In the realm of farming equipment, grasping the intricacies of various machinery is essential for optimal performance and maintenance. This segment aims to shed light on the vital elements that contribute to the functionality of such vehicles, ensuring efficiency and longevity.

Whether you’re a seasoned operator or a newcomer, familiarizing yourself with the structure and organization of components is crucial. By examining these elements, one can better appreciate how they interact and contribute to overall productivity in agricultural tasks.

With the right insights, farmers can ultimately enhance their operational capabilities. This exploration invites readers to delve deeper into the specifics of machinery, equipping them with the knowledge necessary for effective upkeep and informed decision-making.

Overview of Ford 2000 Tractors

This segment explores the iconic machinery known for their reliability and versatility in agricultural tasks. These machines have garnered a reputation for their robust performance, making them a favored choice among farmers and landowners.

Key features include a powerful engine and efficient design, enabling seamless operation across various terrains. The durability of these models ensures they can withstand the demands of intensive farming, while their user-friendly controls make them accessible to operators of all experience levels.

Throughout the years, enhancements have been made to improve functionality and ease of maintenance, allowing users to maximize productivity. Whether for large fields or smaller plots, these machines continue to play a significant role in modern agriculture.

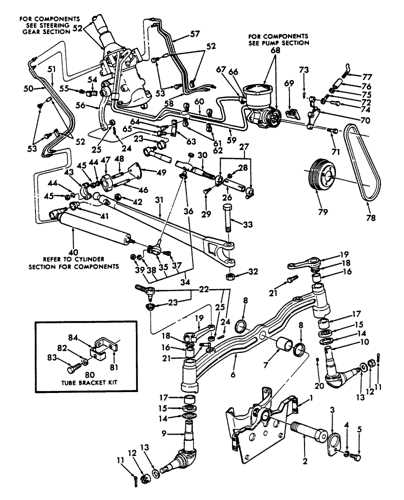

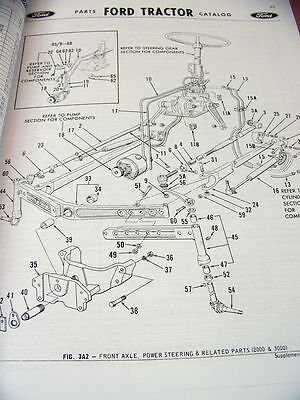

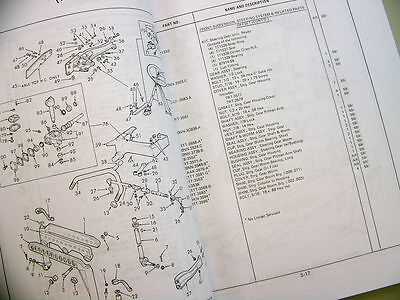

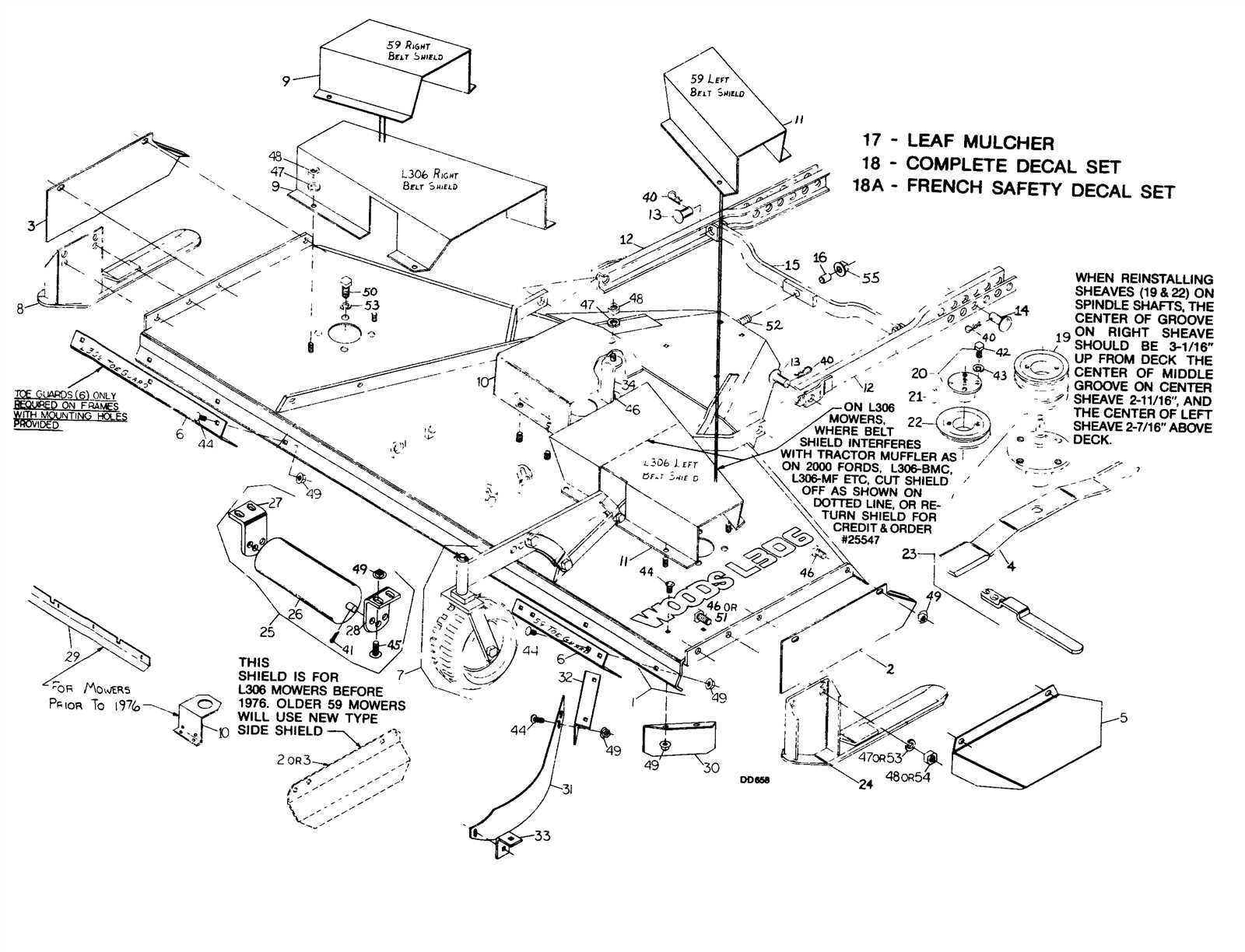

Importance of Parts Diagrams

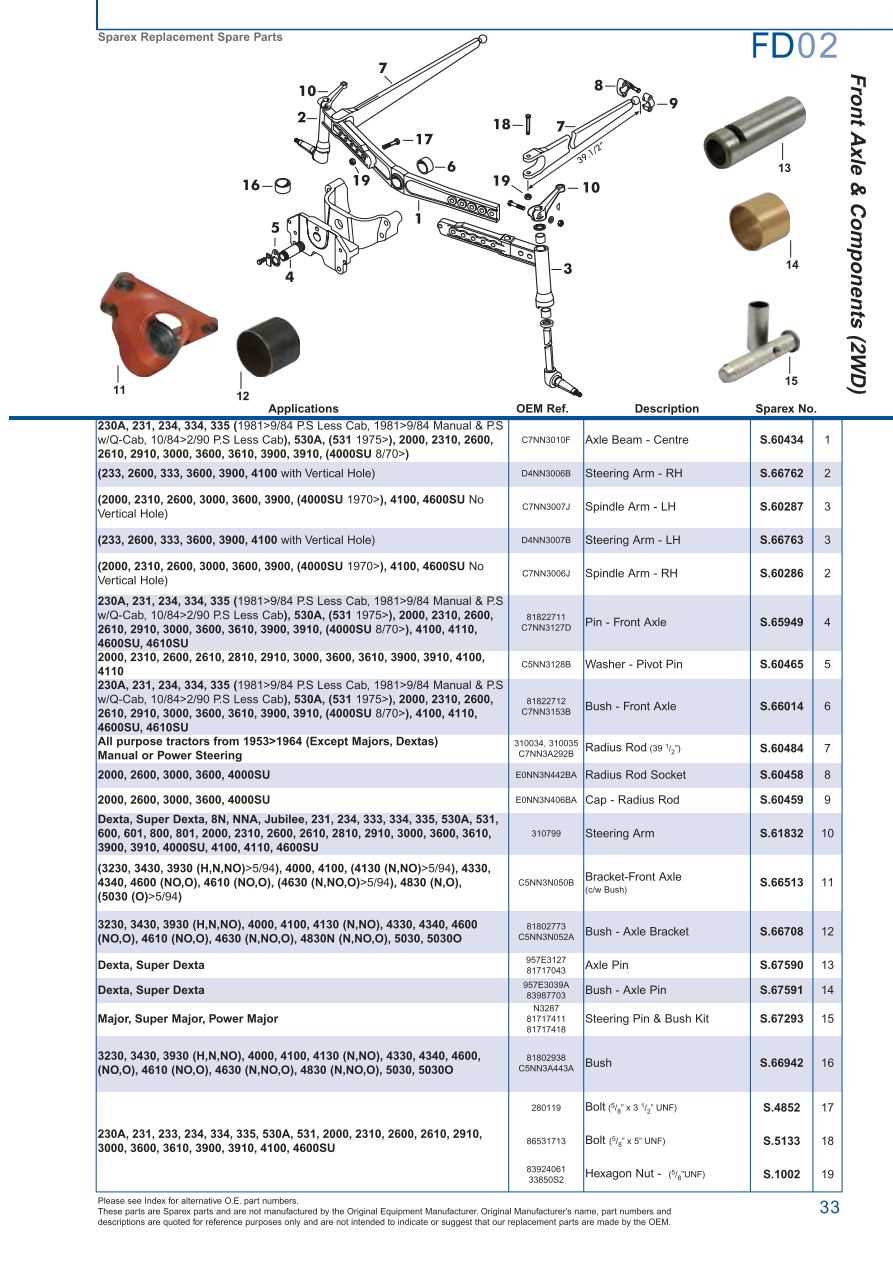

Visual representations of components play a crucial role in understanding complex machinery. They serve as essential tools for both maintenance and assembly, ensuring that every piece is correctly identified and placed. By providing clarity, these illustrations help prevent errors and enhance efficiency in repairs and modifications.

| Benefit | Description |

|---|---|

| Clarity | Visual aids simplify the identification of each element. |

| Efficiency | Streamlined processes reduce time spent on repairs. |

| Error Prevention | Correct placement of components minimizes mistakes. |

| Guidance | Step-by-step visual instructions support users. |

Key Components of the Ford 2000

This section explores the essential elements that contribute to the functionality and efficiency of this iconic machine. Understanding these key features can enhance maintenance and improve overall performance.

Engine System

- Power unit: Provides the necessary force for operation.

- Cooling mechanism: Maintains optimal temperature for performance.

- Fuel delivery: Ensures efficient energy consumption.

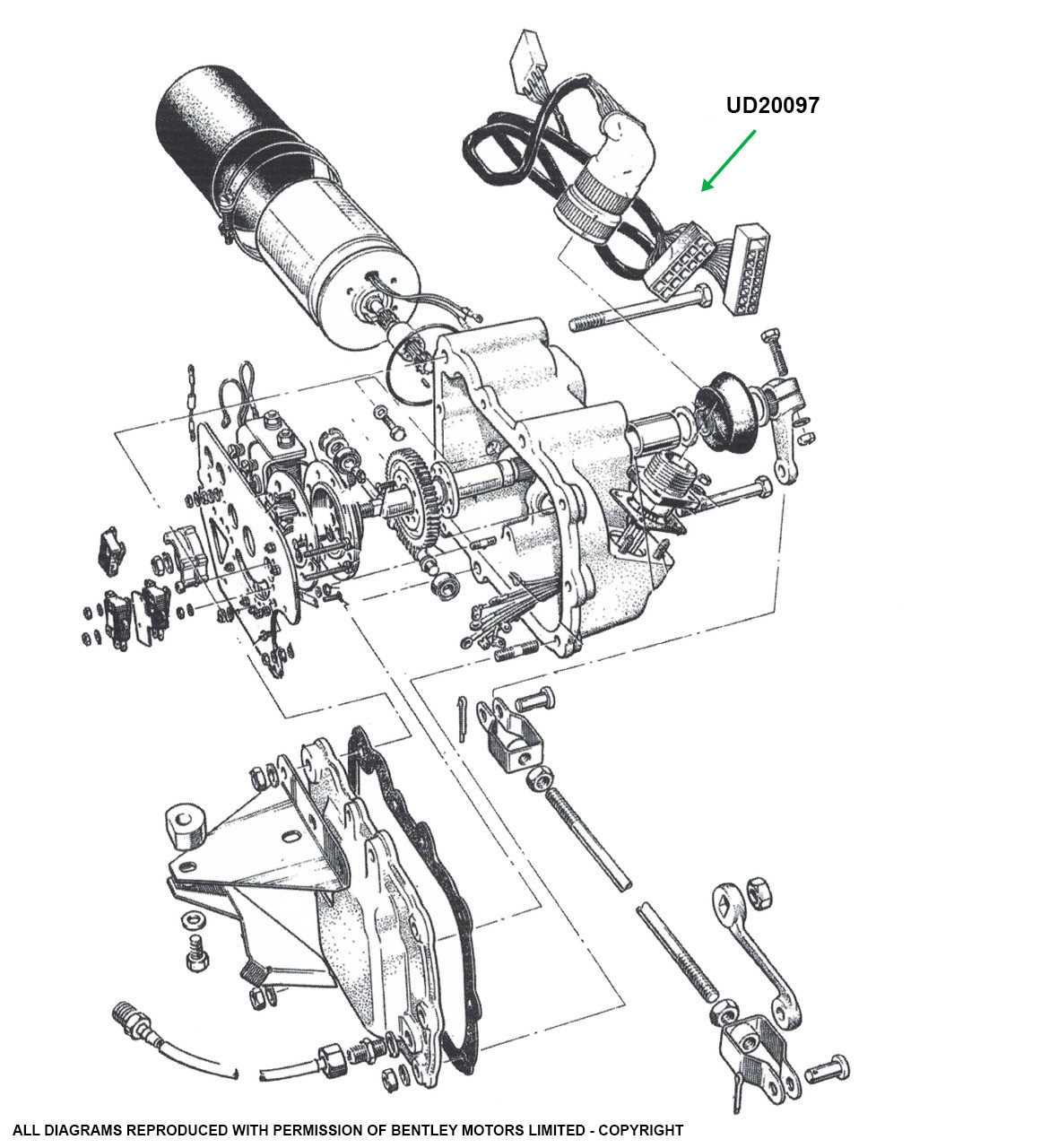

Transmission Features

- Gearbox: Facilitates speed adjustments and torque management.

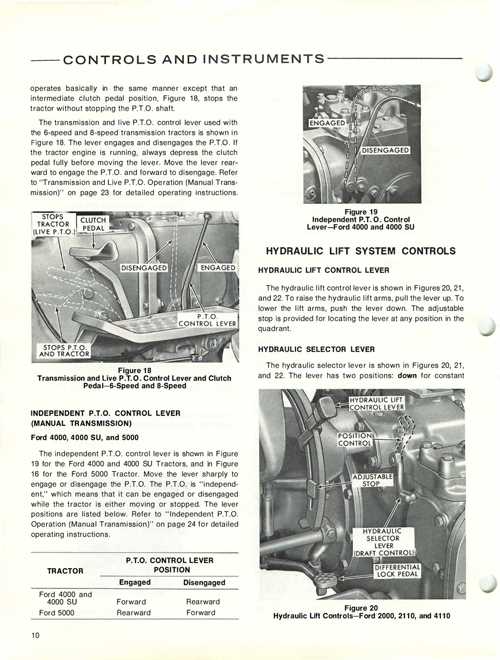

- Clutch system: Enables smooth engagement and disengagement.

- Drive axle: Transfers power to the wheels for mobility.

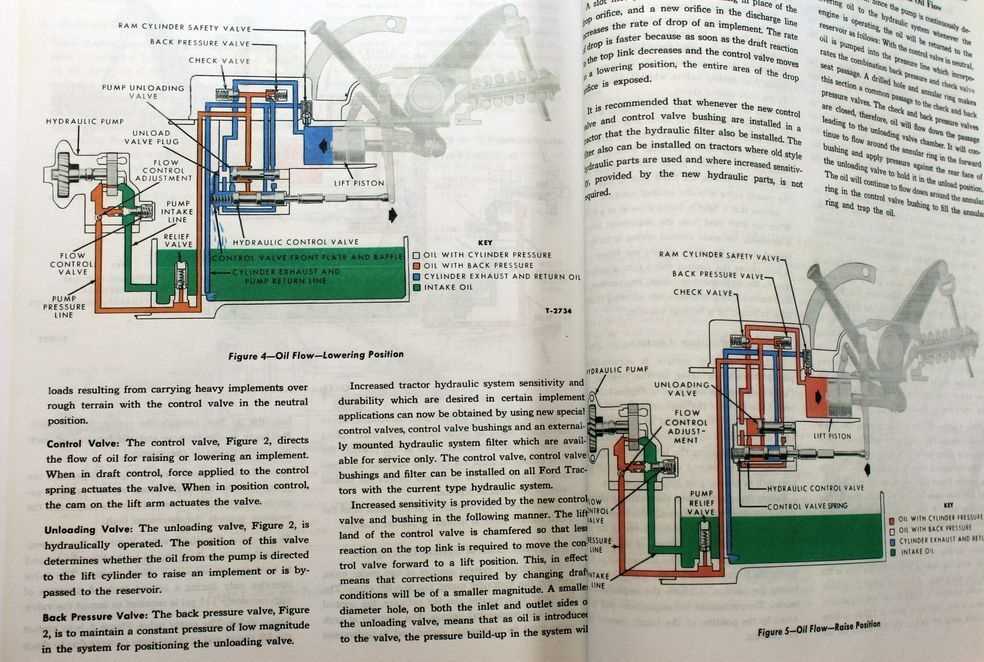

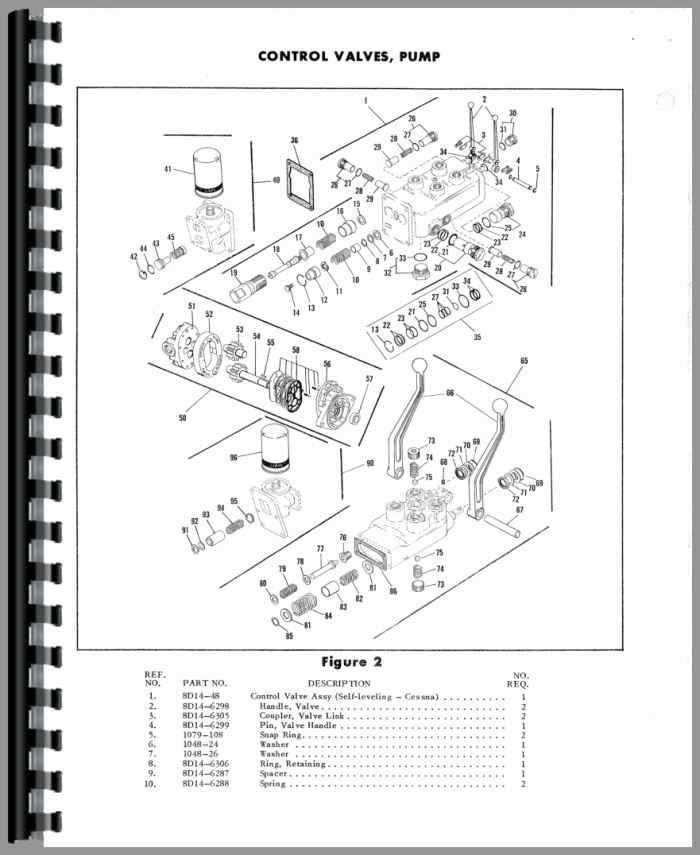

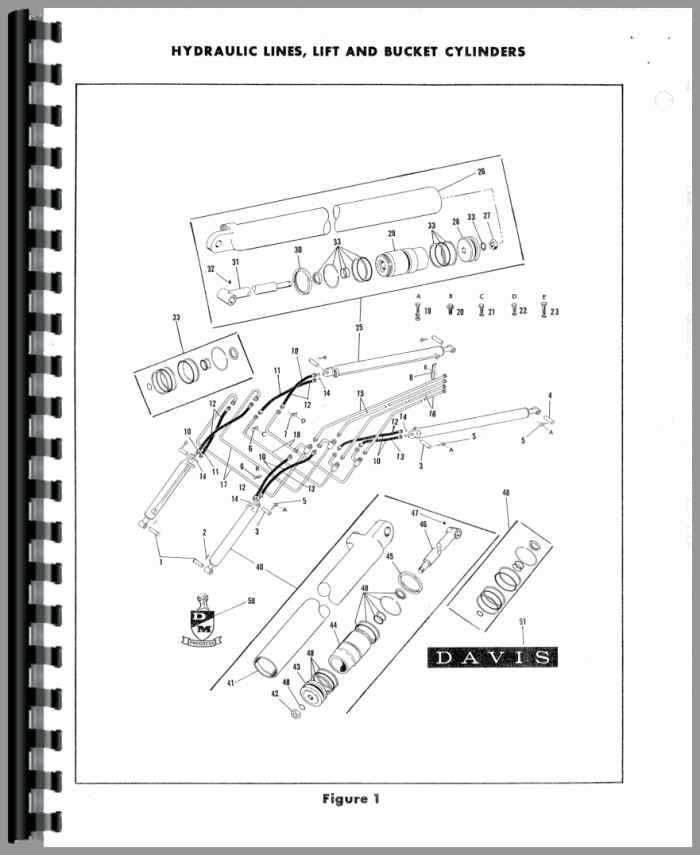

Understanding the Hydraulic System

The hydraulic mechanism plays a vital role in various machinery, enabling efficient operation through fluid power. This system utilizes pressurized liquid to transmit force, allowing for seamless movement and control of components. Understanding its structure and functionality is essential for effective maintenance and troubleshooting.

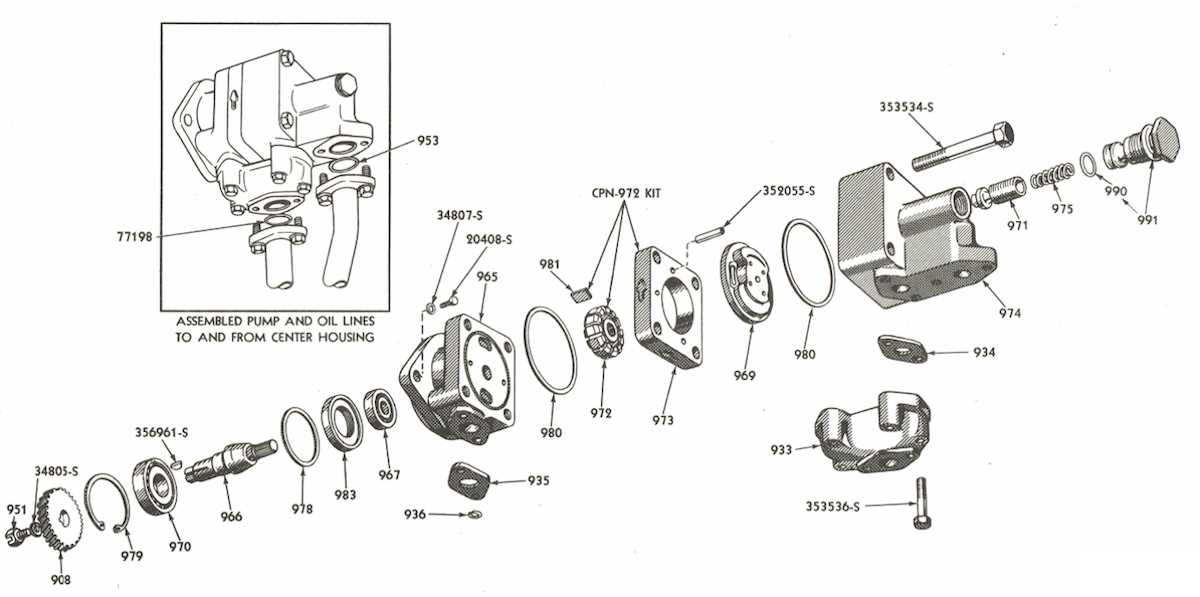

At its core, the hydraulic setup comprises several key elements, including pumps, cylinders, and valves. Pumps generate the pressure required to move the fluid, while cylinders convert that pressure into mechanical motion. Valves regulate the flow, directing the liquid to specific areas of the system as needed.

Maintaining this system involves regular checks for leaks, proper fluid levels, and the condition of seals and hoses. Familiarity with each component’s role enhances one’s ability to diagnose issues and ensure optimal performance, ultimately prolonging the lifespan of the equipment.

Common Issues with Ford 2000 Parts

When dealing with older machinery, several frequent challenges can arise due to wear and tear over time. Understanding these common issues is crucial for effective maintenance and ensuring optimal performance. Machinery components may face deterioration, leading to various operational difficulties that could hinder functionality.

Wear and Tear of Components

One of the primary concerns is the natural degradation of critical components. Seals and gaskets can become brittle, causing leaks and reducing efficiency. Additionally, moving parts may experience excessive friction, leading to a need for lubrication or eventual replacement. Regular inspections can help identify these issues early.

Electrical System Failures

Another common problem involves the electrical system. Wiring and connections can corrode, leading to intermittent faults or complete failures. Battery issues are also prevalent, particularly in older models, where terminals may require cleaning or replacement. Addressing electrical issues promptly is essential to maintain reliable operation.

Where to Find Replacement Parts

Finding suitable components for your machinery is essential for maintaining its functionality and longevity. Several avenues exist for sourcing these essential elements, each with its own advantages.

Online Retailers

- Specialized websites dedicated to agricultural equipment.

- Major e-commerce platforms offering a wide selection.

- Manufacturer’s official online stores.

Local Suppliers

- Farm supply stores with inventory for various models.

- Independent mechanics and repair shops.

- Salvage yards that may have used components.

By exploring these resources, you can effectively locate the necessary replacements for your equipment, ensuring it runs optimally.

Benefits of Using OEM Parts

Opting for original equipment manufacturer components ensures superior quality and compatibility, providing peace of mind for users. These components are specifically designed to fit and function seamlessly, resulting in enhanced performance and durability over time.

Quality Assurance

Using genuine components guarantees a higher standard of craftsmanship, as they are subjected to rigorous testing and quality checks. This leads to reduced likelihood of failures and costly repairs.

Long-Term Cost Savings

While aftermarket alternatives may seem economical initially, they often lead to increased maintenance costs. OEM options, although sometimes pricier upfront, often result in significant savings over the lifespan of the equipment.

| Benefits | OEM Parts | Aftermarket Alternatives |

|---|---|---|

| Quality | High | Variable |

| Compatibility | Perfect Fit | Potential Issues |

| Warranty | Often Included | Limited |

| Longevity | Higher | Lower |

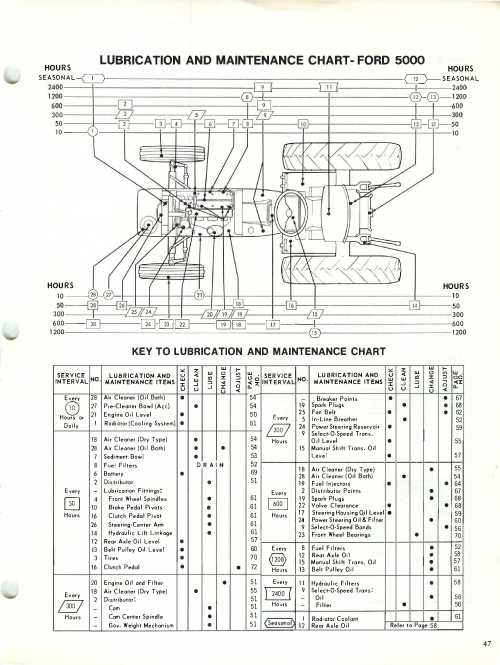

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires regular care and attention. Implementing effective maintenance practices not only extends the lifespan of your equipment but also enhances its performance, ultimately saving you time and money.

Regular Inspections: Conduct routine checks to identify wear and tear early. Focus on critical components and systems to prevent minor issues from escalating into major problems.

Fluid Management: Maintain optimal fluid levels by regularly checking and changing oils, coolants, and hydraulic fluids. Clean fluids contribute to better performance and reduce the risk of overheating or mechanical failure.

Filter Replacement: Replace air, fuel, and oil filters as recommended. Clogged filters can hinder efficiency and lead to engine strain, impacting overall functionality.

Cleaning: Keep your machinery clean to prevent the buildup of dirt and debris. Regularly wash external surfaces and ensure that internal components are free from contaminants that can cause damage.

Follow Manufacturer Guidelines: Adhere to the manufacturer’s maintenance schedule for servicing. These guidelines are tailored to optimize performance and ensure reliability over time.

Use Quality Parts: When replacements are necessary, opt for high-quality components. Using inferior parts can compromise the integrity and efficiency of your machinery.

Operator Training: Invest in proper training for operators to ensure they understand best practices for using and maintaining the equipment. Well-informed operators can significantly reduce the likelihood of misuse and subsequent damage.