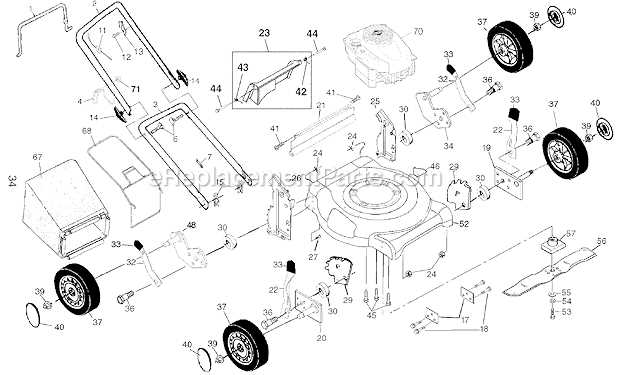

Every machine relies on a complex interplay of various elements that contribute to its overall functionality. Understanding these individual components is essential for maintenance and repair, ensuring longevity and optimal performance. A clear representation of these parts can greatly assist users in troubleshooting and identifying any issues that may arise during operation.

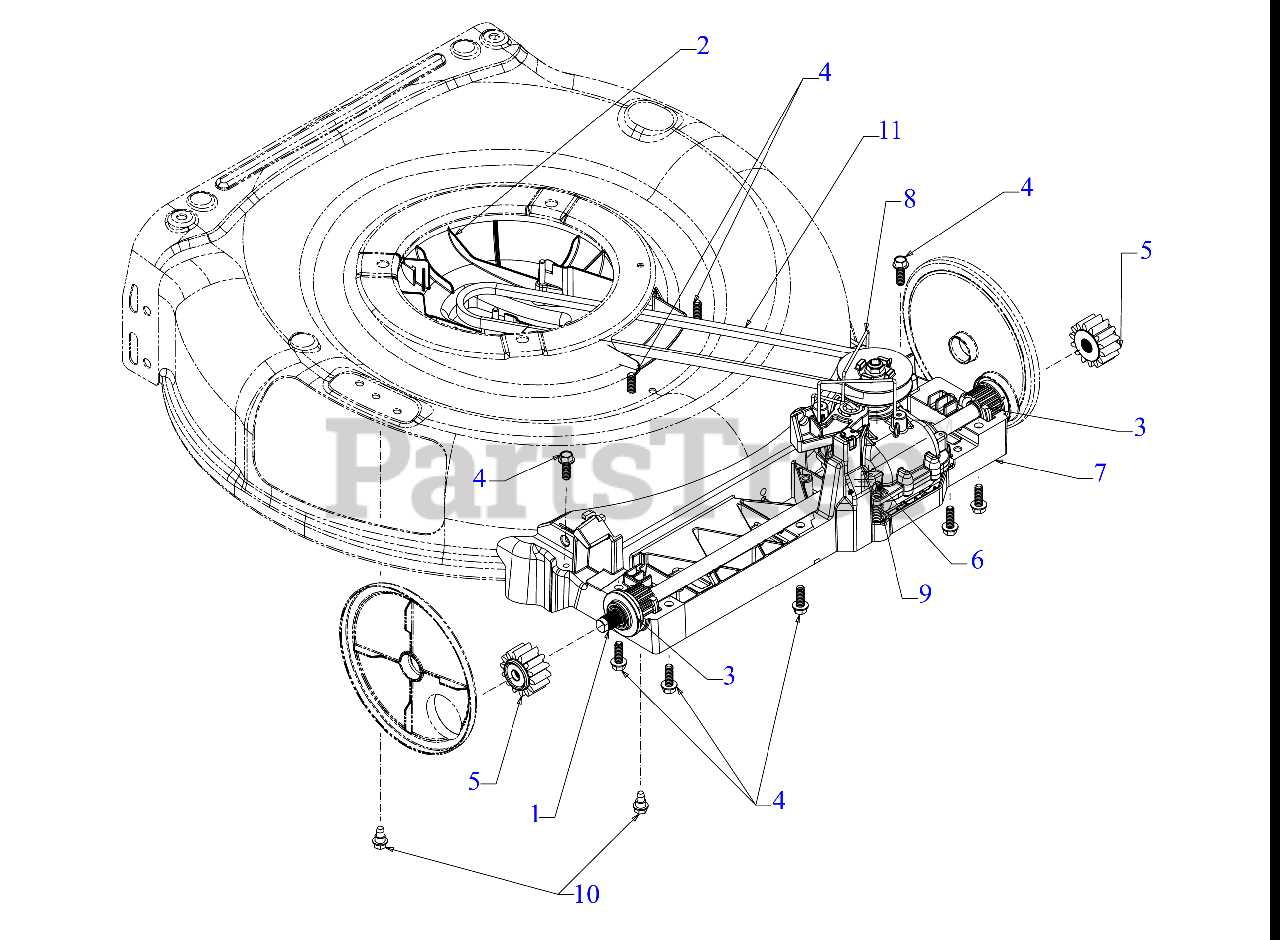

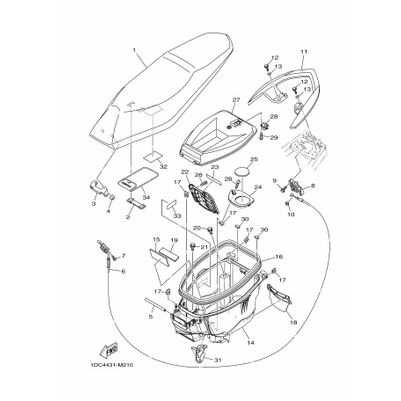

Visual aids play a crucial role in this learning process. They provide a detailed overview of how each part fits into the larger assembly, offering insights into the design and engineering behind the equipment. This clarity not only simplifies repairs but also enhances the user’s ability to perform regular upkeep efficiently.

By familiarizing yourself with the specific components and their arrangement, you can take proactive steps to prevent malfunctions. This knowledge empowers users, making them more confident in handling their tools. As we delve into the specifics of these elements, you’ll discover valuable information that will aid in both understanding and practical application.

Understanding Craftsman M210 Parts

Having a solid grasp of the components that make up your lawn maintenance tool is essential for effective upkeep and repairs. Familiarity with each element can enhance your ability to troubleshoot issues and ensure optimal performance. Knowledge of these individual elements empowers users to perform maintenance tasks with confidence and efficiency.

Every machine comprises various essential elements, each serving a specific function. These components can range from the engine to the cutting mechanism, and understanding how they interact is crucial for smooth operation. When problems arise, being aware of the roles played by each part can lead to quicker diagnostics and repairs.

Additionally, knowing the names and functions of these pieces can facilitate the search for replacements when needed. Whether you’re looking to replace a worn-out item or simply want to keep your tool in peak condition, understanding what each part does will help you make informed decisions.

In summary, acquiring knowledge about the different elements of your lawn care equipment not only aids in maintenance but also extends the lifespan of the tool. By investing time in understanding these components, you can ensure that your equipment continues to perform effectively for years to come.

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations that showcase each element provide clarity, allowing users to identify and source necessary items efficiently. Such illustrations not only enhance comprehension but also streamline the troubleshooting process, making it easier to address issues as they arise.

Enhanced Understanding

Detailed visuals aid users in grasping the relationships between different components. By seeing how parts fit together, individuals can better appreciate the functionality of the entire system. This knowledge is crucial for anyone attempting to disassemble or reassemble equipment, as it minimizes the risk of errors during the process.

Facilitating Repairs

When it comes to fixing machinery, having a clear guide is invaluable. These illustrations serve as a roadmap, directing users to the exact elements that may require attention. This not only saves time but also ensures that replacements are made correctly, ultimately prolonging the lifespan of the equipment.

In summary, visual guides are vital tools that empower users by providing clarity and direction, making maintenance and repair tasks more manageable and efficient.

Key Components of the M210

Understanding the essential elements of this specific model is crucial for effective maintenance and operation. Each part plays a vital role in ensuring optimal performance and longevity. Familiarity with these components helps users troubleshoot issues and perform necessary repairs efficiently.

| Component | Description |

|---|---|

| Engine | Powers the unit, providing the necessary force for operation. |

| Blades | Critical for cutting performance; must be sharp and properly aligned. |

| Handle | Ensures user control and comfort during operation. |

| Deck | Houses the engine and supports the cutting mechanism; important for durability. |

| Wheels | Facilitate movement; size and tread affect maneuverability on various terrains. |

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. Familiarity with symbols, labels, and layout will enable you to identify parts quickly and comprehend their relationships within the system.

Identifying Components

Begin by locating the key that explains the symbols used. Each element should have a corresponding mark or label, making it easier to recognize individual pieces and their functions.

Understanding Relationships

Next, examine how the components connect with one another. Lines or arrows often indicate connections, helping you to visualize the assembly and the order of operations necessary for repairs.

Common Replacement Parts Explained

In the world of maintenance and repairs, understanding the various components that may need substitution is essential for ensuring optimal functionality. Each element plays a crucial role in the overall performance and longevity of the equipment, and recognizing when to replace them can save both time and resources.

One frequently needed component is the engine filter, which ensures that air and fuel flow freely, preventing damage from contaminants. Another vital piece is the spark plug, essential for initiating combustion; worn or faulty plugs can lead to poor performance or starting issues. Additionally, belts and blades are crucial for operation, as they directly affect efficiency and output quality.

Furthermore, seals and gaskets are often overlooked, yet they are critical for preventing leaks and maintaining pressure. Lastly, battery maintenance cannot be understated; a weak or failing battery can render machinery unusable, emphasizing the importance of timely replacement.

Maintenance Tips for Your M210

Regular upkeep of your equipment ensures longevity and optimal performance. By following a few essential practices, you can keep your tools in excellent condition, reducing the risk of breakdowns and enhancing efficiency. Here are some straightforward guidelines to follow.

Routine Inspection

Conducting frequent checks is vital for identifying potential issues before they escalate. Consider the following:

- Inspect for any signs of wear or damage.

- Ensure all components are securely fastened.

- Look for leaks or unusual noises during operation.

Cleaning and Lubrication

Proper cleaning and lubrication contribute significantly to the functionality of your equipment. Follow these steps:

- Wipe down surfaces after each use to remove dirt and debris.

- Apply lubricant to moving parts to prevent friction.

- Check and replace any filters as needed to maintain airflow.

By adhering to these maintenance tips, you can prolong the life of your tools and ensure they perform at their best.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. A variety of sources are available, each offering unique benefits that can cater to your specific needs.

One of the best places to start is with authorized dealers. These retailers provide original components that are guaranteed to fit your machine correctly. Additionally, many of them offer customer support that can assist you in identifying the right items.

Online marketplaces are another excellent option. Websites specializing in equipment accessories often have extensive inventories and competitive pricing. User reviews can help you assess the quality and reliability of the items you are considering.

Don’t overlook local repair shops either. They may carry necessary replacements or be able to order them for you. This option can also provide the advantage of professional advice on installation and maintenance.

Lastly, exploring community forums and groups dedicated to your specific equipment can lead to valuable insights. Members often share their experiences and can point you to trusted sources for obtaining necessary components.

DIY Repairs for M210 Owners

For enthusiasts of power tools, maintaining equipment in peak condition is essential for optimal performance and longevity. This section offers a guide for those who wish to undertake repairs themselves, equipping them with the necessary knowledge and confidence to tackle common issues. By understanding the structure and function of their tools, users can save both time and money while ensuring their devices operate smoothly.

First, identify the most frequent problems that may arise during use. Issues such as motor failure, irregular starting, or power loss can often be resolved with basic troubleshooting. Regular maintenance practices, including cleaning and lubrication, can prevent many complications from occurring in the first place.

When approaching repairs, it’s crucial to gather the right tools and components. Familiarize yourself with the essential items required for disassembly and reassembly. Clear organization of parts during this process will simplify the repair and reduce the risk of losing small pieces.

Documentation is invaluable when making adjustments or replacements. Keeping a manual or referencing online resources can provide insights into proper techniques and specifications. Take notes on any modifications made during repairs, which can aid in future maintenance efforts.

By embracing a do-it-yourself attitude, owners can enhance their skills and foster a deeper appreciation for their equipment. Regular hands-on involvement not only ensures reliability but also empowers users to take control of their tools’ upkeep.

FAQs About Craftsman M210 Parts

This section addresses common inquiries related to components of a specific lawn maintenance tool. Understanding the various elements and their functions can enhance user experience and facilitate better maintenance practices.

| Question | Answer |

|---|---|

| What types of components are essential for operation? | Key elements include the engine, blades, and wheels, each playing a crucial role in performance. |

| Where can I find replacement items? | Replacement components are typically available at local hardware stores or online retailers specializing in lawn care tools. |

| How often should I replace worn elements? | It is advisable to inspect the tool regularly and replace parts as needed, especially before the start of the mowing season. |

| Can I use generic components? | While generic options may fit, it’s best to choose parts specifically designed for optimal compatibility and performance. |

| What is the typical lifespan of these components? | The lifespan varies based on usage and maintenance, but most parts can last several seasons with proper care. |