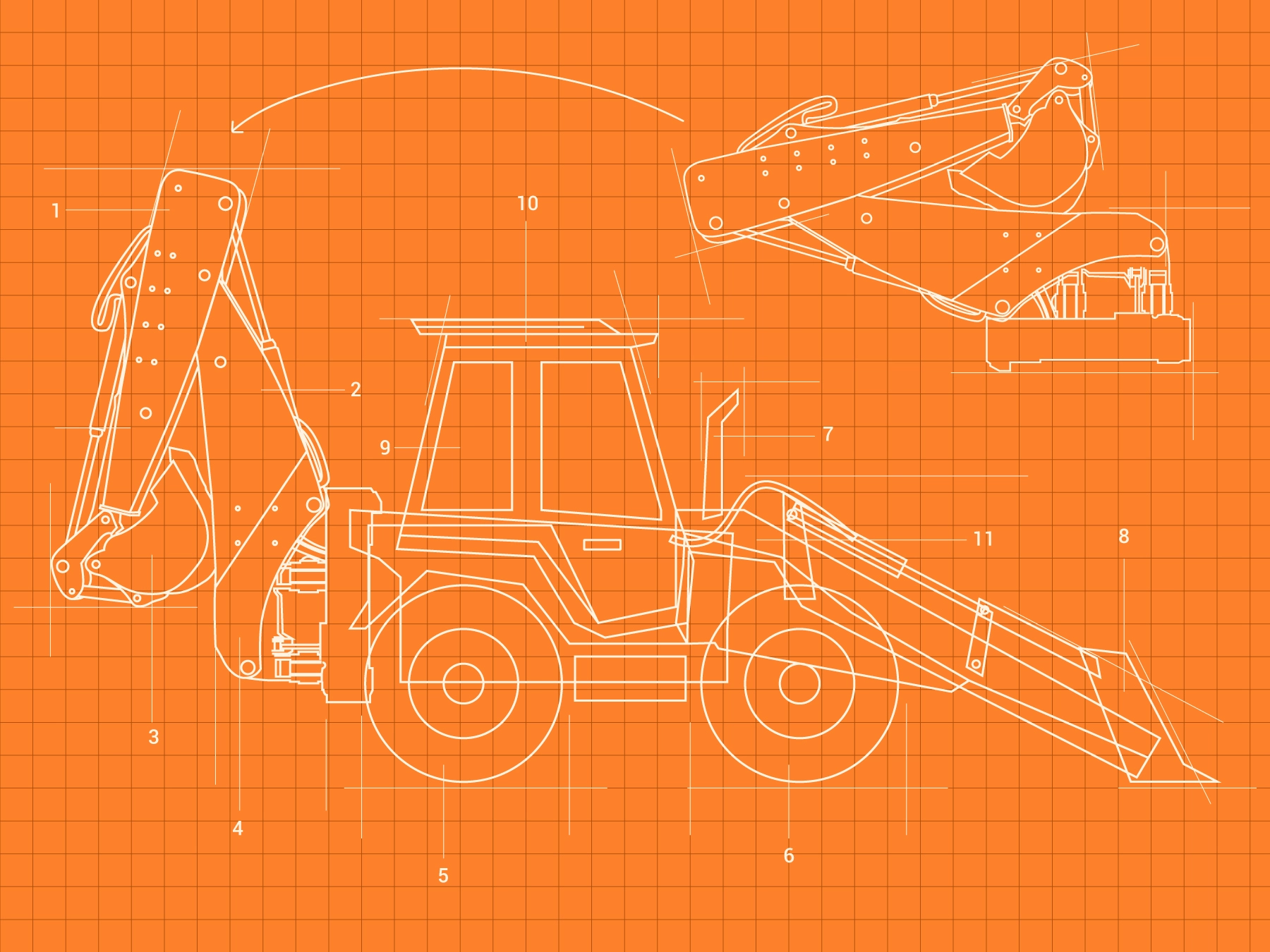

The inner workings of heavy-duty machinery require a deep understanding of its essential elements. This model, known for its reliability in tough working conditions, is composed of numerous interconnected components that work in harmony to ensure smooth operation. Understanding how each part functions within the whole system is crucial for maintenance and repair.

Each section of the machine is designed with precision, ensuring durability and optimal performance. Whether focusing on the engine, hydraulic systems, or control mechanisms, every component plays a vital role in its overall efficiency. Regular inspections and familiarity with the arrangement of these elements can significantly extend the lifespan of the equipment.

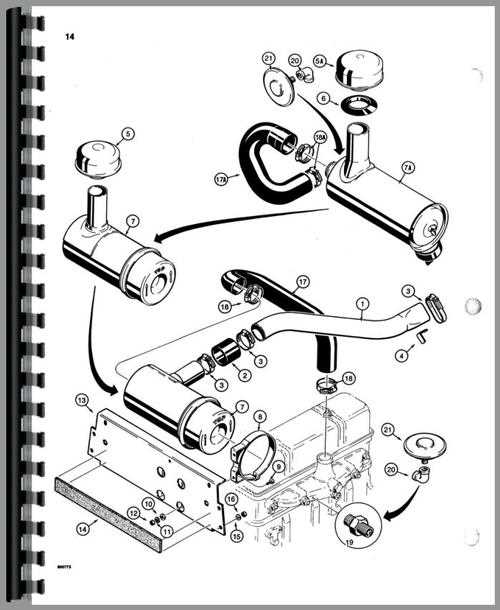

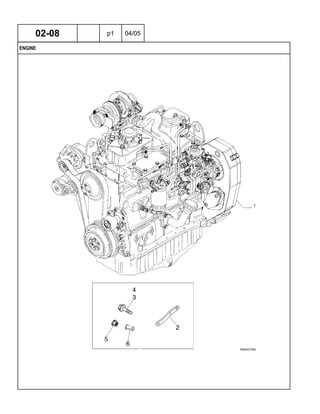

Having a clear visualization of these mechanical parts helps operators and technicians identify issues quickly, making it easier to perform necessary adjustments or replacements. Familiarity with the model’s structure ensures that any potential downtime is minimized, keeping productivity levels high.

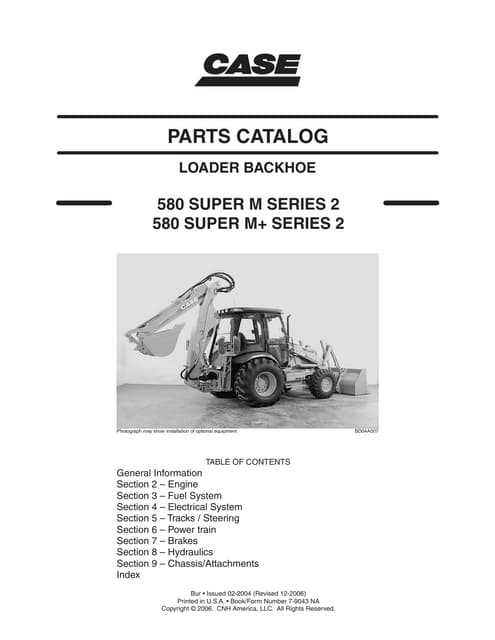

Understanding the Key Components of the Case 580 Super M

The equipment under discussion is a versatile machine designed for various heavy-duty tasks. To fully grasp its functionality, it’s essential to examine the crucial elements that work together to deliver its high performance. Each component plays a significant role in ensuring that the machine operates efficiently, providing both power and precision in its operations.

| Component | Description |

|---|---|

| Engine | A robust power unit that drives the machine, ensuring smooth operation across diverse conditions. |

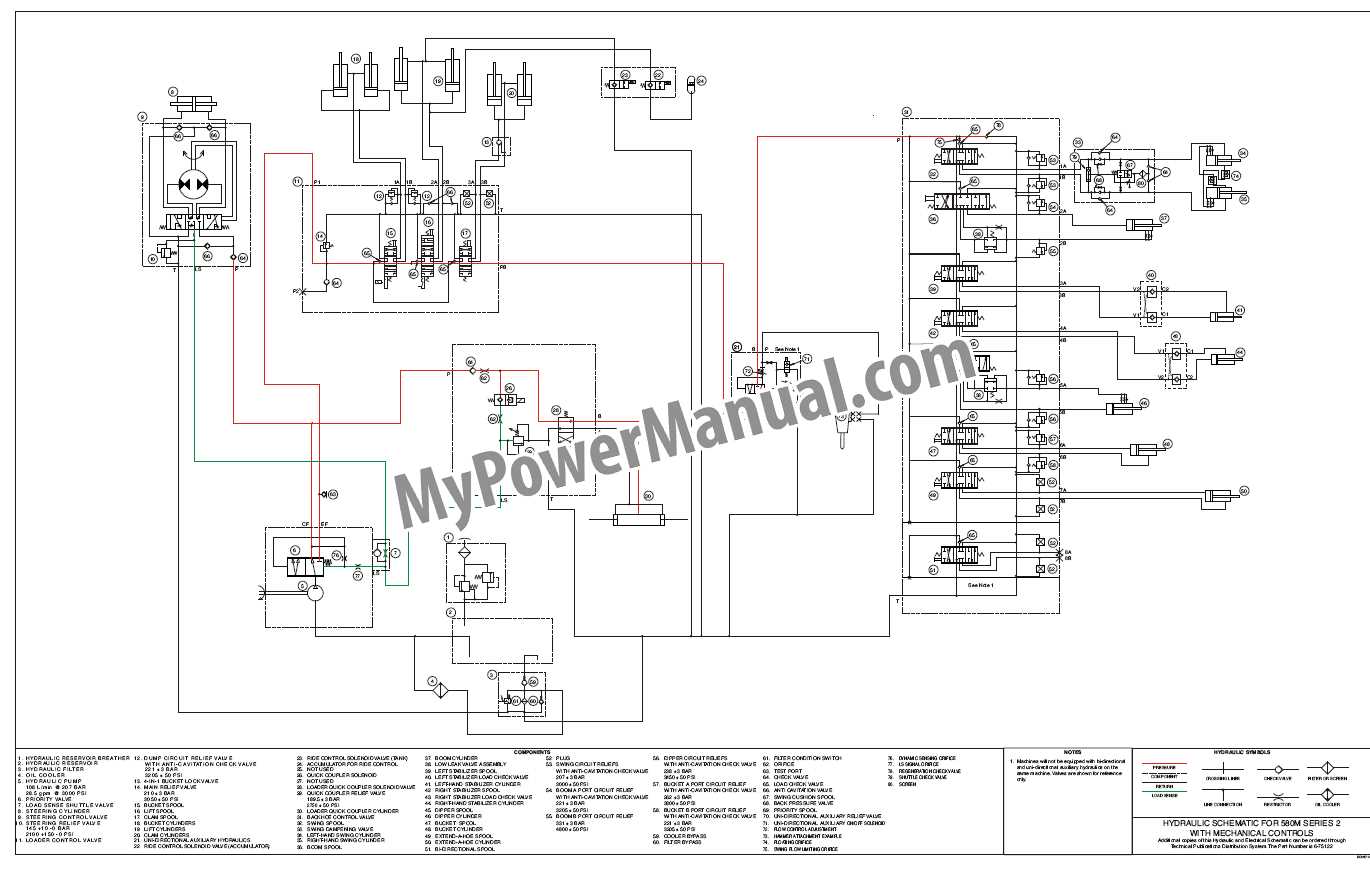

| Hydraulic System | Enables the movement of attachments and implements, providing flexibility and control during tasks. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, offering stability and traction. |

| Axles and Tires | These elements support mobility and ground contact, critical for handling rugged terrains. |

| Component | Function |

|---|---|

| Brake Pedal | Acts as the primary control for activating the brake system. |

| Brake Master Cylinder | Converts pedal pressure into hydraulic force to operate the brakes. |

| Brake Lines | Transmits hydraulic fluid from the master cylinder to the brake components. |

| Brake Calipers | Holds the brake pads and applies pressure to them against the rotor. |

| Brake Pads | Friction material that presses against the rotor to slow or stop the vehicle. |

| Brake Rotors | Disc that the brake pads clamp onto to create friction and stop the wheels. |

| Parking Brake | Mechanical system that keeps the vehicle stationary when parked. |

Front and Rear Axle Diagrams Explained

The understanding of front and rear axle layouts is essential for comprehending the overall functionality of heavy machinery. These components play a critical role in the vehicle’s mobility and stability, influencing how the machine interacts with various terrains. The following sections provide insights into the configurations and significance of these axles.

Understanding Axle Configurations

Axles are crucial elements that connect the wheels and allow for effective load distribution and movement. Their configurations can vary significantly, affecting performance and maneuverability. Here are some common types:

- Live Axles: These are responsible for transmitting power to the wheels while supporting the vehicle’s weight.

- Dead Axles: Unlike live axles, these do not transmit power but help in supporting the structure.

- Steering Axles: These facilitate directional control, especially in complex terrains.

The Importance of Axle Layouts

Proper axle layouts enhance the machine’s performance, ensuring better traction and stability. A well-designed axle system contributes to:

- Improved Load Distribution: This prevents undue stress on any single component.

- Enhanced Maneuverability: Efficient axle designs allow for better handling and turning capabilities.

- Increased Durability: Quality materials and designs extend the lifespan of the vehicle.

In conclusion, a thorough understanding of front and rear axle structures is vital for effective maintenance and operation, ensuring optimal performance in various applications.

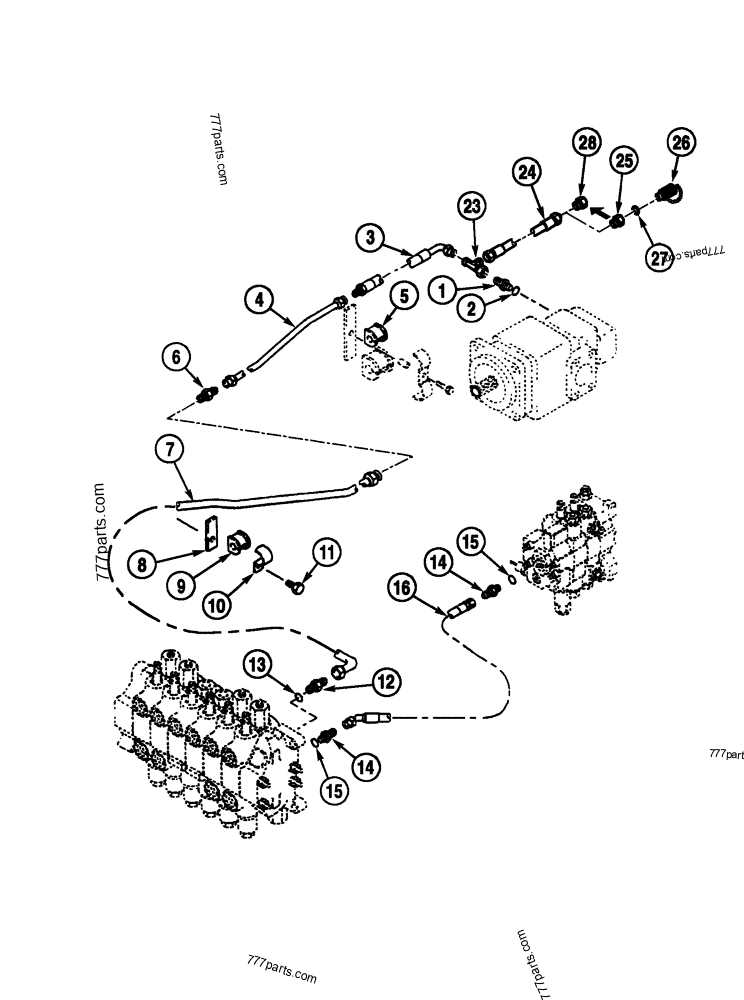

Maintenance Tips Using the Parts Diagram

Regular upkeep of heavy machinery is essential for ensuring longevity and optimal performance. Understanding the various components and their functions can significantly enhance maintenance practices. By utilizing an illustrated guide of the equipment’s assembly, operators can effectively identify and address potential issues before they escalate.

Here are some useful suggestions for maintaining your machinery effectively:

- Conduct routine inspections to identify any wear and tear on components.

- Keep a log of maintenance activities to track the condition of each part over time.

- Utilize a detailed schematic to locate specific components when performing repairs or replacements.

- Ensure all components are correctly lubricated to prevent friction and overheating.

- Follow the manufacturer’s recommendations for maintenance intervals and procedures.

By implementing these practices and regularly consulting the illustrated guide, operators can maintain the machinery in peak condition, enhancing both safety and efficiency.