In the world of welding equipment, having a comprehensive overview of the individual elements is crucial for efficient operation and maintenance. A well-structured representation of these components not only aids in troubleshooting but also enhances the user’s ability to understand how different parts interact with one another.

Exploring the intricacies of a welding unit can significantly improve the overall experience for both novice and experienced operators. Each component plays a vital role in ensuring the functionality and performance of the machine, and being familiar with these elements can lead to more informed decisions regarding repairs and upgrades.

Furthermore, a detailed examination of the internal structure fosters a deeper appreciation for the engineering behind such devices. As users gain insights into how each piece contributes to the overall efficiency, they can optimize their techniques and achieve better results in their welding projects.

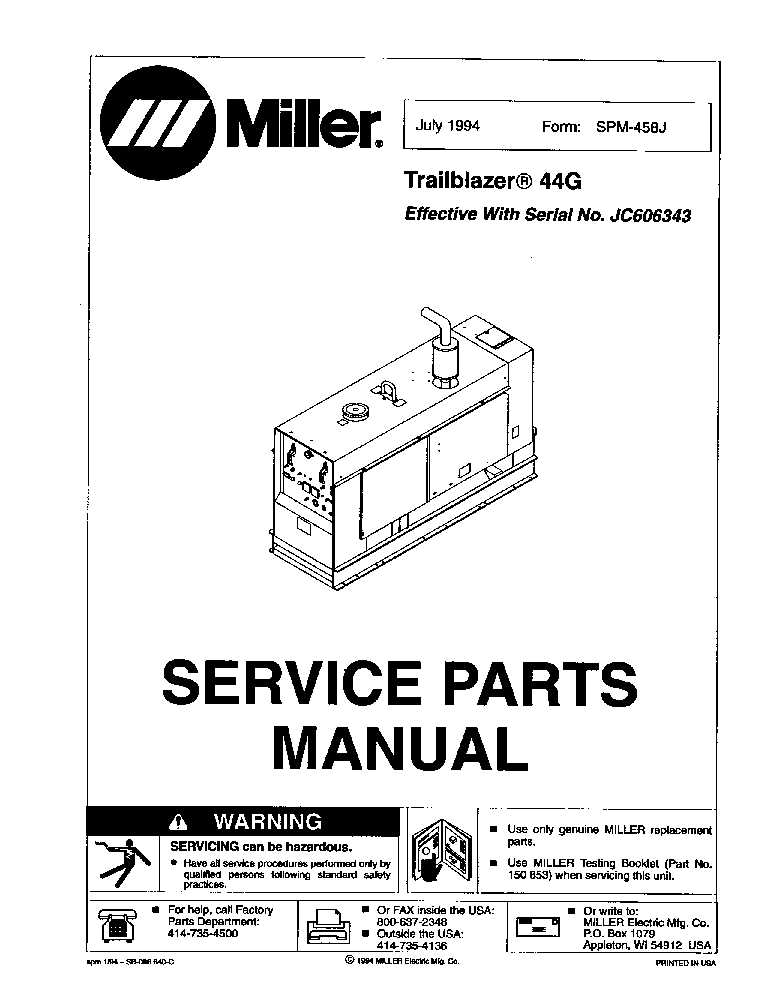

This section provides a comprehensive overview of the equipment in question, detailing its primary functions and significance within various industries. Understanding the essential components is crucial for effective maintenance and operation.

- Introduction to the Equipment

- Explanation of its purpose and applications.

- Importance in professional and industrial settings.

- Key Features

- Highlighting innovative technologies utilized.

- Overview of performance metrics and capabilities.

- Maintenance Considerations

- Importance of regular upkeep for optimal performance.

- Common issues and troubleshooting tips.

- Summary

- Recap of the equipment’s significance and utility.

- Encouragement for proper usage and maintenance practices.

Key Features of the Model

This model stands out due to its innovative design and advanced functionality, making it a popular choice for various applications. With a focus on durability and performance, it caters to the needs of professionals in demanding environments.

Robust Construction

The unit is built to endure harsh conditions, featuring a sturdy exterior that ensures longevity. Its resilience is complemented by high-quality materials that resist wear and tear, making it suitable for prolonged use.

Versatile Operation

This equipment is designed for multifunctional capabilities, allowing users to handle a range of tasks efficiently. The adaptable nature enhances productivity, making it ideal for both industrial and outdoor settings. Ease of use is a hallmark of this model, with intuitive controls that facilitate quick adjustments.

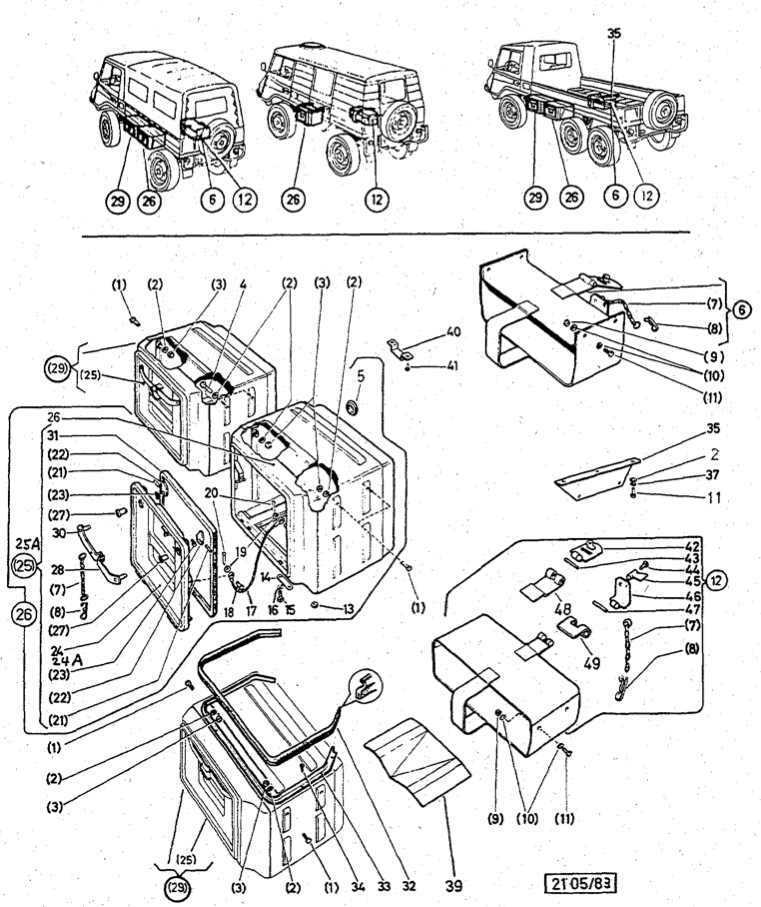

Understanding the Parts Layout

The arrangement of components within a machine is crucial for its overall functionality and maintenance. By familiarizing oneself with the configuration, users can enhance their operational efficiency and ensure proper care. Each segment plays a vital role, contributing to the seamless operation of the equipment.

Identifying the various sections and their interrelations is essential for troubleshooting and upgrades. Components can be categorized based on their specific functions, such as those involved in power generation, control, and output. Recognizing how these elements interact allows users to make informed decisions regarding repairs or modifications.

In addition, understanding the physical positioning of these elements can assist in achieving optimal performance. Knowledge of the layout not only aids in effective repairs but also promotes safe usage, reducing the likelihood of operational hazards. Comprehending this arrangement empowers users to utilize their equipment to its fullest potential.

Essential Components Explained

This section delves into the fundamental elements that contribute to the overall functionality and performance of the unit. Understanding these components is crucial for effective operation and maintenance, ensuring that the equipment operates at its best. Each element plays a vital role, and their interactions are key to achieving optimal results.

Among the primary elements, the engine stands out as the powerhouse, providing the necessary energy for operation. Additionally, the alternator is essential for converting mechanical energy into electrical energy, supplying power to various systems. The control panel serves as the user interface, allowing operators to monitor performance and make necessary adjustments efficiently.

Fuel systems are another critical aspect, ensuring that the engine receives the proper amount of fuel for combustion. Furthermore, the cooling system maintains optimal operating temperatures, preventing overheating and ensuring longevity. Regular inspections and understanding of these components can significantly enhance the reliability and efficiency of the equipment.

Maintenance Guidelines for Longevity

Ensuring the prolonged functionality of machinery requires regular upkeep and attention to specific components. Adhering to systematic maintenance procedures not only enhances performance but also extends the operational lifespan of equipment.

Regular Inspection and Cleaning

- Conduct periodic visual inspections to identify wear or damage.

- Clean external surfaces to prevent dirt accumulation that can hinder operation.

- Check all connections and fittings to ensure they are secure and free from corrosion.

Routine Lubrication

- Apply appropriate lubricants to moving parts according to manufacturer recommendations.

- Replace old lubricants regularly to maintain optimal performance.

- Ensure that lubrication points are easily accessible for timely servicing.

Implementing these guidelines will contribute significantly to maintaining the efficiency and reliability of your equipment, ultimately saving time and costs associated with repairs and replacements.

Common Issues and Troubleshooting

When working with welding equipment, users may encounter various challenges that can affect performance and efficiency. Identifying these problems early and understanding how to address them is crucial for maintaining optimal functionality.

Here are some frequent issues that operators might face:

- Power Supply Problems: Insufficient voltage or power interruptions can hinder operation.

- Welding Inconsistencies: Inconsistent arc stability can result from incorrect settings or equipment wear.

- Overheating: Extended use can lead to overheating, requiring cooldown periods.

- Fuel Supply Issues: Blockages or leaks in the fuel system can cause operational interruptions.

- Electrical Short Circuits: Damage to wires or connectors may lead to shorts, impacting performance.

To troubleshoot these issues effectively, consider the following steps:

- Check the power source and ensure proper voltage levels.

- Inspect cables and connections for any signs of wear or damage.

- Verify the settings against the manufacturer’s recommendations for the specific task.

- Regularly clean and maintain all components to prevent buildup.

- Consult the user manual for specific error codes or troubleshooting guidelines.

By following these guidelines, users can enhance the reliability and longevity of their welding equipment, ensuring efficient operation and minimizing downtime.

Replacement Parts Availability

Ensuring a continuous operation of your equipment often hinges on the accessibility of replacement components. Availability of these essential elements is crucial for maintaining performance and extending the lifespan of machinery. Whether you are dealing with routine maintenance or unexpected repairs, having quick access to suitable replacements can significantly reduce downtime and enhance productivity.

Sources for Components

Numerous suppliers offer a variety of options for sourcing the required elements. Authorized dealers typically provide original equipment, ensuring compatibility and reliability. Additionally, aftermarket providers can present cost-effective alternatives, often with comparable quality. Online marketplaces also serve as valuable resources, connecting users with various vendors, which allows for easy comparison of prices and availability.

Considerations for Selection

When seeking components, it is essential to consider factors such as warranty, quality assurance, and compatibility. Genuine items may come at a premium but offer the best assurance of fit and function. Conversely, aftermarket solutions can provide budget-friendly choices, yet caution is warranted regarding their reliability. Thorough research and consultation with experts can help determine the most suitable options for your specific needs.

Where to Find Diagrams Online

Locating schematics and illustrations for various machinery can significantly enhance understanding and maintenance capabilities. Many resources are available online that provide detailed visuals, enabling users to navigate complex components and systems efficiently.

Manufacturer Websites

Official websites of equipment manufacturers often host a wealth of information, including comprehensive visuals. These platforms typically offer user manuals, technical documentation, and other resources that detail component layouts and functionalities.

Online Forums and Communities

Joining specialized forums or online communities can be invaluable for finding specific illustrations. Members frequently share resources, including schematics, and offer insights based on their experiences, making these platforms a rich source of knowledge.

Upgrading Your Equipment

Enhancing your machinery can significantly improve performance, efficiency, and longevity. Investing in superior components not only ensures better results but also optimizes operational capabilities. When considering upgrades, it’s essential to assess both current requirements and future needs.

Before proceeding with enhancements, consider the following key factors:

- Compatibility: Ensure that new components align with existing systems to avoid functionality issues.

- Performance Benefits: Identify upgrades that will provide tangible improvements in productivity or efficiency.

- Budget Considerations: Analyze costs versus benefits to determine the most economically viable options.

Common upgrades may include:

- Engine Enhancements: Upgrading the engine or its components can lead to increased power output and improved fuel efficiency.

- Control Systems: Modernizing control systems can enhance user interface and automation, leading to better operational management.

- Safety Features: Incorporating advanced safety mechanisms can protect both the operator and the equipment, reducing the risk of accidents.

In conclusion, upgrading your equipment not only enhances performance but also ensures that your operations remain competitive in a rapidly evolving industry. Careful planning and informed decisions will lead to successful enhancements that meet your needs.

Comparative Analysis with Similar Models

This section aims to explore and compare the features and specifications of similar models within the same category, focusing on performance, functionality, and user experience. By examining the similarities and differences, we can provide valuable insights for potential buyers and users looking for alternatives that suit their specific needs.

Performance Metrics

When evaluating competing units, one must consider essential performance metrics, such as output capacity, efficiency, and versatility. Several models boast comparable output ratings, yet variations in fuel consumption and operational efficiency can significantly impact overall user satisfaction. Understanding these differences is crucial for selecting the right device that aligns with intended applications.

Functional Features

Another critical aspect to assess is the functional attributes that enhance usability. Certain units may offer advanced technology features, including digital displays or integrated safety systems, while others focus on robustness and ease of maintenance. By weighing these functional capabilities, potential users can identify which model best fulfills their operational requirements and preferences.