It can come equipped with various blades or line types, allowing for different applications depending on the task at hand.

Handle: The handle provides control and stability during use. Ergonomically designed handles can reduce fatigue and improve maneuverability, making the job easier and more comfortable.

Guard: The protective shield around the cutting area serves to prevent debris from being ejected during operation. This safety feature is essential for both the user and bystanders.

Shoulder Strap: For larger models, a shoulder strap can distribute weight more evenly, making the equipment easier to manage over extended periods. This accessory significantly enhances user comfort.

By familiarizing yourself with these fundamental components, you can ensure proper maintenance and make informed decisions when it comes to repairs or upgrades, ultimately enhancing your trimming experience.

Common Problems and Solutions

When maintaining your outdoor trimming equipment, various issues may arise that can hinder performance. Identifying these problems early can save time and enhance efficiency. Below are some frequent challenges faced by users, along with their corresponding solutions.

| Problem | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Fuel issues, spark plug failure, or air filter blockage | Check fuel levels, replace the spark plug, and clean or replace the air filter. |

| Overheating | Insufficient lubrication or debris buildup | Ensure proper oil levels and clear any debris from cooling vents. |

| Loss of Power | Clogged exhaust or dull cutting blade | Inspect and clean the exhaust, and sharpen or replace the blade as needed. |

| Vibrations During Use | Loose components or worn-out parts | Tighten loose screws and bolts, and check for signs of wear on key components. |

| Fuel Leaks | Deteriorated fuel lines or connections | Inspect and replace damaged fuel lines and ensure all connections are secure. |

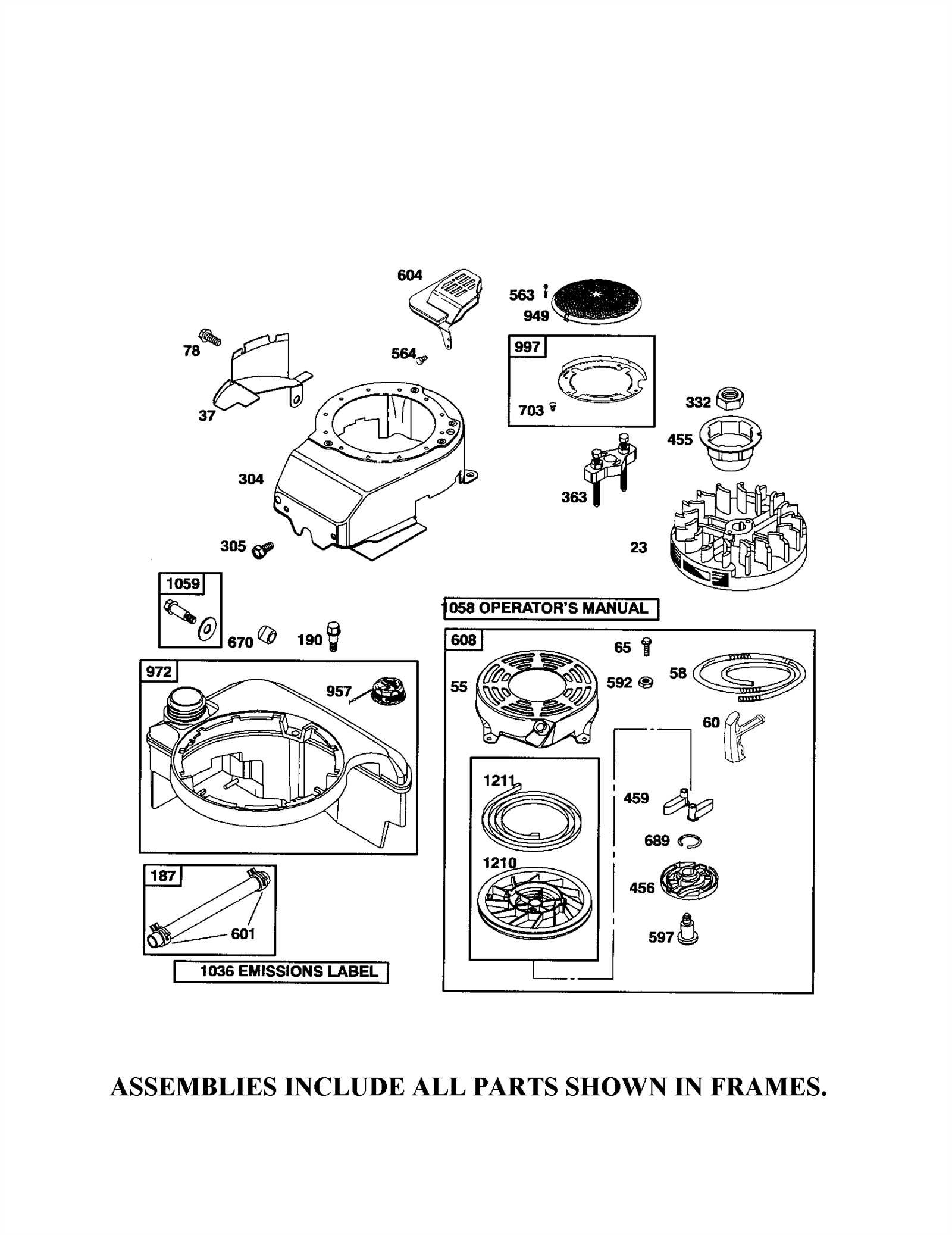

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to troubleshoot and maintain equipment. Whether you are examining a layout, a schematic, or an illustration, grasping the key components and their relationships is crucial. This skill allows you to quickly identify areas of interest and navigate complex information with ease.

First, familiarize yourself with the symbols and notations commonly used in the illustration. Each graphic element often represents a specific function or component. Recognizing these symbols will streamline your comprehension and make it easier to follow the connections between various elements.

Next, pay attention to the organization of the layout. Many illustrations are structured in a way that guides the viewer from one part to another logically. Observing the flow of information can help you piece together how the components interact and where potential issues might arise.

Finally, practice patience when interpreting visuals. It may take some time to fully grasp the intricate details, especially in more complex representations. Take a moment to analyze each segment before drawing conclusions, ensuring a thorough understanding of the entire system.

Maintenance Tips for Longevity

Ensuring the durability of your gardening equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your tools. Following a few simple practices can keep them in top condition for years to come.

Regular Cleaning

Keeping your equipment clean is essential. Debris can accumulate and cause malfunctions. Implement these steps:

- After each use, remove dirt and grass clippings.

- Use a soft brush or cloth to wipe down surfaces.

- Inspect and clean air filters regularly to ensure optimal airflow.

Routine Inspections

Conducting frequent checks can prevent minor issues from escalating into major problems:

- Examine blades for wear and tear, replacing them as needed.

- Check for loose screws or components and tighten them.

- Look for signs of rust or corrosion and address them promptly.

By adhering to these maintenance tips, you can enjoy improved efficiency and a longer operational life for your gardening tools.

Identifying Worn Out Parts

Recognizing when components have degraded is crucial for maintaining optimal performance. Regular inspections can help you determine the condition of each element, ensuring your equipment operates efficiently and safely.

Signs of Wear: Look for visible damage such as cracks, bends, or excessive rust. These indicators often suggest that a replacement is necessary.

Performance Issues: If you notice a decline in functionality, such as decreased power or unusual vibrations, it may point to failing components that require attention.

Maintenance Tips: Keep an eye on the frequency of use and age of the elements, as older items are more prone to wear. Documenting changes can help you anticipate future replacements.

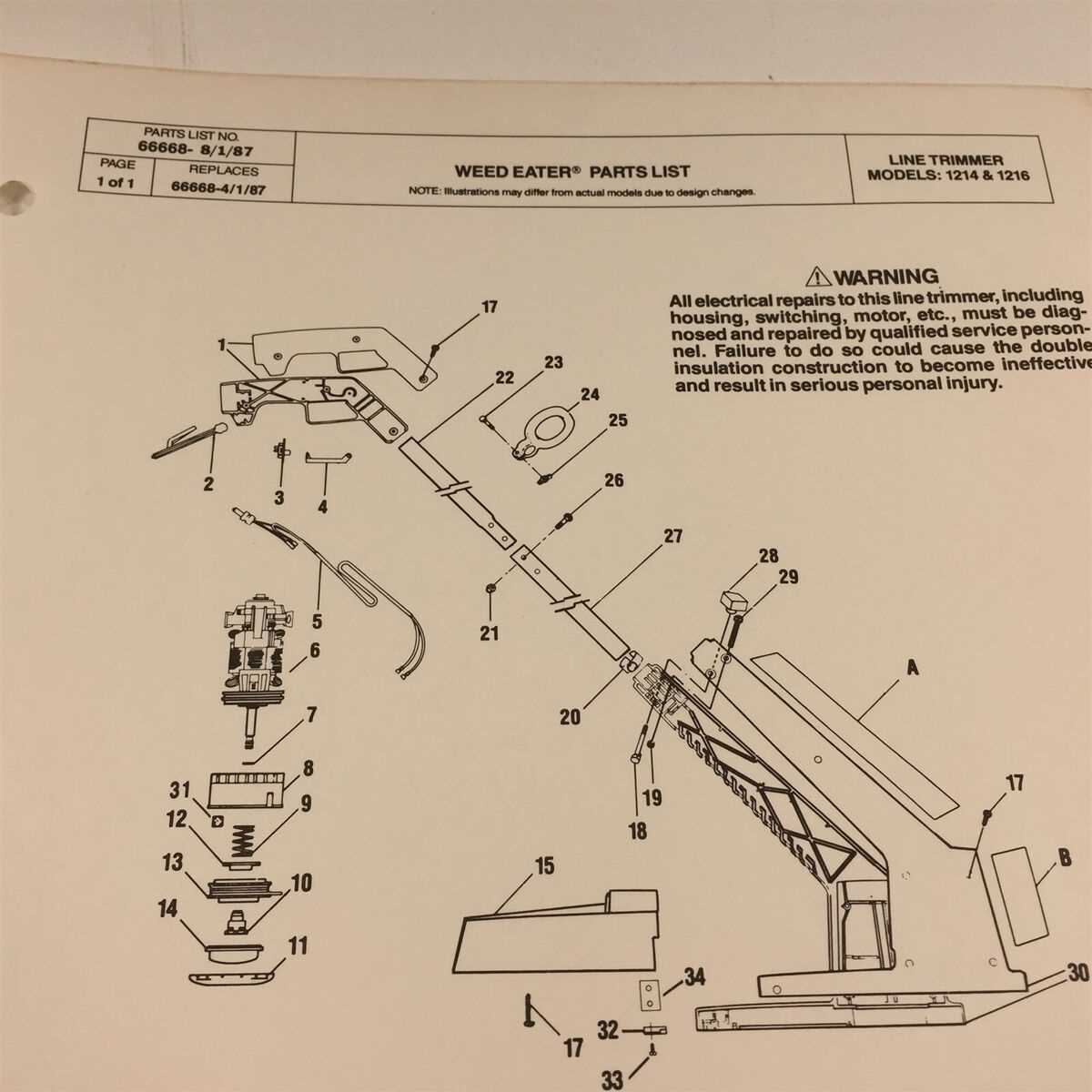

Replacement Parts: What to Consider

When it comes to maintaining outdoor equipment, choosing the right components for replacement is crucial. Proper selection not only ensures optimal functionality but also prolongs the lifespan of your machine. Understanding various factors can guide you in making informed decisions when it’s time for an upgrade or repair.

Compatibility and Specifications

First and foremost, ensure that the new components match the specifications of your existing model. Compatibility is vital; mismatched items can lead to subpar performance or even damage. Referencing the original manufacturer’s guidelines can help identify the right dimensions and compatibility requirements.

Quality and Brand Reliability

Next, consider the quality of the items you’re purchasing. Investing in high-quality replacements from reputable brands may cost more initially, but it can save you money in the long run by reducing the frequency of repairs. Look for reviews and ratings to gauge reliability and performance of different brands.

In summary, taking the time to assess compatibility and quality will lead to better outcomes when replacing essential components for your equipment.

Upgrading Your Weed Wacker

Enhancing your trimming tool can significantly improve its performance and longevity. Whether you’re looking to increase efficiency or adapt to specific tasks, various modifications can make a substantial difference.

Performance improvements can be achieved by swapping out the cutting mechanism for a more advanced version. Consider options that offer better durability and efficiency, allowing for cleaner cuts and less maintenance.

Another vital aspect is ergonomics. Upgrading handles or grips can provide better comfort, reducing fatigue during extended use. This simple adjustment can lead to a more enjoyable experience while working in your garden.

Finally, explore the option of adding attachments for specialized tasks. These tools can help you tackle a wider range of projects, ultimately making your equipment more versatile and effective.

Safety Precautions When Repairing

When engaging in maintenance or fixing outdoor equipment, ensuring safety is paramount. Taking the right precautions can prevent accidents and injuries, allowing you to work effectively and confidently.

Always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. This will shield you from sharp edges, flying debris, and potential hazards during the repair process.

Before starting any work, disconnect the power source to eliminate the risk of accidental startup. It’s essential to inspect tools and equipment for damage or wear, as faulty tools can lead to serious injuries.

Additionally, work in a well-ventilated area to avoid inhaling harmful fumes or dust. Being aware of your surroundings and keeping the workspace organized can further enhance safety.

Lastly, never hesitate to seek assistance if you’re unsure about a specific procedure or repair. Understanding the tasks at hand can greatly reduce risks and ensure a smooth repair process.