In the world of machinery, having a clear visual representation of components is essential for effective maintenance and repair. A well-organized illustration can significantly enhance the understanding of how various elements interact within complex systems. This knowledge empowers operators and technicians to diagnose issues swiftly and perform necessary interventions with confidence.

Delving into the intricacies of a specific model’s configuration reveals not only the arrangement of its constituents but also highlights potential wear points and areas that may require attention over time. Such insights are invaluable for ensuring the longevity and optimal performance of equipment.

By exploring a detailed representation of a machine’s structure, one can grasp the interdependencies among different components. This fosters a deeper appreciation for the engineering behind the design and equips users with the information needed to tackle challenges effectively, thereby promoting a culture of proactive care and maintenance.

Understanding Case 1840 Overview

This section aims to provide a comprehensive look into the mechanisms and functions of a specific machinery model, highlighting its essential features and operational principles. Gaining insight into its components and how they interact can enhance user experience and maintenance efficiency.

Key Features

- Robust construction for durability

- Efficient hydraulic systems for optimal performance

- Ergonomic design for user comfort

- Versatile attachments for various applications

Operational Principles

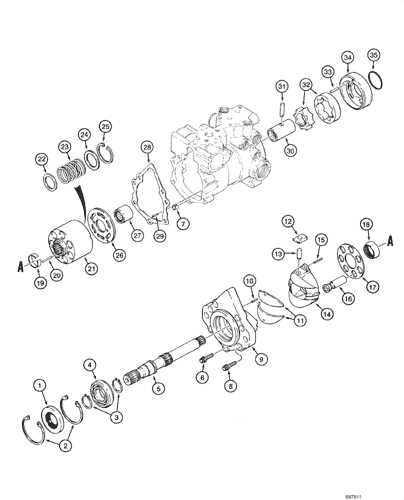

- Power transmission through advanced gearing systems

- Fluid dynamics in hydraulic mechanisms

- Mechanical synergy of moving parts

Key Components of Case 1840

Understanding the essential elements of machinery enhances operational efficiency and maintenance. Each component plays a crucial role in the overall functionality, contributing to both performance and longevity. Here, we explore the primary parts that make up this versatile equipment.

Main Elements

The fundamental aspects of this machinery are designed to work in harmony. Key components include the power system, hydraulic mechanisms, and structural elements. Each part is engineered to support the machine’s tasks effectively.

| Component | Description |

|---|---|

| Powertrain | Drives the machine, providing the necessary energy for operation. |

| Hydraulic System | Facilitates movement and operation of various attachments and tools. |

| Chassis | Offers structural support, ensuring stability during operation. |

| Control System | Enables operator interaction, managing functions and settings. |

| Attachments | Enhances versatility, allowing for various applications and tasks. |

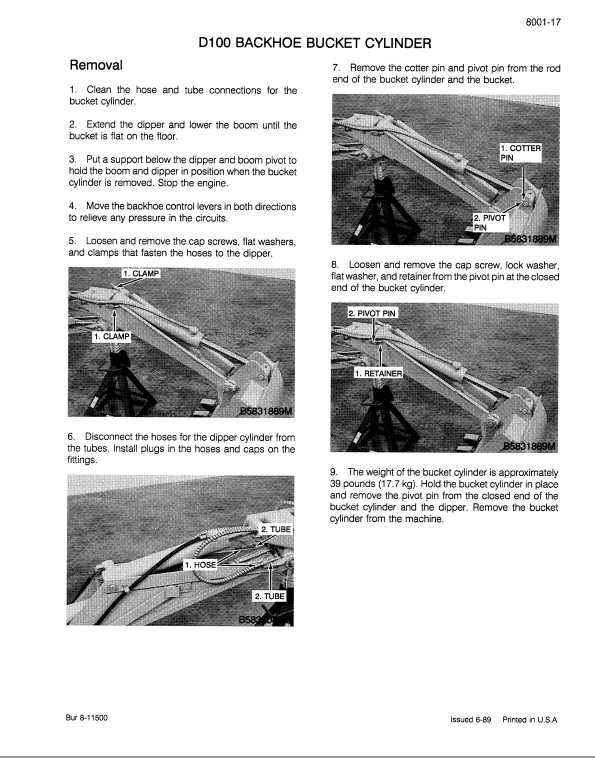

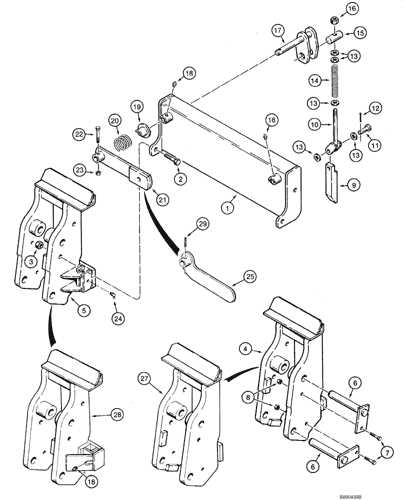

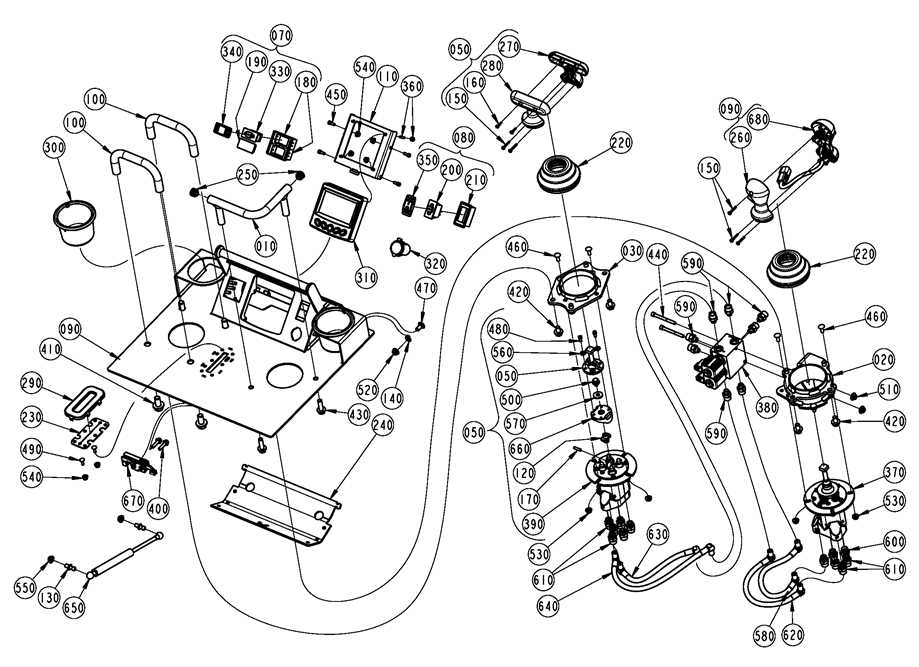

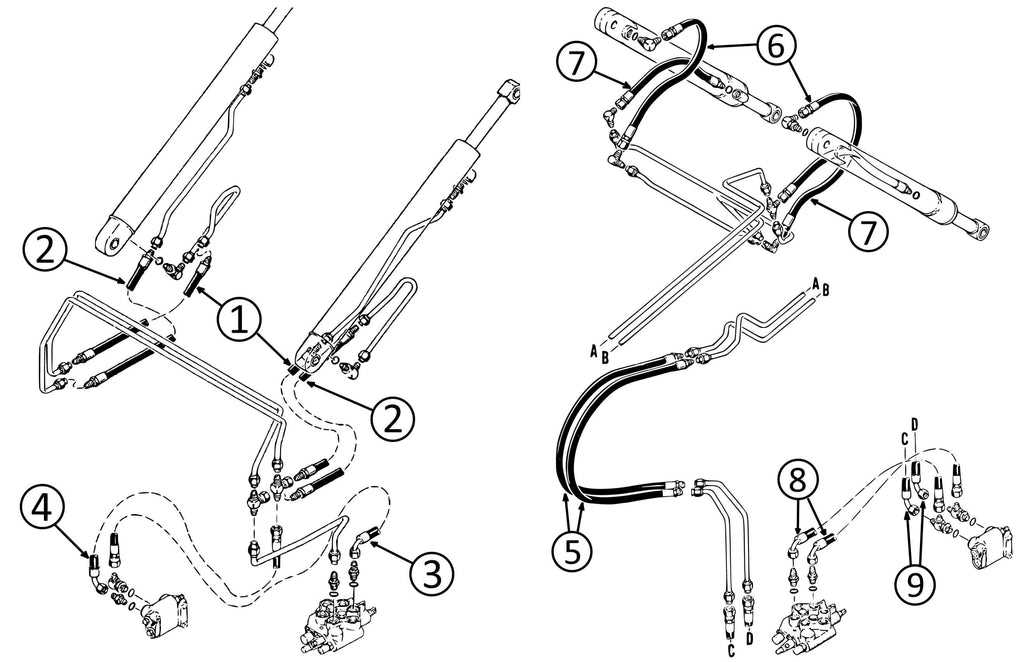

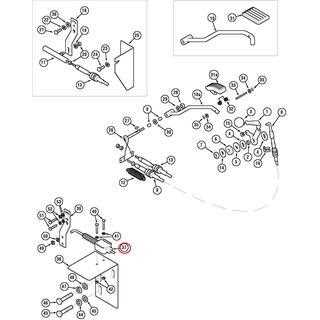

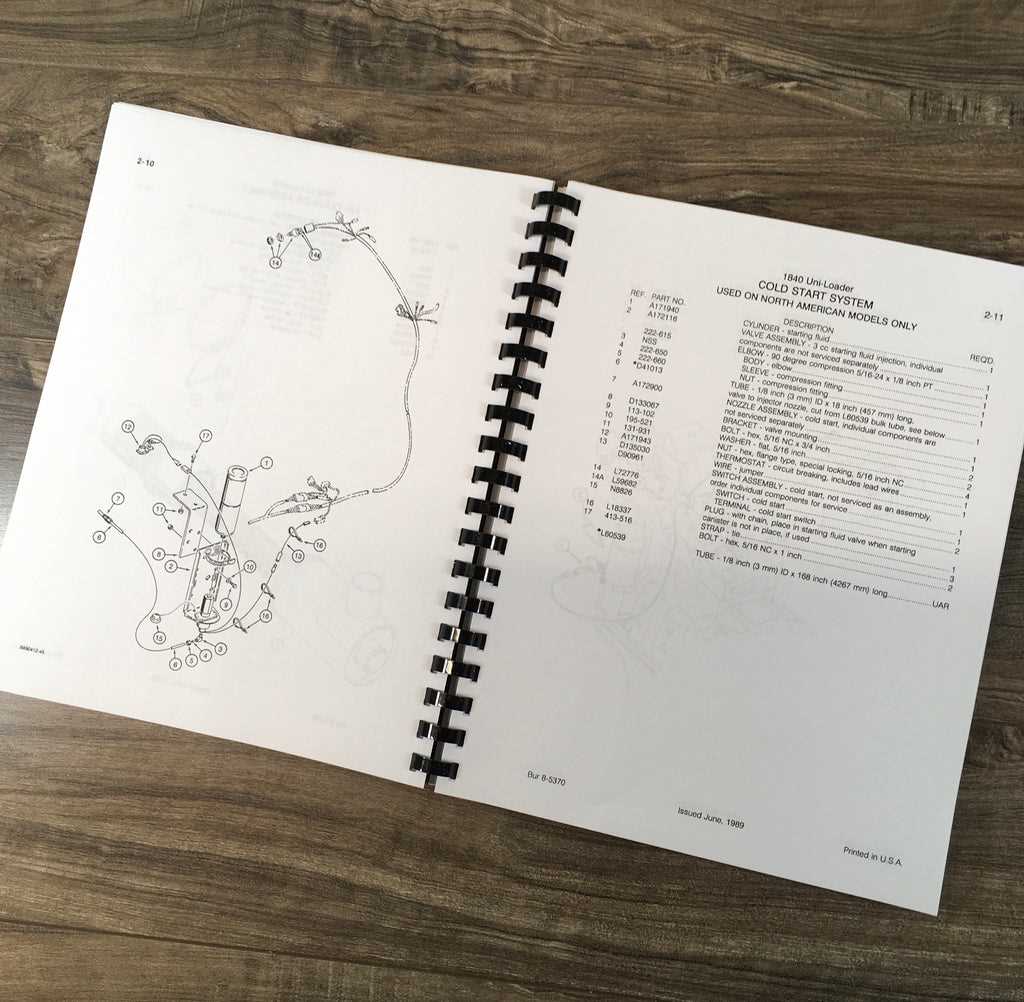

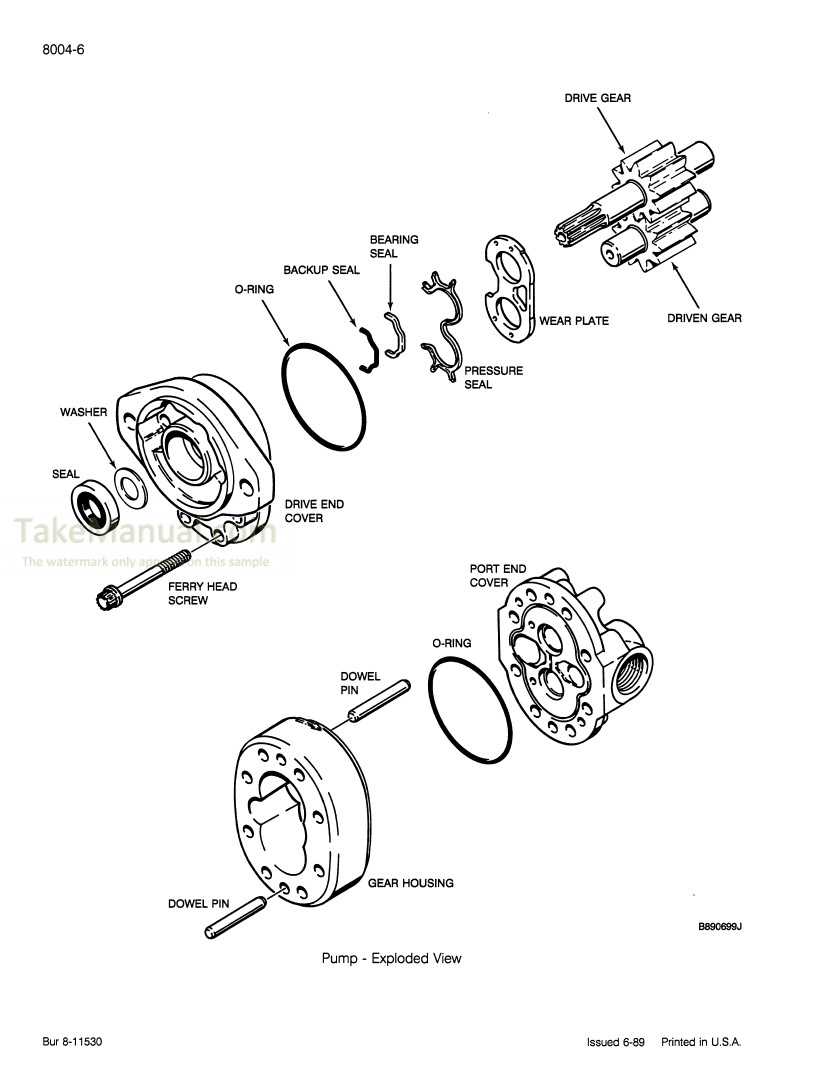

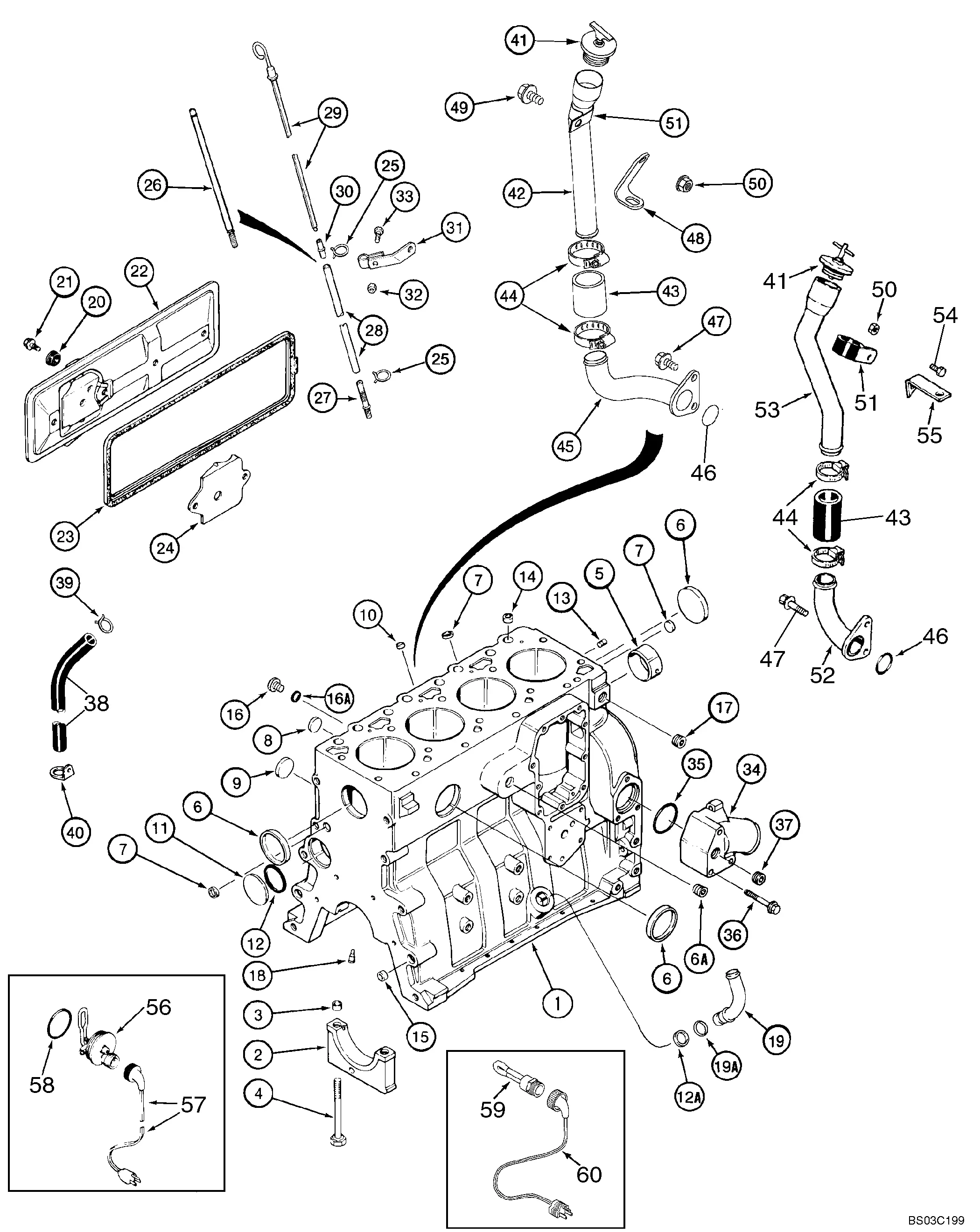

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear and organized view of individual elements, making it easier for technicians and users to identify and understand the relationships between various parts. Such illustrations facilitate efficient troubleshooting, ensuring that issues can be diagnosed and resolved swiftly.

Moreover, these representations serve as essential references during assembly and disassembly processes. By following a structured layout, users can prevent errors, minimize the risk of damage, and enhance overall productivity. This clarity not only supports effective repairs but also extends the lifespan of the equipment, as proper handling is guided by accurate information.

Additionally, these visuals are valuable for training purposes. New technicians can gain a comprehensive understanding of how different components interact within a system. This foundational knowledge is vital for developing their skills and confidence in performing maintenance tasks. Overall, well-crafted visual aids significantly contribute to operational efficiency and safety in any technical environment.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient assembly, maintenance, and troubleshooting. This visual guide can help you quickly identify individual elements and their relationships within a system.

Here are some key points to consider when interpreting these illustrations:

- Familiarize Yourself with Symbols: Each representation often includes unique symbols or codes. Learn what these mean to avoid confusion.

- Identify Groupings: Components are usually categorized into sections. Recognizing these groupings can provide context for their function.

- Follow Numbering or Coding Systems: Many schematics utilize a numbering system that indicates the order of assembly or the connection sequence. Pay attention to these details.

- Refer to a Legend or Key: Often, there is a reference section that explains the various symbols, codes, and component functions. Always check this first.

- Consider the Flow of Operation: Understanding how the components interact can give insight into their roles within the system.

By mastering these elements, you will enhance your ability to navigate complex representations effectively, leading to improved understanding and execution of tasks related to the machinery.

Common Issues with Case 1840

In the realm of heavy machinery, operators often encounter various challenges that can affect performance and efficiency. Understanding these typical problems can help in proactive maintenance and timely repairs, ensuring that equipment remains in optimal condition. This section highlights some of the most frequent concerns faced by users, along with potential solutions.

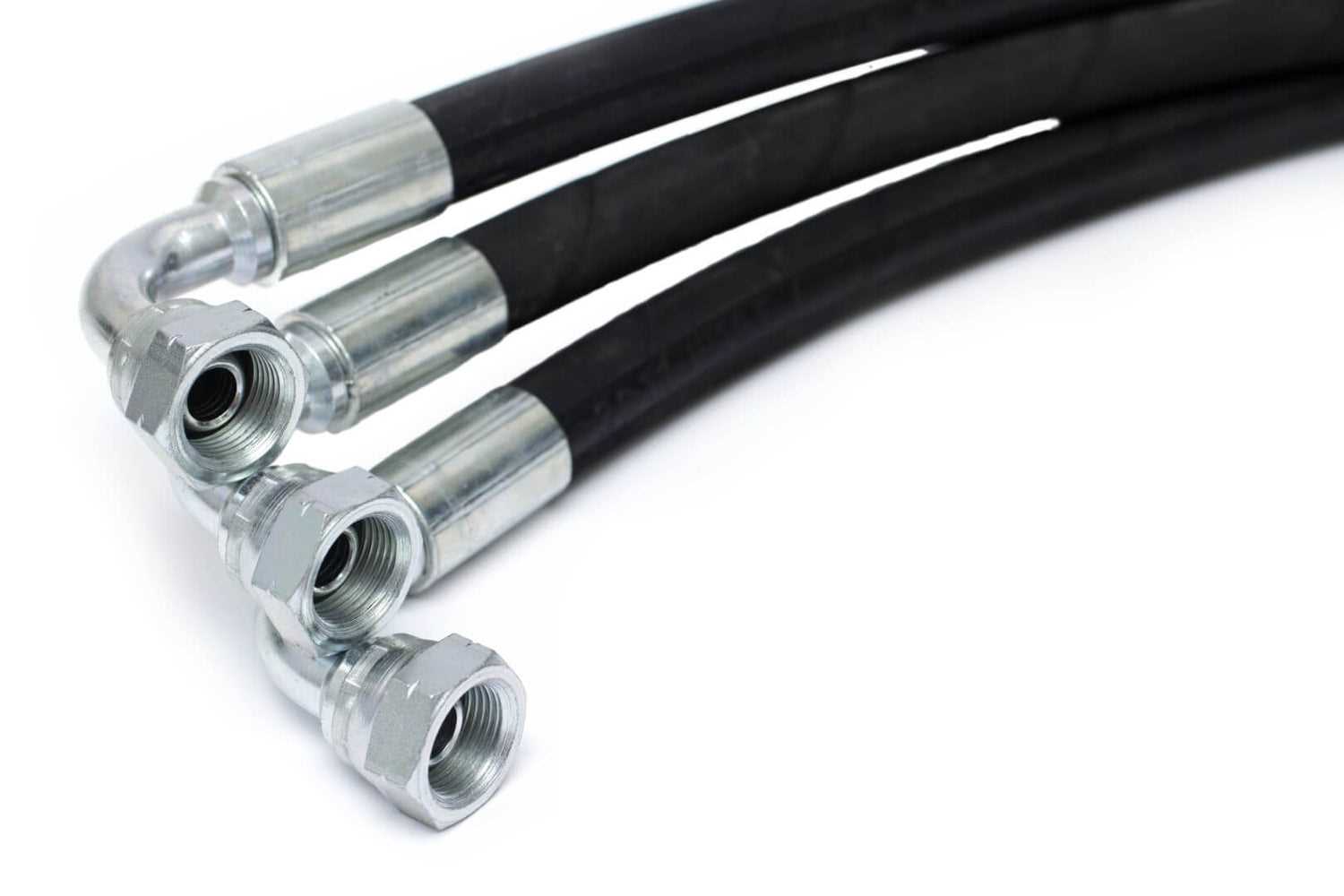

Hydraulic System Failures

One of the most prevalent issues involves the hydraulic system. Leaks can develop in hoses or connections, leading to reduced lifting power and responsiveness. Additionally, contaminated fluid may compromise the entire hydraulic circuit, causing erratic behavior. Regular inspection and replacing worn components can mitigate these risks.

Electrical System Malfunctions

Another common area of concern is the electrical system. Problems such as faulty wiring or defective sensors can lead to unexpected shutdowns or failure to start. Ensuring that all connections are secure and performing routine checks on the electrical components can help prevent these disruptions.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of the equipment, reducing the risk of unexpected breakdowns. By adopting a systematic approach to upkeep, users can maximize the benefits of their investment and maintain optimal functionality over time.

Routine Inspections

Conducting periodic examinations is crucial for identifying potential issues before they escalate. Look for wear and tear, loose components, and signs of corrosion. Keeping a maintenance log can help track the condition of your equipment over time.

Lubrication and Cleaning

Proper lubrication is essential to minimize friction and wear on moving parts. Additionally, keeping the machinery clean prevents the buildup of dirt and debris, which can hinder performance. Follow the manufacturer’s recommendations for lubrication intervals and cleaning procedures.

| Task | Frequency | Notes |

|---|---|---|

| Inspect Components | Monthly | Check for wear and signs of damage. |

| Lubricate Moving Parts | Every 500 hours | Use the recommended lubricant. |

| Clean Filters | Every 100 hours | Replace if heavily contaminated. |

| Check Fluids | Weekly | Ensure proper levels for optimal performance. |

Where to Find Replacement Parts

Locating components for machinery can be a straightforward process if you know where to look. Various resources are available, both online and offline, that cater to the needs of enthusiasts and professionals alike. Whether you seek original equipment or high-quality alternatives, understanding your options is crucial.

Online Resources

Numerous websites specialize in machinery components, offering extensive catalogs and user-friendly interfaces. You can find specific items through dedicated platforms or general marketplaces. Some recommended options include:

| Website | Type of Components |

|---|---|

| MachineryTrader.com | New and used parts |

| eBay | Various listings |

| Amazon | OEM and aftermarket |

Local Dealers and Salvage Yards

For those who prefer hands-on assistance, local distributors and salvage yards can be invaluable. These places often carry a range of components, and staff can provide guidance based on your specific needs. Networking with fellow users may also lead to discovering hidden gems.

Comparing Case 1840 Models

This section aims to explore the various iterations of a popular machinery model, highlighting their unique features and specifications. Understanding these differences can assist users in selecting the right version for their needs, whether for operational efficiency or specific tasks.

Key Variations

Different models exhibit distinct characteristics that cater to diverse operational requirements. Analyzing these variations provides insight into performance and functionality.

Specifications Overview

| Model Type | Engine Power | Operating Weight | Load Capacity |

|---|---|---|---|

| Standard | 50 HP | 4,000 lbs | 2,000 lbs |

| High Torque | 55 HP | 4,200 lbs | 2,200 lbs |

| Heavy Duty | 60 HP | 4,500 lbs | 2,500 lbs |