The world of vintage agricultural equipment is both fascinating and intricate. Enthusiasts and professionals alike appreciate the significance of understanding the components that make up these iconic machines. A thorough grasp of their structure not only enhances repair and maintenance efforts but also fosters a deeper appreciation for their engineering. Knowledge of each element’s role can transform a seemingly mundane task into an engaging challenge.

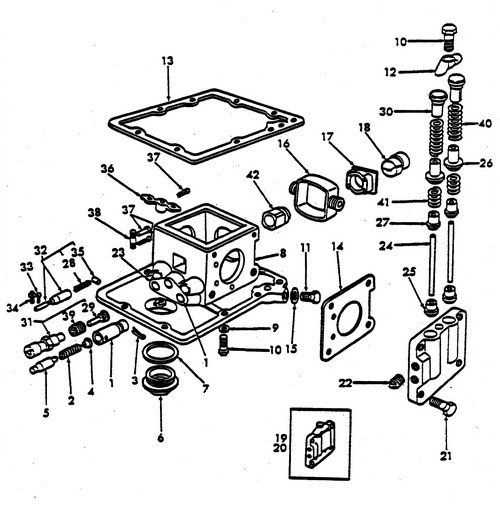

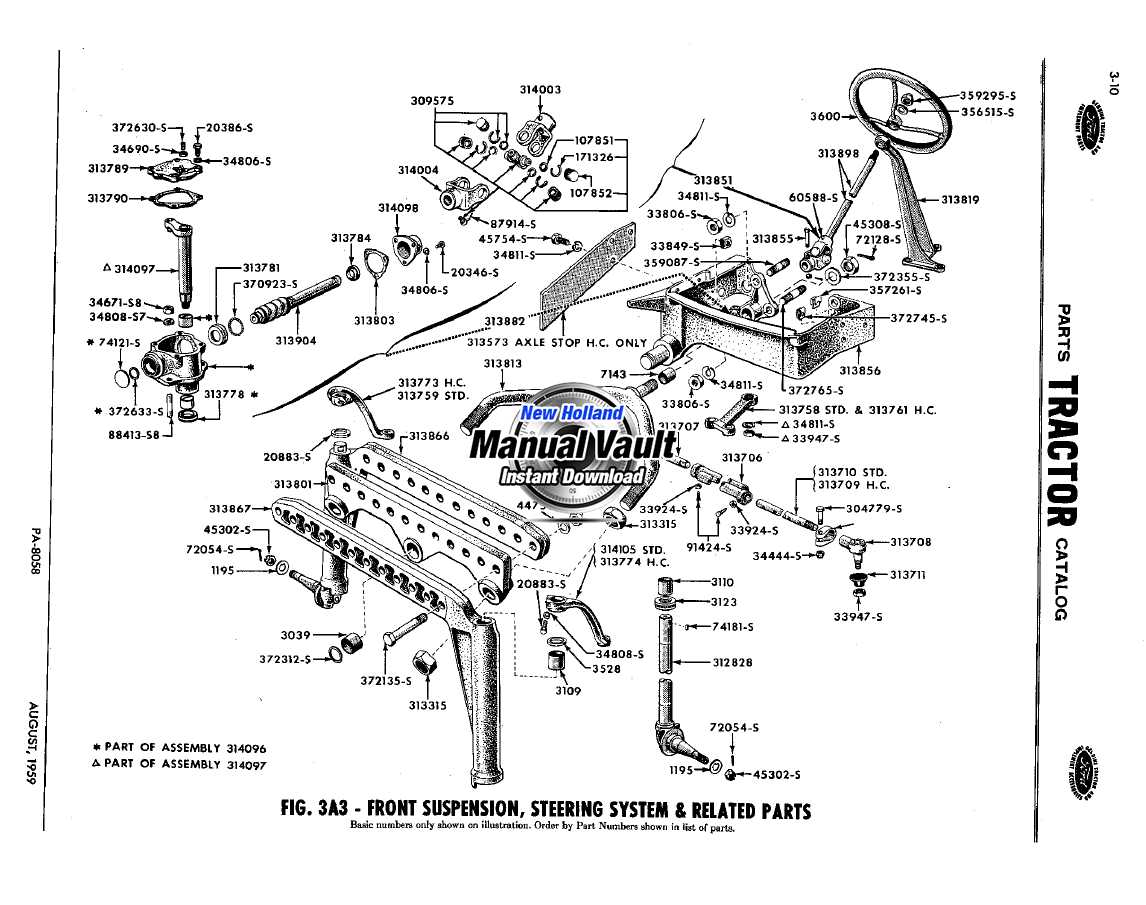

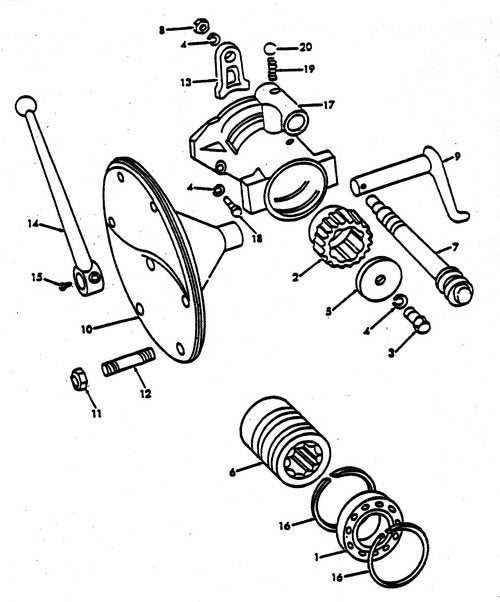

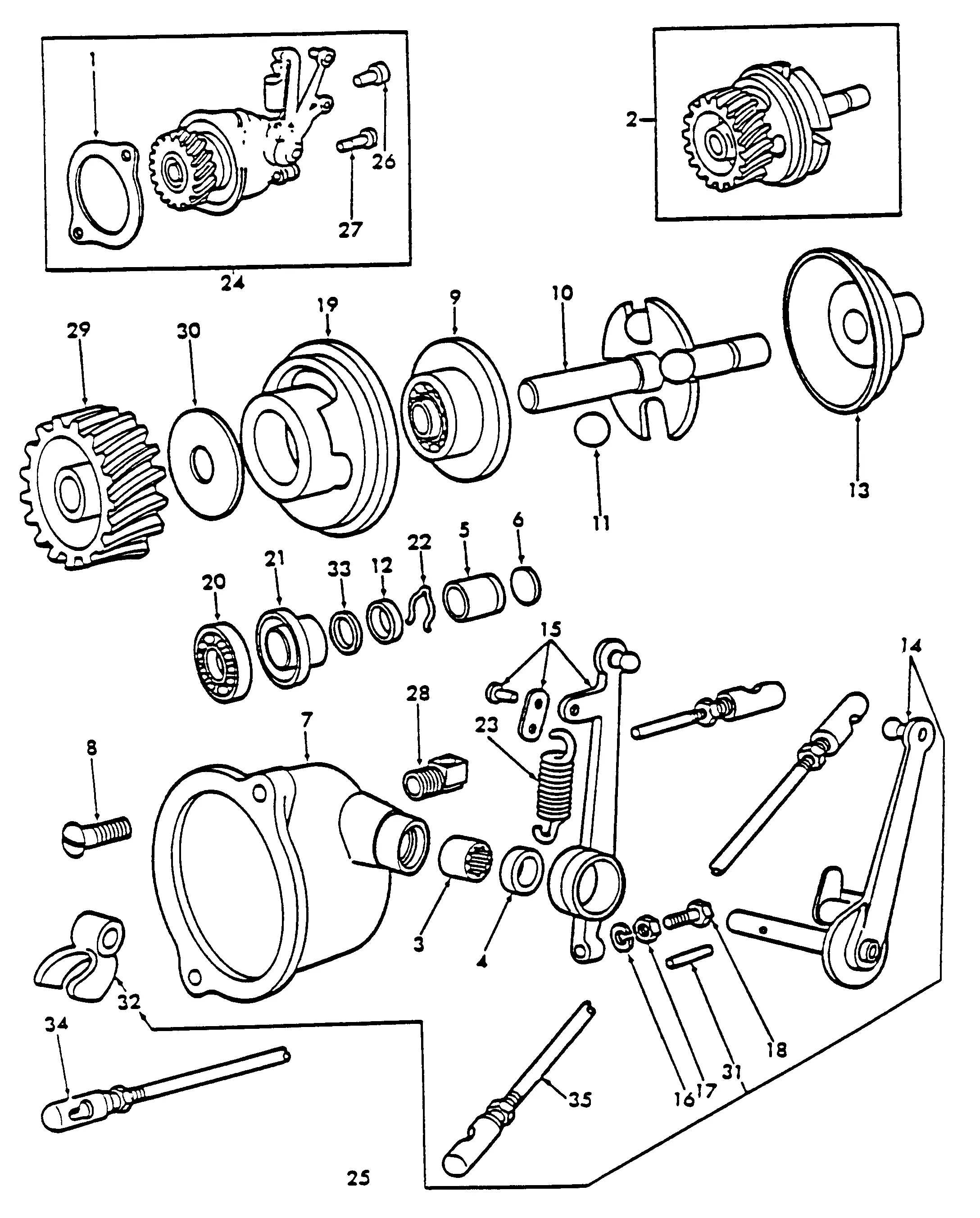

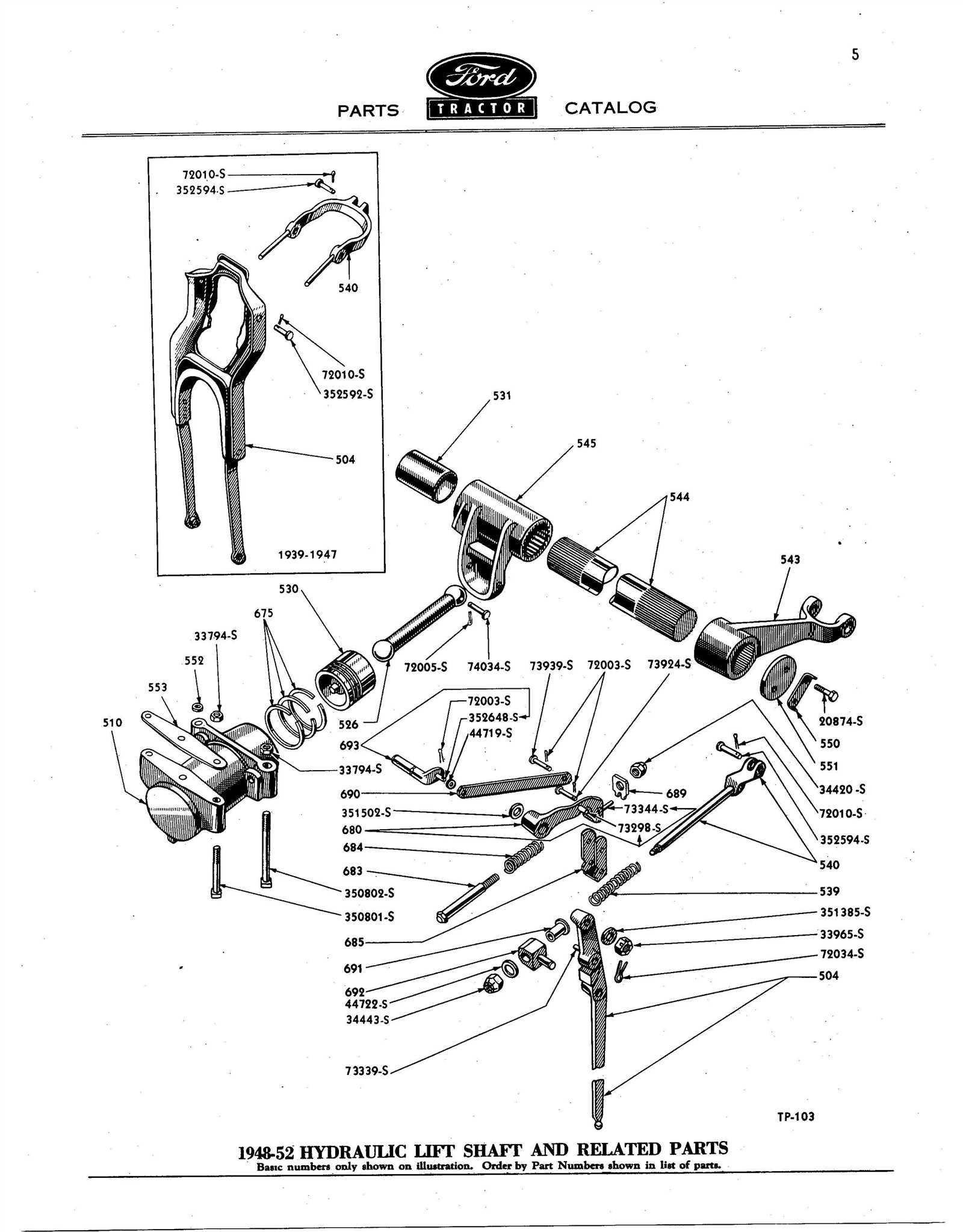

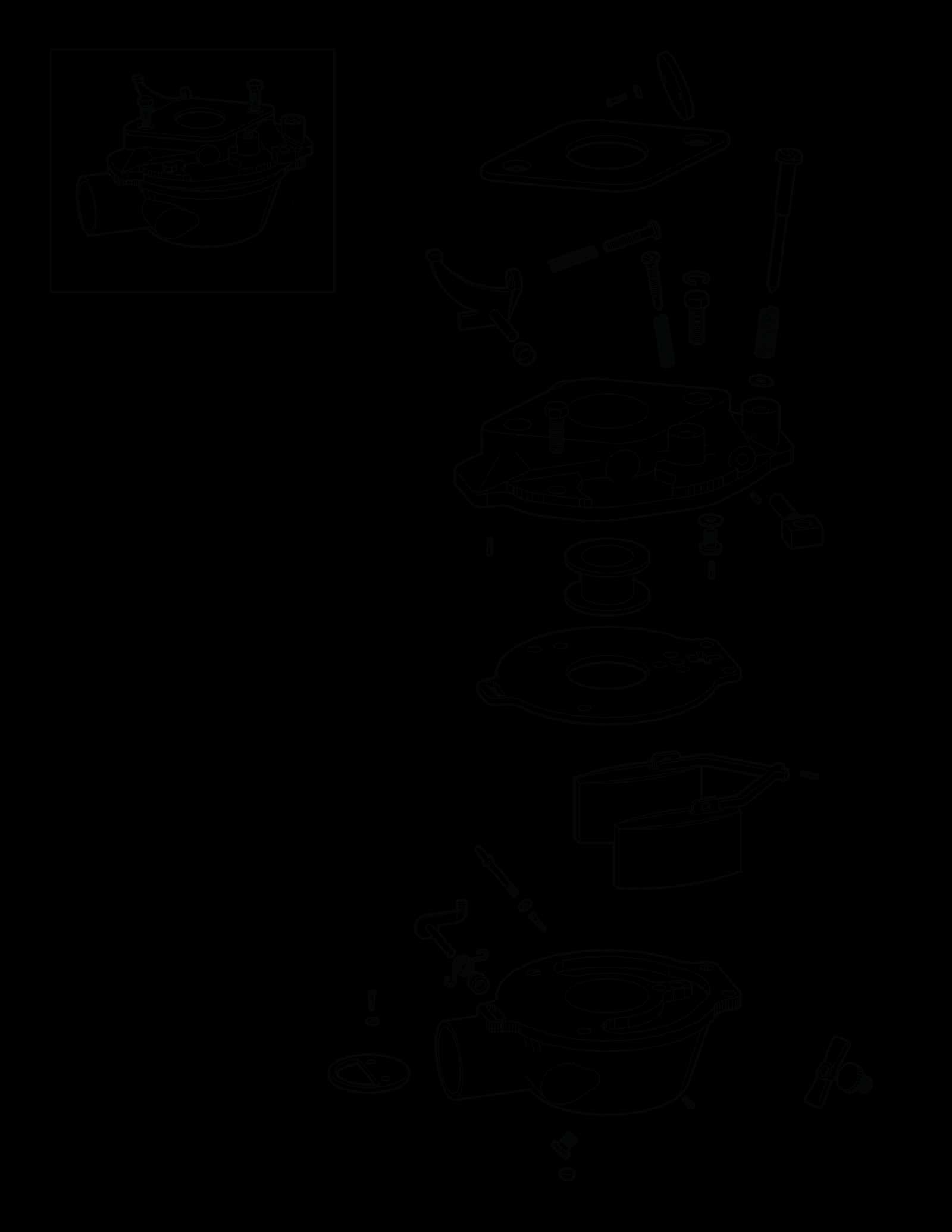

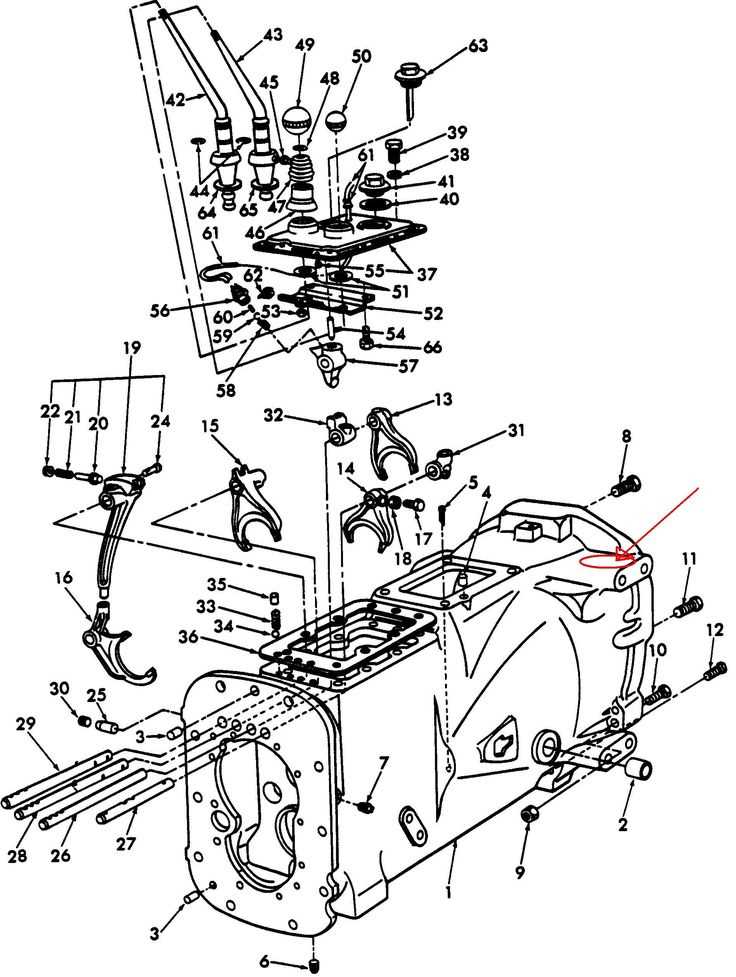

For those interested in maintaining or restoring older models, having access to clear visual representations of their assembly is invaluable. These illustrations serve as essential guides, helping individuals identify and locate each segment efficiently. They provide clarity in a landscape often characterized by mechanical complexity, ensuring that both novice and experienced operators can navigate the nuances of their machinery.

Additionally, recognizing the interconnectedness of various components highlights the importance of proper upkeep. Each segment plays a crucial role in overall functionality, making it essential to stay informed about any potential issues. This awareness can prevent minor concerns from escalating into significant problems, ultimately preserving the longevity and reliability of these classic machines.

Understanding 8N Ford Tractor Basics

Gaining a solid grasp of the essential components and functionality of the 8N model is crucial for effective operation and maintenance. This classic machine has become a staple for many enthusiasts and farmers alike, thanks to its reliable performance and user-friendly design. Understanding its fundamental aspects can enhance your experience and ensure longevity.

Key Features of the 8N Model

This iconic machine is known for its distinctive engineering and robust capabilities. Among its most notable attributes are the three-point hitch system and the efficient power take-off (PTO). These features significantly improve versatility, allowing for various attachments and implements to be utilized. Additionally, the reliable engine and transmission contribute to its enduring popularity.

Maintenance and Care

Regular upkeep is essential for sustaining performance over time. This includes routine checks of the fluid levels, filters, and belts. Proper maintenance not only extends the lifespan of the equipment but also ensures optimal operation during tasks. Familiarizing yourself with the essential maintenance routines will provide peace of mind and enhance your overall experience.

Key Components of the 8N Tractor

The 8N model is a remarkable machine renowned for its efficient operation and versatility in agricultural tasks. Understanding its essential elements can greatly enhance the user’s ability to maintain and optimize performance. Each component plays a vital role, contributing to the overall functionality and reliability of this classic implement.

Engine: At the heart of this implement lies a robust engine that delivers the necessary power for various applications. Its design ensures efficient fuel consumption while providing sufficient torque for demanding tasks.

Transmission: The transmission system is critical for controlling speed and direction. It features a simple yet effective design that allows smooth gear shifts, enabling the operator to adapt to different work conditions seamlessly.

Hydraulic System: This model boasts an advanced hydraulic system that enhances lifting capabilities. It provides the force required to operate implements and tools, making it indispensable for various tasks in the field.

Steering Mechanism: Precision in steering is vital for maneuverability, and the 8N incorporates a reliable mechanism that ensures easy navigation through tight spaces and uneven terrain.

Chassis: The sturdy chassis of this machine provides a solid foundation, supporting all components while ensuring durability under heavy loads. Its design enhances stability and balance, making it suitable for various terrains.

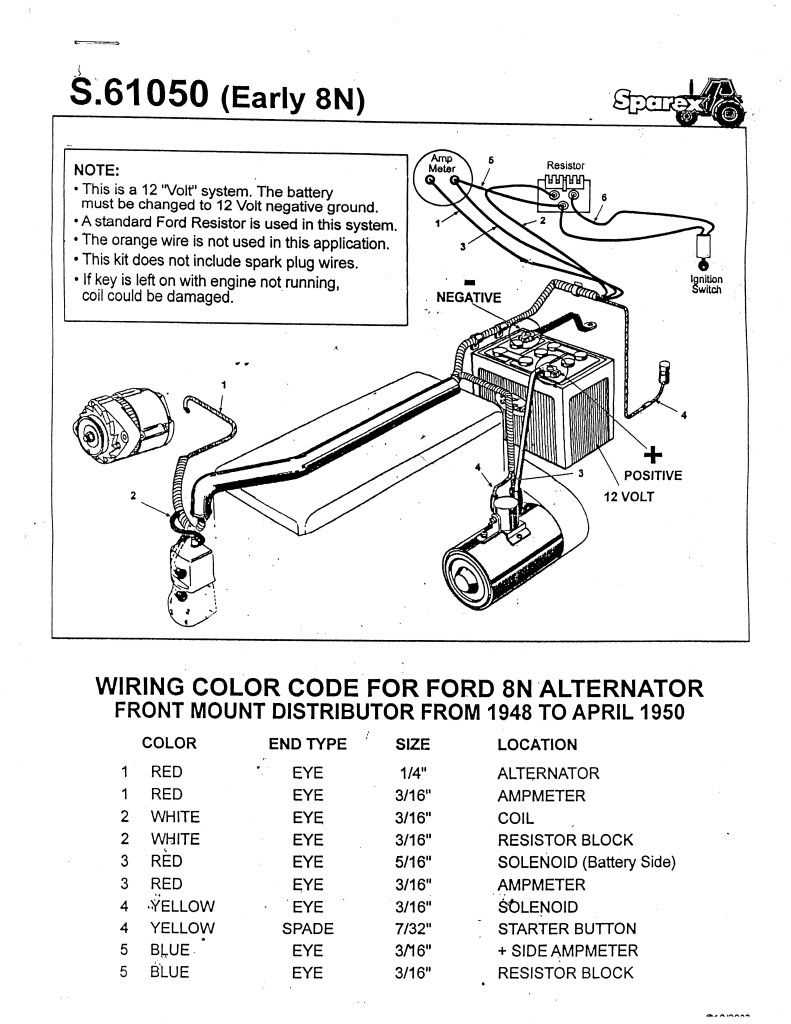

Electrical System: An efficient electrical system powers the ignition and lighting, ensuring reliable operation during both day and night. It incorporates essential components that enhance overall functionality.

In summary, the 8N model is equipped with a range of essential elements that work together to deliver impressive performance. Understanding these key components allows users to appreciate the machine’s design and maintain it effectively for years to come.

Common Parts Replacement Procedures

Replacing components in machinery is essential for maintaining optimal performance and longevity. Understanding the basic procedures can enhance efficiency and ensure safety during the process.

-

Preparation: Gather all necessary tools and components before starting. Ensure the work area is clean and organized.

-

Disassembly: Carefully remove the old component. Follow these steps:

- Identify and remove any fasteners.

- Disconnect any linked systems, such as electrical or hydraulic connections.

- Take note of the arrangement for reassembly.

-

Installation: Position the new component accurately. Steps include:

- Reconnect any systems that were disconnected.

- Secure with appropriate fasteners, ensuring a snug fit.

- Verify that all connections are properly attached.

-

Testing: After installation, perform a functionality test. Look for:

- Unusual noises or vibrations.

- Leaking fluids or irregular operations.

- Correct responses to controls.

Regularly reviewing these procedures can greatly enhance the efficiency of your maintenance tasks.

Where to Find Parts Diagrams

Locating visual guides for machinery components is essential for effective repairs and maintenance. These resources provide clear illustrations that aid in identifying individual elements and understanding their functions. With the right references, anyone can enhance their mechanical knowledge and streamline the repair process.

Online Resources

The internet offers a wealth of information, with numerous websites dedicated to providing detailed illustrations and manuals. Many manufacturers have official sites that host downloadable resources, while community forums often share valuable insights and user-generated content.

Local Dealerships and Workshops

Visiting local dealerships or specialized workshops can also be beneficial. These establishments typically have physical copies of manuals and may assist in sourcing specific components. Additionally, they often have experienced staff who can offer advice based on years of practical knowledge.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sources that provide downloadable manuals and guides. |

| Community Forums | User-generated content and discussions that offer insights and shared resources. |

| Local Dealerships | Physical locations where manuals and components can be sourced directly. |

| Repair Shops | Experienced professionals who can provide guidance and advice on maintenance. |

Identifying Component Numbers

Understanding the various components of machinery is crucial for maintenance and repairs. Each element is assigned a unique identifier, making it easier for users to locate replacements or make necessary adjustments. This system not only aids in organization but also enhances the efficiency of service operations, ensuring that every piece is accurately referenced.

Recognizing component numbers involves familiarizing oneself with the structure of these identifiers. Typically, they comprise a combination of letters and digits, each representing specific attributes such as size, type, and compatibility. Knowledge of these codes allows operators to communicate effectively with suppliers and technicians.

To effectively identify these numbers, one should consult the equipment manual or relevant catalogs. These resources provide detailed explanations of the codes, often accompanied by visual aids. Keeping a record of commonly used identifiers can also streamline the process, reducing downtime during repairs.

When acquiring replacements, always verify the component numbers to ensure compatibility. Incorrect identifiers can lead to mismatches, resulting in additional costs and delays. By mastering the identification of component numbers, users can enhance their operational knowledge and contribute to the longevity of their machinery.

Maintenance Tips for 8N Ford Tractors

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a structured maintenance routine can prevent costly repairs and enhance efficiency, allowing for a smoother operation over time.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace old oil to ensure proper lubrication and engine health. |

| Air Filter Check | Monthly | Inspect and clean the air filter to maintain airflow and performance. |

| Tire Pressure | Weekly | Check and adjust tire pressure for optimal traction and fuel efficiency. |

| Battery Maintenance | Monthly | Inspect terminals and fluid levels to ensure reliable starting. |

| Grease Fittings | Every 50 hours | Lubricate fittings to reduce wear on moving parts. |

Upgrades for Enhanced Tractor Performance

Improving the efficiency and power of agricultural machinery can significantly impact productivity. Various enhancements can be implemented to achieve optimal performance, ensuring that these machines operate at their best.

Engine Modifications

- High-performance air filters to increase airflow.

- Upgraded fuel injectors for better fuel delivery.

- Enhanced exhaust systems to improve engine breathing.

Transmission Improvements

- Installing a heavy-duty clutch for better torque transfer.

- Upgrading gears for smoother shifting and increased durability.

- Adding a performance chip to optimize power management.

Resources for Tractor Restoration Enthusiasts

For those passionate about rejuvenating vintage machinery, finding reliable resources is essential. Whether you are a novice or a seasoned restorer, having access to comprehensive information can significantly enhance the restoration journey. From manuals to community forums, a wealth of tools and knowledge awaits restoration enthusiasts eager to bring these machines back to life.

Online Communities and Forums

Engaging with fellow aficionados can provide invaluable insights and support. Numerous online platforms offer forums where individuals can share experiences, seek advice, and discuss techniques. These communities often feature threads dedicated to specific models, allowing members to exchange tips, troubleshoot issues, and celebrate successes together.

Manuals and Documentation

Accessing repair manuals and documentation is crucial for understanding the intricacies of any machine. Many online resources provide downloadable manuals that detail specifications, assembly instructions, and maintenance guidelines. These documents serve as vital references throughout the restoration process, ensuring that every aspect is meticulously attended to.

Safety Practices While Working on Tractors

Ensuring safety while performing maintenance on heavy machinery is crucial to prevent accidents and injuries. Proper precautions can significantly reduce risks associated with operating complex equipment.

Always wear appropriate protective gear, including gloves, goggles, and steel-toed boots, to shield yourself from potential hazards. This gear is essential for minimizing injuries from sharp objects and flying debris.

Before starting any work, conduct a thorough inspection of the machinery. Look for signs of wear and tear, loose components, or leaks. Addressing these issues beforehand can prevent accidents during operation.

Keep your workspace organized to avoid tripping hazards and to ensure that tools and materials are easily accessible. A tidy environment enhances focus and efficiency while working.

Always follow manufacturer guidelines for maintenance and repairs. These instructions are designed to ensure safety and proper functioning, making them vital for effective operations.

Never work alone when performing complex tasks. Having a partner can provide assistance in case of an emergency and allows for safer collaboration on repairs.

Finally, stay aware of your surroundings and potential hazards. Awareness is key to avoiding accidents and ensuring a safe working environment.