The intricate world of farming machinery relies on numerous individual elements working in harmony. Each component plays a vital role in ensuring the efficient operation of equipment designed for land cultivation and maintenance. A comprehensive understanding of these elements can significantly enhance both the performance and longevity of agricultural tools.

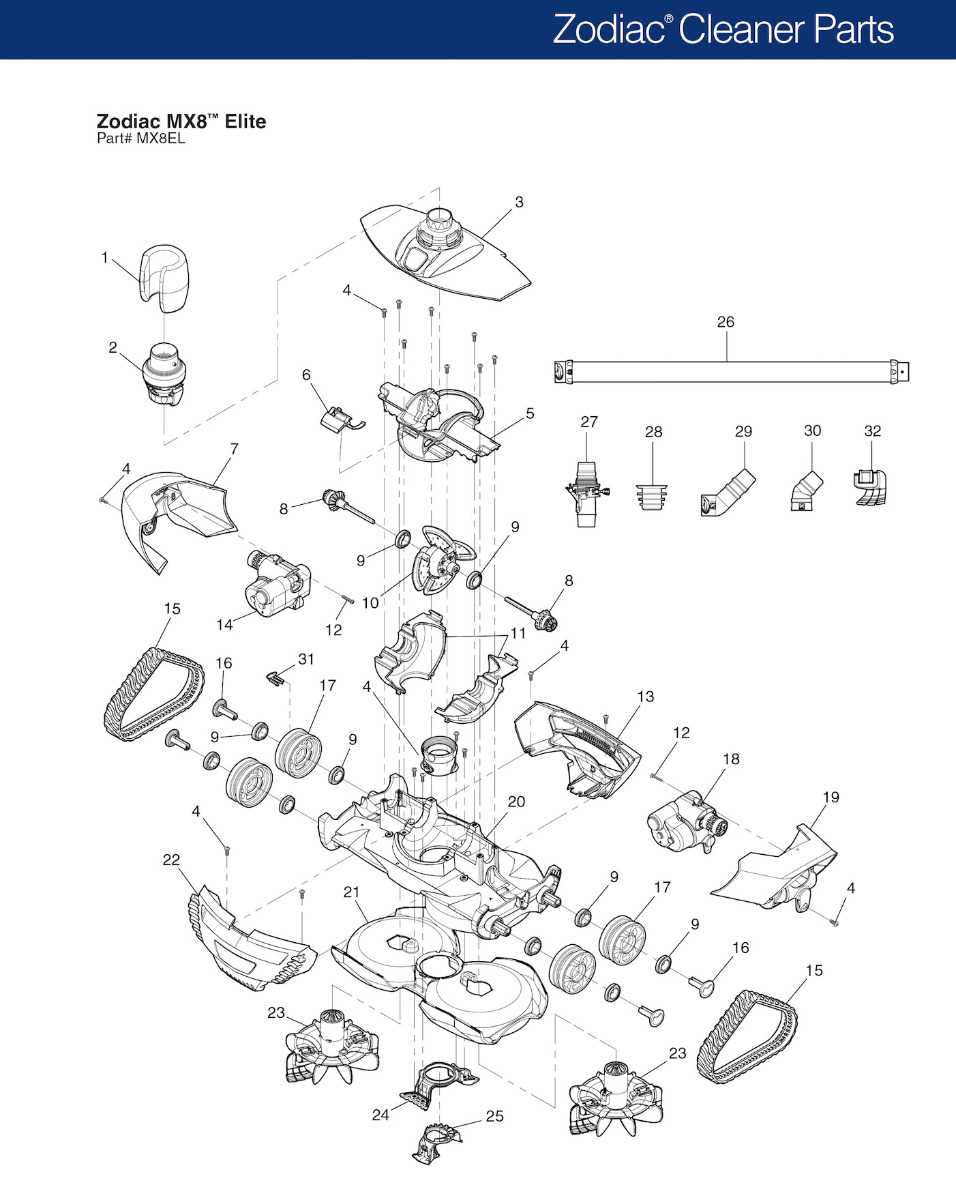

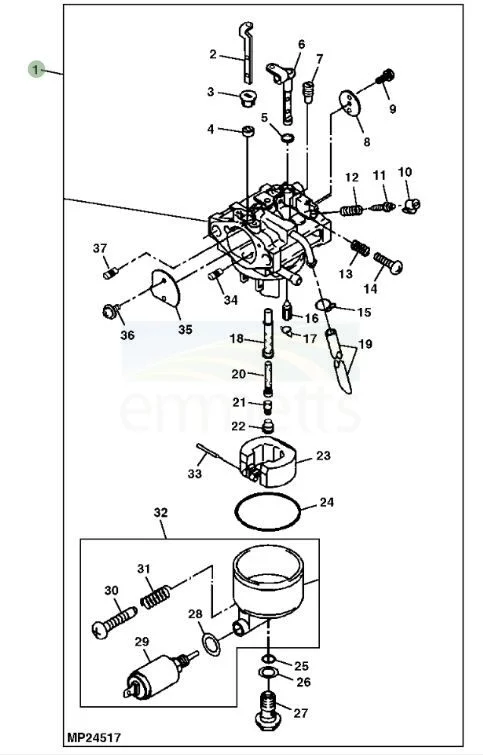

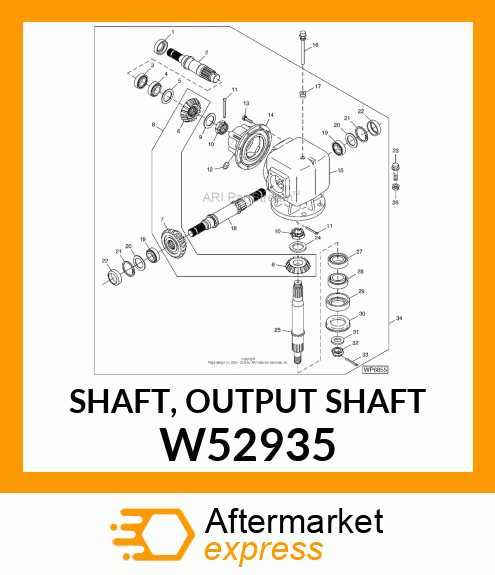

For operators and maintenance personnel, visual representations of machinery assemblies offer invaluable insights. By examining detailed layouts, one can quickly identify the placement and relationship of various components, facilitating easier troubleshooting and repairs. This approach not only streamlines maintenance tasks but also empowers users to make informed decisions regarding their equipment.

Furthermore, familiarizing oneself with the specific characteristics of each segment can lead to improved performance and productivity. Recognizing how each part functions within the overall system allows for better handling and usage, ultimately contributing to more efficient farming practices. Embracing this knowledge is essential for anyone involved in the agricultural sector.

Understanding John Deere MX6 Components

This section explores the various elements that make up the equipment, focusing on their functions and interactions. A comprehensive grasp of these components is essential for optimal performance and maintenance.

Main Components

- Cutting System

- Drive Mechanism

- Frame Structure

- Safety Features

Functionality Insights

- The cutting system is designed for efficiency and precision.

- The drive mechanism ensures smooth operation and reliability.

- The frame structure provides stability and support.

- Safety features protect the operator and enhance usability.

Overview of MX6 Assembly Parts

This section provides an insight into the various components that come together to form the assembly of the equipment in question. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Main Components

- Frame Structure

- Cutting Mechanism

- Drive System

- Hitch Assembly

- Safety Features

Maintenance Tips

- Regularly inspect the cutting mechanism for wear.

- Check connections in the drive system for looseness.

- Ensure safety features are functional before use.

Key Features of the MX6 Model

This model stands out for its robust construction and advanced functionality, making it an ideal choice for various agricultural tasks. Its design integrates efficiency and durability, allowing users to achieve optimal performance in demanding environments.

Durability and Construction

Engineered for Longevity: The framework of this machine is built with high-quality materials that withstand rigorous use, ensuring a longer lifespan. Enhanced resilience makes it suitable for challenging terrains.

Efficiency and Performance

Optimal Cutting Capability: The unit features a cutting system that provides precise results, minimizing downtime and maximizing productivity. Advanced technology allows for smoother operation, ensuring tasks are completed swiftly and effectively.

Importance of Maintenance for MX6

Regular upkeep is crucial for ensuring the longevity and efficiency of agricultural equipment. Proper care not only enhances performance but also reduces the risk of unexpected breakdowns, ultimately saving time and resources.

Benefits of Routine Care

Engaging in consistent maintenance helps to identify potential issues before they escalate. This proactive approach ensures optimal functionality, leading to improved productivity and lower operational costs.

Best Practices for Upkeep

Implementing a structured maintenance schedule is essential. Key tasks include inspecting components, lubricating moving parts, and replacing worn elements. Adopting these measures significantly contributes to the reliability and efficiency of the equipment.

Common Issues with MX6 Parts

When dealing with machinery components, several challenges may arise that can affect performance and longevity. Understanding these issues is crucial for maintaining operational efficiency and minimizing downtime. Common concerns often relate to wear and tear, improper alignment, and environmental factors that impact the integrity of various elements.

Wear and Tear

One of the most prevalent problems involves the gradual deterioration of components due to constant use. Over time, parts may become worn down, leading to reduced effectiveness. Regular inspection and timely replacement are essential to prevent failures that can halt operations and incur significant repair costs.

Misalignment and Installation Errors

Another issue frequently encountered is misalignment during assembly. When components are not properly aligned, they can cause increased strain, resulting in premature failure. Ensuring accurate installation and periodic alignment checks can help mitigate these risks and enhance the overall performance of the equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance. Fortunately, there are several avenues to explore when seeking out the necessary replacements. Understanding where to search can streamline the process and ensure you find quality items that fit your needs.

Online Retailers

Numerous online platforms specialize in agricultural machinery and accessories. These sites typically offer a wide range of options, making it easier to find what you require.

- Official brand websites

- Third-party retailers

- Auction sites for used items

- Dedicated machinery parts marketplaces

Local Suppliers

Exploring nearby suppliers can also yield great results. Building relationships with local businesses may provide access to valuable expertise and immediate assistance.

- Authorized dealers

- Farm supply stores

- Equipment rental companies

- Salvage yards for used components

By utilizing both online and local resources, you can efficiently find the necessary items to keep your machinery in top condition.

Tips for Repairing MX6 Equipment

Proper maintenance and repair of agricultural machinery are crucial for ensuring longevity and optimal performance. Understanding the intricacies of the equipment can greatly aid in efficient troubleshooting and restoration.

Regular Inspections

Conducting routine checks on your machinery can help identify potential issues before they escalate. Look for signs of wear, unusual noises, or fluid leaks, as these can indicate areas needing attention.

Use Quality Replacement Components

When replacing damaged or worn-out elements, opt for high-quality components that meet manufacturer specifications. This choice not only enhances performance but also extends the lifespan of your equipment.

Upgrading Your MX6 Attachments

Enhancing your equipment’s functionality can significantly improve productivity and efficiency in various tasks. Upgrades not only optimize performance but also extend the lifespan of your machinery. By selecting the right components, you can tailor your tools to better meet your specific needs.

Evaluating Compatibility: Before proceeding with upgrades, it’s crucial to assess the compatibility of new components with your existing setup. This ensures seamless integration and minimizes operational issues.

Choosing Quality Components: Investing in high-quality attachments is essential for achieving the ultimate performance. Durable materials and reliable designs contribute to effective operation and reduced maintenance costs.

Consulting Experts: Engaging with professionals or forums can provide valuable insights into the best upgrades available. They can offer recommendations based on real-world experiences, helping you make informed decisions.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages for equipment longevity and performance. These high-quality items are specifically designed to fit and function seamlessly with your machinery, ensuring optimal efficiency and reliability.

Quality Assurance: OEM components are subjected to rigorous testing and quality control processes, guaranteeing that they meet the manufacturer’s strict standards. This results in enhanced durability and a lower likelihood of premature failure.

Perfect Fit: One of the key benefits is that these components are tailored to the exact specifications of your machinery. This precision ensures that installation is straightforward and that the equipment operates as intended, minimizing downtime and maintenance costs.

Warranty Protection: Using original components often helps preserve the warranty on your machinery. Many manufacturers stipulate that only OEM parts should be used to maintain warranty coverage, protecting your investment in the long term.

Resale Value: Equipment that has been maintained with original components typically retains a higher resale value. Prospective buyers are often more willing to invest in machinery with documented use of genuine parts, as it indicates proper maintenance and care.

In summary, opting for original components significantly contributes to the overall efficiency, reliability, and longevity of your equipment, making it a wise choice for any operator.