Understanding the intricate assembly of agricultural machinery is essential for optimal performance and maintenance. This section aims to provide insights into the various elements that constitute a particular model, emphasizing their roles and functionalities.

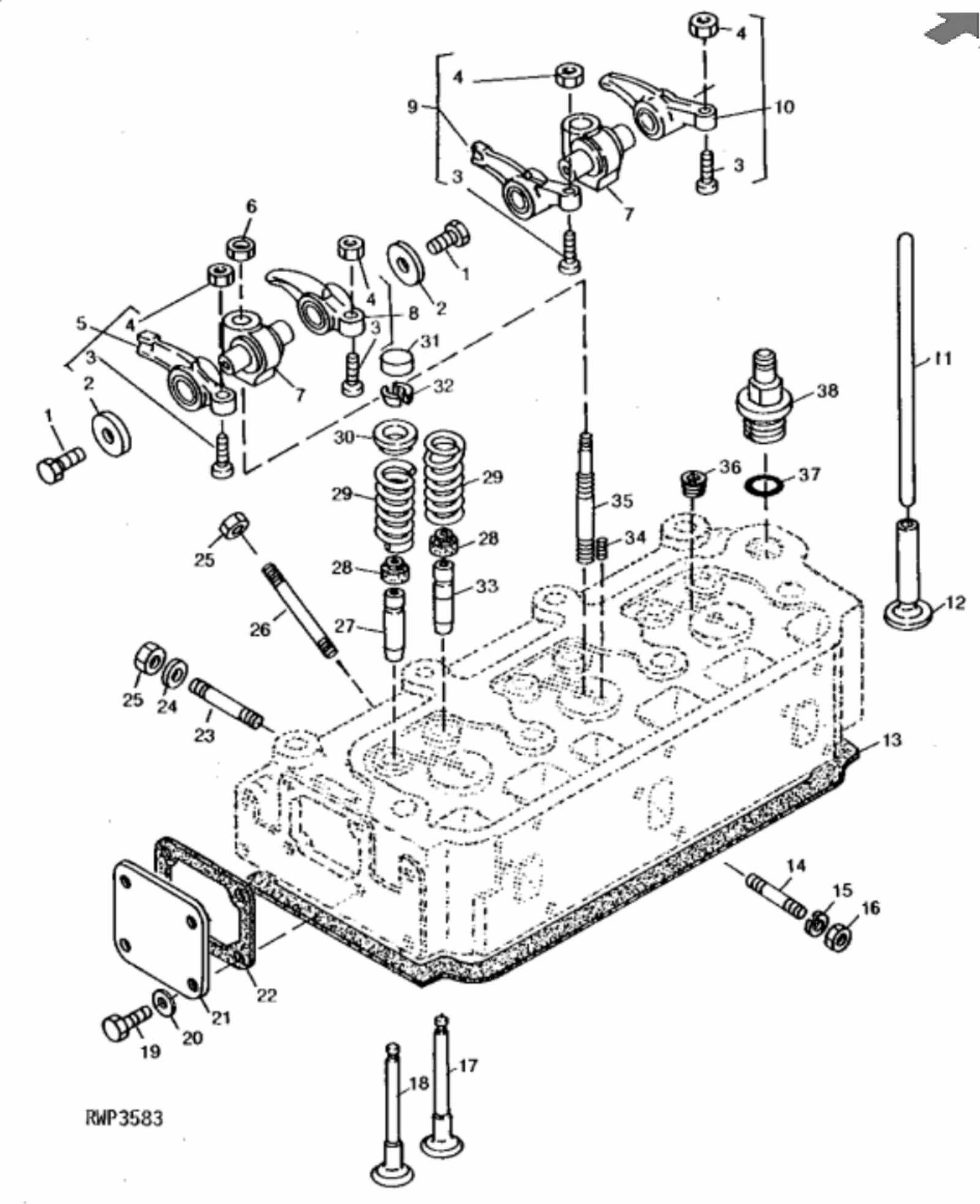

Detailed illustrations play a crucial role in visualizing how these components interact within the system. By examining these graphics, users can gain a deeper appreciation for the engineering that underlies efficient agricultural operations.

Furthermore, an exploration of these essential mechanisms not only aids in repairs but also enhances the user’s knowledge, ultimately leading to better decision-making in terms of upgrades and modifications. Diving into the specifics allows enthusiasts and professionals alike to enhance their understanding of this vital machinery.

Understanding John Deere 850 Tractor Parts

Exploring the essential components of agricultural machinery is crucial for efficient operation and maintenance. Familiarity with various elements can significantly enhance performance and longevity, ensuring that the equipment runs smoothly during demanding tasks.

Key Components Overview

Each segment plays a vital role, contributing to the overall functionality of the equipment. Recognizing these segments allows operators to troubleshoot effectively and perform timely repairs.

Common Elements and Their Functions

| Component | Function |

|---|---|

| Engine | Power generation for operation |

| Transmission | Transmits power to wheels |

| Hydraulic System | Controls attachments and implements |

| Chassis | Supports all components |

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair. These illustrations serve as essential references, enabling users to identify and source the necessary items with ease. Accurate depictions not only streamline the replacement process but also reduce the risk of errors during assembly or disassembly.

Enhancing Efficiency

Detailed visuals improve overall efficiency by allowing technicians to quickly locate and understand each element’s function. This clarity minimizes downtime, ensuring that machinery remains operational and productive. When each piece is properly identified, the workflow becomes smoother, ultimately leading to better outcomes.

Reducing Costs

Utilizing correct visual guides can significantly lower expenses related to repairs. By ensuring that the right components are chosen from the start, unnecessary purchases and returns can be avoided. This not only saves money but also enhances the longevity of the equipment by promoting appropriate usage of its elements.

Common Issues with John Deere 850

Many users encounter various challenges when operating this model. Understanding these frequent problems can help in timely maintenance and prevent costly repairs. Below are some of the most commonly reported issues.

- Starting Problems: Difficulty in starting the engine is often reported. This may be due to battery issues, fuel supply problems, or electrical system failures.

- Hydraulic System Failures: Users frequently experience issues with hydraulic functions, such as slow response or complete failure. This may stem from leaks, low fluid levels, or worn-out components.

- Transmission Issues: Gear shifting difficulties can arise, leading to jerky movements or inability to change gears. This can be attributed to low transmission fluid or internal wear.

- Cooling System Problems: Overheating can occur, often due to blocked radiators or low coolant levels. Regular checks are essential to prevent engine damage.

- Electrical System Failures: Flickering lights or non-functioning instruments may indicate electrical problems. Corroded connections or blown fuses are common culprits.

Addressing these issues promptly can enhance the performance and longevity of the machine. Regular maintenance checks are crucial for early detection and resolution of potential problems.

Where to Find Replacement Parts

When your agricultural equipment requires new components, locating high-quality replacements can be essential for maintaining optimal performance. Fortunately, there are several reliable sources where you can find the necessary items to ensure your machine runs smoothly.

- Authorized Dealers: Start with official dealerships that specialize in the brand. They often have access to the latest inventory and genuine components.

- Online Marketplaces: Websites like eBay, Amazon, and specialized agricultural sites can offer a wide variety of choices, often at competitive prices.

- Local Parts Suppliers: Visit nearby stores that focus on agricultural machinery. They can provide valuable advice and immediate access to components.

- Salvage Yards: Consider visiting salvage or recycling yards that deal with agricultural machinery. You might find used but functional parts at a fraction of the cost.

- Manufacturer Websites: Check the official websites of manufacturers for catalogs or online ordering systems, which may also offer technical support.

Utilizing these resources can help you efficiently find the replacements needed to keep your equipment in peak condition, ensuring reliability and performance on the field.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. By following a few essential practices, you can significantly extend its operational life and enhance performance. Regular maintenance not only prevents unexpected breakdowns but also keeps your equipment running smoothly.

Regular Inspections

Conducting frequent assessments is vital. Look for signs of wear and tear, fluid leaks, or any unusual noises. Addressing issues promptly can prevent minor problems from escalating.

Fluid Changes

Routine replacement of oils and other fluids is crucial for optimal function. Fresh fluids reduce friction and help maintain ideal operating temperatures.

| Maintenance Task | Frequency |

|---|---|

| Inspect for leaks | Monthly |

| Change oil | Every 50 hours |

| Check filters | Every 100 hours |

| Tighten bolts | Every 200 hours |

Exploring Aftermarket Options

When it comes to enhancing machinery performance and longevity, aftermarket alternatives provide a compelling route. These options often come with unique benefits, such as improved pricing and availability, as well as innovative features that can cater to specific user needs. Evaluating these alternatives can lead to significant enhancements in functionality and efficiency.

Benefits of Aftermarket Alternatives

Choosing aftermarket components can yield numerous advantages. Many users report lower costs compared to original equipment offerings, making it a budget-friendly choice. Additionally, some aftermarket suppliers focus on specific improvements or adaptations, leading to higher performance standards in certain applications.

Key Considerations

Before deciding on aftermarket selections, several factors should be considered. Quality and compatibility are paramount, as well as the reputation of the supplier. Thorough research can help ensure that the chosen alternatives meet the necessary standards for durability and effectiveness.

| Factor | Consideration |

|---|---|

| Cost | Generally lower than OEM options |

| Quality | Varies by supplier; research is essential |

| Compatibility | Ensure fit for the specific model |

| Supplier Reputation | Check reviews and feedback from users |

Step-by-Step Repair Guide

In this section, we will explore a comprehensive approach to restoring machinery components, ensuring optimal functionality and longevity. Following a structured process not only simplifies the task but also enhances the overall effectiveness of the repairs.

1. Assess the Issue: Begin by thoroughly examining the machinery to identify any problems. Look for signs of wear, damage, or malfunction that may require attention.

2. Gather Necessary Tools: Collect all required tools and materials before starting the repair. This will streamline the process and reduce interruptions.

3. Disassemble Components: Carefully take apart the affected parts, documenting each step. This will aid in reassembly and ensure no components are lost.

4. Clean and Inspect: Clean all disassembled parts and inspect them for damage. Replace any worn or broken pieces with high-quality alternatives.

5. Reassemble: Begin reassembling the machinery, following your documentation closely. Ensure that each part fits correctly and is securely fastened.

6. Test Functionality: Once reassembly is complete, conduct thorough testing to ensure everything operates smoothly. Address any issues that arise during this phase.

7. Final Checks: Perform a final inspection to confirm that all components are in place and functioning as intended. Regular maintenance will help prevent future issues.

How to Identify Original Parts

Recognizing authentic components is crucial for maintaining performance and longevity. Understanding the features that distinguish original items from replicas can save time and money while ensuring reliability.

Key Features of Authentic Components

- Branding: Look for manufacturer logos or markings.

- Quality: Genuine items typically exhibit superior craftsmanship.

- Packaging: Original products often come in branded packaging.

Verification Steps

- Research the manufacturer’s official website for specifications.

- Consult authorized dealers for confirmation.

- Check for serial numbers or unique identifiers.

Benefits of Regular Inspections

Conducting routine assessments of equipment is crucial for maintaining optimal performance and longevity. Regular evaluations not only enhance efficiency but also help in identifying potential issues before they escalate into costly repairs. This proactive approach ensures that machinery operates smoothly, reducing downtime and improving overall productivity.

Cost Savings

Investing time in frequent checks can lead to significant savings over time. By addressing minor problems early, operators can prevent extensive damage that requires expensive parts and labor. Timely maintenance minimizes the risk of unexpected failures, ultimately reducing the overall operational costs.

Increased Safety

Ensuring that equipment is in good working order is essential for the safety of operators and those nearby. Regular inspections help to identify hazards, such as worn components or leaks, that could pose risks. By prioritizing safety, organizations can foster a safer work environment, thereby reducing accidents and enhancing employee morale.