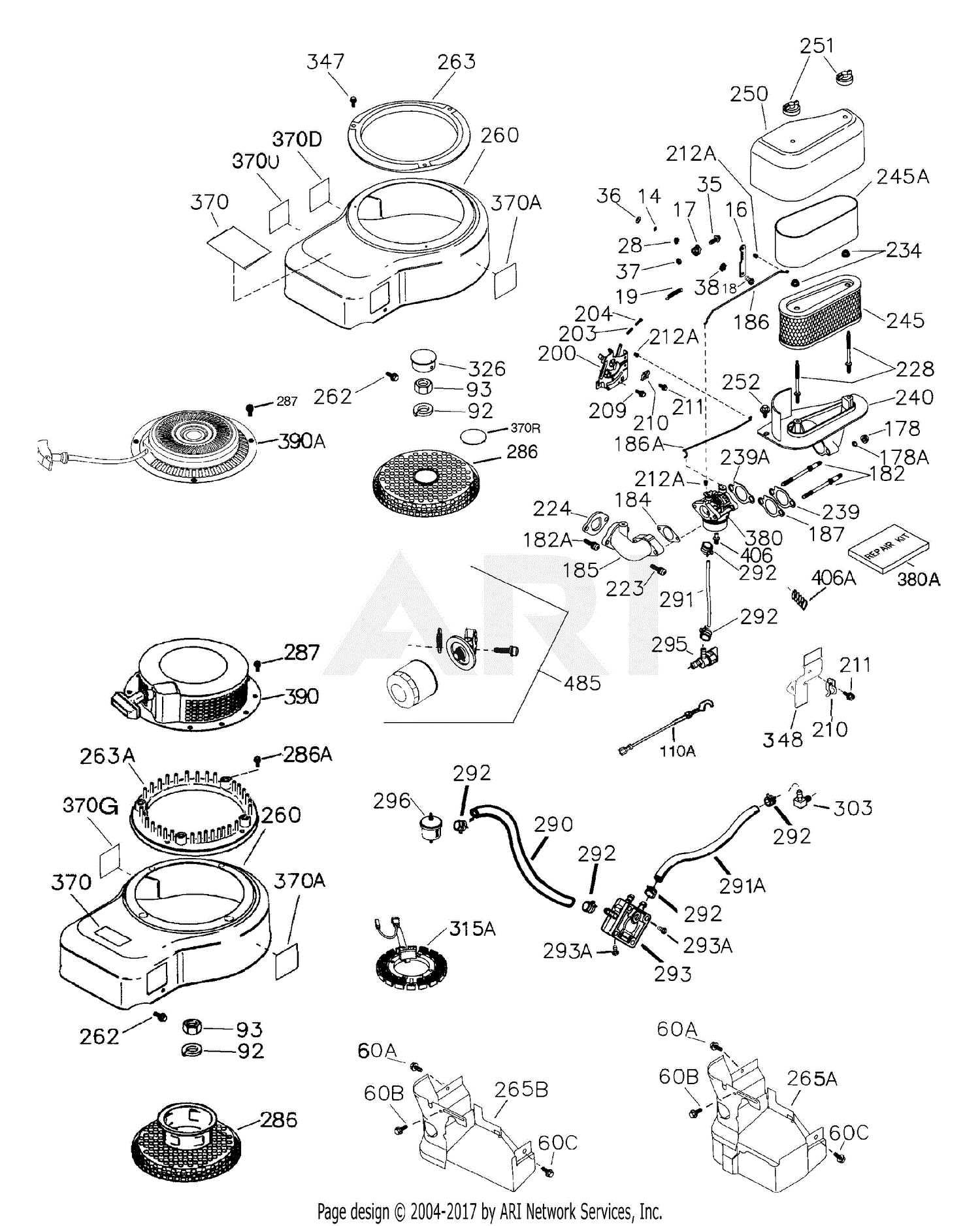

When it comes to maintaining and repairing your machinery, a comprehensive visual representation of its components is essential. This visual guide serves as an invaluable resource, helping you identify each part and its function within the overall assembly. Whether you are a seasoned technician or a DIY enthusiast, having a clear overview can greatly enhance your understanding and efficiency in addressing issues that may arise.

Each element of your equipment plays a crucial role in its performance and longevity. Familiarizing yourself with these components not only aids in troubleshooting but also empowers you to make informed decisions when it comes to repairs and replacements. By exploring this detailed illustration, you can ensure that your device remains in optimal condition, ultimately saving time and resources.

Furthermore, an organized layout of the machinery’s features can simplify the often complex process of maintenance. With the right information at hand, you can easily locate specific parts, facilitating smoother repairs and enhancing the overall experience of working with your equipment. Knowledge of each component’s placement and function can lead to more effective handling and care.

Understanding the Craftsman LT1500

When it comes to maintaining and enhancing the performance of lawn care equipment, having a clear understanding of its components is crucial. This knowledge allows users to efficiently manage repairs and ensure their machinery runs smoothly. Familiarity with various elements can also aid in the identification of potential issues before they escalate.

Key Features of the Equipment

This particular model boasts several features that make it suitable for diverse lawn care tasks. From its robust engine to user-friendly controls, each aspect contributes to its overall effectiveness. Users can benefit from understanding how these elements interact and support each other, leading to optimal performance.

Common Components and Their Functions

Recognizing the roles of individual components is essential for troubleshooting and maintenance. Below is a summary of the main parts typically found in such machinery:

| Component | Function |

|---|---|

| Engine | Provides power to the machine for cutting and maneuvering. |

| Deck | Houses the cutting blade, ensuring efficient grass trimming. |

| Transmission | Facilitates movement and speed adjustments. |

| Wheels | Ensure mobility across different terrains. |

By understanding these essential components and their functions, users can not only enhance their machinery’s lifespan but also improve their overall lawn care experience.

Common Parts and Their Functions

Understanding the various components of a lawn care machine is essential for proper maintenance and operation. Each element plays a specific role in ensuring the equipment functions smoothly and efficiently. Familiarity with these components can help users diagnose issues and carry out effective repairs or replacements when needed.

Key Components

The engine serves as the powerhouse, converting fuel into mechanical energy. Its proper functioning is critical for the entire system. The transmission transmits power from the engine to the wheels, facilitating movement across various terrains. Additionally, the cutting deck is responsible for the actual grass cutting, featuring blades that rotate at high speeds to deliver a clean finish.

Supportive Elements

Wheels and tires are vital for mobility, providing traction and stability. The battery supplies electrical energy necessary for starting the engine and powering lights. Belts and pulleys are essential for transferring power between different components, ensuring smooth operation throughout the machine. Regular inspection and maintenance of these elements contribute to the longevity and reliability of the equipment.

How to Access the Parts Diagram

Gaining access to the schematic representation of components for your machine can significantly enhance your understanding and ability to maintain it. This resource serves as a visual guide, allowing you to pinpoint specific elements and their interrelations.

Follow these steps to easily find the schematic:

| Step | Action |

|---|---|

| 1 | Visit the official website or trusted retailers that specialize in equipment. |

| 2 | Navigate to the support or product resources section. |

| 3 | Enter the model number in the search bar for precise results. |

| 4 | Download or view the available illustrations directly. |

By following these guidelines, you can effectively delve into the necessary visuals that will aid in your maintenance tasks.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. By following a few essential practices, you can significantly extend its lifespan and maintain efficiency throughout its use.

- Regular Cleaning: Keep all components free from dirt and debris. Use a soft brush and cloth to clean surfaces regularly.

- Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer to reduce friction and wear.

- Check and Replace Filters: Inspect air and fuel filters periodically. Replace them as needed to ensure smooth operation.

- Inspect Belts and Cables: Look for signs of wear or damage. Replace any frayed or cracked belts to avoid performance issues.

- Battery Maintenance: Keep terminals clean and ensure connections are secure. Test the battery regularly to avoid unexpected failures.

By adhering to these practices, you can enhance the performance and longevity of your equipment, ensuring it operates efficiently for years to come.

Replacing Worn-Out Components

Maintaining optimal performance in any machinery often requires the timely substitution of aged or damaged elements. Recognizing signs of wear is essential for ensuring longevity and efficiency. This section explores the process of identifying and replacing these critical parts to restore functionality.

Identifying Signs of Wear

Common indicators include unusual noises, decreased efficiency, and visible deterioration. Regular inspections can help detect these issues early, preventing further damage and costly repairs.

Steps for Replacement

To effectively replace components, gather the necessary tools, refer to the specific guidelines for your machinery, and follow safety protocols. Begin by removing the defective part carefully, then install the new element, ensuring it fits securely and functions properly.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. There are several reliable sources that offer a wide range of options to ensure your machinery continues to operate smoothly.

- Official Manufacturer Website: Check the official site of the equipment’s manufacturer. They often provide a catalog of available components along with detailed specifications.

- Local Hardware Stores: Many local hardware retailers stock common components. Visiting these stores can also provide you with the advantage of immediate assistance from knowledgeable staff.

- Online Retailers: Numerous online platforms specialize in selling equipment components. Popular websites include:

- Amazon

- eBay

- Specialized tool supply sites

- Salvage Yards: For hard-to-find items, consider checking salvage yards. These places can be treasure troves for older or discontinued components.

- Community Forums: Engage with online communities or forums dedicated to machinery. Members often share resources and may know where to find specific components.

- Local Repair Shops: Repair professionals usually have access to suppliers and can help you find the right components or offer alternative solutions.

Utilizing these resources will greatly enhance your chances of finding the necessary components to keep your equipment in top condition.

Tools Needed for Repairs

When it comes to performing maintenance and fixes on machinery, having the right equipment is essential for achieving optimal results. The proper tools not only facilitate the repair process but also ensure safety and efficiency. Familiarity with these instruments will enhance your capability to troubleshoot and address any issues that may arise.

Essential Hand Tools

Basic hand tools are fundamental for any repair task. Wrenches, screwdrivers, pliers, and hammers are among the most commonly used. Each tool serves a specific purpose, allowing you to tighten or loosen components, secure parts, and handle various fasteners with ease. A comprehensive toolset will prepare you for any unexpected challenges during the repair process.

Power Tools and Accessories

In addition to hand tools, power tools can significantly expedite repairs and improve precision. Drills, impact wrenches, and saws may be necessary for more complex tasks. Accessories like drill bits and sanding pads enhance functionality, enabling you to tackle a variety of jobs efficiently. Utilizing power tools can reduce physical strain and save time, making them invaluable for any maintenance project.

Safety Precautions During Maintenance

Ensuring safety while conducting maintenance tasks is paramount. Proper precautions not only protect the individual performing the work but also preserve the integrity of the equipment. A proactive approach can prevent accidents and enhance overall efficiency during the maintenance process.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including gloves, goggles, and sturdy footwear to protect against injuries.

- Power Disconnection: Before starting any maintenance, disconnect the power source to eliminate the risk of accidental activation.

- Work Area Organization: Keep the workspace clean and free of clutter to minimize hazards and ensure easy access to tools.

By adhering to these fundamental guidelines, individuals can significantly reduce the likelihood of accidents and ensure a smoother maintenance process.

- Tools Inspection: Regularly check tools for damage or wear to avoid malfunction during use.

- Proper Lifting Techniques: When moving heavy components, use correct lifting methods or seek assistance to avoid strain or injury.

- Read Manuals: Familiarize yourself with the equipment’s manual to understand specific safety recommendations and procedures.

By following these safety measures, maintenance tasks can be performed with greater confidence and security, leading to improved outcomes and a safer working environment.

Customer Reviews and Experiences

This section aims to highlight the thoughts and insights of users who have engaged with various components and accessories for their outdoor equipment. Their feedback can provide valuable perspectives on performance, durability, and ease of use.

Many users express satisfaction with the quality and reliability of the products, noting how well they function in different conditions. One common theme is the seamless compatibility with existing models, which enhances the overall experience and ensures smooth operation.

However, some reviews mention challenges related to installation or specific maintenance requirements. These insights serve as a reminder of the importance of proper guidance and support when selecting components.

Ultimately, the shared experiences from the community can greatly aid prospective buyers in making informed decisions and optimizing their equipment’s performance.