Exploring the intricacies of agricultural machinery can significantly enhance operational efficiency. This section aims to illuminate the various elements that contribute to the functionality of a specific model in the realm of farming equipment.

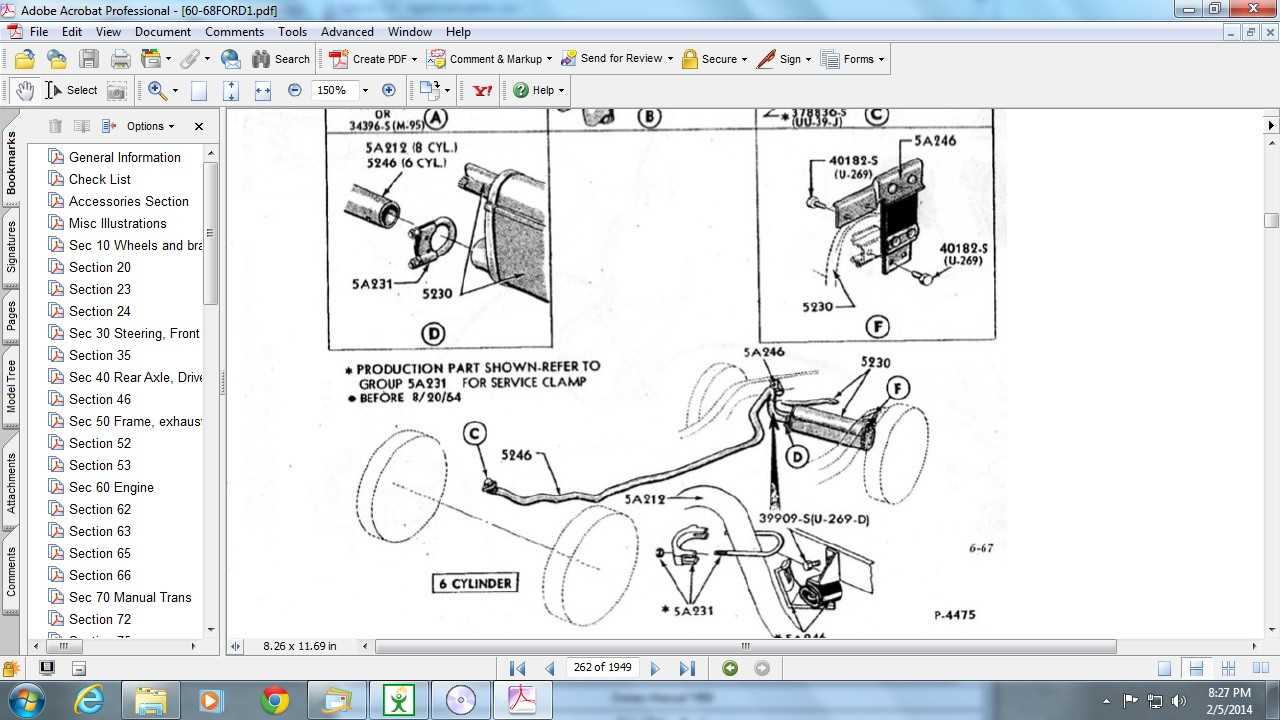

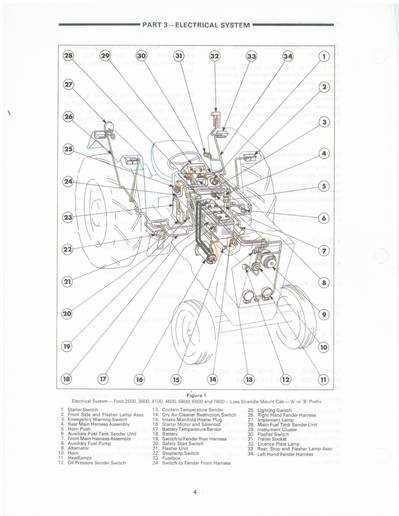

By dissecting the assembly of crucial components, users can better appreciate the mechanics behind their performance. A clear representation of these parts serves as a valuable reference for both maintenance and troubleshooting.

Engaging with the detailed layouts allows enthusiasts and professionals alike to delve into the ultimate nuances of their machinery. Such insights pave the way for informed decisions and optimal care, ensuring longevity and reliability.

Understanding Ford 3600 Tractor Components

In the realm of agricultural machinery, comprehending the various elements that constitute these powerful machines is essential for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and durability, impacting overall functionality.

The engine serves as the heart of the machine, converting fuel into mechanical energy. Its design influences the power output and efficiency, making regular inspections crucial to prevent operational issues.

The transmission system is responsible for controlling the speed and torque, enabling smooth operation across diverse terrains. Understanding the types of transmissions available can aid in selecting the right configuration for specific tasks.

The hydraulic system allows for versatile operations, powering attachments and implements. Familiarity with its components, such as pumps and cylinders, is essential for troubleshooting and effective use.

The chassis provides structural integrity, supporting various components while facilitating mobility. Awareness of the undercarriage and frame conditions can prevent failures during heavy-duty tasks.

Maintenance of these essential parts is key to prolonging the lifespan and enhancing the efficiency of the machinery. Regular checks and timely replacements can save time and costs in the long run.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for effective maintenance and repair. Accurate schematics serve as invaluable references, ensuring that users can identify the correct pieces needed for assembly or replacement. This clarity not only streamlines the repair process but also reduces the risk of errors that could lead to further complications.

Enhanced Understanding and Efficiency

Having a detailed visual guide fosters a better grasp of the system’s configuration. Technicians and hobbyists alike benefit from a clear layout, which aids in identifying connections and functions of each element. This understanding translates to improved efficiency, allowing for quicker repairs and reduced downtime.

Minimized Errors and Costs

Utilizing precise illustrations significantly diminishes the likelihood of mistakes during the repair process. When individuals can accurately pinpoint the required components, they are less likely to purchase incorrect items or undertake unnecessary work. This not only saves time but also helps in managing expenses effectively.

Common Issues with Ford 3600 Parts

When operating heavy machinery, users often encounter a range of challenges related to components and their functionality. Understanding these issues can lead to better maintenance and enhanced performance. Recognizing frequent problems is essential for ensuring longevity and reliability in any equipment.

Wear and Tear: Components are subject to natural deterioration over time due to regular use. This wear can lead to decreased efficiency, requiring timely replacements to maintain optimal performance.

Hydraulic System Failures: Issues in the hydraulic system can arise from leaks or damaged seals. Such problems often result in a significant loss of power, affecting the overall operation of the machine.

Electrical Problems: Malfunctions in the electrical system, such as faulty wiring or failing alternators, can cause operational disruptions. Regular inspections are crucial to prevent these issues from escalating.

Fuel System Clogs: Accumulation of debris or contaminants can block fuel lines, leading to poor engine performance. Regular cleaning and maintenance of the fuel system are essential to avoid these complications.

Transmission Issues: Difficulties in shifting gears may indicate problems with the transmission system. Identifying and addressing these issues promptly can prevent more serious mechanical failures.

By being aware of these common challenges, operators can take proactive steps to maintain their machinery effectively, ensuring it remains in good working condition for years to come.

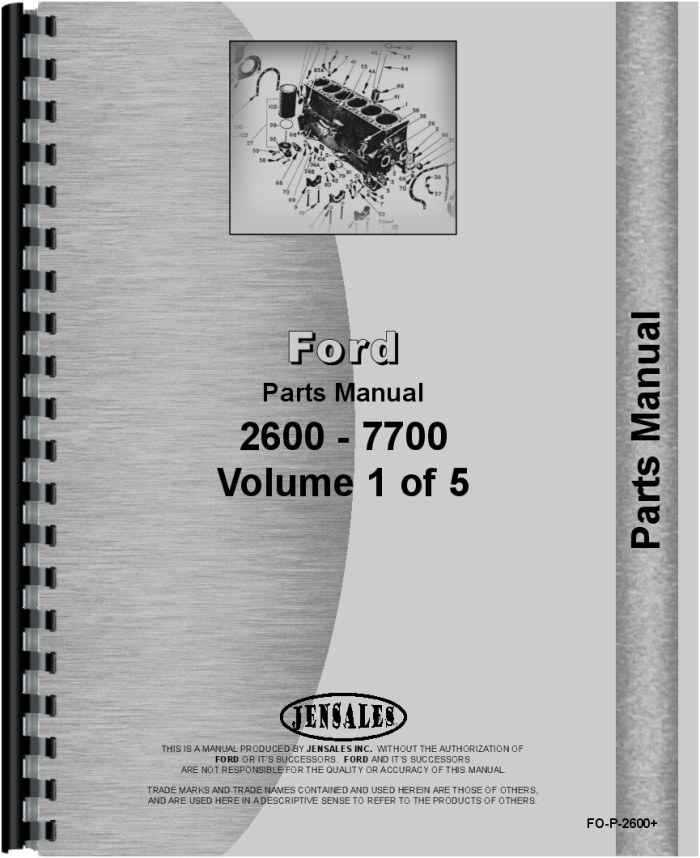

Where to Find Replacement Parts

Locating suitable components for your agricultural machinery can significantly enhance its performance and longevity. Whether you are conducting routine maintenance or need a specific item for repairs, understanding where to search is essential for a successful outcome. Various sources offer a range of options to ensure you find what you need efficiently.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in original equipment, providing reliable components that ensure compatibility and durability. |

| Online Marketplaces | Platforms like eBay or Amazon often feature a variety of vendors, offering both new and used items at competitive prices. |

| Local Salvage Yards | These locations can be treasure troves for affordable, pre-owned components, often in good condition. |

| Specialty Parts Suppliers | These businesses focus on specific machinery and often provide both original and aftermarket options tailored to your needs. |

| Online Forums and Communities | Joining groups dedicated to machinery enthusiasts can lead to valuable recommendations and connections for sourcing parts. |

Maintenance Tips for Ford 3600

Proper upkeep of your machinery is essential to ensure its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. Here are some effective strategies to keep your equipment in top shape.

Regular Inspections

Fluid Changes and Filter Replacements

Ensure that oil, coolant, and fuel are changed at recommended intervals. Fresh fluids are crucial for smooth operation and can significantly reduce the risk of breakdowns. Don’t forget to replace filters to maintain cleanliness and efficiency in the systems.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components offers numerous advantages that enhance the overall performance and longevity of machinery. These elements are designed specifically for compatibility, ensuring seamless integration and optimal functionality.

- Quality Assurance: OEM components meet rigorous standards, ensuring reliability and durability.

- Perfect Fit: Designed for specific models, they eliminate issues related to misalignment and poor performance.

- Warranty Protection: Using original components often helps maintain warranty coverage on the equipment.

- Enhanced Performance: OEM parts contribute to improved efficiency and effectiveness in operations.

- Resale Value: Equipment maintained with original components typically retains higher resale value.

Upgrading Your Ford 3600 Tractor

Enhancing your agricultural machinery can significantly improve efficiency and performance. A thoughtful upgrade strategy can lead to better productivity and longevity.

Consider the following areas for enhancement:

- Engine Performance

- Hydraulic System

- Transmission Upgrades

- Cab Comfort

- Implement Compatibility

Each upgrade offers unique advantages:

- Engine Performance: Boost horsepower and fuel efficiency with a new intake system or exhaust.

- Hydraulic System: Improve lifting capacity with a more robust hydraulic pump.

- Transmission Upgrades: Opt for a gear reduction system for better torque.

- Cab Comfort: Install ergonomic seats and climate control for improved operator comfort.

- Implement Compatibility: Add attachments that expand functionality.

Careful selection of upgrades can lead to the ultimate enhancement of your equipment’s capabilities.

Comparing Ford 3600 to Other Models

This section explores the similarities and differences between a particular model and its contemporaries in the same category. Understanding these distinctions can help users make informed decisions when selecting machinery for their agricultural or industrial needs. By analyzing various features, performance metrics, and user experiences, one can appreciate how this model stands out or falls short in comparison to others.

Key Features Overview

When comparing various models, it’s essential to consider key specifications such as engine power, fuel efficiency, and operational capabilities. These elements play a significant role in determining suitability for specific tasks and overall user satisfaction.

| Feature | This Model | Competitor A | Competitor B |

|---|---|---|---|

| Engine Power (HP) | 45 | 50 | 40 |

| Fuel Efficiency (MPG) | 18 | 16 | 20 |

| Lift Capacity (lbs) | 2000 | 2200 | 1800 |

User Experience and Feedback

User feedback is a critical aspect of understanding how a model performs in real-world conditions. Reviews often highlight aspects such as ease of use, maintenance requirements, and overall reliability, offering valuable insights for potential buyers.