The world of agricultural machinery is intricate, with each machine consisting of various interconnected elements that play crucial roles in its operation. Grasping the layout and function of these components is essential for both maintenance and effective use. By exploring the specific arrangement of these elements, operators can enhance their understanding of how these machines function and how to address potential issues that may arise.

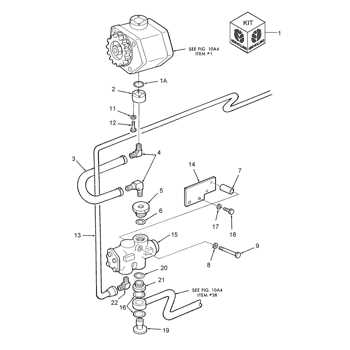

Detailed illustrations and schematics serve as valuable resources for anyone looking to delve deeper into the mechanics of their equipment. These visual aids provide a clear representation of the intricate relationships between various sections, allowing users to identify components easily and understand their functions. The clarity offered by these resources empowers operators to make informed decisions regarding repairs and upgrades.

In this exploration, we will focus on the vital aspects of a well-known agricultural model. By examining its components systematically, users can better appreciate the craftsmanship behind the machinery and the importance of each element. This knowledge not only improves operational efficiency but also contributes to the longevity of the equipment, ensuring it remains a reliable asset in agricultural endeavors.

Understanding the Ford 1710 Tractor

This section explores a particular model of agricultural machinery, focusing on its structure, functionality, and the key components that contribute to its performance. By examining these elements, users can gain insights into maintaining and optimizing this robust machine for various farming tasks.

Key Features

The discussed model is known for its durability and efficiency. It is equipped with essential functionalities that enhance productivity in fieldwork. A detailed understanding of these features helps users appreciate its capabilities.

Maintenance and Care

| Component | Function |

|---|---|

| Engine | Powers the machine and drives performance |

| Transmission | Transfers power to the wheels for movement |

| Hydraulics | Operates attachments and enhances functionality |

Key Components of the Ford 1710

This section focuses on the essential elements that contribute to the functionality and efficiency of a well-known agricultural vehicle. Understanding these critical components can aid in proper maintenance and enhance operational performance. Each part plays a vital role in ensuring the machine operates smoothly and meets the demands of various agricultural tasks.

Core Elements

Among the most significant components are the engine, transmission, and hydraulic system. These elements work in unison to deliver power and control, making it possible to perform a range of farming activities. Knowledge of how each part functions can help operators troubleshoot issues and maximize productivity.

Specifications Overview

| Component | Description | Function |

|---|---|---|

| Engine | Four-cylinder, liquid-cooled | Powers the machine and drives attachments |

| Transmission | Dual-range gearbox | Provides speed control and torque adjustment |

| Hydraulic System | Open-center design | Controls implements and attachments |

| Front Axle | Independent suspension | Enhances maneuverability and stability |

| Cab | Ergonomically designed | Ensures operator comfort and visibility |

Importance of Proper Parts Identification

Accurate identification of components plays a crucial role in maintaining machinery and ensuring optimal performance. When each element is correctly recognized, it allows for more efficient repairs, minimizing downtime and extending the lifespan of the equipment. Misidentifying a single piece can lead to complications, impacting not only the functioning of the machine but also safety and productivity.

Enhancing Maintenance Efficiency

Understanding the specific requirements of each element simplifies the maintenance process. When operators can swiftly locate the right components, it leads to quicker service times and reduces the likelihood of errors during repairs. This efficiency can significantly decrease operational costs and improve the overall reliability of the machinery.

Preventing Costly Errors

Inaccurate identification can result in purchasing incorrect components, leading to wasted resources and time. By ensuring each part is properly recognized, organizations can avoid unnecessary expenses and maintain a streamlined workflow. Proper identification not only safeguards investments but also promotes a culture of precision and accountability within maintenance teams.

Where to Find Parts Diagrams

Locating detailed schematics for machinery can greatly enhance repair and maintenance efforts. Understanding the layout and components can help ensure efficient troubleshooting and replacement.

- Manufacturer’s Official Website

- Authorized Dealers and Distributors

- Online Forums and Communities

- Specialized Repair Manuals

- Parts Retailers and E-commerce Platforms

Each of these sources can provide valuable insights, enabling users to delve deeper into the intricacies of their equipment and find the ultimate solutions for their needs.

Common Issues with Ford 1710 Parts

Every piece of machinery has its unique set of challenges, often stemming from the wear and tear of various components. Understanding these common challenges is essential for effective maintenance and repair. Identifying issues early can significantly enhance the longevity and performance of the equipment, preventing more extensive and costly repairs down the line.

Worn Out Components

One of the most frequent problems encountered involves worn components. Over time, elements such as seals, gaskets, and bushings can degrade due to continuous use. This degradation can lead to leaks and decreased efficiency, necessitating timely replacements to maintain optimal functionality.

Electrical System Failures

Another prevalent issue involves the electrical system. Corrosion or damage to wiring harnesses and connectors can lead to intermittent or complete failures of critical systems. Regular inspection of electrical connections and components is vital to ensure reliability and to avoid sudden malfunctions during operation.

Aftermarket vs. OEM Parts Explained

When it comes to maintaining or repairing machinery, the choice between replacement components can significantly affect performance and longevity. Understanding the differences between original equipment manufacturer (OEM) items and those produced by third-party manufacturers is essential for making informed decisions. Each option has its advantages and disadvantages, which can impact not only functionality but also overall value.

What are OEM Components?

Original equipment manufacturer components are made by the same company that produced the original items in the machinery. These components are designed to meet specific standards and quality assurances set forth by the manufacturer, ensuring a perfect fit and compatibility. Users often trust OEM items for their reliability, as they mirror the original specifications and performance.

Understanding Aftermarket Components

Aftermarket components are produced by companies other than the original manufacturer. They can range from high-performance alternatives to budget-friendly options. While these items may vary in quality and performance, many are engineered to meet or exceed the standards of OEM offerings. The flexibility of the aftermarket allows users to find tailored solutions that can enhance performance or reduce costs.

| Feature | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Generally high, as they meet original specifications | Varies widely; some may exceed OEM quality |

| Cost | Typically more expensive | Often more affordable, with a range of prices |

| Availability | Limited to manufacturer networks | Widely available from various suppliers |

| Warranty | Usually includes a manufacturer warranty | Warranties vary by manufacturer |

| Fitment | Exact fit for the intended application | May require adjustments for optimal fit |

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires a proactive approach to upkeep and care. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. By following a few key practices, you can prevent costly repairs and ensure that your machine operates efficiently for years to come.

First and foremost, always adhere to the manufacturer’s maintenance schedule. This includes routine checks and servicing of crucial components. Regular oil changes, filter replacements, and fluid level checks are essential for keeping the engine and hydraulic systems in optimal condition.

Another vital aspect of maintenance is to inspect and clean air filters regularly. A clean air intake promotes better combustion and enhances engine efficiency. Additionally, examining belts and hoses for wear and tear can prevent breakdowns and ensure smooth operation.

Pay attention to the cooling system as well. Ensure that coolant levels are sufficient and that there are no leaks in the system. Overheating can lead to severe damage, so regular checks are crucial. Maintaining the electrical system by testing battery health and cleaning terminals can also prevent electrical failures.

Finally, don’t overlook the importance of proper storage. When not in use, keep the equipment in a dry, sheltered location to protect it from the elements. Using covers can further shield it from dust and debris, maintaining its condition over time.

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of your machine can significantly impact productivity and longevity. By focusing on various enhancements, you can achieve better output, reduced downtime, and a smoother operational experience. Upgrading specific components is essential for those seeking to maximize their investment and performance capabilities.

Engine Enhancements: Upgrading to a high-performance air filter can improve airflow, resulting in better combustion and increased horsepower. Consider also investing in a quality fuel injector to enhance fuel delivery, which leads to improved engine response and efficiency.

Transmission Modifications: Optimizing the transmission system can lead to smoother shifts and enhanced power delivery. Installing a performance clutch can ensure better engagement, while adjusting gear ratios may provide a more suitable power band for various tasks.

Hydraulic System Improvements: Enhancing hydraulic components, such as pumps and cylinders, can result in quicker response times and increased lifting capacity. Consider upgrading to a higher-capacity hydraulic pump to facilitate more demanding tasks without straining the system.

Tire Upgrades: Selecting the right tires for your needs can improve traction and stability, making a noticeable difference in performance. Investing in wider, high-traction tires can enhance grip and maneuverability in challenging terrains.

Electrical System Enhancements: Modernizing the electrical system can increase reliability and efficiency. Upgrading to LED lighting can improve visibility while reducing power consumption. Additionally, a high-output alternator can ensure that all electrical components function optimally, especially under heavy loads.

Implementing these upgrades can transform your equipment, making it more efficient and reliable for any task. Whether it’s enhancing power, efficiency, or overall performance, each improvement plays a vital role in achieving outstanding results.