The effective operation of any farming equipment relies on a thorough comprehension of its individual elements. This section delves into the intricate structure of a popular piece of machinery used in the agricultural sector, offering insights into its various components and their functionalities. By familiarizing oneself with these elements, operators can enhance maintenance practices and improve overall performance.

Each segment of this machinery plays a critical role in ensuring smooth operation and efficiency. From the power unit to the implements that facilitate various tasks, understanding how these parts interact is vital for troubleshooting issues and executing repairs. This knowledge empowers users to make informed decisions, prolong the lifespan of their equipment, and optimize productivity on the field.

Moreover, comprehending the layout and relationship between components aids in identifying potential areas for improvement or upgrades. This section will provide an overview of essential elements, elucidating their purposes and significance within the machinery framework. Whether you are a seasoned operator or a newcomer to the world of agricultural machinery, this exploration will serve as a valuable resource for enhancing your operational expertise.

Overview of Ford 3910 Tractor

This section provides a comprehensive look at a specific model known for its reliability and efficiency in agricultural tasks. With a strong reputation among users, this machine is designed to meet the demands of various farming activities, offering a blend of power and versatility. Its engineering emphasizes functionality, making it a preferred choice for many who seek dependable equipment in their daily operations.

Key Features

The machinery is equipped with several notable features that enhance its performance. The engine delivers substantial horsepower, ensuring that it can handle heavy loads with ease. Additionally, its user-friendly controls allow for seamless operation, making it accessible for both experienced operators and newcomers. The robust construction ensures durability, even in challenging environments, while the adaptable design permits the attachment of various implements, thereby expanding its utility.

Maintenance and Care

Regular maintenance is crucial for prolonging the lifespan of this equipment. Adhering to a scheduled service routine not only optimizes performance but also prevents potential issues that may arise from wear and tear. Users are encouraged to consult the manufacturer’s guidelines for maintenance tasks, including fluid changes and inspections of key components. By doing so, operators can ensure that their machinery remains in peak condition, ready to tackle the demands of any task.

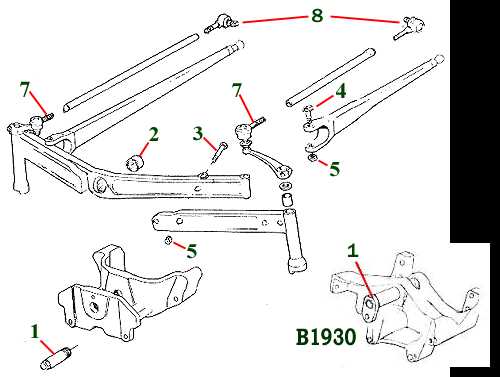

Importance of Parts Diagrams

Visual representations of components are crucial for effective maintenance and repair. They provide essential insights into how individual elements fit together and function as a whole. Understanding these illustrations can significantly enhance the efficiency of repairs and upgrades.

Here are some key benefits of using these visual guides:

- Enhanced Clarity: Illustrations simplify complex structures, making it easier to identify each element and its specific role.

- Time Efficiency: Quick reference to these visuals can expedite the diagnostic process, reducing downtime during repairs.

- Accurate Identification: They assist in recognizing the exact components required for maintenance, minimizing errors in ordering or replacing parts.

- Improved Communication: These visuals serve as a common language among technicians, facilitating discussions and instructions related to repairs.

- Educational Resource: They are valuable tools for training new technicians, providing a clear understanding of how systems operate.

In conclusion, visual representations are indispensable for anyone involved in maintenance or repair tasks. They not only streamline processes but also contribute to the longevity and reliability of machinery.

Key Components of Ford 3910

The efficiency and performance of agricultural machinery largely depend on its crucial elements. Understanding these vital components can enhance maintenance practices and ensure optimal functionality over time. In this section, we will explore the essential mechanisms that contribute to the overall operation of this specific agricultural vehicle.

Powertrain System

The powertrain is the heart of any machine, transmitting power from the engine to the wheels. This system typically includes the engine, transmission, and drive shafts. A well-maintained powertrain ensures smooth operation and can significantly improve the machine’s performance, especially in demanding tasks.

Hydraulic System

The hydraulic system plays a pivotal role in facilitating various functions, such as lifting and steering. It operates through the use of hydraulic fluid to transfer power. Key components include pumps, cylinders, and valves, all of which must be regularly checked to prevent leaks and maintain efficiency.

Regular inspections and maintenance of these essential components are crucial for maximizing the lifespan and efficiency of the equipment. Understanding their functions will aid operators in identifying issues early and addressing them effectively.

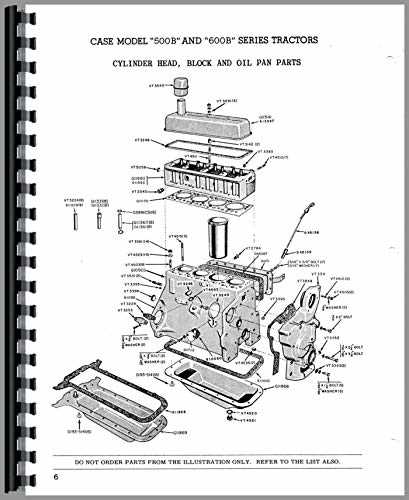

Understanding the Engine Assembly

The engine assembly serves as the heart of any mechanical vehicle, providing the necessary power for operation. This complex unit comprises various components that work in unison to ensure optimal performance and efficiency. Grasping the intricacies of this assembly is essential for effective maintenance and troubleshooting, allowing operators to maximize the longevity and functionality of their machinery.

At its core, the engine assembly includes several key elements that contribute to its overall operation. Each component plays a specific role, from fuel delivery to combustion and exhaust management. Understanding how these parts interact can significantly enhance one’s ability to diagnose issues and carry out repairs.

| Component | Description |

|---|---|

| Cylinder Head | Houses the intake and exhaust valves, playing a critical role in the combustion process. |

| Pistons | Move up and down within the cylinders, converting combustion energy into mechanical motion. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion to drive the vehicle. |

| Camshaft | Controls the timing of valve openings and closings, ensuring efficient engine operation. |

| Oil Pump | Circulates oil throughout the engine to lubricate moving parts and prevent wear. |

By familiarizing oneself with these components and their functions, operators can better appreciate the engineering behind the machinery. This knowledge not only aids in everyday usage but also empowers users to tackle maintenance tasks effectively, ensuring sustained performance over time.

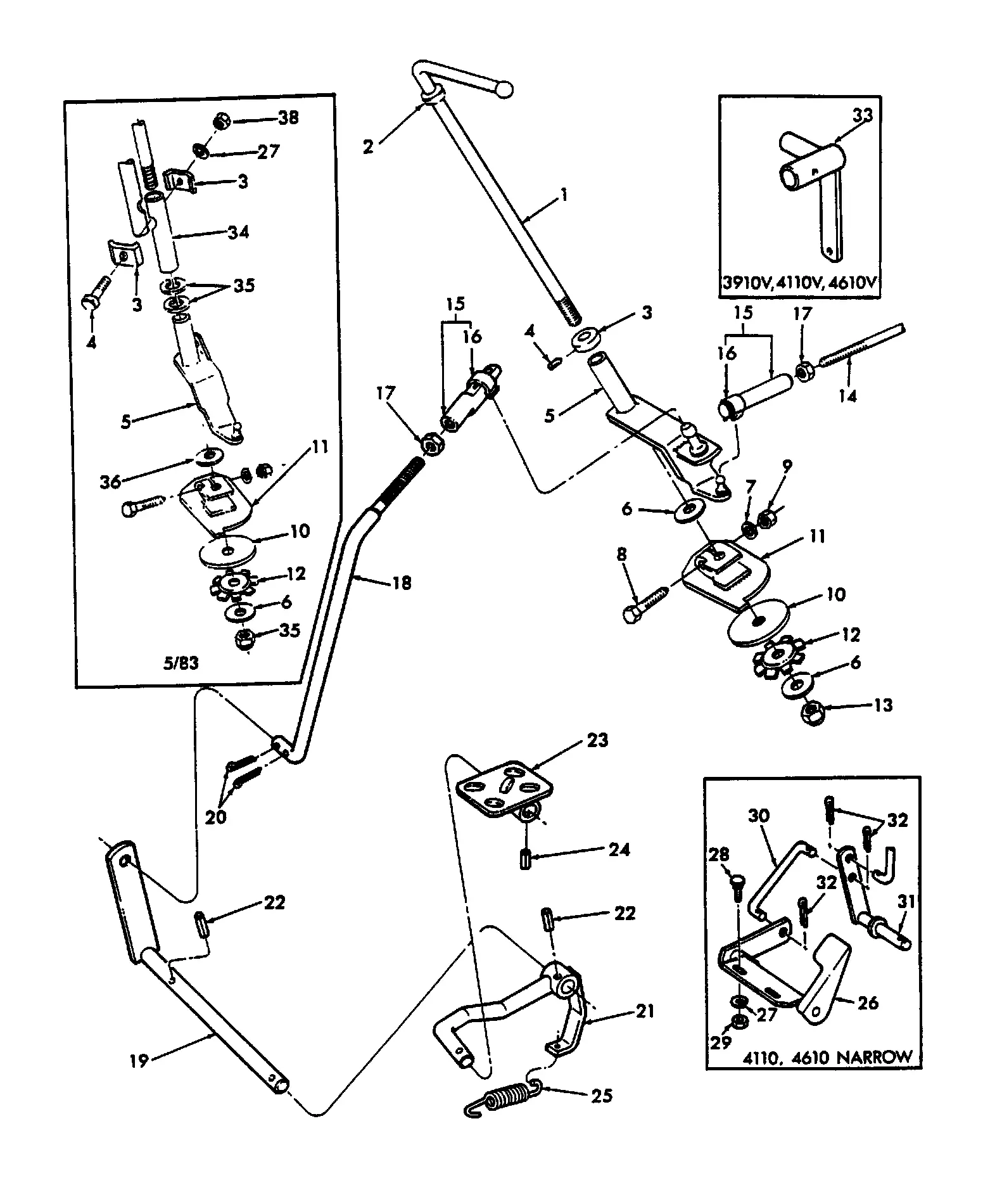

Hydraulic System and Its Function

The hydraulic system is a crucial component in various machinery, designed to transfer power and facilitate the operation of multiple functions. This mechanism utilizes fluid under pressure to perform work, making it essential for tasks that require significant force or precision. Understanding its structure and functionality helps in maintaining efficiency and effectiveness in equipment operations.

At its core, the hydraulic system comprises several key elements, each playing a vital role in its overall performance. The main components include the pump, reservoir, actuator, and control valves. Each part collaborates to convert mechanical energy into hydraulic energy, enabling the machinery to perform a wide range of tasks.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates flow and pressure, driving the hydraulic fluid through the system. |

| Reservoir | Stores hydraulic fluid and allows for thermal expansion and fluid return. |

| Actuator | Converts hydraulic energy back into mechanical energy to perform work. |

| Control Valves | Regulate the flow and direction of the hydraulic fluid to various components. |

In summary, the hydraulic system’s ability to harness fluid dynamics allows for efficient operation across numerous applications. Regular maintenance and understanding of its components ensure optimal performance and longevity of the machinery.

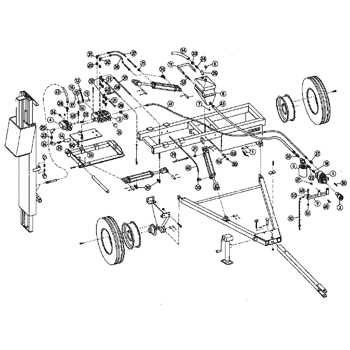

Transmission Parts and Their Roles

The transmission system is crucial for converting engine power into usable motion, ensuring that the vehicle can operate efficiently under various conditions. Understanding the components involved in this system provides insights into their specific functions and how they contribute to overall performance.

Key Components of the Transmission System

Central to the operation of the transmission are several key elements that work in harmony. These include the gearbox, which facilitates the selection of different speed ratios, and the clutch, which allows for smooth engagement and disengagement of power. Additionally, the torque converter plays a vital role in transferring rotational force while accommodating changes in speed and load.

Importance of Maintenance

Regular maintenance of the transmission system is essential to prevent wear and tear on these components. This includes routine checks of fluid levels, ensuring that seals and gaskets are in good condition, and inspecting for any signs of leakage. Proper upkeep not only enhances performance but also prolongs the lifespan of the entire drivetrain system.

Electrical System Wiring Diagram

The electrical network of machinery plays a crucial role in ensuring proper functionality and reliability. Understanding how different components interconnect allows for efficient troubleshooting and maintenance. This section will outline the essential elements and relationships within the electrical framework, highlighting their importance in the overall operation.

Key components of the electrical system include:

- Battery: Provides the necessary power for starting and operating various systems.

- Alternator: Generates electricity to recharge the battery and power the electrical components when the engine is running.

- Starter Motor: Engages the engine during startup, drawing power from the battery.

- Wiring Harness: A collection of wires that connects all electrical components, allowing for signal transmission and power distribution.

- Fuses: Protect the electrical system by preventing overloads and short circuits.

- Switches: Control the flow of electricity to various components, allowing the operator to manage different functions effectively.

In order to ensure optimal performance, it’s important to regularly inspect and maintain the electrical connections. This includes:

- Checking for frayed or damaged wires.

- Ensuring all connectors are secure and free of corrosion.

- Testing fuses and replacing any that are blown.

- Verifying the functionality of switches and electrical components.

By understanding and maintaining the electrical network, operators can enhance the efficiency and longevity of the equipment.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of machinery requires diligent care and attention. Regular upkeep not only enhances efficiency but also extends the operational life of essential components. By implementing a proactive maintenance strategy, owners can avoid costly repairs and downtime.

Regular Inspections

Conducting frequent assessments of your equipment is crucial. Look for signs of wear or damage, including leaks, corrosion, and loose connections. Early detection of potential issues can prevent more significant failures down the line.

Fluid Changes and Replacements

Consistently replacing fluids such as oil, coolant, and hydraulic fluid is vital for optimal performance. These fluids lubricate and protect internal parts from friction and overheating. Follow the manufacturer’s recommendations for change intervals to ensure that the machinery operates smoothly.