In the realm of heavy machinery, comprehending the configuration of various components is essential for effective maintenance and repair. Each piece of equipment is designed with specific elements that work in harmony to ensure optimal performance. By familiarizing oneself with the arrangement of these elements, operators and technicians can enhance their efficiency and troubleshoot issues more effectively.

Visual representations serve as valuable tools in this understanding, providing a clear overview of how individual segments interact within the larger system. These illustrations not only highlight the relationships between components but also simplify the process of identifying parts that may require attention or replacement.

By delving into the intricacies of machinery layouts, one can gain insights into the operational mechanisms and improve overall functionality. Mastering this knowledge equips users with the ability to maintain their equipment in peak condition, ultimately leading to increased productivity and reduced downtime.

Understanding Case 580 Super K Parts

When it comes to heavy machinery, knowing the individual components is crucial for effective maintenance and operation. Each element plays a significant role in ensuring the equipment functions smoothly, contributing to overall performance and longevity. This section delves into the various segments that make up this robust machine, highlighting their importance and interconnections.

Components of this equipment can be categorized into several key groups, including mechanical, hydraulic, and electrical systems. Each category serves distinct functions, from providing power and control to ensuring safe operation. Understanding these categories allows operators to better diagnose issues and perform necessary repairs.

Moreover, familiarity with these elements aids in identifying compatible replacements when repairs are needed. Recognizing the specific roles of each section not only enhances troubleshooting skills but also minimizes downtime, ultimately leading to more efficient workflow and productivity.

In conclusion, gaining insight into the various components of this machinery equips users with the knowledge necessary to maintain optimal functionality, thereby extending the lifespan of the equipment and enhancing overall operational efficiency.

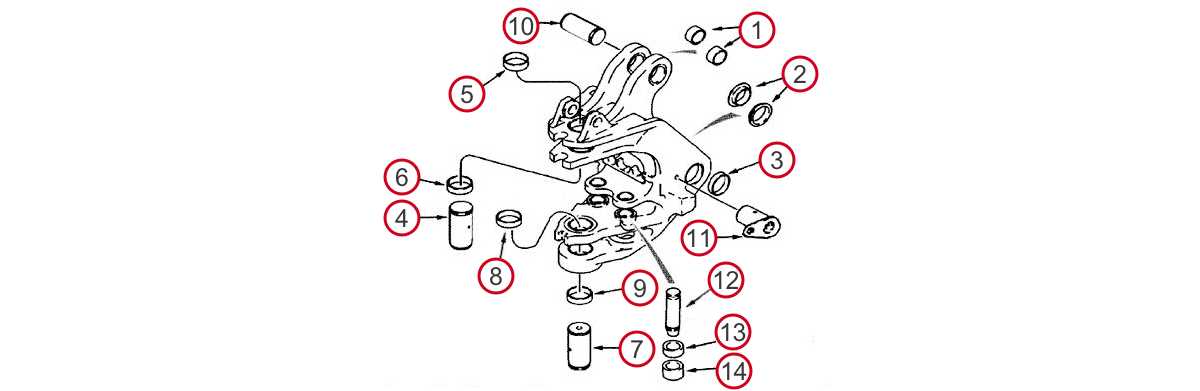

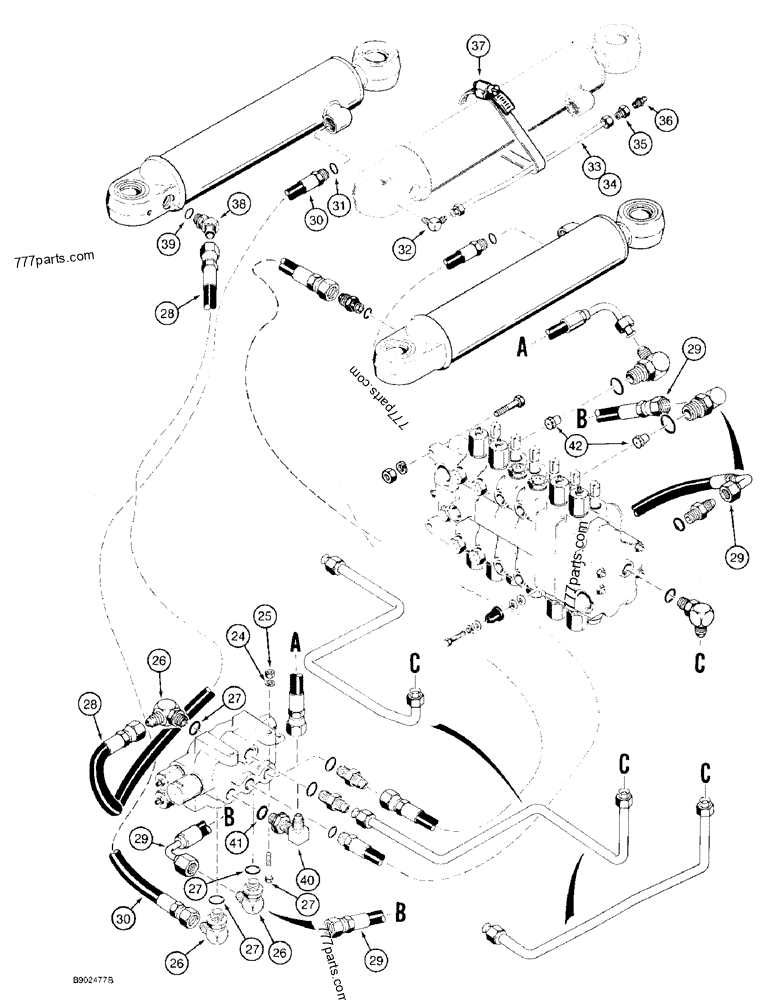

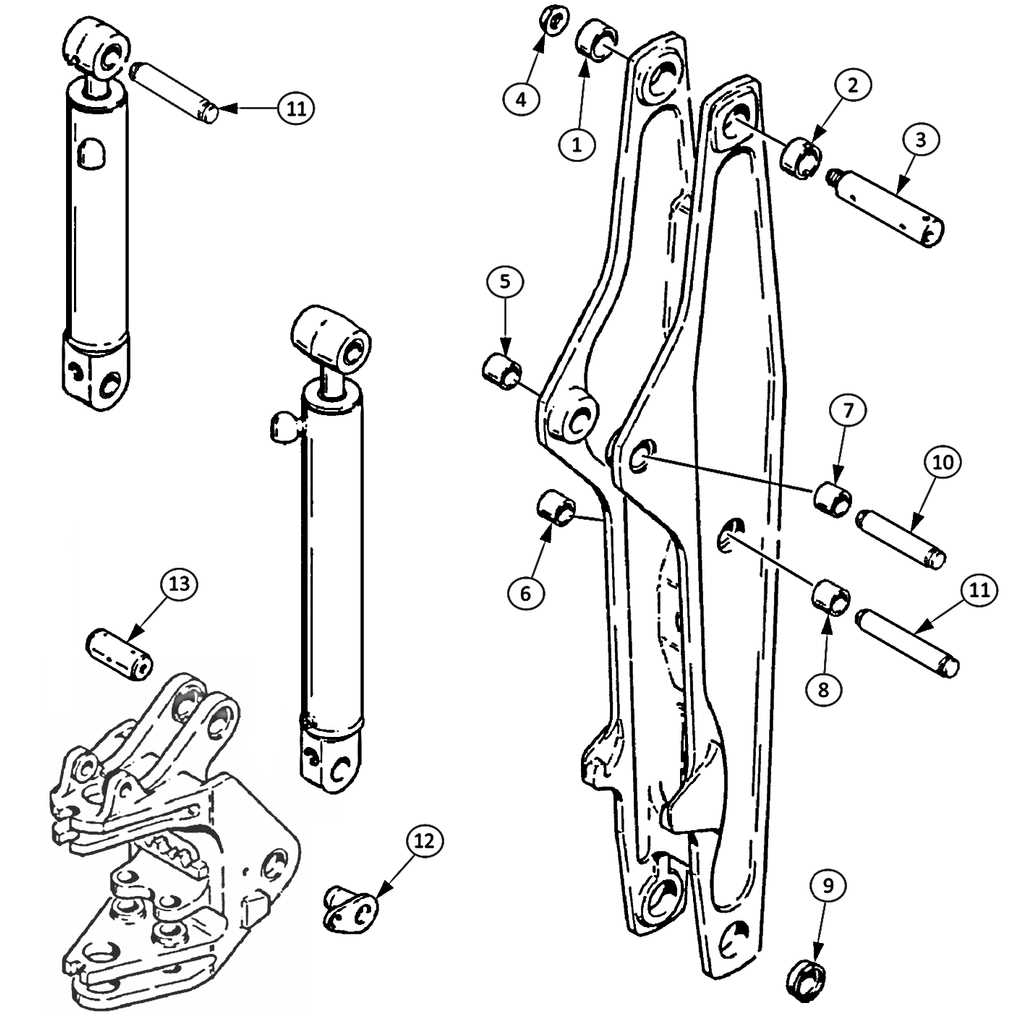

Overview of Parts Diagram

The visual representation of components is essential for understanding the intricate relationships and functions within machinery. This graphical layout serves as a valuable reference for technicians and enthusiasts alike, providing clarity on the arrangement and purpose of each element.

Importance of Visualization

Utilizing a comprehensive illustration aids in troubleshooting and maintenance. It allows users to quickly identify components, ensuring efficient repairs and replacements. The organized structure simplifies the complexity often associated with mechanical systems.

Key Features to Consider

When examining such visuals, look for labels that denote specific parts, as well as groupings that indicate functional relationships. These elements enhance comprehension and facilitate the ultimate goal of successful operation and maintenance.

Importance of Accurate Diagrams

Precise visual representations are crucial for effective maintenance and repair processes. They serve as essential tools for technicians, providing clear guidance and facilitating a better understanding of complex systems. When these illustrations are detailed and accurate, they significantly reduce the likelihood of errors during assembly and troubleshooting.

Enhanced Efficiency

Well-crafted visual aids streamline workflows by allowing professionals to quickly identify components and their interrelations. This efficiency not only saves time but also minimizes the risk of costly mistakes, enabling smoother operations in various settings.

Facilitation of Learning

Accurate illustrations also play a vital role in training new personnel. They enable learners to grasp intricate concepts more readily, fostering a deeper understanding of equipment and enhancing overall skill development in the field.

Common Components of the Machine

Understanding the key elements of heavy machinery is essential for efficient operation and maintenance. Each component plays a vital role in the overall functionality, ensuring the equipment performs optimally in various tasks. Familiarity with these parts aids in troubleshooting and enhances the lifespan of the machine.

Hydraulic System

The hydraulic system is crucial for powering various functions, such as lifting and digging. It operates through a series of pumps, cylinders, and hoses that facilitate the movement of fluids. This system provides the necessary force to perform heavy-duty tasks, making it a cornerstone of the equipment’s efficiency.

Engine Assembly

The engine assembly serves as the powerhouse of the machinery. It converts fuel into mechanical energy, driving the machine’s operations. This component includes various parts such as the crankshaft, pistons, and valves, all working in unison to ensure smooth and reliable performance. Regular maintenance of the engine is essential to prevent breakdowns and extend operational life.

How to Read the Diagram

Understanding a schematic representation is crucial for effective maintenance and troubleshooting. This visual tool provides a clear overview of components and their interconnections, enabling users to identify parts and their functions efficiently.

Key Elements to Observe

- Symbols: Familiarize yourself with the various icons used to represent components.

- Labels: Pay attention to annotations that indicate specific functions or part numbers.

- Connections: Follow lines that illustrate how different elements are interconnected.

Steps to Follow

- Start by identifying the main components listed.

- Examine the relationships between different parts to understand their workflow.

- Refer to the legend or key to decode any unfamiliar symbols.

Maintenance Tips for Parts

Ensuring the longevity and efficiency of your machinery requires regular attention to its components. Proper care not only extends their lifespan but also enhances overall performance. Here are some essential guidelines to keep in mind.

Regular Inspections

Frequent assessments of your machinery’s elements are crucial. Look for signs of wear, rust, or damage. Early detection can prevent larger issues, ensuring that everything operates smoothly. Schedule these inspections at regular intervals for the best results.

Lubrication and Cleaning

Keeping components clean and well-lubricated is vital for optimal functioning. Use appropriate oils and greases as recommended by the manufacturer. Regular cleaning helps eliminate debris that could cause friction or blockage, maintaining efficiency and performance.

Finding Replacement Parts Easily

Locating suitable components for machinery can often seem daunting. However, understanding where to search and what resources are available can simplify the process significantly.

To streamline your search, consider the following strategies:

- Utilize online marketplaces specializing in machinery components.

- Join forums and communities where enthusiasts share their knowledge.

- Consult manufacturer websites for official recommendations and resources.

By leveraging these methods, you can enhance your ability to find the necessary replacements without unnecessary hassle.

Cost Considerations for Components

When maintaining heavy machinery, understanding the financial aspects of individual elements is crucial for effective budgeting. The expenses associated with these components can vary significantly based on quality, brand, and availability. Being aware of these factors can help owners make informed decisions and ensure the longevity of their equipment.

| Component | Average Cost | Quality Impact |

|---|---|---|

| Engine Parts | $500 – $2000 | High-quality parts often last longer and enhance performance. |

| Hydraulic Systems | $300 – $1500 | Investing in reliable systems can prevent costly failures. |

| Transmission Components | $400 – $1800 | Premium options may improve efficiency and reduce wear. |

Resources for Further Information

For those seeking additional insights into the machinery components and their configurations, a variety of resources are available. These materials can enhance understanding and assist in troubleshooting, maintenance, and repairs. Below is a compilation of useful references to explore.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Official guides providing detailed information on operation and servicing. | Visit Here |

| Online Forums | Community-driven platforms for sharing experiences and advice among users. | Visit Here |

| Video Tutorials | Visual guides demonstrating maintenance techniques and repairs. | Visit Here |

| Parts Suppliers | Websites specializing in machinery components, offering diagrams and listings. | Visit Here |

| Technical Support | Contact options for professional assistance with specific issues. | Visit Here |