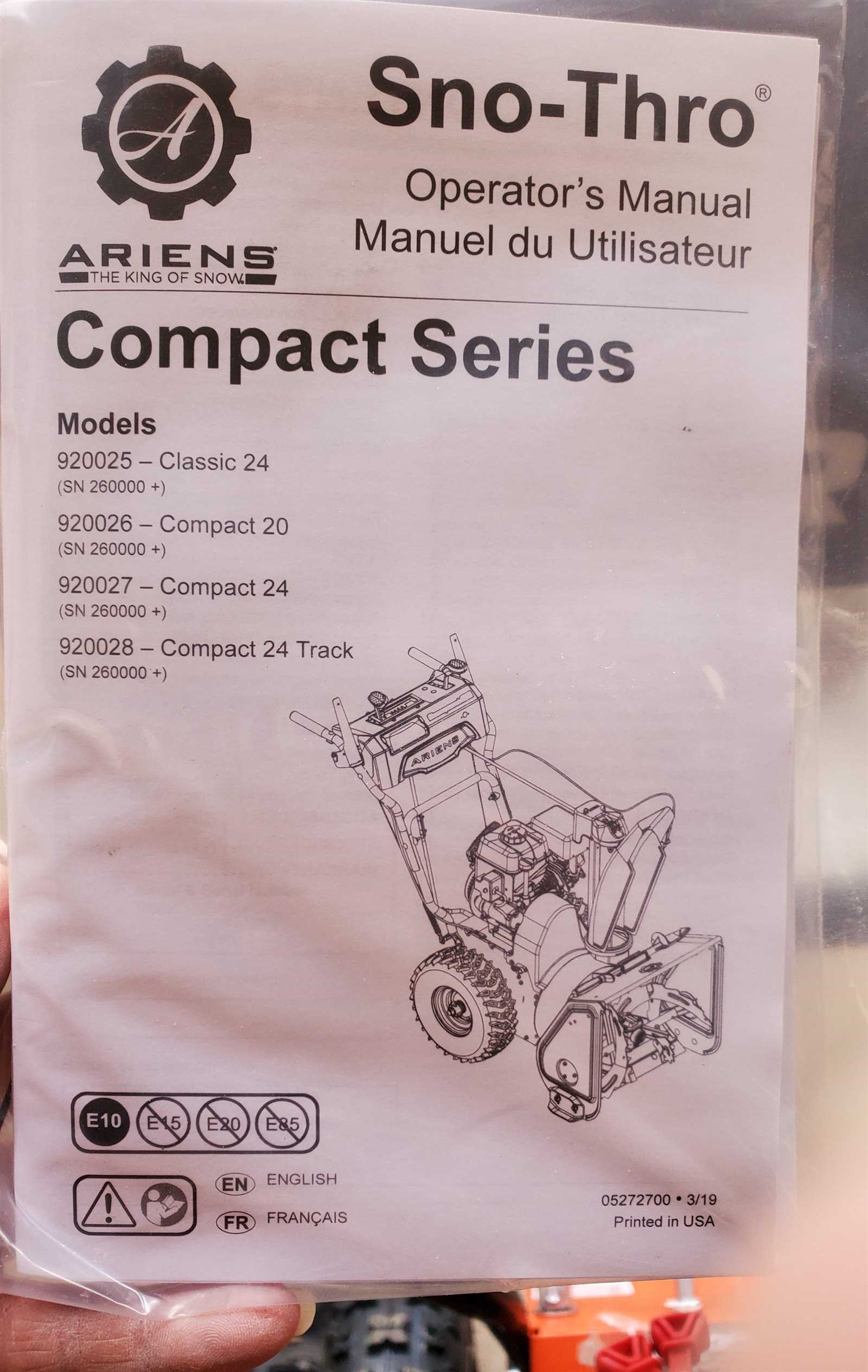

When it comes to efficiently clearing snow, each element of the machine plays a crucial role. Every single component works together, ensuring smooth operation even in the harshest conditions. Familiarizing yourself with these elements can help you maintain the equipment in top shape, ensuring reliability and longevity.

Each section of this guide will delve into different mechanical and structural aspects. From the primary moving parts to smaller elements, we will explore how they interact and what you need to know for optimal care and troubleshooting. This comprehensive understanding is essential for anyone looking to keep their machine performing at its best.

We will break down the key sections of the machine, highlighting their functions and providing tips for maintenance. Whether you’re looking to replace or simply inspect certain elements, this overview will equip you with the knowledge to handle any task confidently.

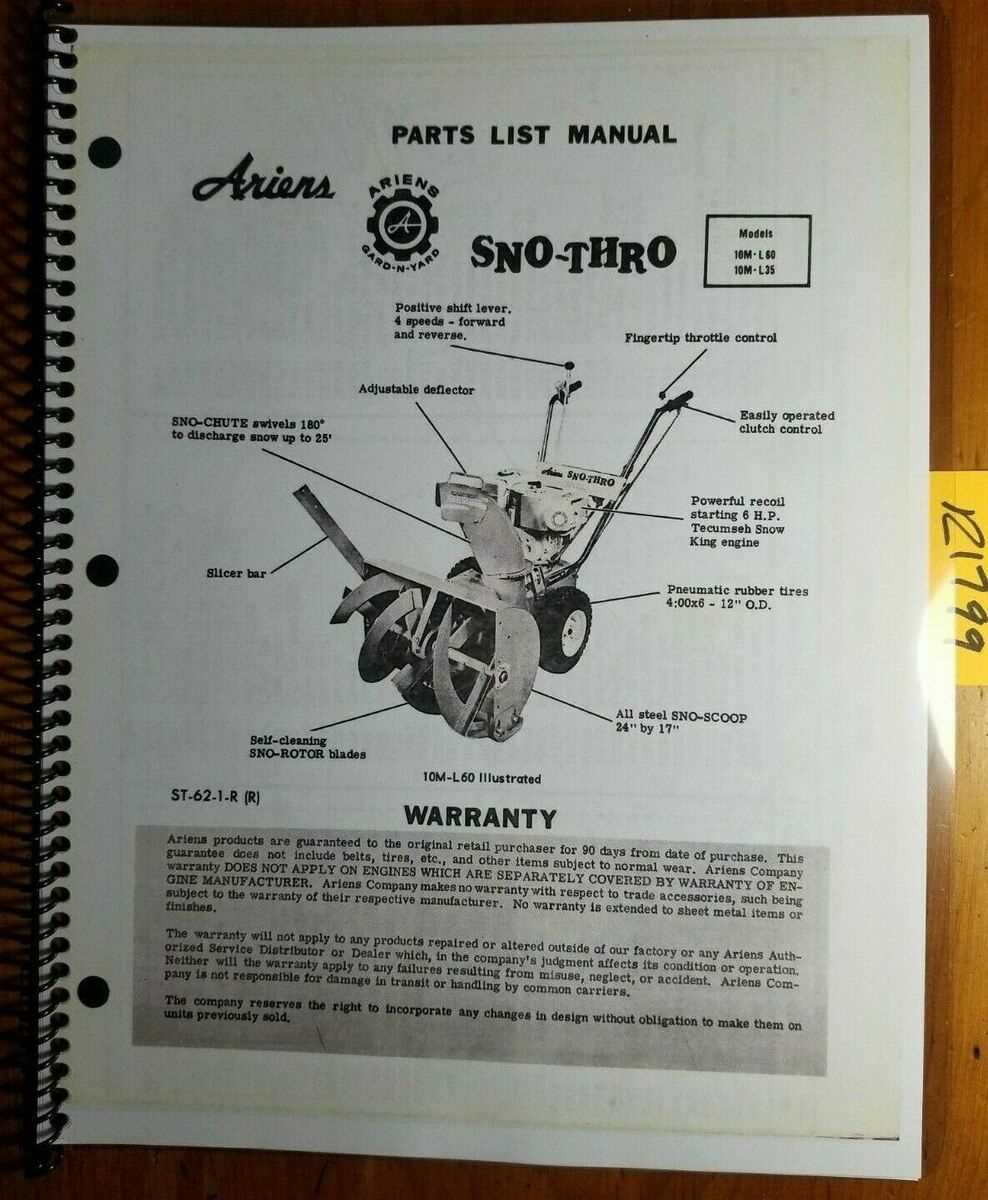

Ariens Deluxe 28: Key Components Overview

This section provides an in-depth look at the crucial mechanical elements of this robust snow removal machine. By understanding the structure and functionality of these essential components, users can ensure smooth operation and perform routine maintenance effectively.

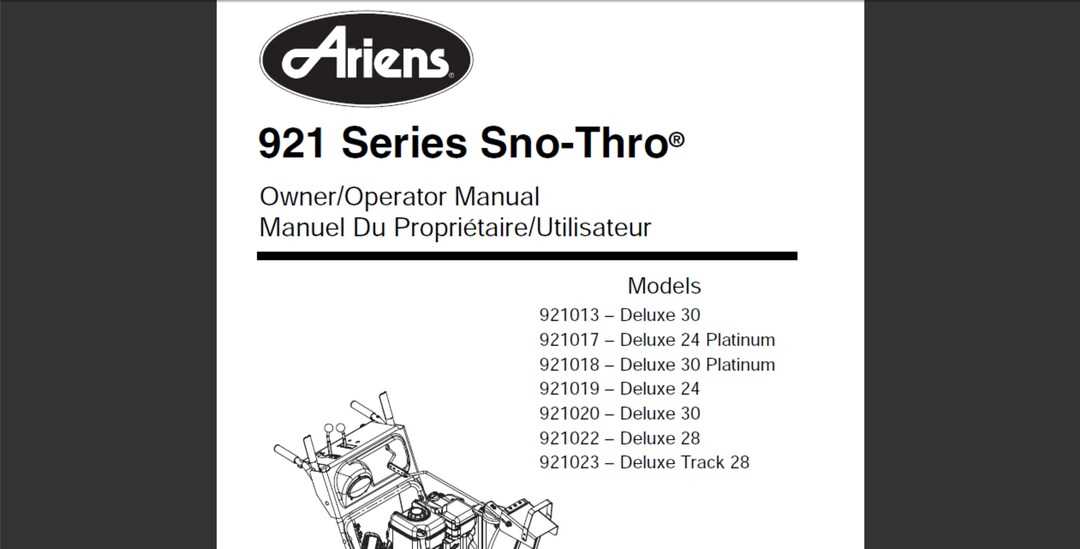

Engine and Power System

The machine is powered by a high-performance engine designed for cold weather conditions. This engine drives the entire operation, ensuring that the unit performs reliably, even in harsh environments.

- Fuel-efficient motor for extended runtime

- Electric start feature for easy activation in freezing temperatures

- Throttle control to adjust speed and power

Snow Clearing Mechanism

The clearing system is built for heavy-duty tasks, allowing the machine to handle deep and compacted snow. The rotating elements work together to gather and discharge snow efficiently.

- Auger blades that cut through ice and snow

- Impeller that throws the cleared snow through the chute

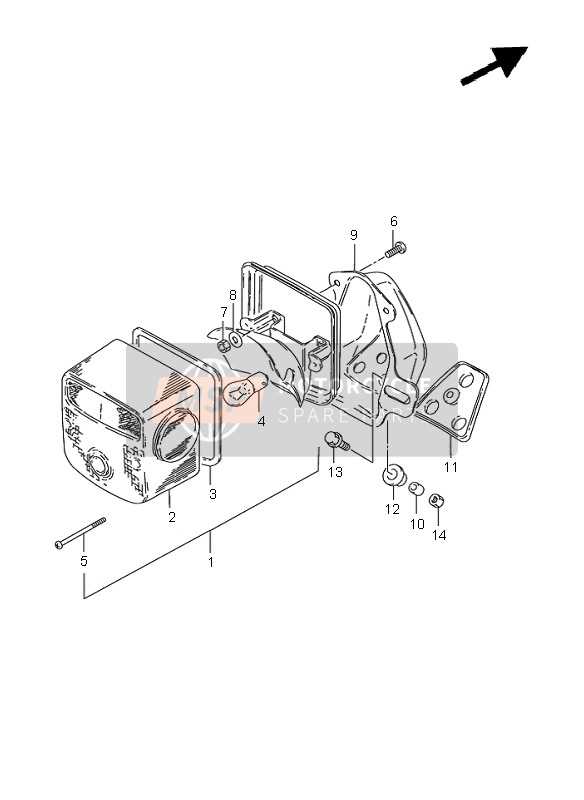

- Understanding the Engine Assembly

The engine assembly plays a pivotal role in ensuring the efficiency and functionality of any outdoor equipment. It consists of multiple components working in unison to generate the power required for smooth operation. This section explores the various elements that make up this critical system, highlighting their significance and the way they interact to deliver optimal performance.

Key Components of the Engine

The engine assembly consists of several essential elements, each contributing to the machine’s overall efficiency. From the combustion chamber, where fuel is converted into energy, to the exhaust system, which manages emissions, understanding these parts is key to maintaining long-lasting functionality. Below is a breakdown of the primary components:

Component Function Cylinder Houses the piston and facilitates combustion. Piston Converts combustion energy into mechanical movement. Cr Exploring the Drive System Layout

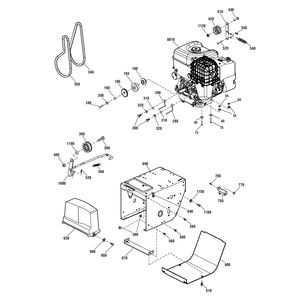

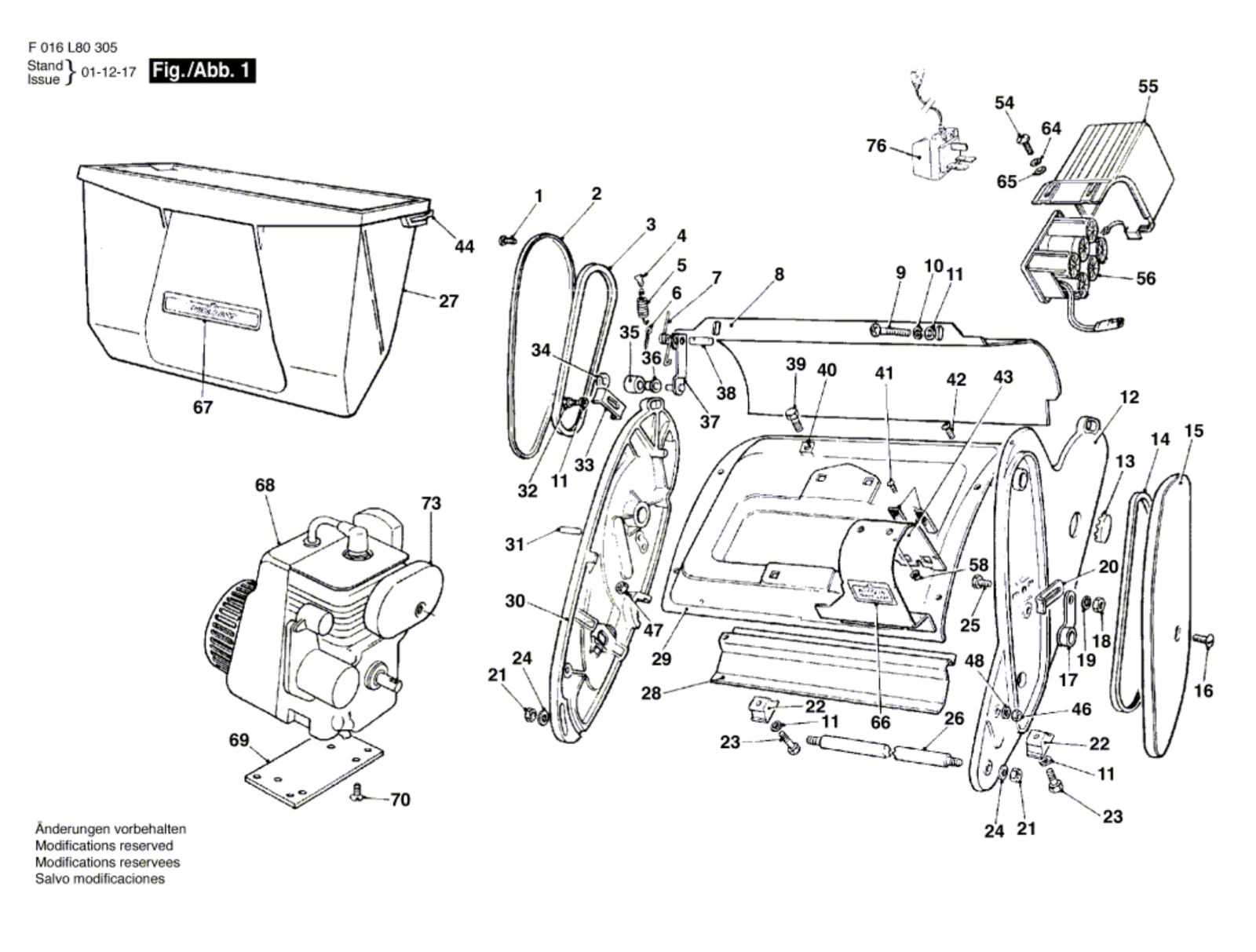

The drive mechanism plays a crucial role in the overall performance of the machine. Understanding how the components work together can help improve maintenance practices and ensure smooth operation. The layout of the system involves various interconnected parts that work in harmony to propel the device forward and maintain stability across different terrains.

Key Components of the Drive System

Several essential elements contribute to the functionality of the drive mechanism. These include the transmission, wheels, and traction controls. Each part must be in good condition to ensure the machine moves efficiently and responds effectively to user input. Regular inspections of these elements are vital for prolonging the lifespan of the equipment.

Transmission and Power Distribution

The transmission system is responsible for distributing power from the engine to the wheels. It ensures that the appropriate amount of torque is applied, depending on the conditions. Adjustments to this component may be necessary when the device encounters rough or uneven terrain. By managing power distribution, the system allows for precise control during operation.

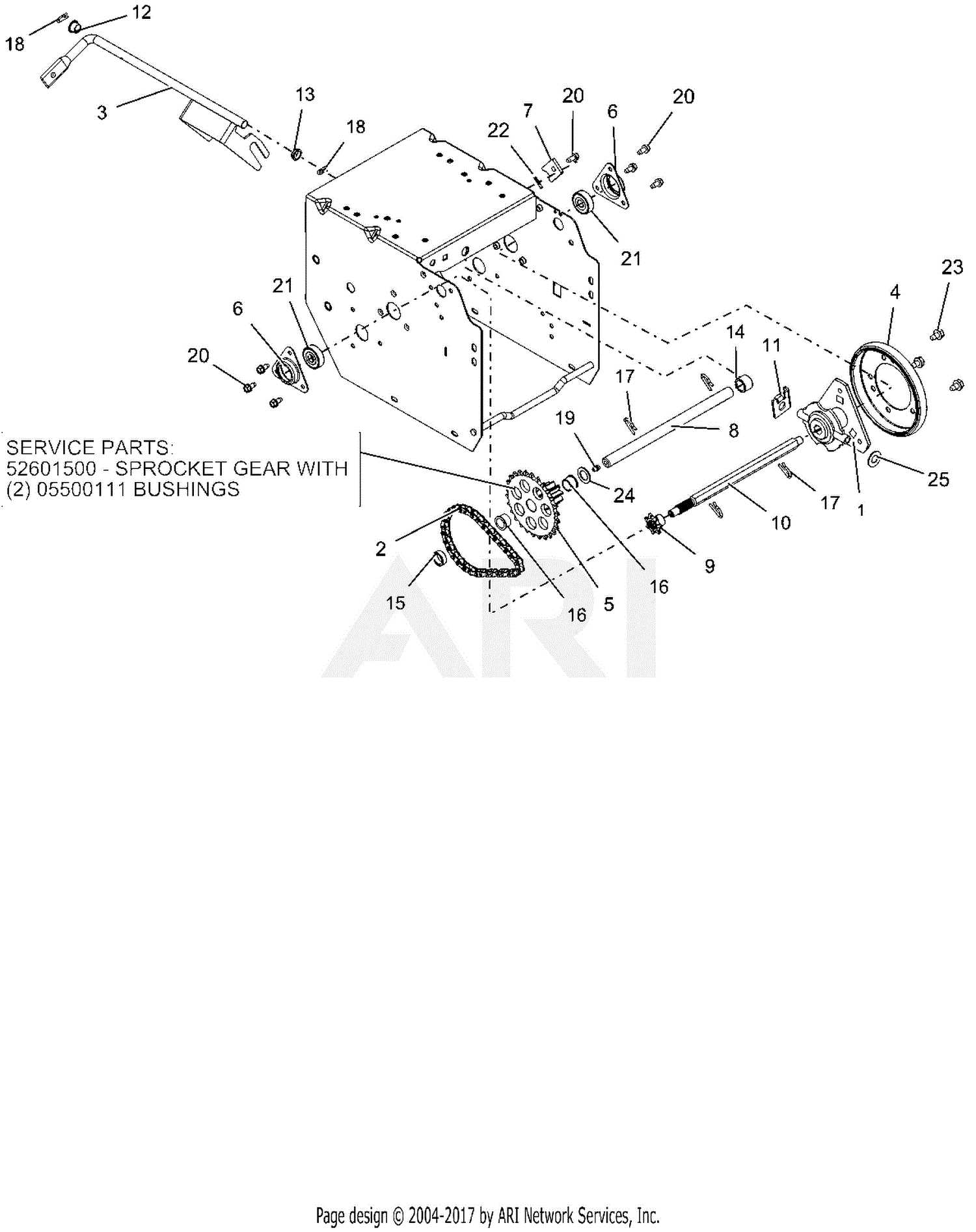

Auger and Impeller Mechanism Breakdown

The auger and impeller assembly is essential for efficiently handling and moving heavy loads of snow. By working together, these components ensure that snow is both collected and expelled with optimal force, making the overall system more effective. In this section, we’ll explore how these two mechanisms interact and the key elements involved in their operation.

Function of the Auger

The auger’s role is to cut into the snow and pull it toward the center of the machine. Its rotating blades are designed to handle various snow conditions, whether light or heavy, ensuring consistent performance. This cutting action allows the system to intake snow efficiently, preparing it for the next stage of processing.

Role of the Impeller

Once the snow is collected, the impeller takes over by accelerating the snow through the discharge chute. This fast-spinning component ensures that snow is thrown far from the machine, preventing blockages and maintaining a clear path. The impeller’s powerful thrust completes the process, allowing for continuous clearing in challenging conditions.

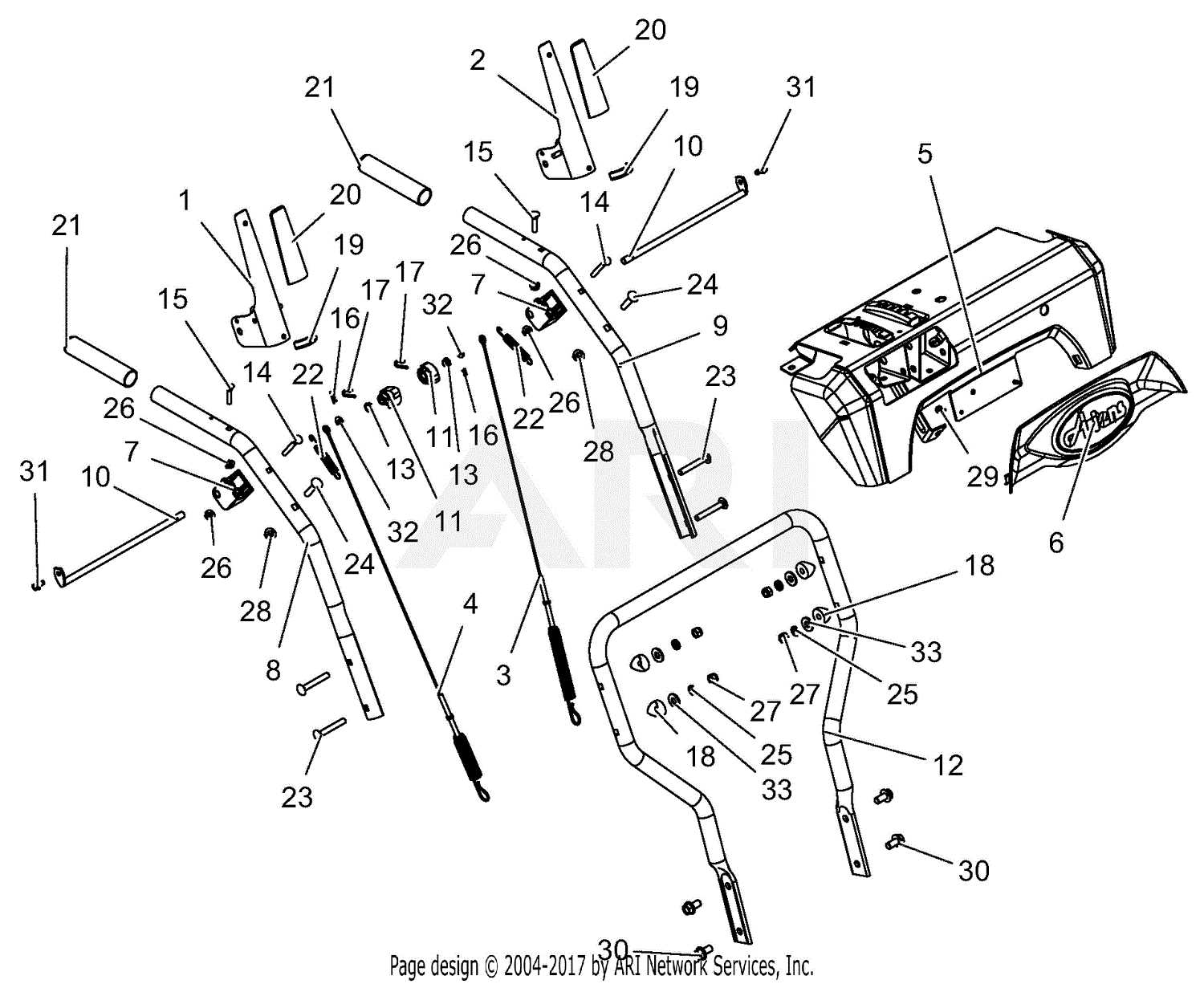

Control Panel and Handlebar Functions

The control interface and handlebar mechanisms offer users the ability to manage and adjust key features with ease. Understanding the placement and purpose of these elements is essential for smooth operation, ensuring that all adjustments can be made comfortably and safely during use.

Main Controls

The primary levers and switches located on the handlebar provide control over essential functions such as forward and reverse movement. These are ergonomically designed to offer quick access, allowing users to engage or disengage the system as needed.

Additional Features

Other functions include settings for speed adjustments and directional guidance. These controls, typically positioned within reach, ensure efficient maneuvering and offer additional options for customizing the experience. The layout of the controls is optimized to enhance operational efficiency.

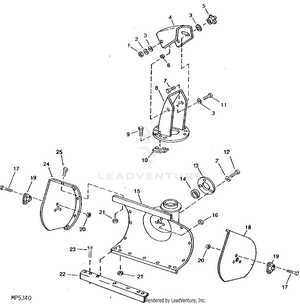

Chute Direction and Adjustment System

The system responsible for directing and adjusting the discharge chute plays a crucial role in optimizing the performance of snow clearing equipment. This mechanism allows operators to control the trajectory of snow being expelled, ensuring effective clearing of driveways and walkways.

At its core, the chute direction system typically consists of a lever or handle that enables users to modify the angle of the chute. By adjusting this angle, one can dictate where the snow is thrown, making it easier to manage snow accumulation in specific areas. This feature is particularly beneficial in tight spaces where precision is necessary.

Moreover, many models incorporate a user-friendly adjustment mechanism, often utilizing a cable or crank system for seamless operation. This ensures that even in harsh weather conditions, the chute can be easily positioned without excessive effort. Regular maintenance of this system is essential to maintain its functionality and prolong its lifespan, as debris and ice can hinder smooth movement.

Understanding the importance of the chute direction and adjustment system empowers operators to enhance their snow removal efficiency, making winter tasks less daunting.

Wheels and Track Drive Configuration

The arrangement of wheels and the mechanism for track propulsion play a crucial role in the overall functionality of outdoor equipment. This configuration directly influences maneuverability, traction, and performance in various conditions. Understanding how these components interact helps users optimize the efficiency of their machines.

Wheels are essential for providing stability and ease of movement across flat terrains. Typically designed with tread patterns that enhance grip, these components ensure a smooth ride and effective navigation. The choice of wheel size can impact the ground clearance and ability to traverse obstacles, making it important to select wheels that best suit the operational environment.

In contrast, the track drive system is particularly beneficial for tackling uneven or soft ground. This configuration distributes weight more evenly, reducing the risk of sinking into mud or snow. Tracks provide superior traction and stability, allowing the equipment to operate efficiently on challenging surfaces. Their design often includes a series of linked segments that flex, adapting to the contours of the terrain while maintaining a robust connection to the drive system.

Ultimately, the selection between wheels and a track drive system hinges on the specific tasks at hand. Users should consider factors such as terrain type, load capacity, and desired maneuverability to make informed decisions that enhance performance and productivity.

Electrical System and Wiring Pathways

The electrical architecture of outdoor power equipment plays a crucial role in its overall functionality and reliability. Understanding the various components and their interconnections is essential for effective troubleshooting and maintenance. This section explores the key elements of the electrical framework and the pathways through which the current flows, ensuring optimal performance during operation.

Key Components

- Battery: Supplies electrical energy to start the engine and power electrical accessories.

- Ignition System: Initiates the combustion process by creating a spark at the right time.

- Alternator: Generates electricity to recharge the battery and power electrical systems while the engine runs.

- Fuses: Protect the electrical circuits by preventing overloads and short circuits.

- Wiring Harness: A collection of wires that connect different components, allowing for the flow of electricity.

Wiring Pathways

The wiring pathways facilitate the distribution of electrical power throughout the machine. Understanding these routes is vital for diagnosing issues or performing repairs. Below are the primary pathways:

- Power Supply Route: Begins at the battery, supplying energy to the ignition system and other electrical components.

- Signal Path: Carries signals between the ignition system and the engine control unit, ensuring synchronized operation.

- Accessory Circuit: Powers additional features such as lights and heating elements, enhancing user experience.

- Grounding Circuit: Provides a return path for electrical current, preventing buildup and ensuring safety.

Maintaining the integrity of the electrical system and its pathways is essential for reliable operation. Regular inspection and timely repairs can prevent more significant issues and prolong the lifespan of the equipment.

Maintenance Tips for Long-lasting Performance

Ensuring the longevity and optimal performance of your equipment requires regular attention and care. Implementing effective maintenance practices not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few key guidelines, you can keep your machinery running smoothly for years to come.

Routine Cleaning

One of the simplest yet most effective ways to prolong the life of your device is through regular cleaning. Removing dirt, debris, and any accumulated residues helps prevent wear and tear. Always inspect the unit after use and clean any areas that may be prone to buildup. This practice not only maintains appearance but also enhances functionality.

Regular Inspections

Frequent checks of critical components are essential for early detection of potential issues. Pay close attention to moving parts, belts, and connections. By identifying signs of wear early on, you can address problems before they escalate, ensuring reliable operation. Keeping a maintenance log can also help track the condition and performance of your equipment over time.