In the realm of mechanical systems designed for lifting and hauling, a thorough comprehension of the individual elements is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality of these complex machines. By exploring the intricate relationships between these elements, one can gain insights into their performance and reliability.

Identification of key constituents within these systems allows for better troubleshooting and enhancement. Recognizing how each piece interacts with others not only aids in repairs but also fosters a deeper appreciation for engineering design. Whether you are a novice or an experienced operator, understanding these mechanisms enhances both safety and efficiency.

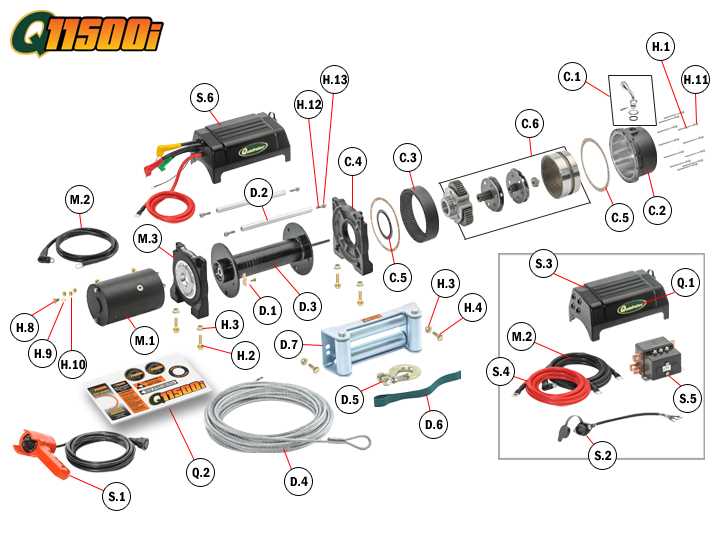

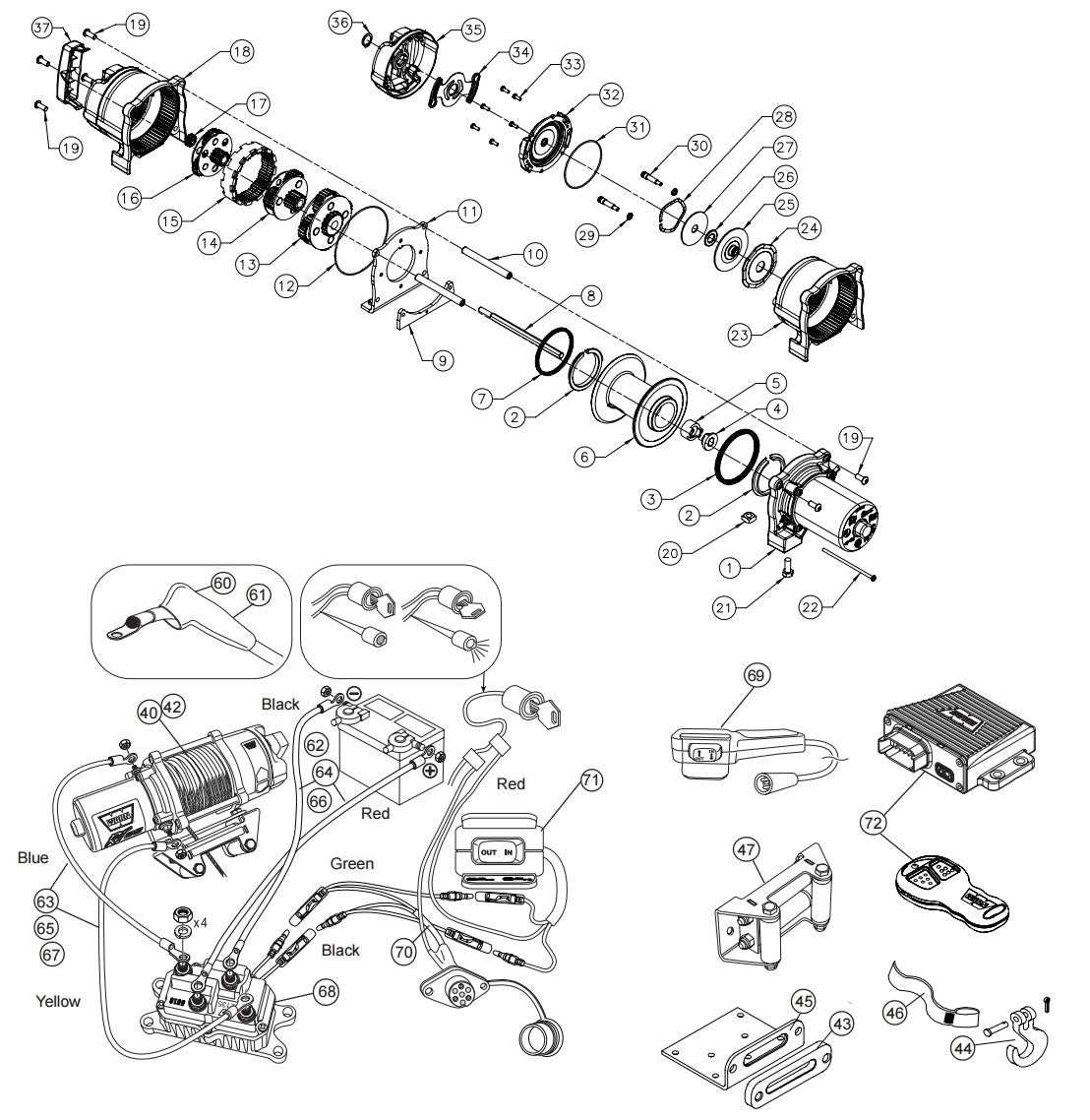

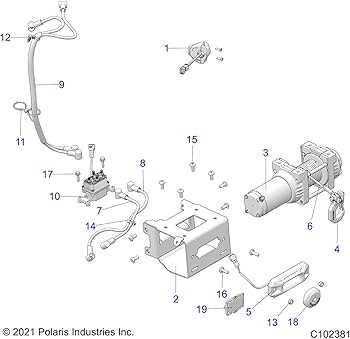

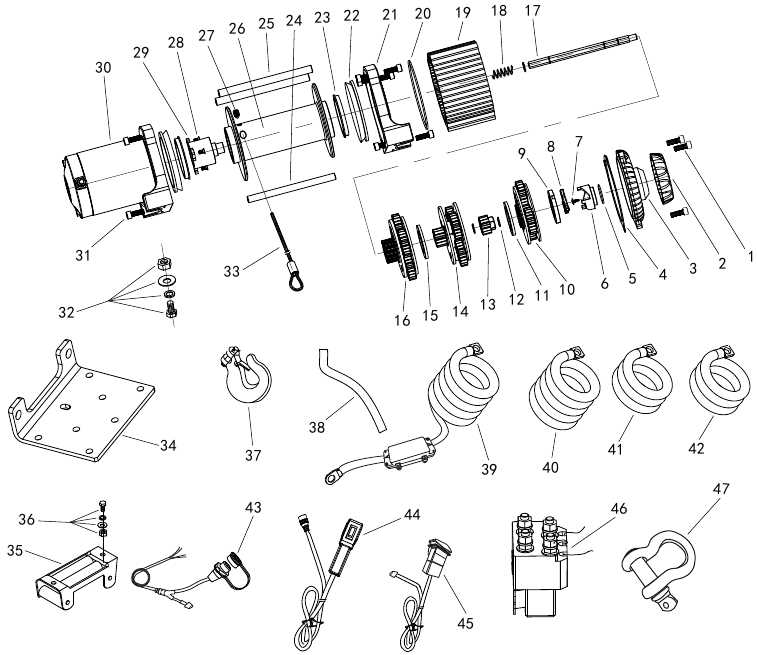

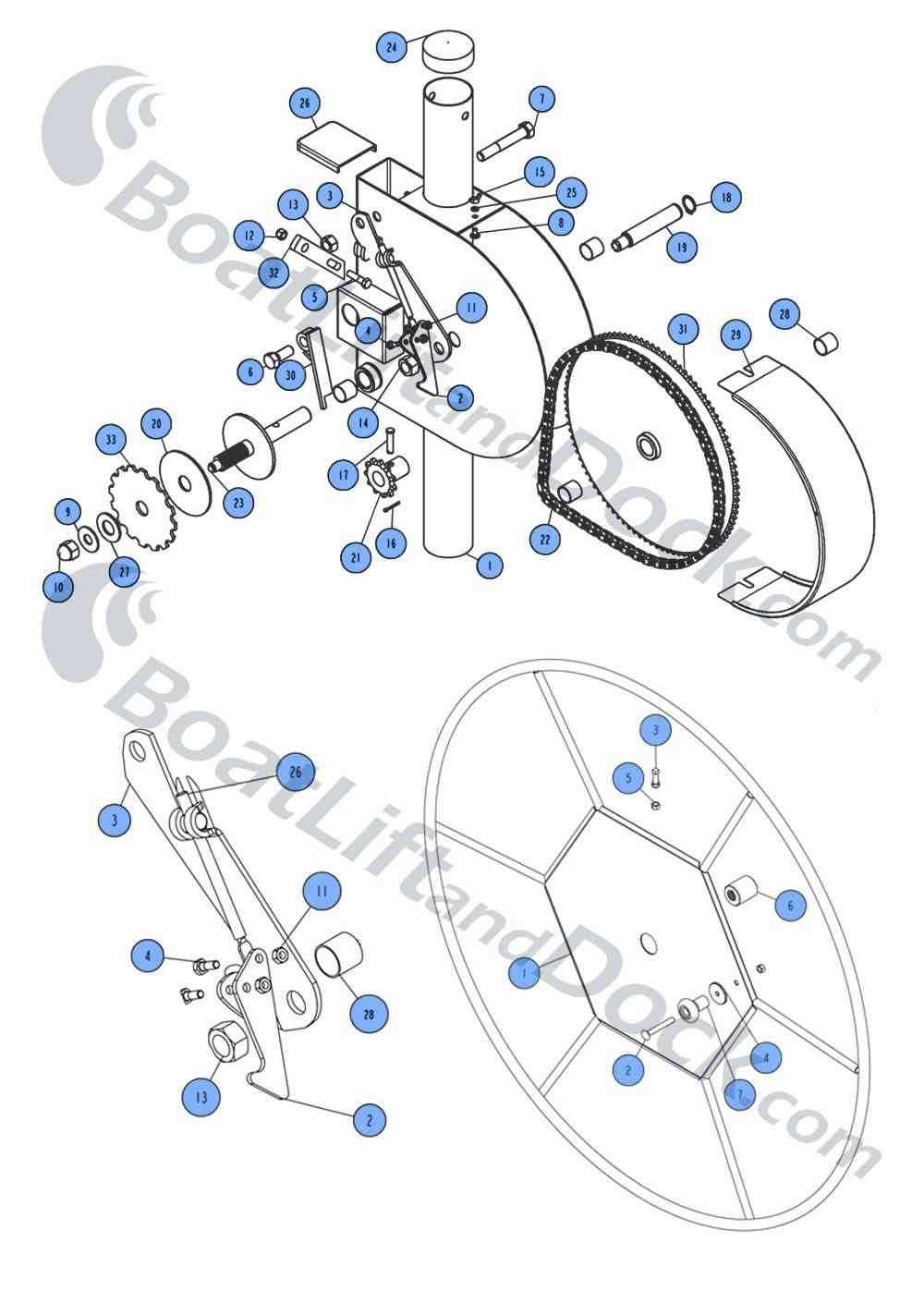

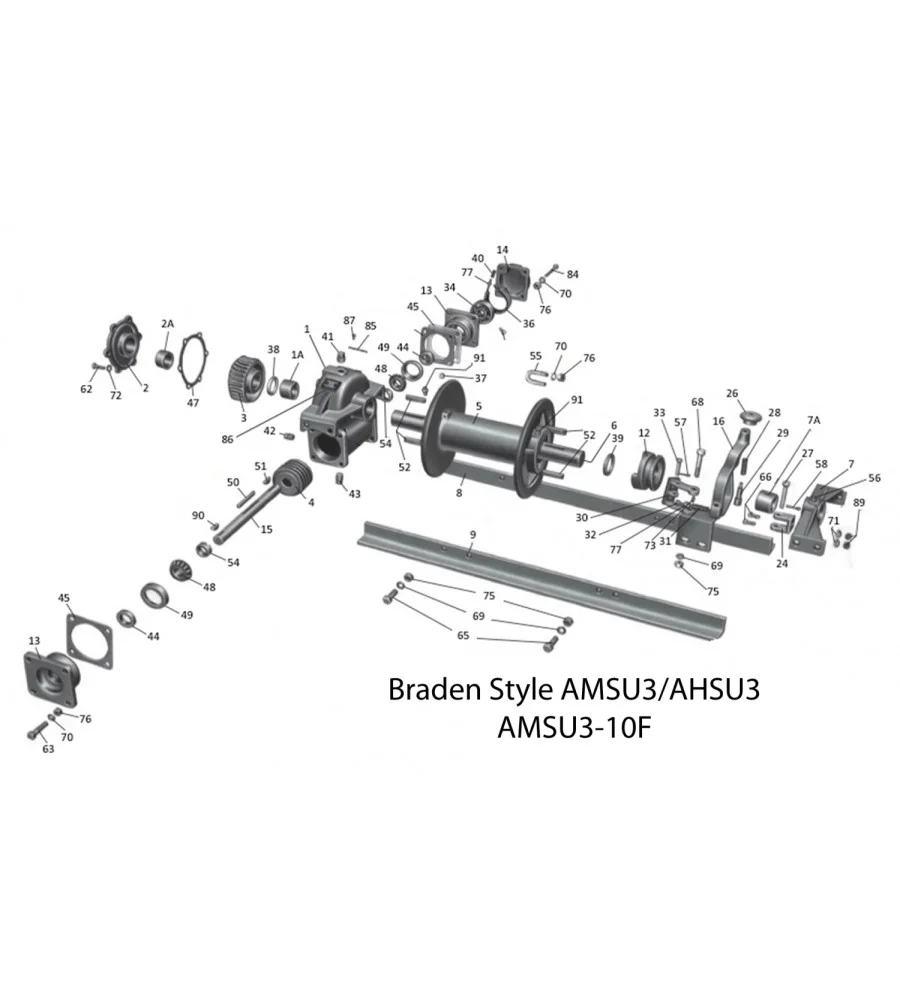

Furthermore, visual representations can significantly aid in grasping the structure and function of various components. By examining these illustrations, individuals can familiarize themselves with terminology and operational principles, ensuring that they are well-equipped to manage and utilize these powerful machines effectively. With this knowledge, users can confidently approach both routine inspections and more complex technical challenges.

Understanding Winch Components

Grasping the essential elements of a hoisting mechanism is crucial for both operation and maintenance. Each element plays a specific role in ensuring that the entire system functions efficiently, allowing for the reliable lifting and pulling of heavy loads. A thorough comprehension of these components not only enhances performance but also contributes to safety and longevity.

Key Elements

Among the fundamental components are the drive unit, which powers the system, and the spool, responsible for managing the cable or rope. The drum, another vital element, holds the lifting medium and allows for controlled deployment and retraction. Understanding the interaction between these key elements is essential for effective operation.

Maintenance and Safety

Regular inspection of each component is paramount to prevent failures and accidents. Lubrication, adjustments, and timely replacements can significantly extend the life of the mechanism and ensure safe use. Awareness of the individual roles and maintenance requirements of each part fosters a proactive approach to care and operation.

Types of Winches and Their Uses

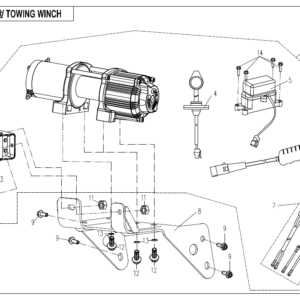

Various mechanical devices are essential in lifting and pulling heavy objects, each designed for specific tasks and environments. Understanding the different categories available can enhance efficiency and safety in various applications.

Manual and Electric Devices

Manual devices rely on human effort to operate, making them ideal for lighter loads or situations where electricity is unavailable. In contrast, electric devices provide greater power and convenience, suitable for heavy lifting in industrial settings or construction sites.

Marine and Off-Road Variants

Marine models are specifically designed to withstand harsh aquatic conditions, often used for anchoring or mooring vessels. Off-road versions cater to adventurous activities, enabling vehicles to navigate rugged terrains by pulling them out of challenging situations.

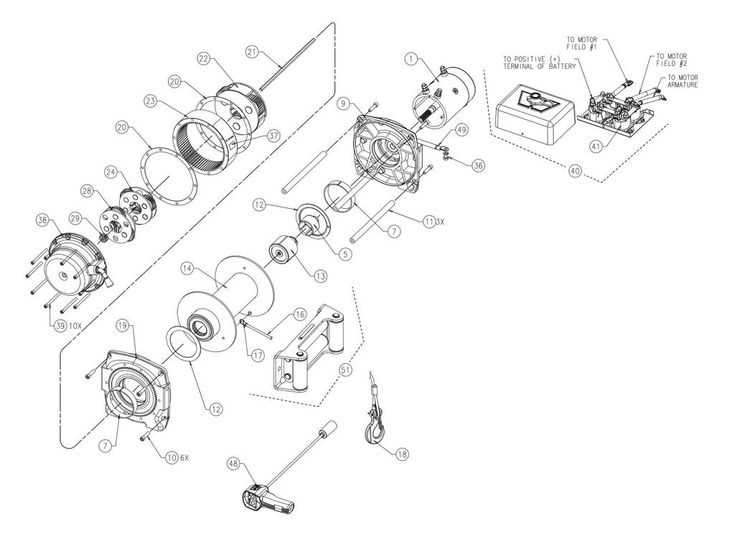

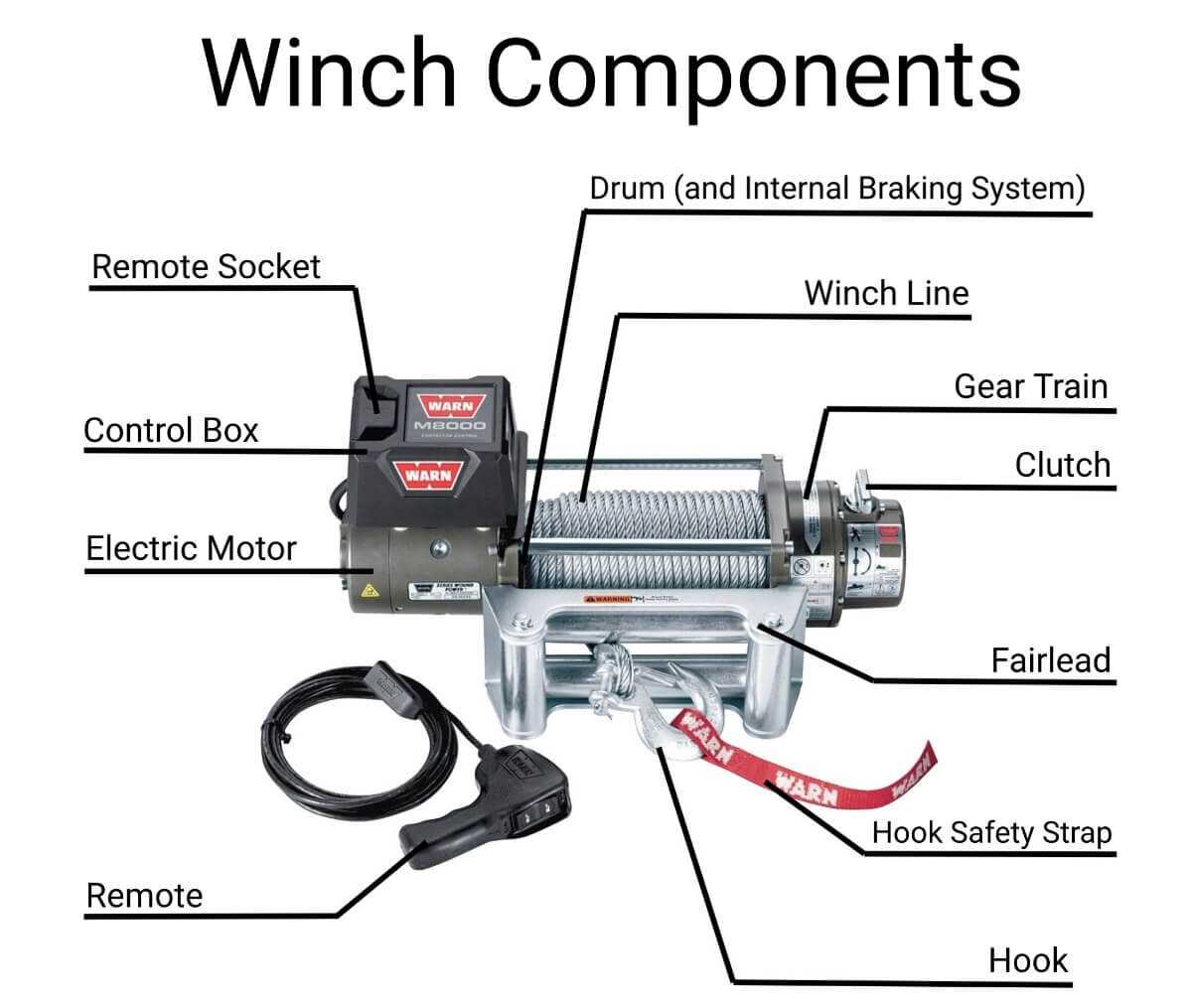

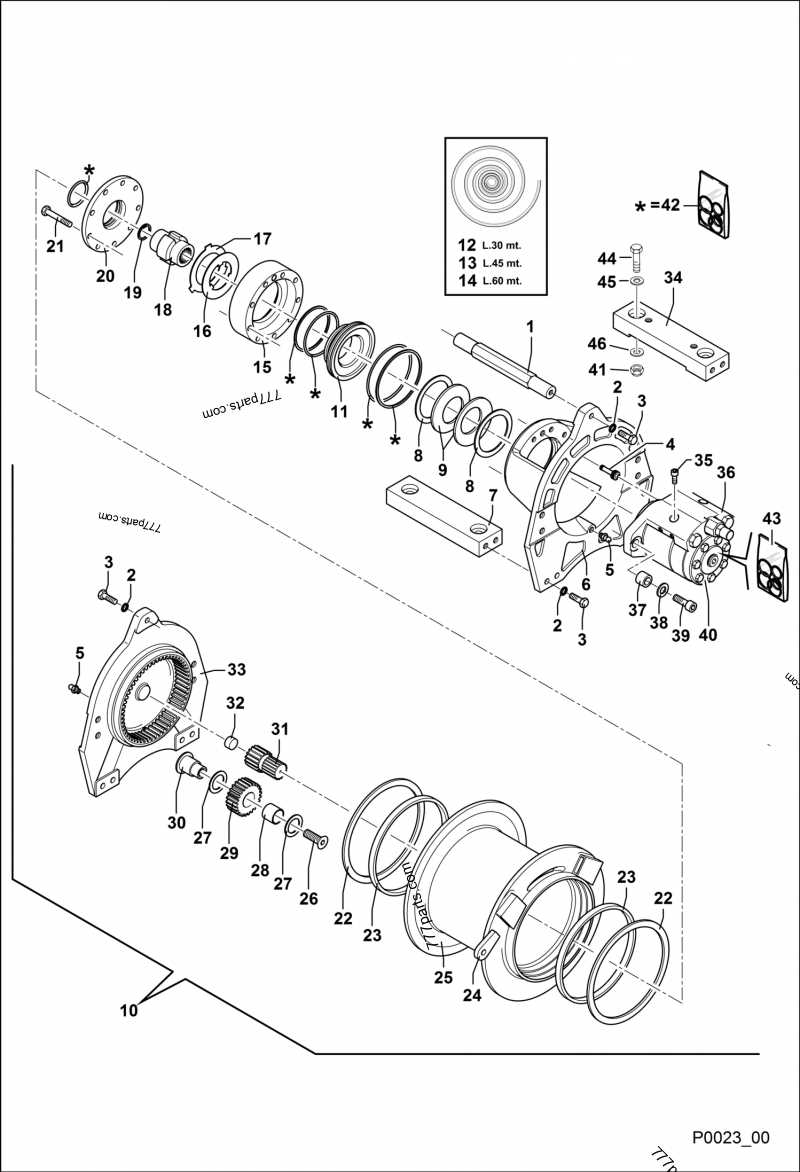

Key Parts of a Winch Diagram

Understanding the essential components of a pulling mechanism is crucial for effective operation and maintenance. Each element plays a significant role in ensuring efficiency and reliability, contributing to the overall performance of the system. Familiarity with these components helps in troubleshooting and optimizing usage.

Essential Components

At the heart of the mechanism is the drum, which houses the cable or rope, allowing for retraction and extension. Connected to the drum is the motor, providing the necessary power to operate the system. Additionally, the gear assembly plays a vital role in controlling the speed and torque, ensuring that the load is managed effectively.

Supporting Elements

Equally important are the brake system, which prevents accidental release of tension, and the mounting plate, providing stability during operation. The control mechanism enables the user to manage the device with precision, ensuring safe and efficient use. Understanding these components enhances the ability to operate the system effectively and safely.

How to Read Winch Diagrams

Understanding technical illustrations related to lifting mechanisms is essential for effective operation and maintenance. These visuals provide a blueprint that reveals the arrangement and functionality of various components, enabling users to grasp their roles and interconnections.

To effectively interpret these illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Identify common symbols used to represent different elements. This knowledge helps in recognizing parts quickly.

- Identify Key Components: Look for the main elements such as drums, gears, and control systems. Understanding their placement aids in grasping overall functionality.

- Follow the Flow: Trace the operational pathways depicted in the illustration. This will clarify how energy is transferred through the system.

- Check Annotations: Pay attention to any notes or labels that provide additional context or specifications related to the components.

By following these steps, one can gain a comprehensive understanding of the intricate workings within these mechanical systems, ultimately enhancing both safety and efficiency during use.

Maintenance Tips for Winch Parts

Regular upkeep of your mechanical lifting devices is essential for ensuring their longevity and optimal performance. Implementing a systematic maintenance routine can prevent unexpected failures and enhance efficiency during operation. By following these tips, you can help ensure that your equipment remains in excellent condition.

Routine Inspection

Conduct frequent checks to identify signs of wear and tear. Look for any unusual noises, rust, or signs of damage. Regularly inspect cables and fasteners, ensuring they are secure and free from corrosion. Early detection of issues can save time and money in repairs.

Lubrication and Cleaning

Keep all moving components properly lubricated to minimize friction and prevent overheating. Use the recommended lubricants and apply them as per the manufacturer’s guidelines. Additionally, clean all surfaces to remove dirt and debris, which can contribute to wear over time. A clean mechanism operates more smoothly and efficiently.

Common Issues with Winch Components

In the realm of mechanical devices designed for pulling and lifting, several challenges can arise that may hinder performance and safety. Understanding these potential problems is crucial for effective maintenance and optimal operation. This section delves into the most frequently encountered issues associated with the various elements involved in these systems.

1. Wear and Tear: Over time, components can experience significant wear, leading to diminished efficiency. Friction and load stress contribute to this degradation, often requiring timely replacement to ensure reliability.

2. Corrosion: Exposure to moisture and harsh environments can result in rust and corrosion, especially on metallic components. Regular inspections and protective coatings can mitigate this risk, prolonging the lifespan of critical elements.

3. Misalignment: Incorrect alignment of the mechanism can cause uneven stress distribution, leading to premature failure. Ensuring proper alignment during installation and routine checks is essential for smooth operation.

4. Electrical Failures: In systems that incorporate electronic controls, failures in wiring or components can disrupt functionality. Regular testing of electrical systems is necessary to identify and rectify issues before they escalate.

5. Insufficient Lubrication: Lack of proper lubrication can lead to increased friction, overheating, and ultimately, component breakdown. Establishing a regular maintenance schedule that includes lubrication is vital for sustaining performance.

By being aware of these common challenges, operators can take proactive measures to enhance the reliability and efficiency of their mechanical systems.

Choosing the Right Winch for Your Needs

Selecting the appropriate lifting device for your specific requirements is essential for ensuring efficiency and safety during various tasks. With numerous options available, understanding your needs and the features of these tools can significantly impact your decision-making process.

When considering which device to utilize, keep the following factors in mind:

- Weight Capacity: Assess the maximum load you will be handling. Choose a device with a suitable weight rating that provides a safety margin.

- Power Source: Determine whether you need an electric or manual model. Electric versions offer convenience, while manual types can be more reliable in remote locations.

- Speed and Gear Ratio: Evaluate the speed at which the load needs to be lifted. A higher gear ratio typically allows for slower and more controlled lifting.

- Durability: Consider the materials used in construction. Devices made from high-quality materials can withstand harsh conditions and last longer.

- Mounting Options: Identify how and where the device will be installed. Ensure compatibility with your existing setup or consider portable solutions.

- Additional Features: Look for extra functionalities such as wireless controls, braking systems, or safety mechanisms that can enhance usability.

By carefully evaluating these aspects, you can select a lifting tool that not only meets your immediate needs but also offers long-term reliability and performance.

Upgrading Winch Parts Effectively

Improving the functionality and performance of your equipment can significantly enhance its efficiency and longevity. This process often involves selecting high-quality components that not only fit seamlessly but also meet specific operational requirements. Understanding how to navigate this upgrade journey can lead to better results and greater satisfaction in use.

Choosing the Right Components

When considering enhancements, it’s essential to assess the compatibility and quality of each element. Look for options that provide superior strength and durability, as these attributes contribute to improved overall performance. Researching reputable manufacturers and reading user reviews can guide you in making informed decisions.

Installation and Maintenance Tips

Proper installation is crucial for ensuring that new components function effectively. Following the manufacturer’s instructions and using the appropriate tools will minimize the risk of issues. Regular maintenance checks are also vital; they help in identifying wear and tear early, allowing for timely interventions. Establishing a routine maintenance schedule can keep your system running smoothly for years to come.