Farming machinery is a cornerstone of modern agricultural operations, and its efficient functioning relies on a well-coordinated system of mechanical and fluid-driven components. Every machine is designed to tackle specific tasks with precision, which makes understanding the internal structure crucial for maintaining optimal performance. Knowledge of how these systems interact can prevent breakdowns and enhance the machine’s lifespan.

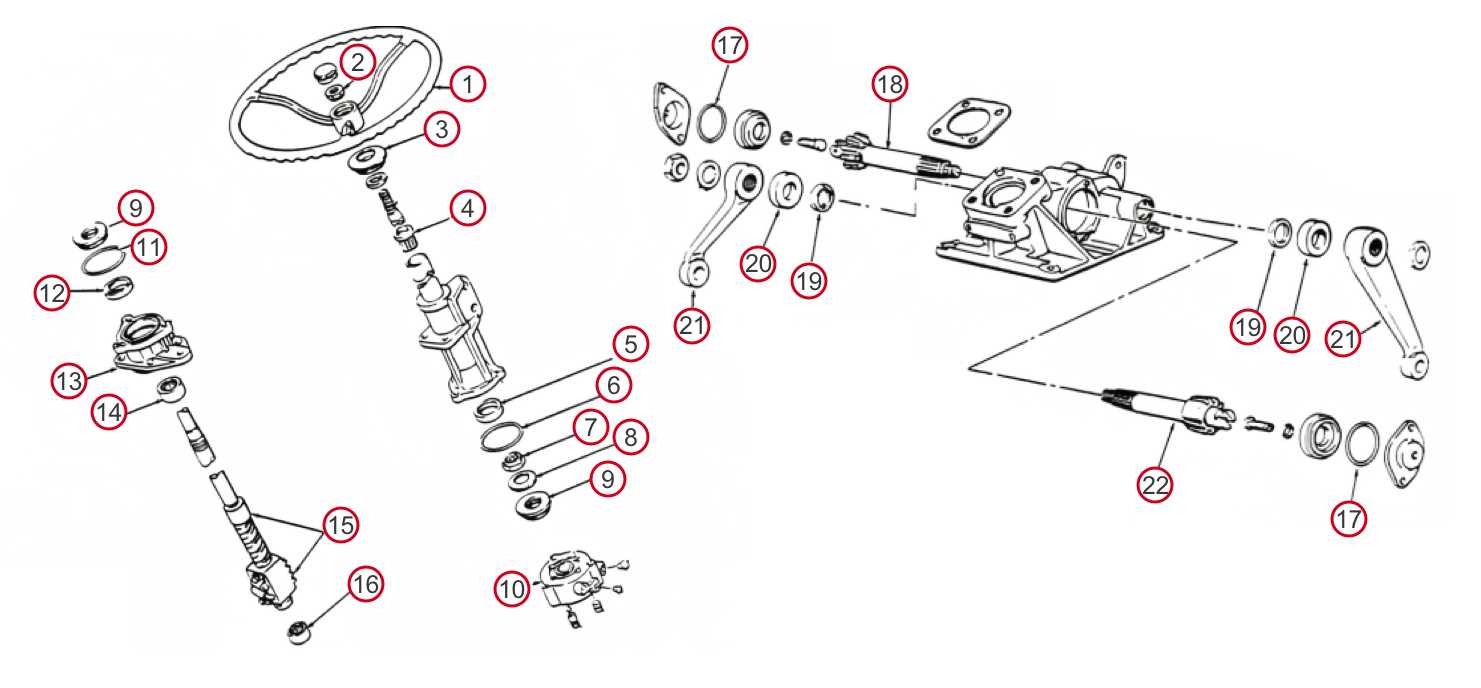

System layout plays a significant role in ensuring the smooth operation of essential functions, such as lifting, steering, and power transmission. By studying the configuration of the key elements, operators and technicians can pinpoint areas for improvement or repair. This knowledge serves not only to facilitate troubleshooting but also to guide adjustments during routine maintenance.

Flow of energy through the mechanical elements determines the efficiency of the entire system. Understanding how forces are transmitted from one section to another helps in diagnosing issues, whether related to pressure loss or improper engagement of connected systems. Detailed analysis of these connections enables a more hands-on approach to addressing the unique needs of each machine model.

Understanding Hydraulic Systems in Tractors

Machines used in agriculture and construction rely on a complex network to perform heavy-duty tasks with efficiency. At the heart of these machines, a system is responsible for converting power into motion, enabling the operation of various implements. This mechanism allows precise control over lifting, pushing, and pulling actions, making it indispensable for modern-day machinery.

Within this system, force is transmitted through fluid under pressure. This fluid travels through a network of hoses and cylinders, facilitating the movement of large, heavy components with minimal effort. By adjusting the pressure within the system, operators can control the force applied, allowing for a wide range of activities such as lifting heavy loads or adjusting attachments with ease.

When understanding how these systems work, one must recognize the importance of components like pumps, valves, and cylinders. Pumps are responsible for circulating fluid under pressure, while valves control the flow and direction of this fluid. Cylinders, on the other hand, convert the pressurized fluid into mechanical motion, creating the physical force needed to perform tasks like lifting or tilting.

The efficiency and reliability of such systems are essential for the smooth operation of machinery, especially when dealing with demanding tasks. Routine maintenance and timely inspections are key to ensuring that each element of the system works in harmony, reducing downtime and extending the lifespan of equipment.

Importance of Ford Tractor Maintenance

Regular care and upkeep of farming machinery are essential to ensure its longevity and optimal performance. Neglecting maintenance can lead to costly repairs and potential downtime, impacting productivity. Understanding the significance of proper servicing and attention to detail can help avoid common issues and extend the lifespan of the equipment.

Key Benefits of Routine Servicing

- Prevents unexpected breakdowns and costly repairs.

- Improves fuel efficiency, reducing operational costs.

- Enhances performance, ensuring tasks are completed faster and more effectively.

- Increases the resale value of the equipment.

- Maintains safety standards, reducing the risk of accidents or malfunctions.

Essential Maintenance Tasks

- Regularly checking and replacing the oil.

- Inspecting belts, hoses, and filters for wear and tear.

- Maintaining tire pressure and alignment for proper traction.

- Cleaning air and fuel filters to ensure smooth operation.

- Lubricating moving parts to prevent excessive friction and wear.

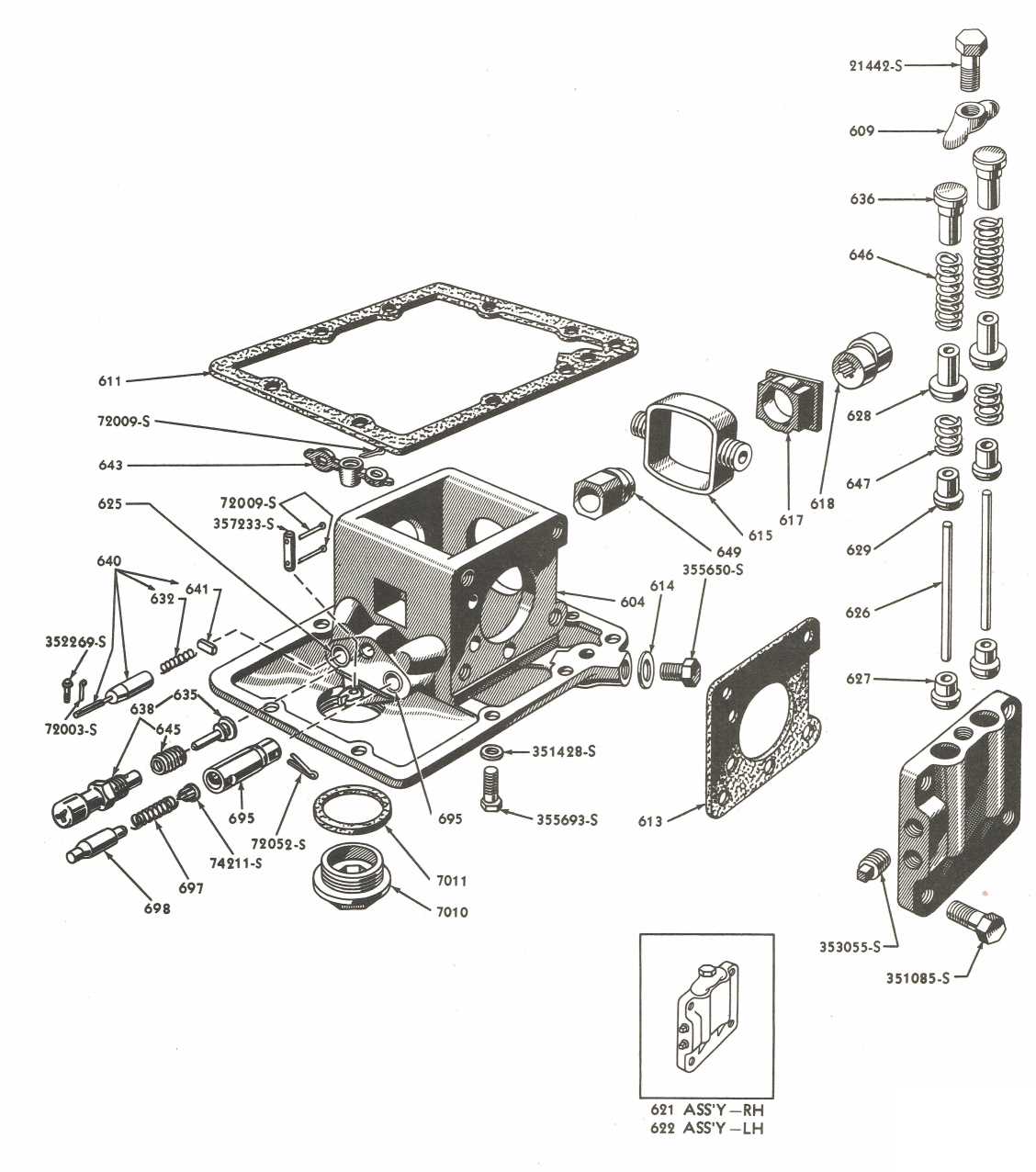

Key Components of Hydraulic Systems

In any machine relying on fluid power, certain essential elements work together to enable effective movement and control. These components are designed to control the flow and pressure of the fluid, ensuring the smooth operation of the system. A well-maintained setup can provide both strength and precision in a wide variety of applications, from construction to agriculture and beyond.

Power Source and Fluid Reservoir

The system requires a primary power source, often a pump, that pushes fluid through the system. The fluid reservoir stores the liquid, allowing it to flow continuously. The pump is responsible for generating the necessary pressure, while the reservoir ensures the system can maintain a constant supply of fluid to perform tasks without interruption.

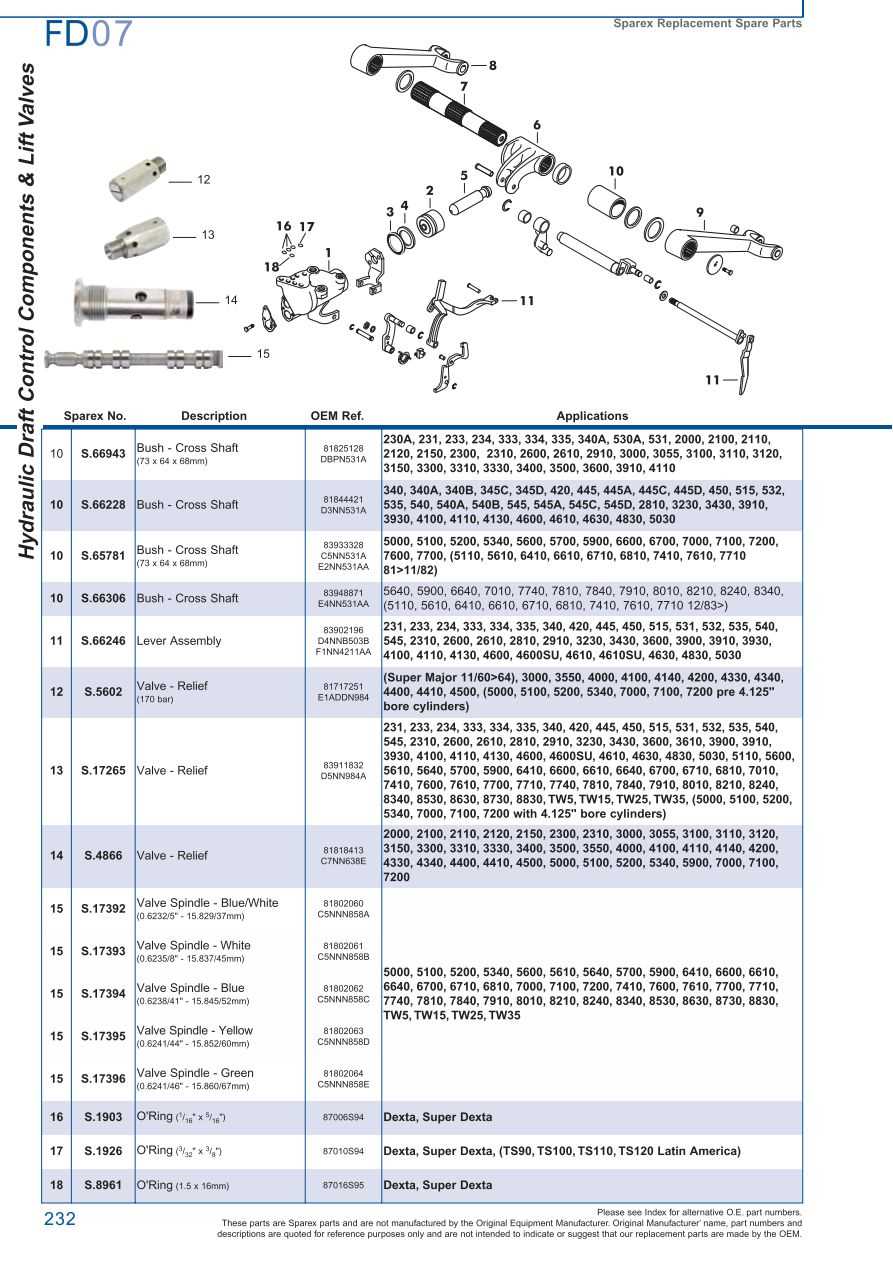

Control Valves and Actuators

Control valves regulate the flow and direction of the fluid, enabling precise control of motion. These valves are crucial for directing the energy to various parts of the system, such as actuators that convert fluid pressure into mechanical movement. Actuators, including cylinders and motors, perform tasks like lifting, pushing, or rotating, depending on their specific design and function within the setup.

Common Hydraulic Issues in Tractors

Many agricultural machines rely on fluid-powered systems for optimal performance. However, issues within these systems can lead to reduced efficiency, mechanical failure, or even complete stoppage. Understanding and identifying these common problems is crucial for maintaining smooth operations on the field. Below are some of the frequent concerns operators might encounter with fluid-based systems in these machines.

Low Fluid Levels

One of the most common issues is insufficient fluid levels, which can lead to poor system performance. When the fluid is low, it compromises the system’s ability to generate the necessary force for operations such as lifting, steering, or operating attachments. This issue can stem from leaks, improper maintenance, or contamination of the fluid itself.

Contamination of Fluid

Contaminants such as dirt, water, and air can enter the system, causing corrosion, blocked filters, or even system failure. Contaminated fluid can lead to reduced efficiency and may even damage critical components, resulting in costly repairs.

| Cause | Effect |

|---|---|

| Low Fluid Levels | Inability to generate sufficient force for operations, leading to inefficient performance. |

| Fluid Contamination | Corrosion, damage to components, and clogging of filters. |

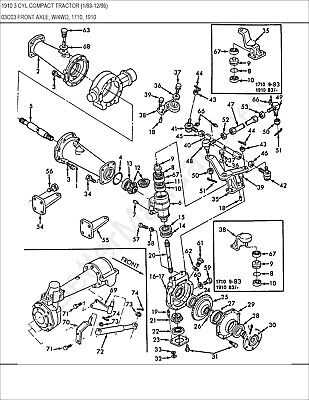

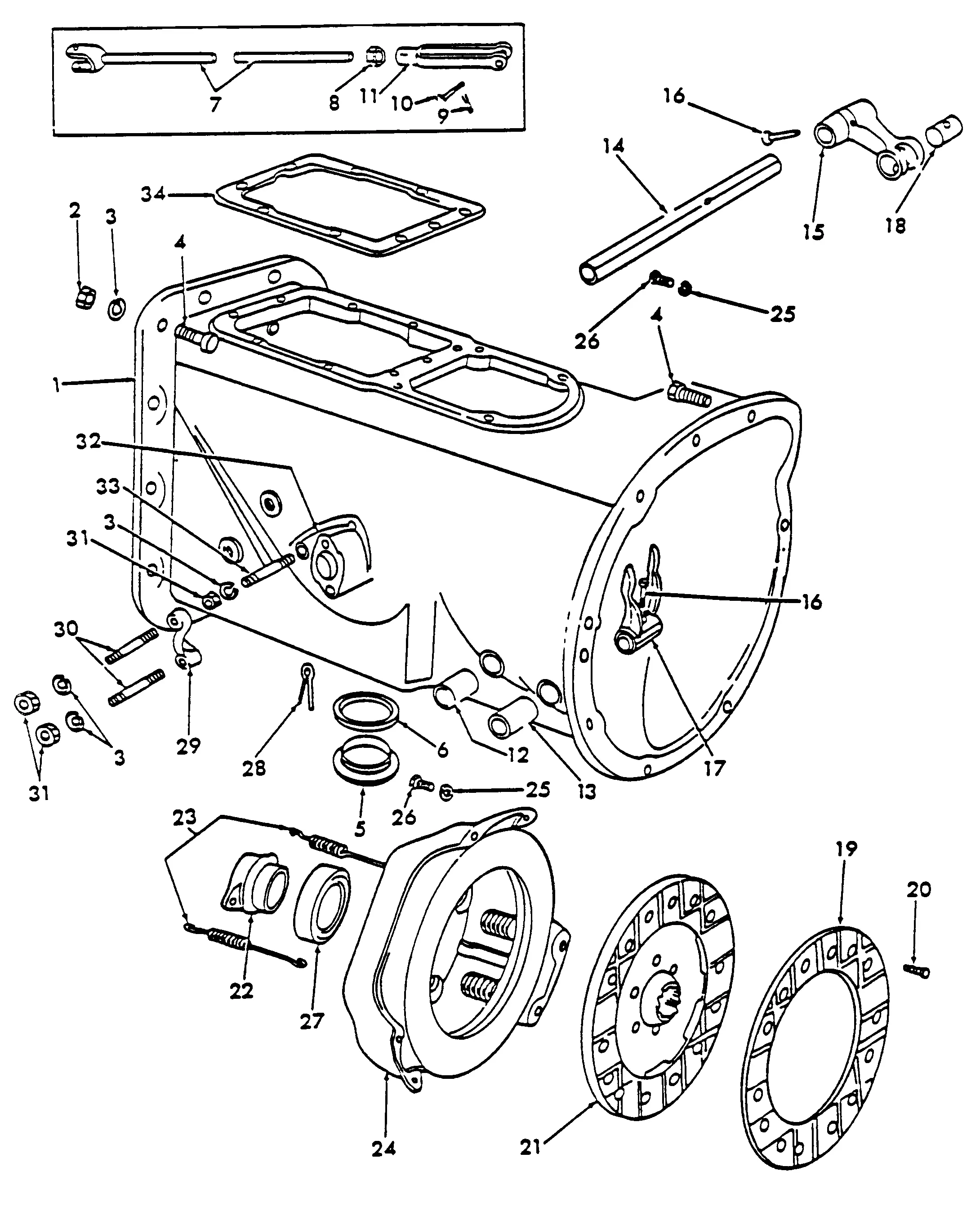

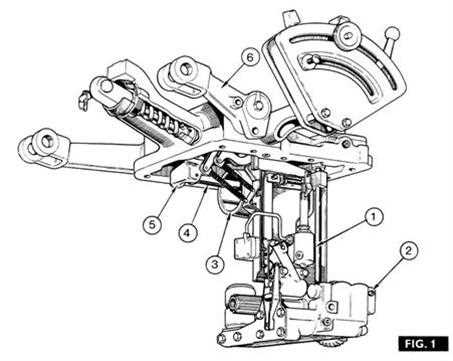

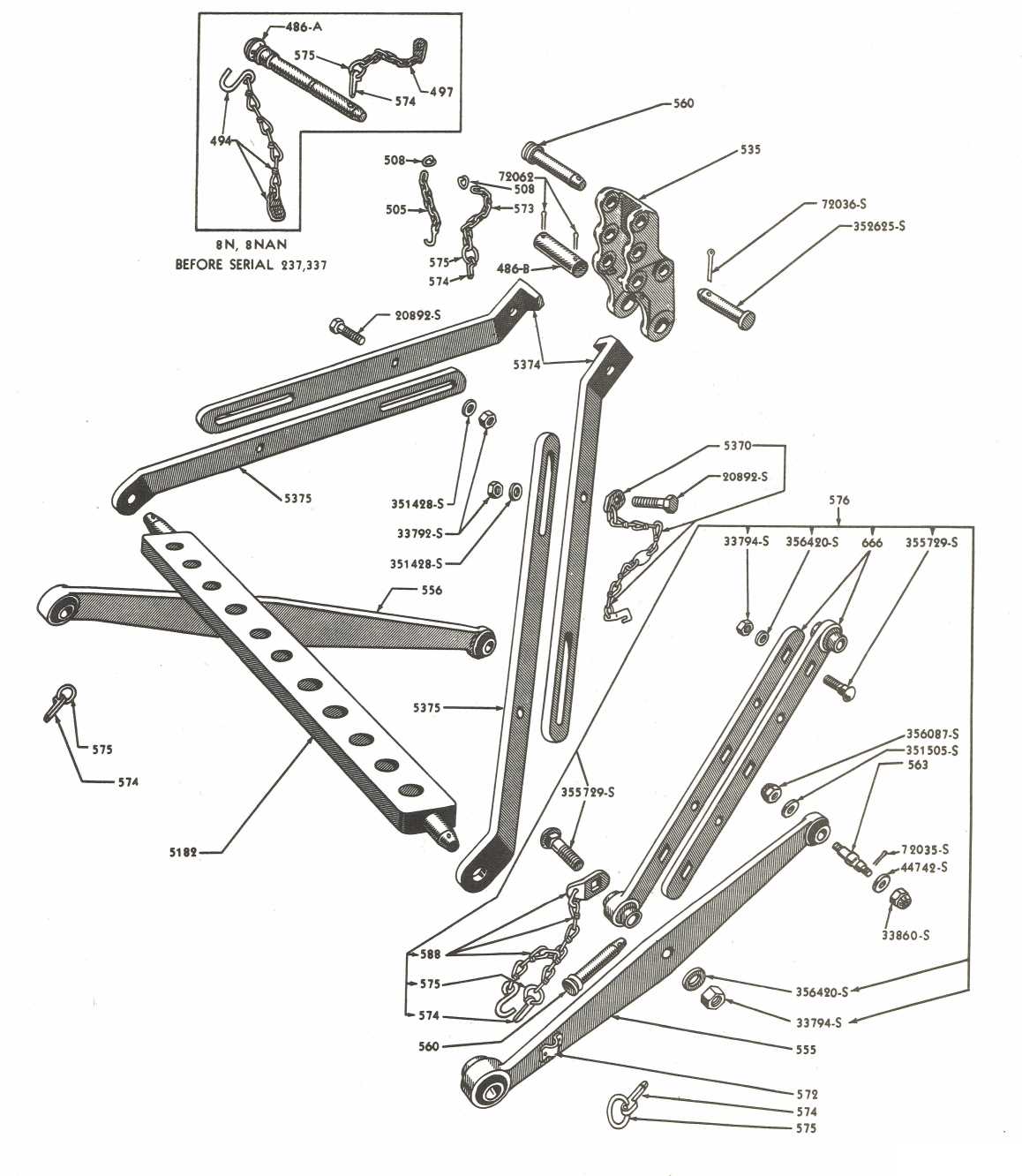

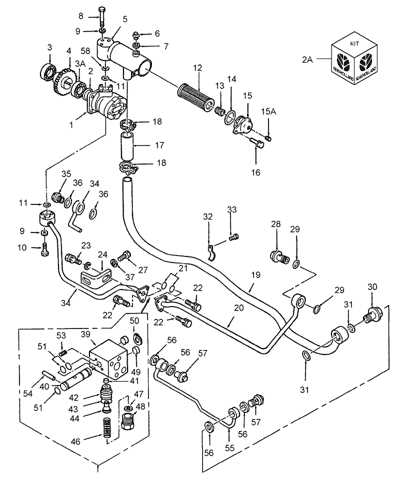

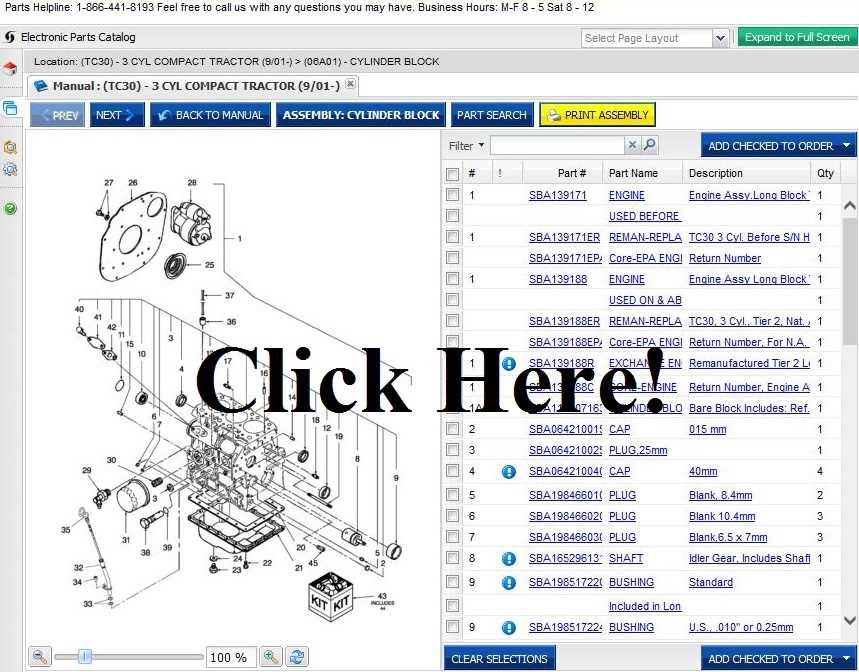

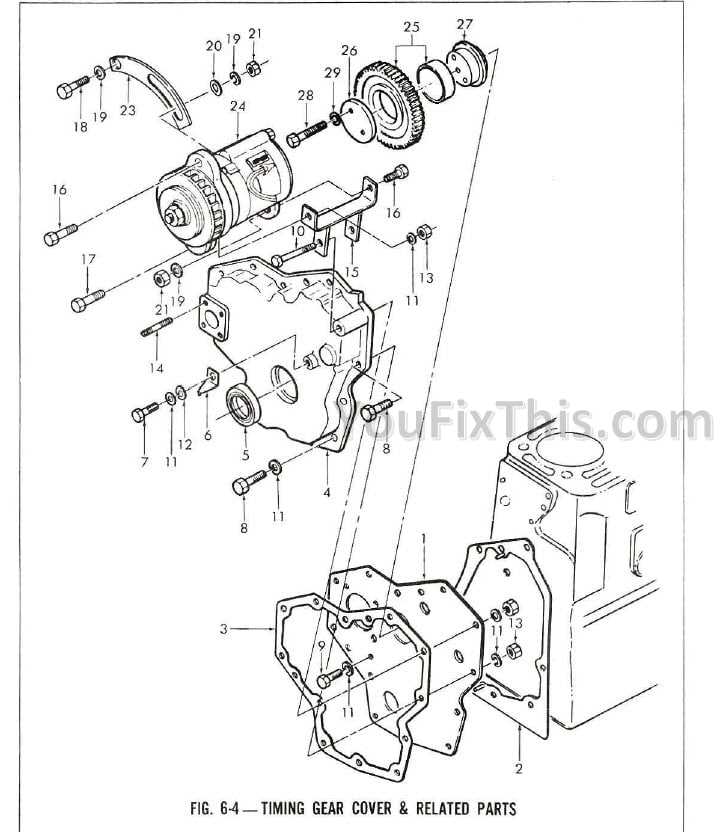

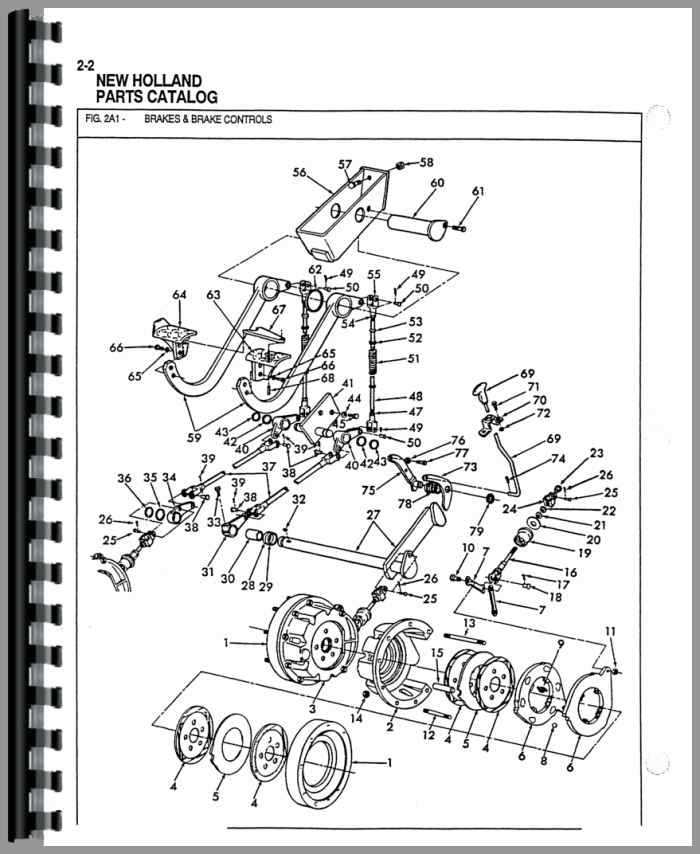

How to Read Parts Diagrams

Understanding visual representations of mechanical components is essential when performing maintenance or repairs. These illustrations offer a clear view of how different elements fit together, providing a comprehensive overview of assembly and disassembly. By interpreting these visual guides correctly, you can identify individual components and their relationships within a larger system, simplifying the process of troubleshooting or upgrading machinery.

When examining such representations, focus on key aspects such as labels, numbers, and the arrangement of parts. Each part is typically assigned a specific reference number, which corresponds to a list detailing its specifications. The orientation and connections between components are also shown, highlighting how each piece interacts with others within the assembly.

| Reference Number | Component Name | Description |

|---|---|---|

| 1 | Pump Assembly | Includes all the elements involved in fluid transfer within the system. |

| 2 | Valve Block | Controls the flow of liquids to different parts of the machine. |

| 3 | Filter | Removes impurities from the fluid to ensure smooth operation. |

It’s important to also pay attention to any special notations or symbols, which can indicate specific functions, orientations, or assembly requirements. Understanding the placement and interaction of these elements will allow for more efficient repairs and replacements.

Tools Needed for Hydraulic Repairs

When performing repairs on fluid systems, having the right tools is essential for ensuring the job is done efficiently and safely. Whether you’re fixing leaks, replacing components, or troubleshooting issues, using the appropriate equipment can make a significant difference in the quality of the work. The tools required will vary depending on the complexity of the task, but some items are commonly needed for most maintenance activities involving fluid-driven mechanisms.

Basic Tools

Before diving into more specialized instruments, it’s important to gather the fundamental tools that will assist in disassembling and assembling various components. These basic tools are crucial for handling routine repairs.

- Wrenches (adjustable and socket types)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Hammers (rubber and standard)

- Pipe cutters and tubing benders

Specialized Equipment

For more intricate tasks, there are a few specialized instruments designed specifically for working with fluid systems. These tools help ensure precision and prevent damage to sensitive components.

- Pressure gauges

- Fluid extractors

- Sealant applicators

- Torque wrenches

- Filtration tools

By ensuring you have the right mix of basic and specialized tools, you can tackle a wide range of repair tasks with confidence and efficiency. Having the proper instruments not only saves time but also reduces the risk of further damage during maintenance operations.

Upgrading Your Tractor’s Hydraulic System

Improving the performance of the fluid-powered mechanism that controls various attachments and tools on your machine can significantly enhance its efficiency and versatility. Whether you’re looking for better lifting capacity, smoother operation, or faster response times, updating the key components of the system is an excellent way to achieve these goals. A well-optimized setup can reduce wear and tear, increase productivity, and extend the lifespan of your equipment.

Investing in quality components is crucial when considering upgrades. For instance, high-performance pumps and valves can provide a more reliable and consistent flow, leading to more precise control. Moreover, choosing the right seals and hoses ensures that the system remains leak-free and operates at peak efficiency. Consider examining the compatibility of new parts with your existing configuration before making a purchase.

Regular maintenance also plays a key role in maximizing the benefits of any enhancements you implement. Even with upgraded parts, periodic checks for wear and tear, as well as the proper calibration of the system, are essential for long-term performance. With the right improvements and upkeep, you can expect smoother operation and improved productivity for years to come.

Safety Tips for Tractor Maintenance

When performing routine maintenance on large machinery, it is crucial to prioritize safety to prevent accidents and ensure the equipment functions efficiently. Regular checks and repairs can help avoid costly breakdowns, but mishandling can lead to injuries or equipment damage. Understanding key safety measures is essential for anyone working with such heavy-duty machinery.

Always start by turning off the engine and disconnecting the power source before performing any inspections or repairs. This simple step reduces the risk of accidental starts, which could lead to serious injuries. Additionally, ensure the machinery is stable and secure before attempting any work, especially when lifting or supporting components.

Wearing appropriate personal protective equipment (PPE), such as gloves, safety boots, and eye protection, is vital. Many tasks, like handling heavy tools or dealing with pressurized systems, pose risks of injury, so safety gear can provide an extra layer of protection.

Ensure that all tools and equipment are in good working order before use. Dull, damaged, or faulty tools can be hazardous and may make the repair process more difficult. Additionally, always follow the manufacturer’s guidelines and consult the user manual for specific instructions on maintenance procedures to avoid incorrect handling.

Lastly, keep the work area clean and well-lit. A cluttered or poorly lit environment increases the risk of accidents, making it difficult to locate tools or see the parts you’re working on clearly. A tidy workspace helps ensure that you can work efficiently and safely.